Flexible OLED cover plate laminating and assembling equipment

A technology for assembling equipment, cover plates, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

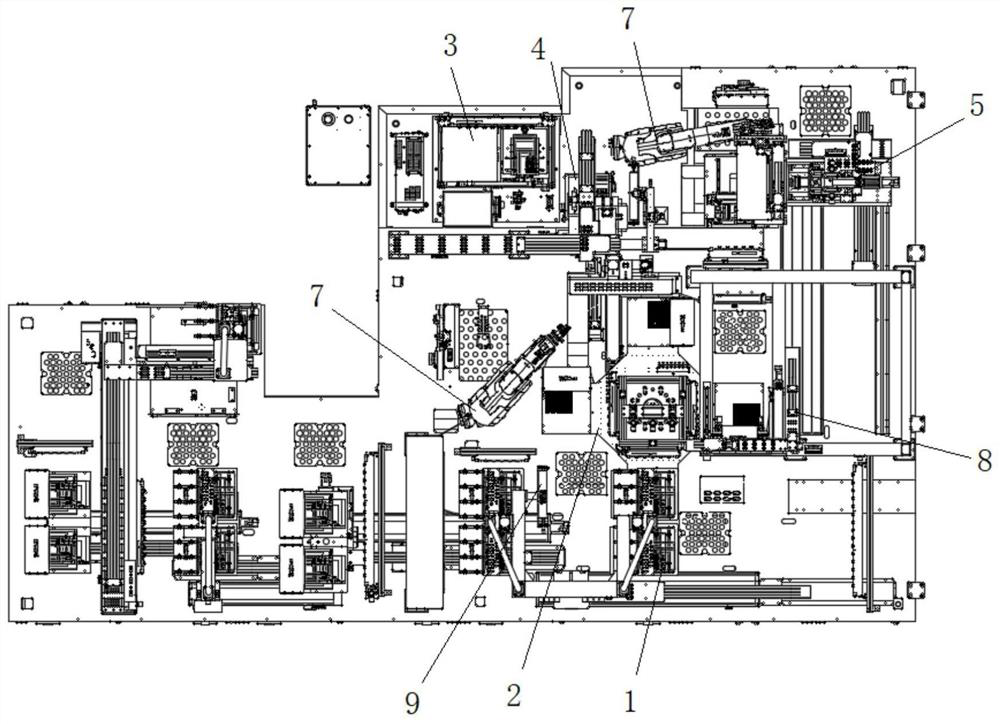

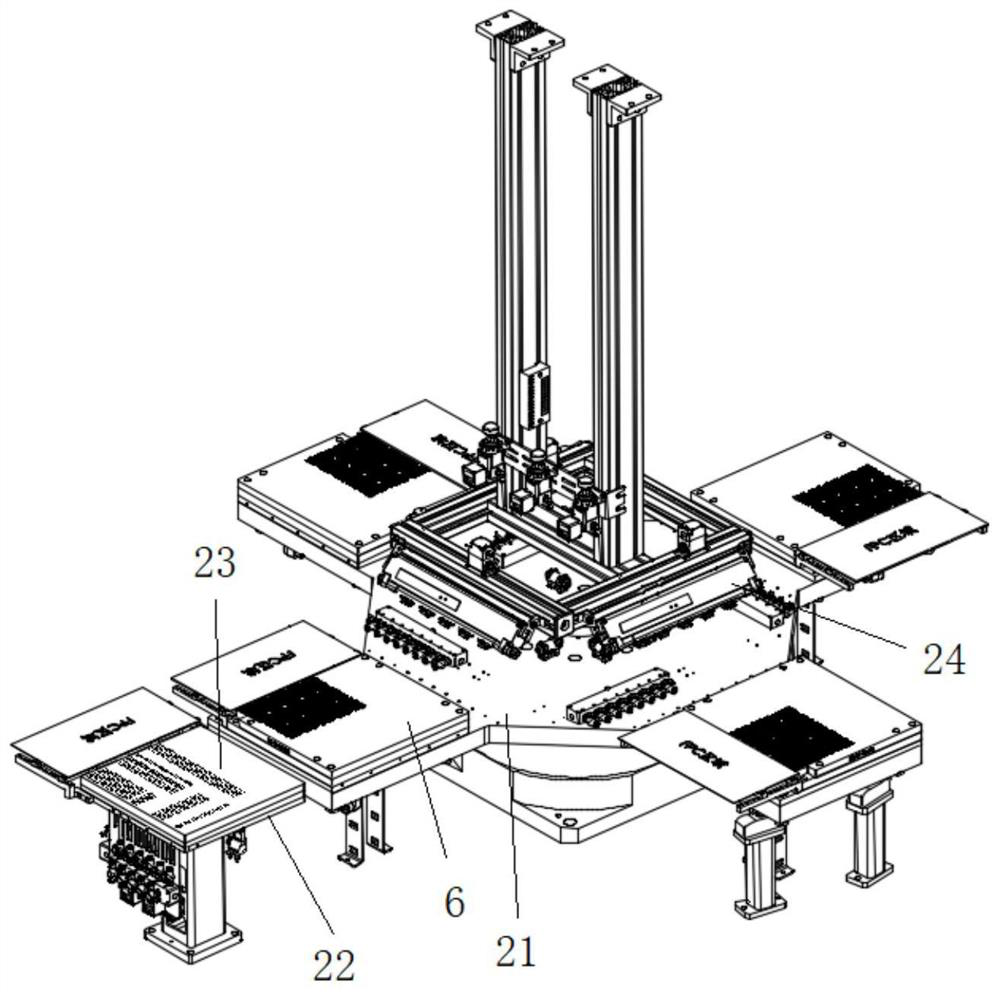

[0038] refer to Figure 1-12 As shown, this embodiment is a flexible OLED cover laminating and assembling equipment, including a handling platform 1 for transferring the attached OLED board, a turntable platform 2 for receiving the OLED board on the side of the handling platform 1, and a The silo device 3 for storing the cover glass, the transfer platform 4 cooperating with the hopper device 3, the transfer attachment transfer device 5 positioned and moved along the transfer platform 4 and the turntable platform 2, used to tear off the OLED The surface film of the plate 6 and the film tearing manipulator device 7 for tearing off the surface film of the cover glass 61 , and the visual inspection device 8 arranged above the turntable platform 2 .

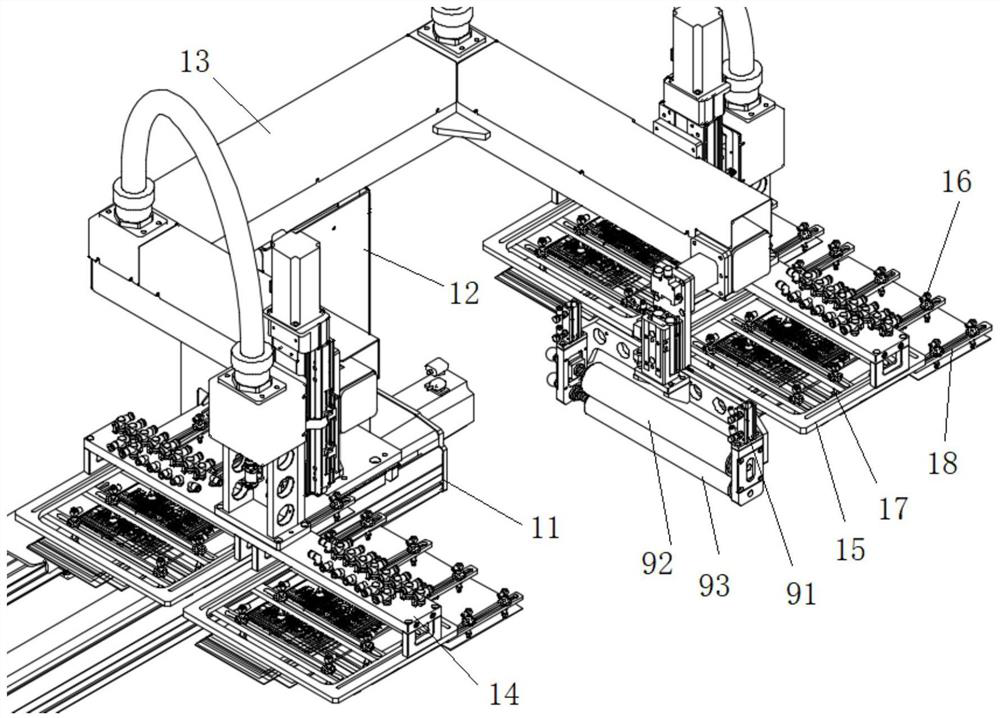

[0039] The transport platform 1 includes a linear module 11 and a double-station adsorption assembly that moves along the linear module 11; a stand 12 is installed on the linear module 11, and a U-shaped horizontal frame 13 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com