Removing device and removing method for polarizer

A polarizer and display panel technology, which is applied in chemical instruments and methods, optics, nonlinear optics, etc., can solve the problems of display panel fragmentation and poor removal efficiency, and achieve the effect of avoiding fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

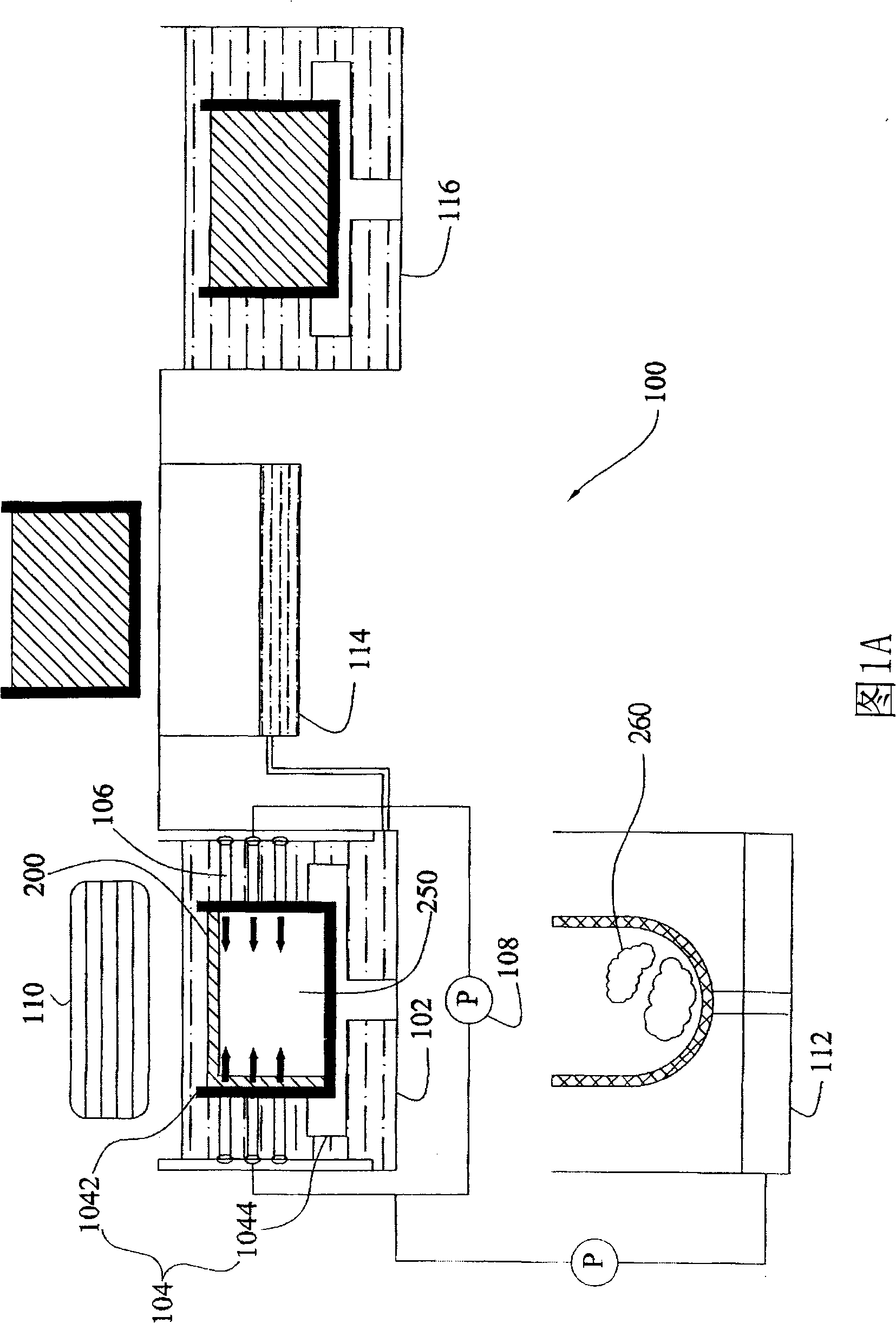

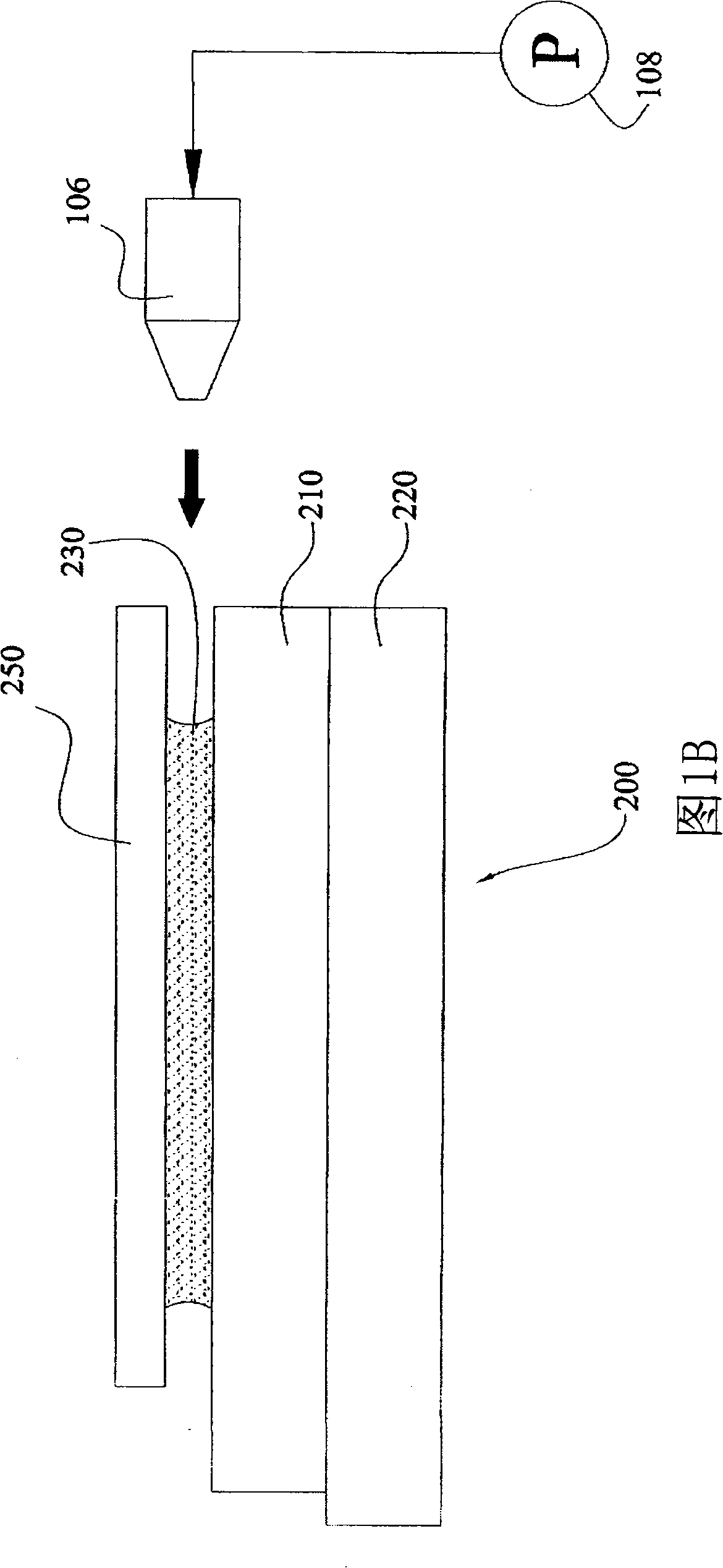

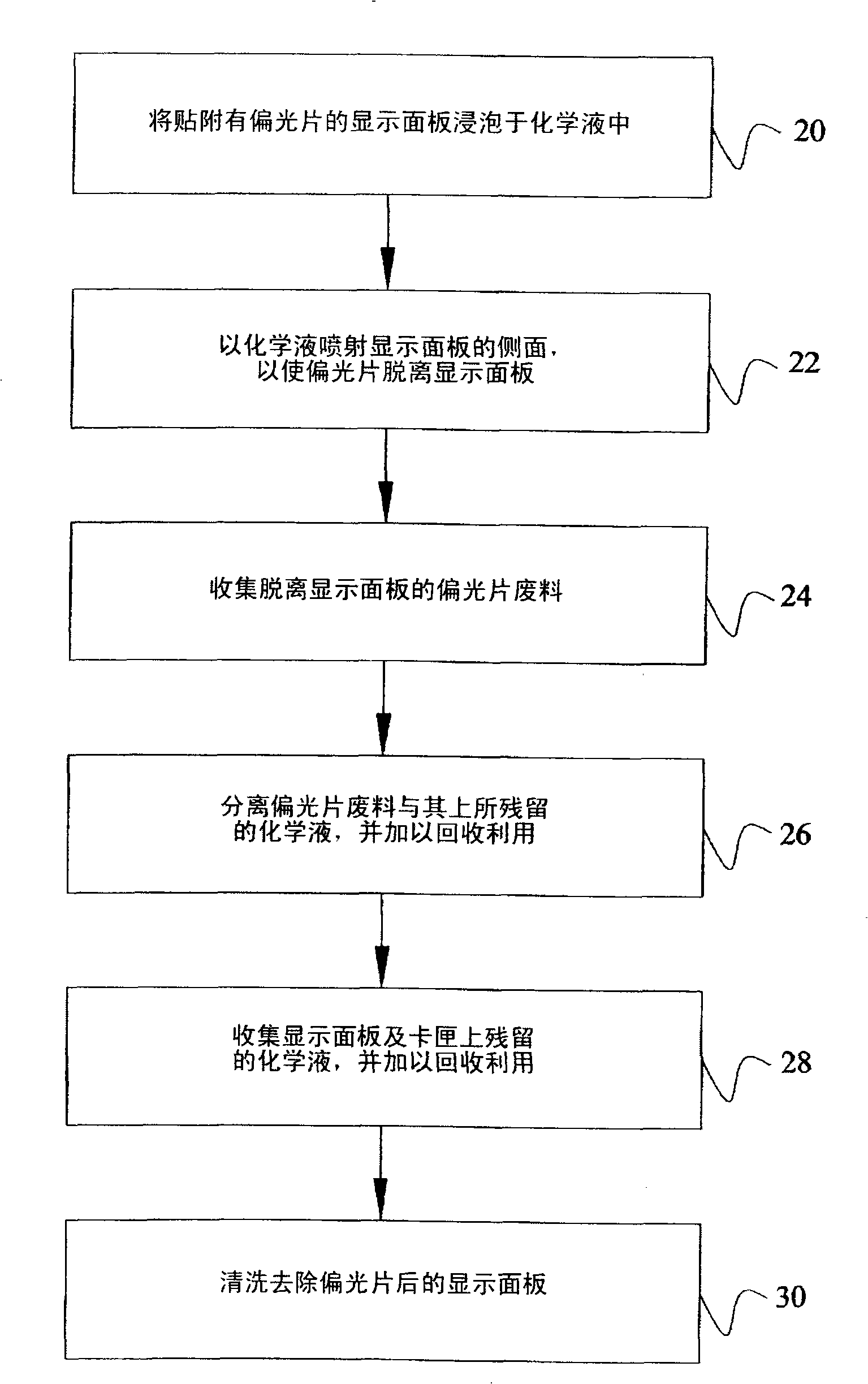

[0046] 1A and 1B below show an embodiment of the polarizer removing apparatus of the present invention. The polarizer removal device 100 is used to process the display panel 200 having the polarizer 250 on the surface, wherein the display panel 200 includes two glass substrates 210 and 220 , and the polarizer 250 is attached to the glass substrate 210 of the display panel 200 through a glue 230 . 230 is pressure sensitive adhesive (PSA, Pressure Sensitive Adhesive). Those skilled in the art know that any material of the substrate 200 or the colloid 230 can be used in the present invention, and the polarizer 250 can also be attached to the glass substrate 220 .

[0047] As shown in FIG. 1A , the polarizer removal device 100 includes a film removal tank 102 , a carrier unit 104 , an ejector 106 , a chemical solution supply unit 108 , a fan 110 , a waste collection tank 112 , a chemical solution collection tank 114 , and a cleaning tank 116 .

[0048] The film removing tank 102 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com