Winnowing and dedusting rice drying equipment

A drying equipment and rice technology, applied in grain drying, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of scorched particles, high processing cost, poor drying uniformity, etc., and achieve complete separation and structural design optimization. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

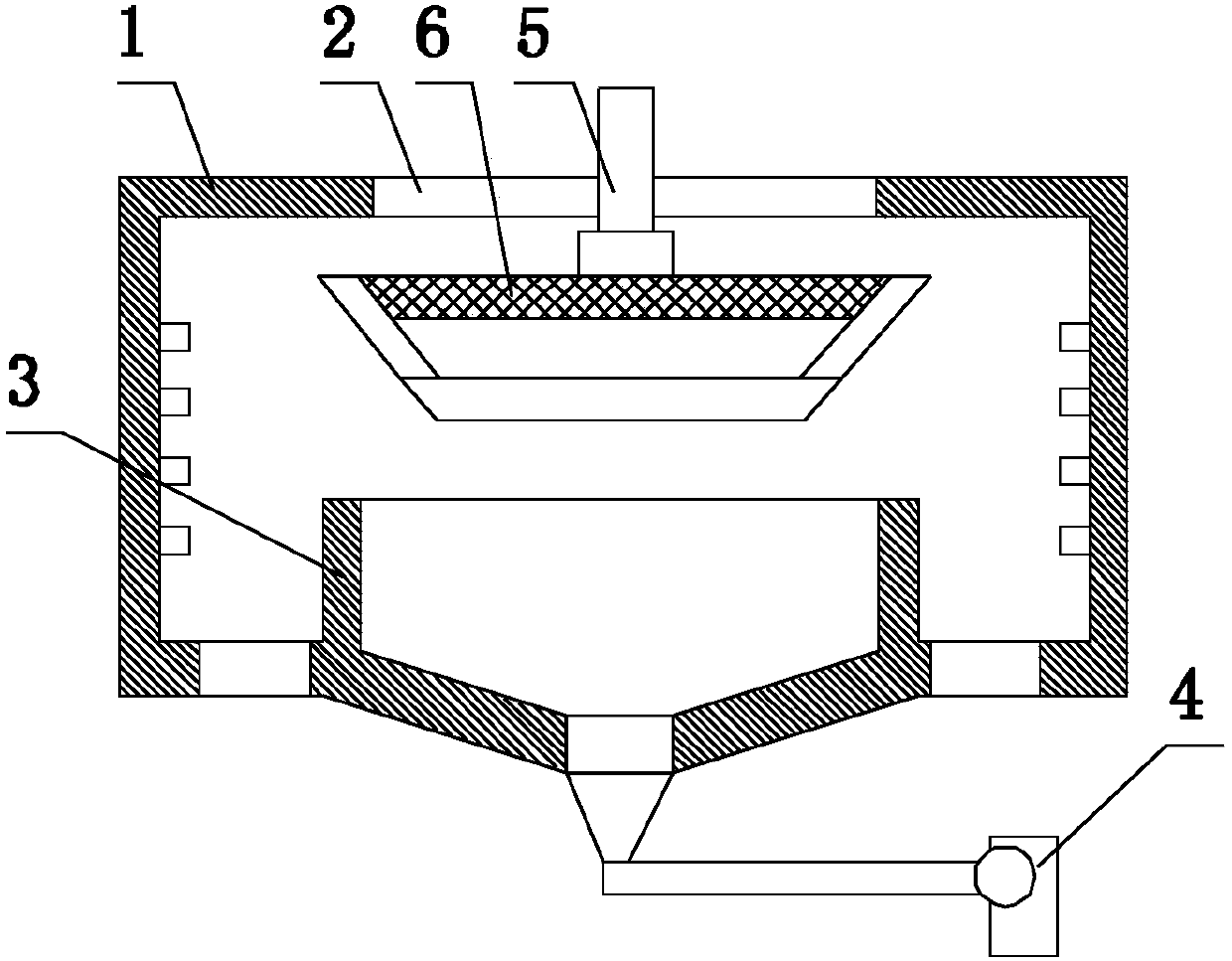

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a kind of wind separation and dedusting rice drying equipment proposed by the present invention.

[0016] refer to figure 1 , a kind of air selection and dust removal rice drying equipment proposed by the present invention, comprising: a housing 1, a flange 2, a material distributing device, an annular partition 3, a blower mechanism, an air induction mechanism 4, and a driving mechanism;

[0017] The inside of the shell 1 is provided with a receiving space with a top opening, the flange 2 is horizontally arranged at the opening, and the flange 2 is provided with an installation opening. The shell 1 includes an upper shell and a lower shell, and the inner wall of the upper shell is provided with a plurality of air blowing holes, through which the air blowing mechanism blows air into the accommodating space;

[0018] The distributing device comprises a feeding pipe 5 and a distributing pan 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com