Slurry treatment system

A treatment system and mud technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of collection difficulties, damage, large size, etc., and save volume and space , Avoid accumulation and solidification, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

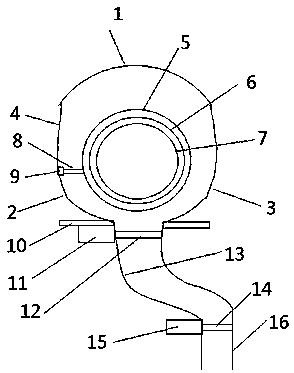

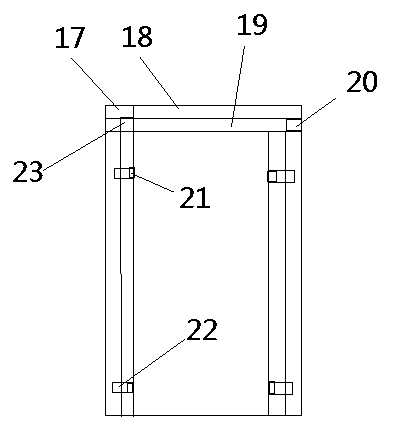

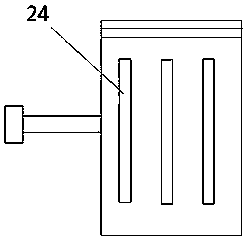

[0038] As shown in the figure: a mud treatment system, including liquid collection tank, conveying pipeline, centrifuge, centrifuge motor, control valve, mixing cylinder, flocculant pump, mud pump, mud tank, mixing cylinder motor, conveyor belt, inlet Mud pipe, discharge valve, bracket; the centrifuge includes first arc, second arc, third arc, connecting section, outer wall, middle wall, inner wall, scraper rod, scraper, multi-functional tank, outer maintenance plate, inner maintenance Pan, liquid discharge purge port, top wall of liquid discharge pipe, liquid discharge pipe, auxiliary purge port, mud discharge grid; the mud pump transports the mud in the mud pool to the mixing cylinder, and the flocculant pump transports the flocculant to the mixing tank. The motor of the mixing cylinder drives the blades inside the mixing cylinder to stir. The control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com