Suction head component

A component and connecting plate technology, applied in the direction of suction cups, connecting components, conveyor objects, etc., can solve the problems of low work efficiency, inability to attach, and angle restrictions when attaching, so as to achieve high work efficiency and adjustable angle , the effect of precise height positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

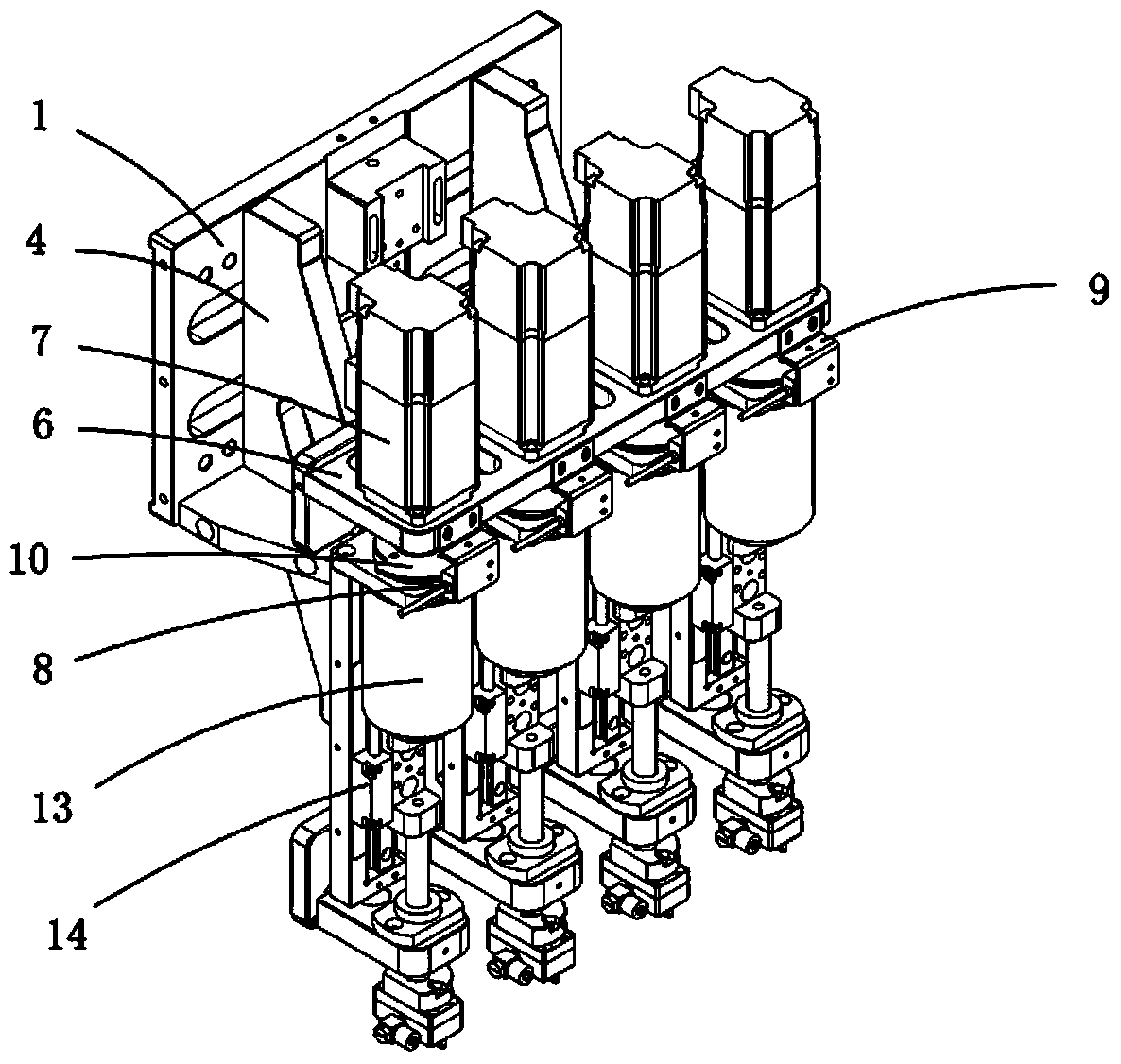

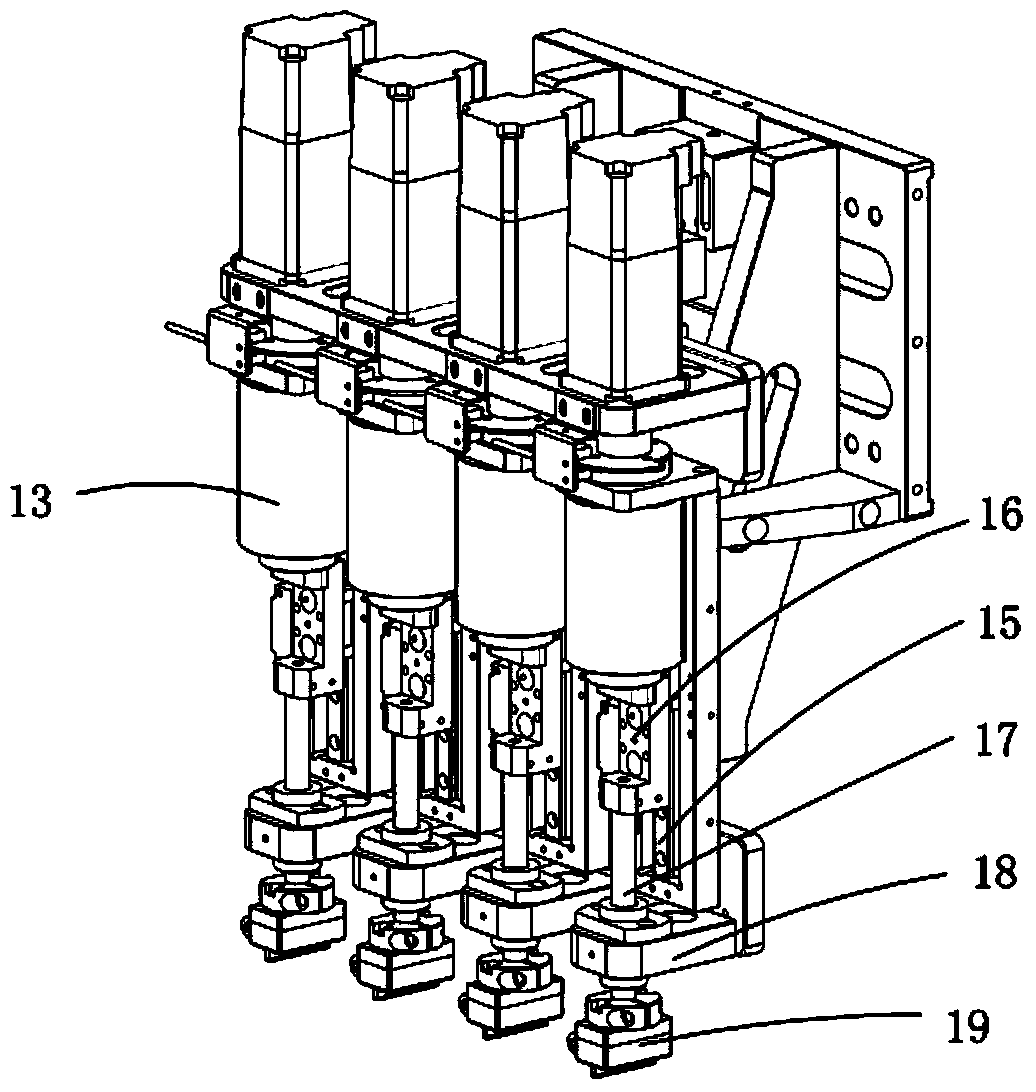

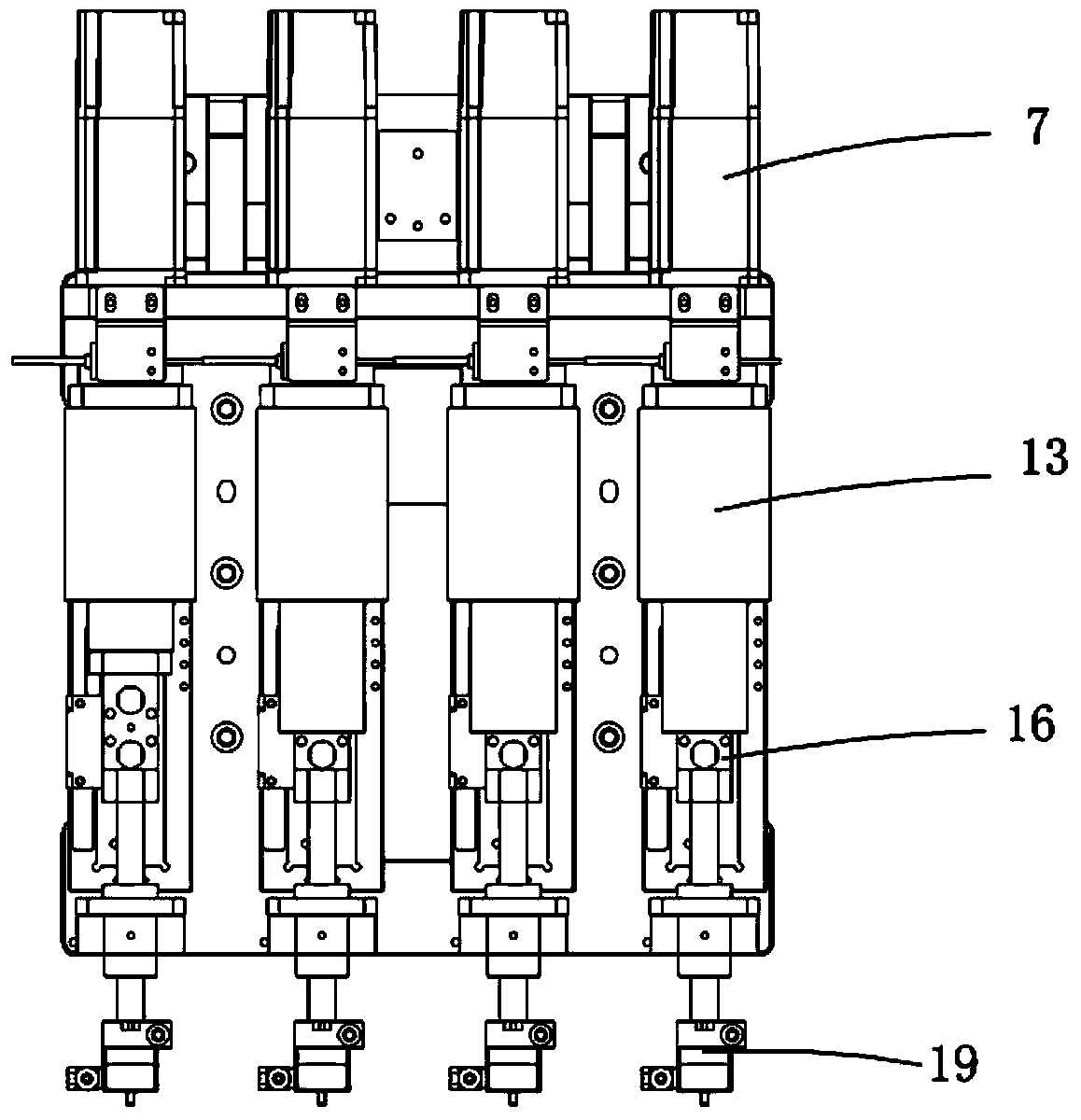

[0018] Examples, see attached Figure 1~4 , a suction head assembly, which includes a mounting plate 1, a connecting plate a2, a connecting plate b3, a reinforcing plate a4, a reinforcing plate b5 and a suction module, the connecting plate a is vertically installed on the right side of the mounting plate, the The connecting plate b is vertically installed on the right side of the connecting plate a, and the mounting plate and the connecting plate a are strengthened and fixed by the reinforcing plate a, and the connecting plate b and the connecting plate a are strengthened and fixed by the reinforcing plate b; the suction mold The set includes motor mounting plate 6, deviation correction servo motor 7, deviation correction sensor 8, deviation correction sensor fixing seat 9, induction sheet 10, horizontal plate 11, vertical plate 12, voice coil motor 13, grating ruler 14, slide rail 15, suction Head connection block 16, guide rail 17, suction head fixing block 18 and suction he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com