Method and device for the laser-supported detachment of a section from a planar glass element

A seed part, glass technology, applied in the field of internal separation of glass components, can solve the problems of damage, lower economic benefits, cost, etc., and achieve the effect of high edge quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

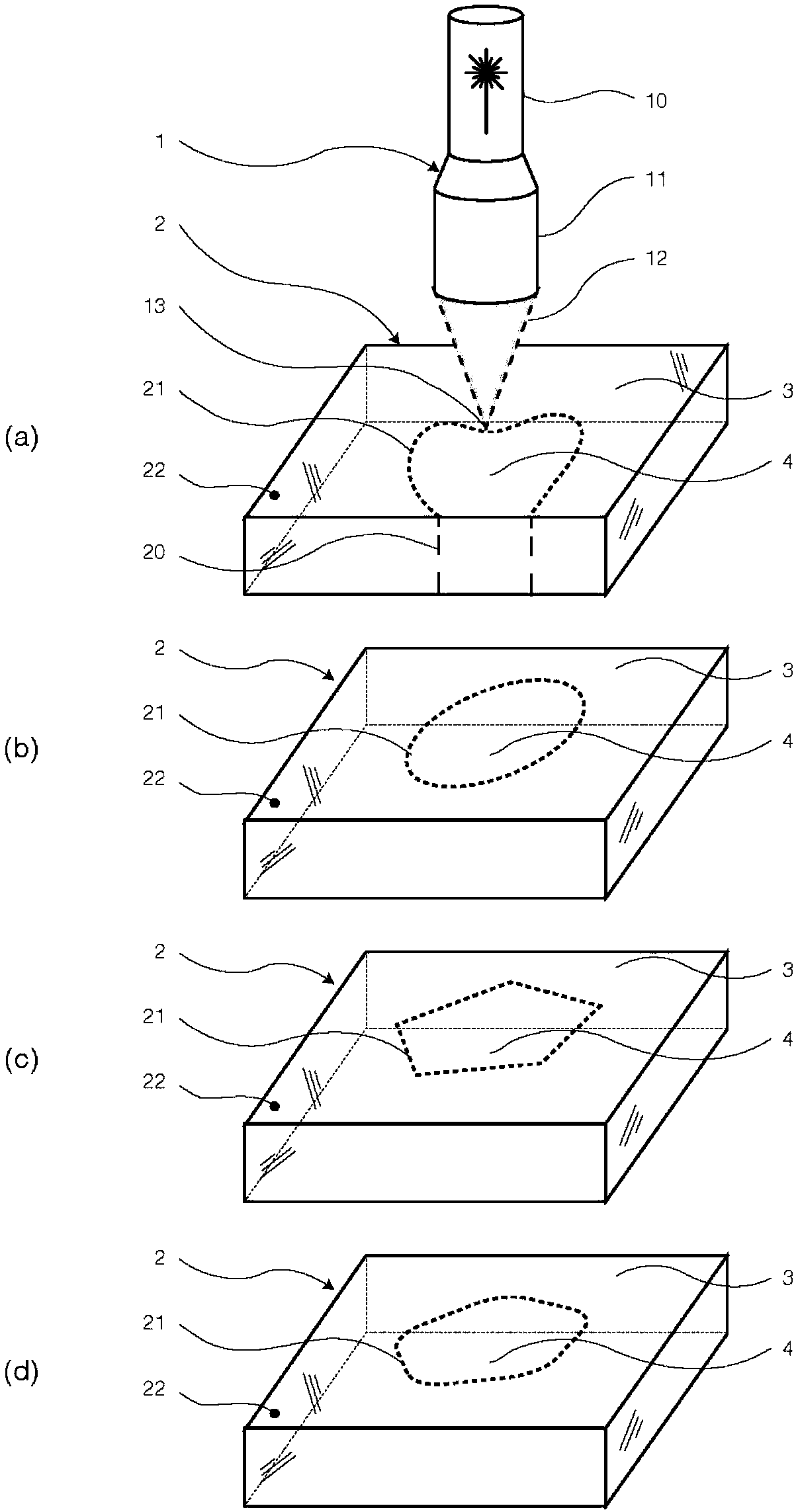

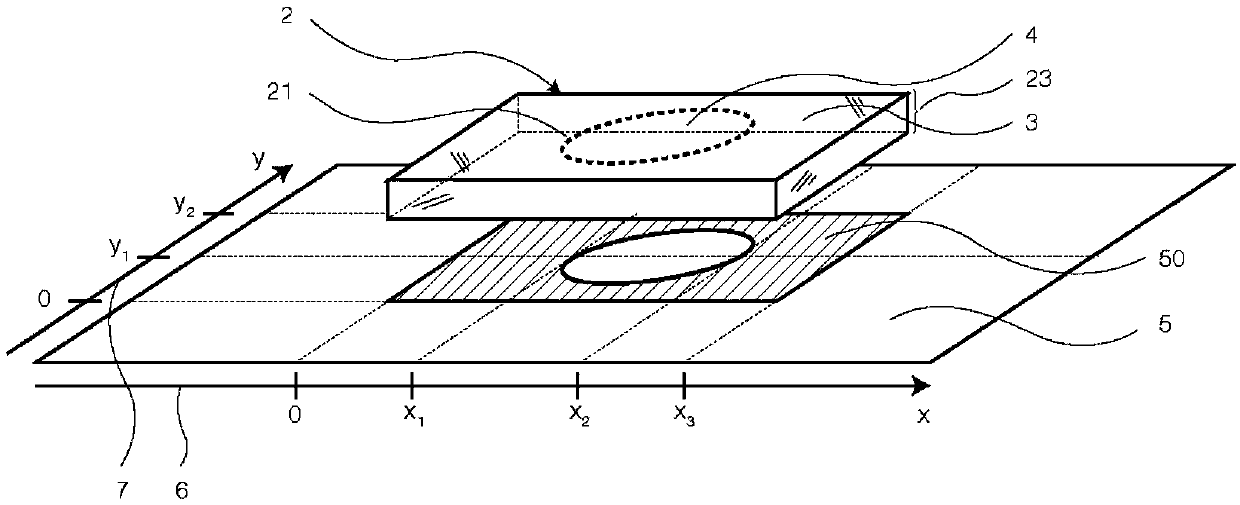

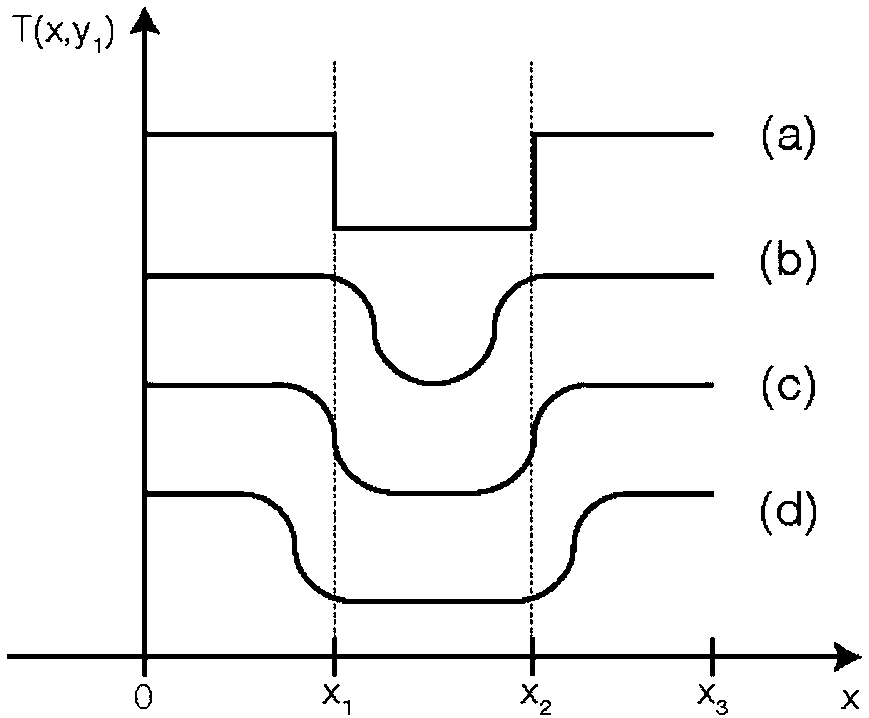

[0098] figure 1 A laser processing device 1 is schematically shown, with which a glass element 2 is micro-perforated by introducing a filiform lesion 20 along a defined separation line 21 and thus prepared for subsequent separation.

[0099] The laser treatment device 1 comprises an ultrashort pulse laser 10 whose laser pulses 12 are directed onto the glass element 2 . For this purpose, the laser pulse 12 is focused on the glass element 2 by means of a focusing device 11 . The wavelength of the ultrashort pulse laser 10 is selected such that the laser pulse 12 can penetrate into the glass element 2 .

[0100] The laser pulse 12 here generates a plasma in the volume of the glass component 2 which leads to filamentary damage 20 . The point of incidence 13 of the laser pulse 12 on the glass element 2 is continuously moved on the surface 22 along the defined separation line 21 .

[0101] The separation line 21 is defined here in such a way that the separation line can completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com