Rubber carpet feeding system

A technology of feeding system and rubber carpet, applied in the field of carpet processing equipment, can solve the problems of large manual error of laying materials, reduced product quality stability, differences, etc., and achieve the effect of quality improvement, quality improvement, and weight control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

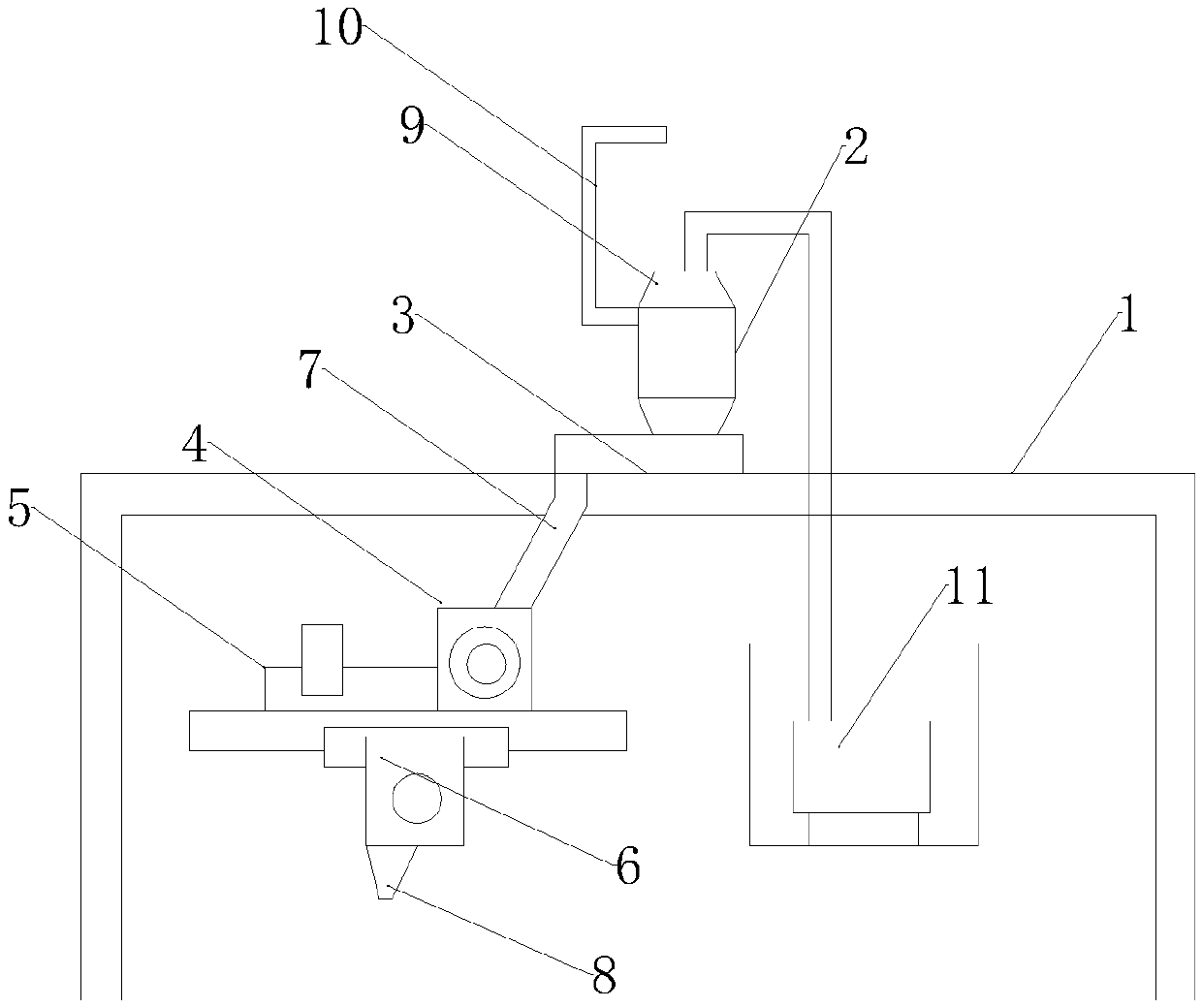

[0022] A rubber carpet feeding system, frame 1, feeding cylinder 2, distributor 3, primary mixer 4, glue injection machine 5 and secondary mixer 6; the feeding cylinder, distributor, primary mixer, glue injection The machine and the secondary mixer are arranged on the frame from top to bottom, and a distributing machine is arranged directly below the lower barrel, and the distributing machine is connected with the primary mixer through the conveying device 7, and the glue injection machine is arranged on On one side of the primary mixer, the secondary mixer communicates with the primary mixer through a pipeline; a material spreading port 8 is arranged below the secondary mixer;

[0023] The lower barrel is provided with a top cover 9, the lower barrel is provided with an exhaust pipe 10, and the lower barrel is connected with a fan 11;

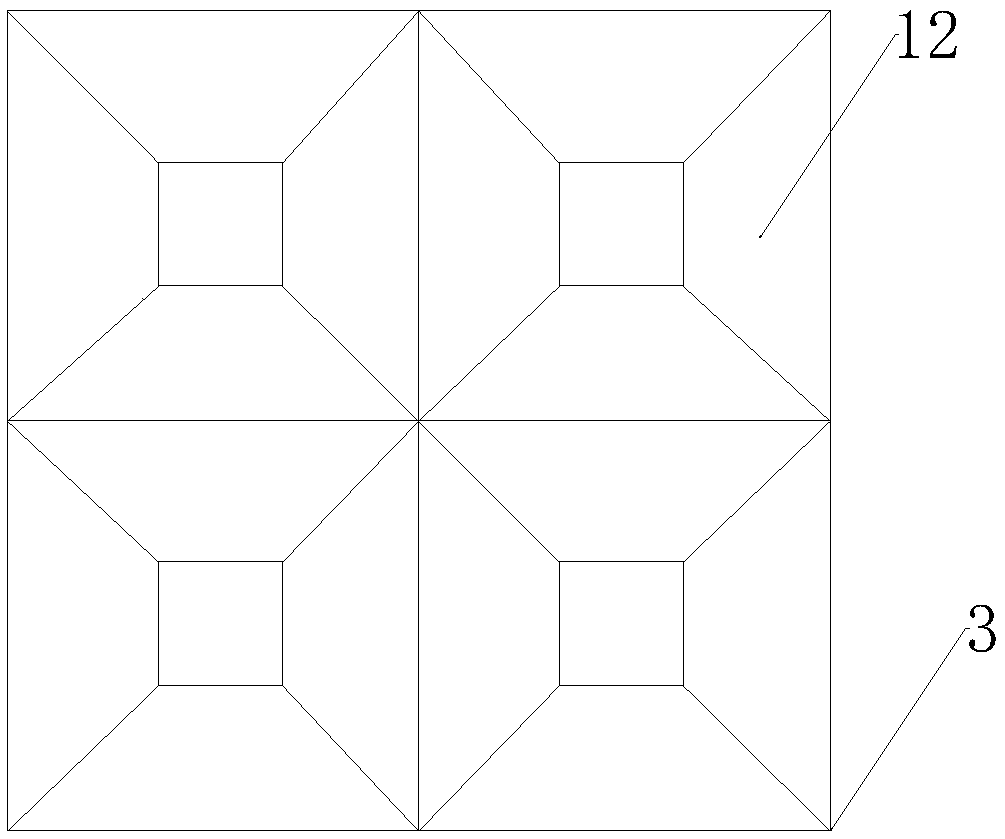

[0024] The distribution machine is a square bucket structure, the top of the distribution machine is a "field"-shaped partition, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com