Flexible screen body bending and attaching machine

A flexible screen and attachment machine technology, applied in the field of display screens, can solve problems such as position error, low installation accuracy of flexible screens, and affecting the quality of OLED display screens, and achieve a high level of automation and improve the effect of attachment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

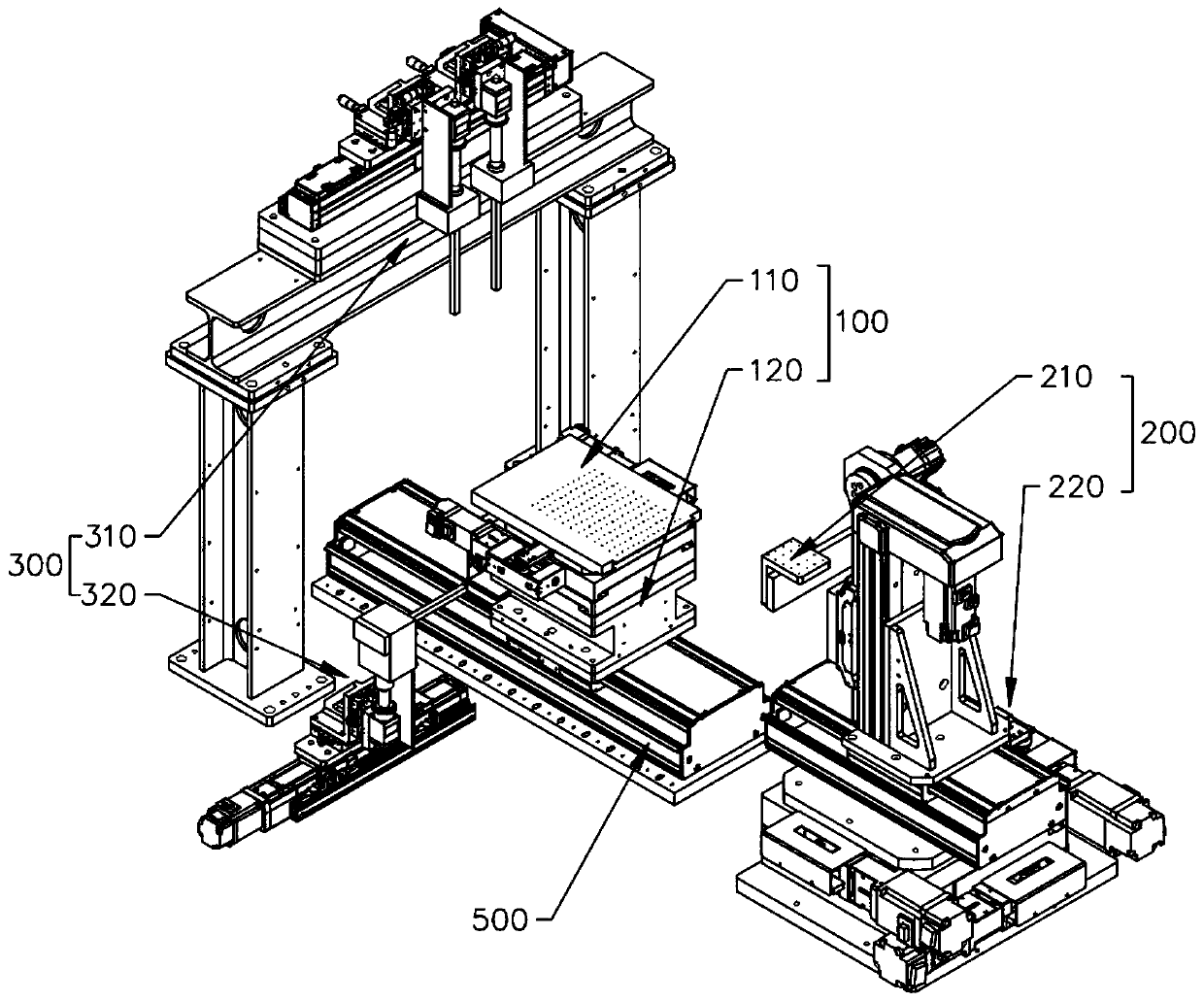

[0041] The first aspect of the embodiments of the present invention provides a flexible screen bending and attaching machine, including a workbench 100, a bending mechanism 200, and a positioning adjustment mechanism.

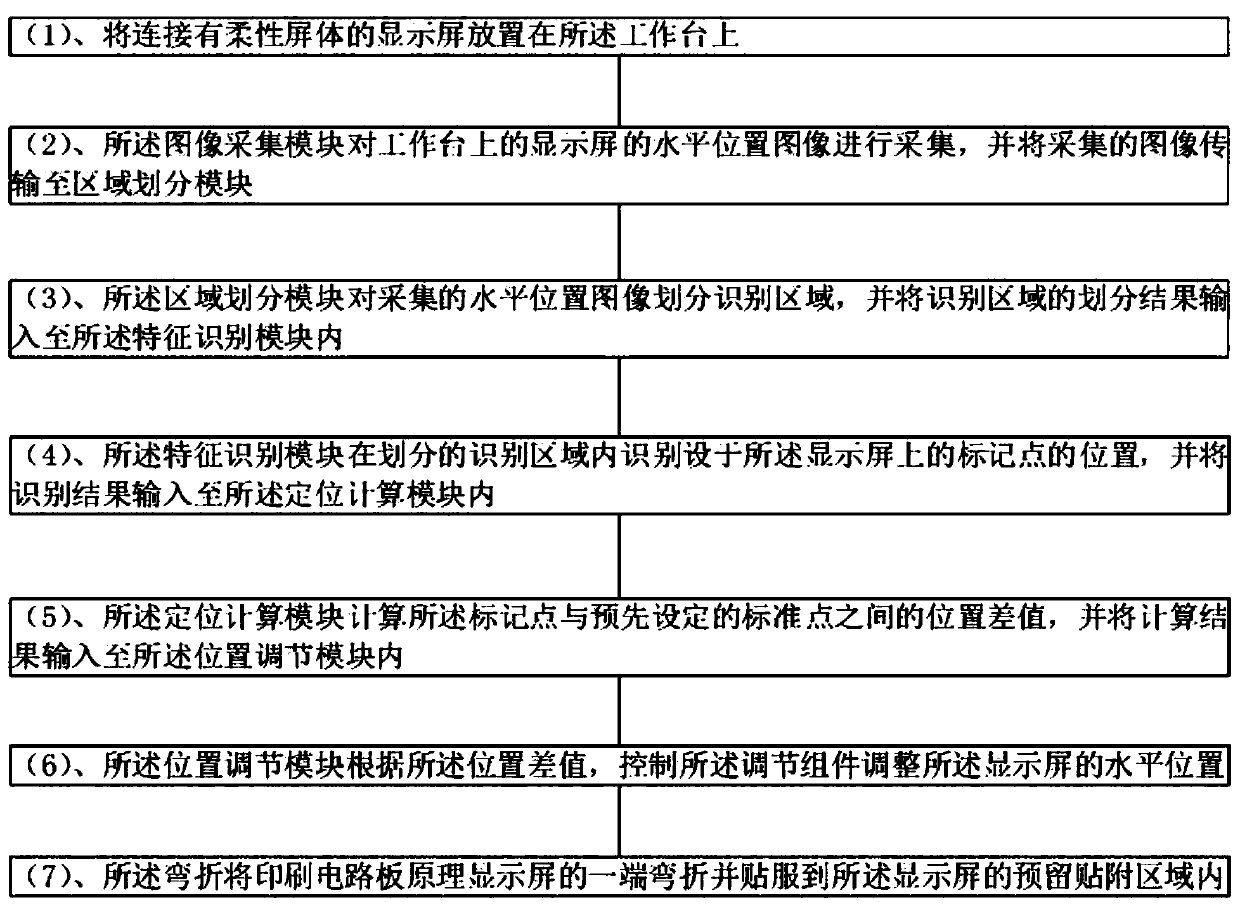

[0042] The workbench 100 is used to carry the display screen, which includes: a loading fixture 110 for fixing the display screen and an adjustment assembly for adjusting the position of the loading fixture 110 .

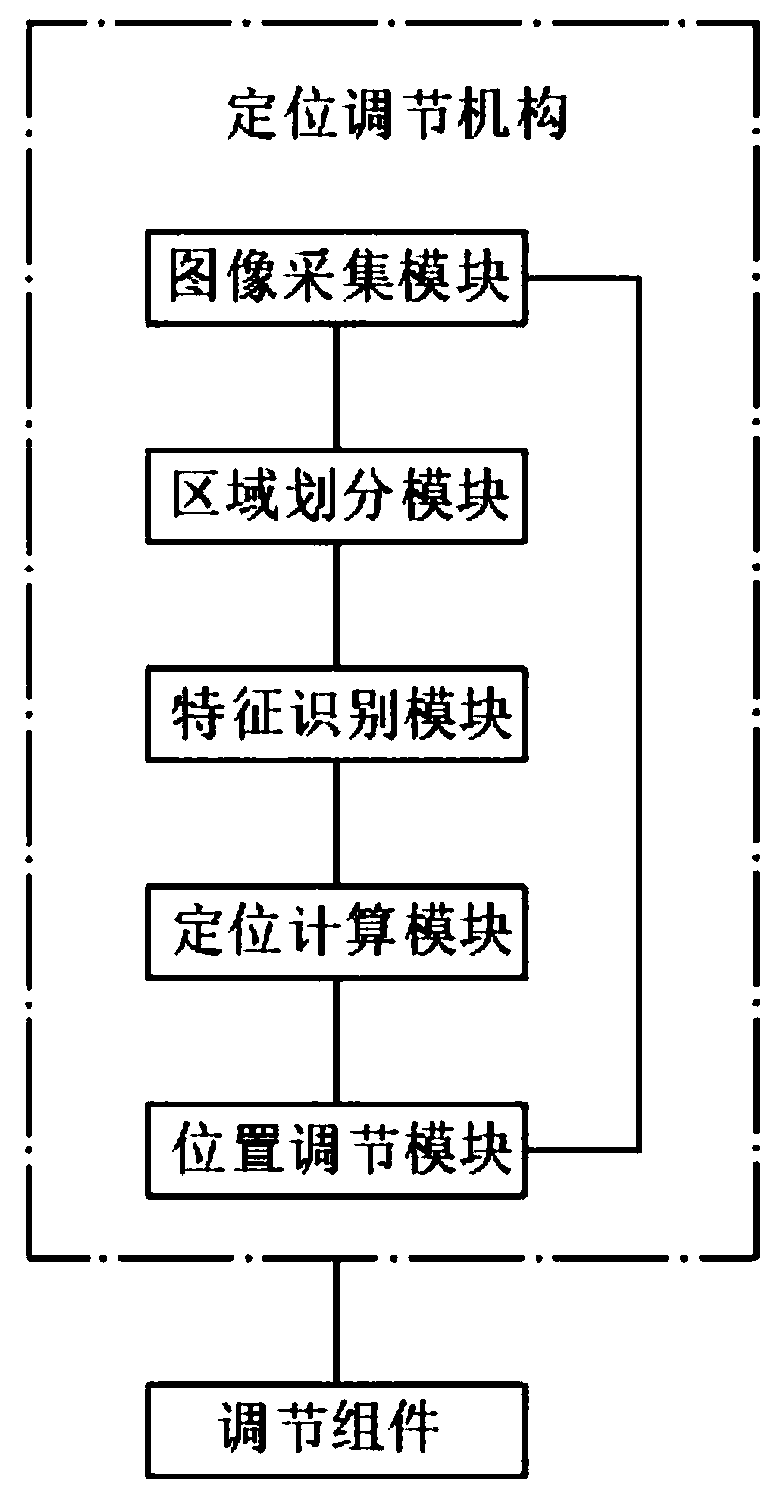

[0043] The positioning adjustment mechanism is used to detect whether the horizontal position of the display screen on the workbench 100 falls within a preset range, and if it does not fall within a preset range, send an adjustment command to the adjustment component, The horizontal position of the display screen is adjusted by driving the adjusting component; if it falls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com