Transfer roller with adjustable vacuum adsorption force and method for attaching thin film by using transfer roller

一种真空吸附、转写的技术,应用在化学仪器和方法、应用、家里用具等方向,能够解决基板破片、黏性无法控制等问题,达到避免破片、易操作、提升贴附良率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

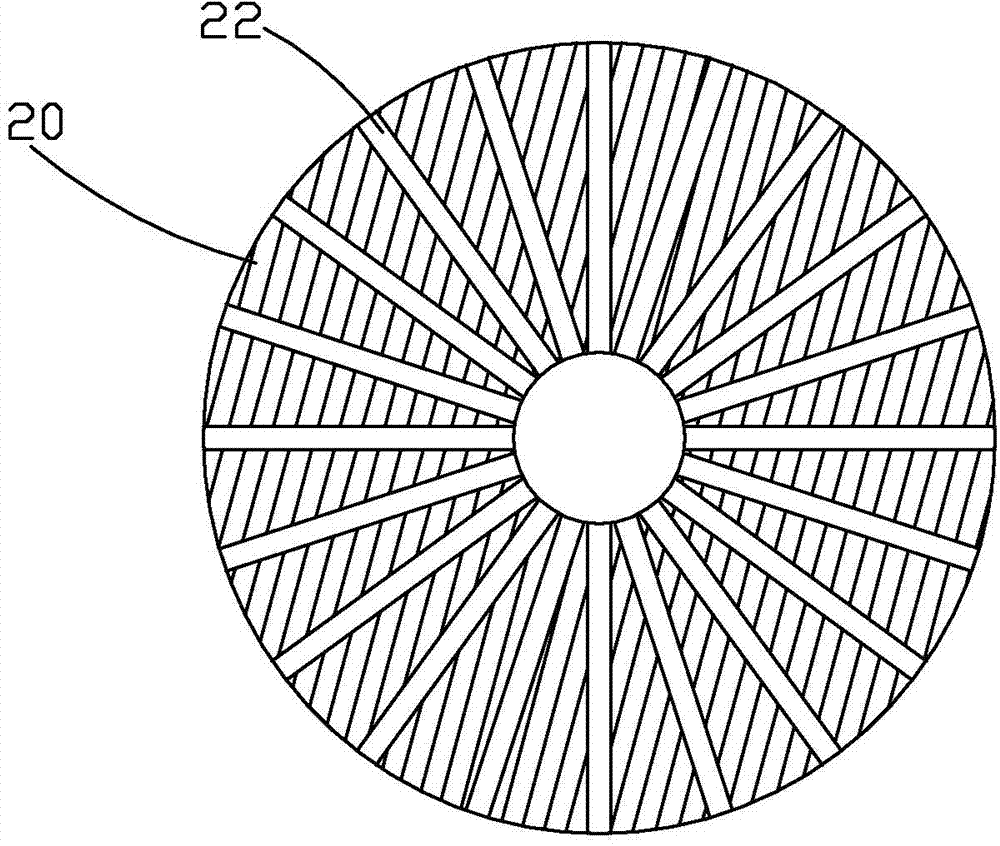

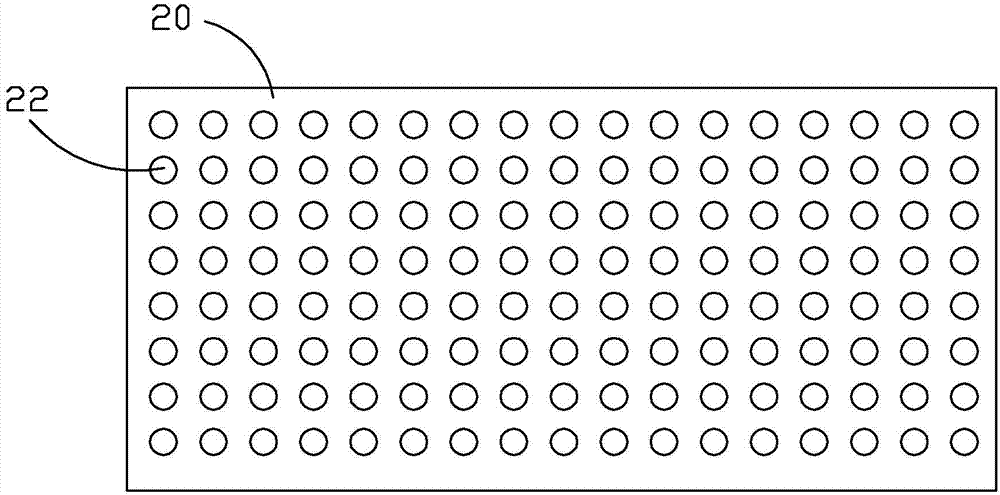

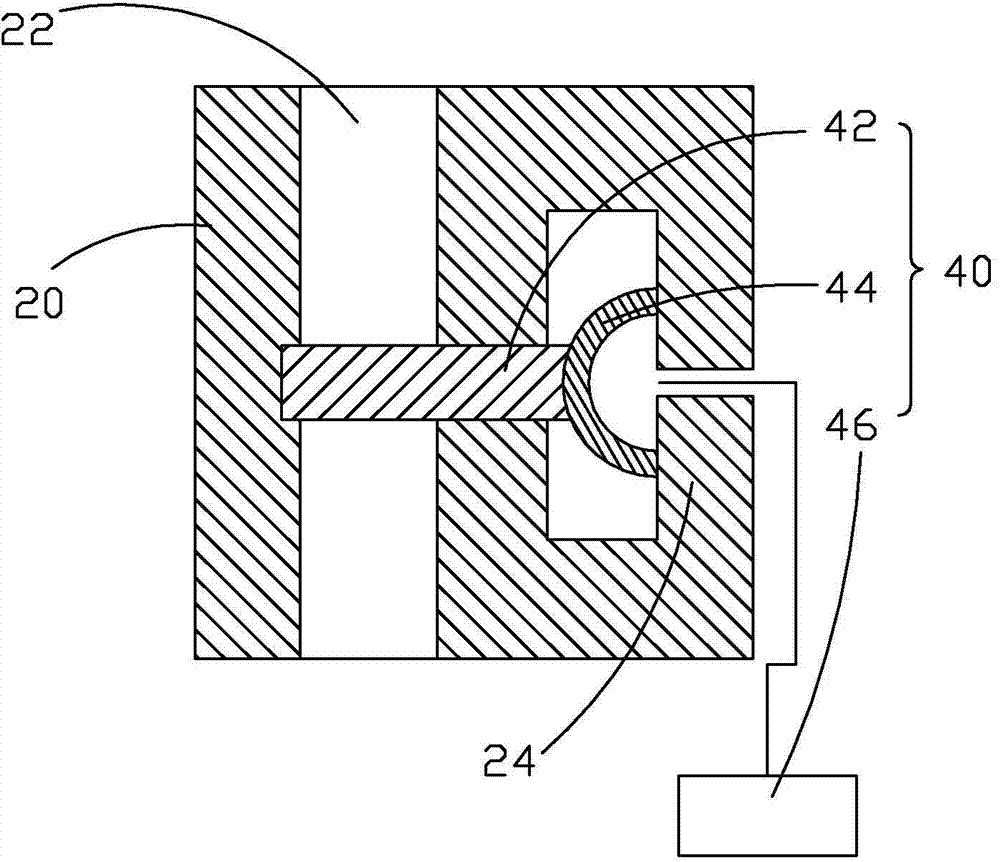

[0034] see Figure 1 to Figure 5 , the present invention provides a transfer roller with adjustable vacuum adsorption force, comprising: a roller body 20 and several adjusting devices 40 installed on the roller body 20, and several suction pipes 22 are evenly distributed in the roller body 20, The regulating device 40 is set corresponding to the suction pipeline 22, and the suction pipeline 22 is sucked by the suction device. Each regulating device 40 includes: a valve 42 arranged on the suction pipeline 22, The piezoelectric ceramic 44 connected to the valve 42 and the control circuit 46 electrically connected to the piezoelectric ceramic 44, the roller body 20 is provided with a mounting part 24 corresponding to each suction pipeline 22, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com