Double-group winding machine

A technology of winding machine and winding mechanism, which is applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc. It can solve the problems affecting the feeding and winding of the coil skeleton, the support block is easy to wear, and the production efficiency is reduced. , to achieve the effect of reducing space volume and manufacturing cost, saving space volume, and avoiding operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

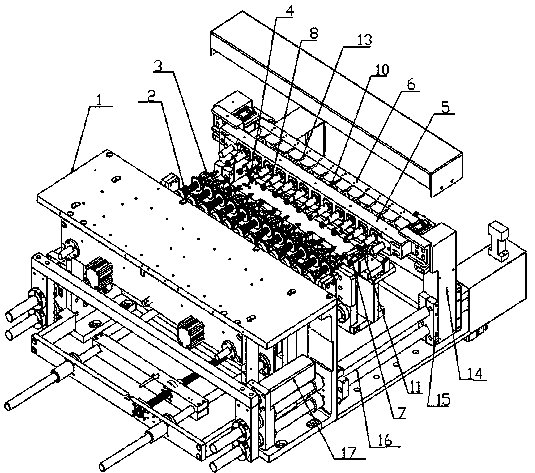

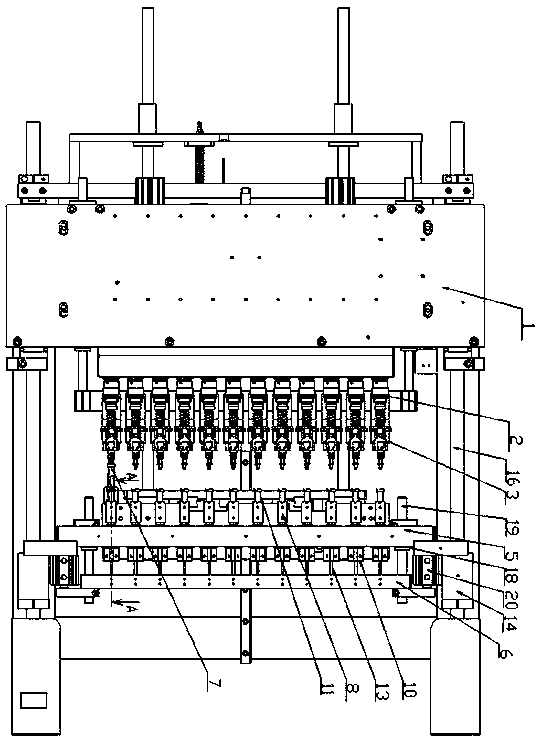

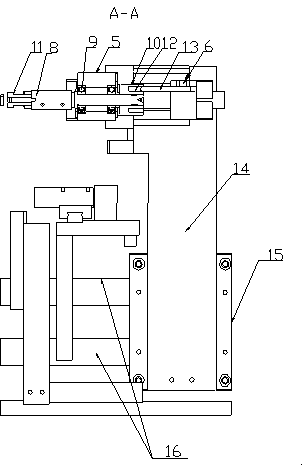

[0041] Such as Figures 1 to 4 As shown, the present invention discloses a double-group winding machine, which includes a frame 1, several winding spindles 2 equidistant and horizontally installed on the front side of the frame 1, a double-group winding mechanism above the frame 1 and a package The glue mechanism, the feeding mechanism directly in front of the frame 1, each winding spindle 2 is equipped with a fixture 3 for installing the coil skeleton 62, the feeding mechanism, the double-set winding mechanism and the rubber covering mechanism are respectively connected to the winding spindle The jig 3 on the 2 cooperates to realize feeding, double-group winding and rubber encapsulation.

[0042] The feeding mechanism includes a feeding plate 4 directly in front of the frame 1 and a skeleton mounting seat B installed on the feeding plate 4 and corresponding to the winding main shaft 2 one by one. The upper end surface of each skeleton mounting seat B has a The coil frame ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com