T-FOF plasma cleaning and ACF attaching combined mechanism for

A plasma cleaning, 1.T-FOF technology, applied in cleaning methods and utensils, chemical instruments and methods, electrical components, etc., can solve the problems of time-consuming attachment accuracy and cleanliness, influence, XYQ axis cannot be adjusted automatically, etc. , to achieve the effect of easy adjustment and saving time for adjusting the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: the concrete structure of the present invention is as follows:

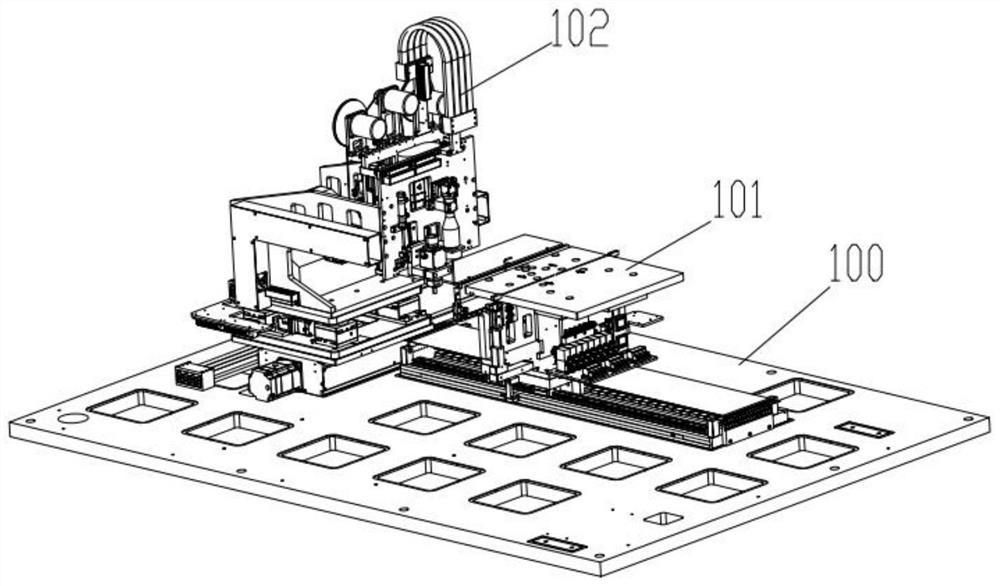

[0047] Please refer to attached Figure 1-6 , a combination mechanism of plasma cleaning of T-FOF and ACF of the present invention, comprising:

[0048] base plate 100;

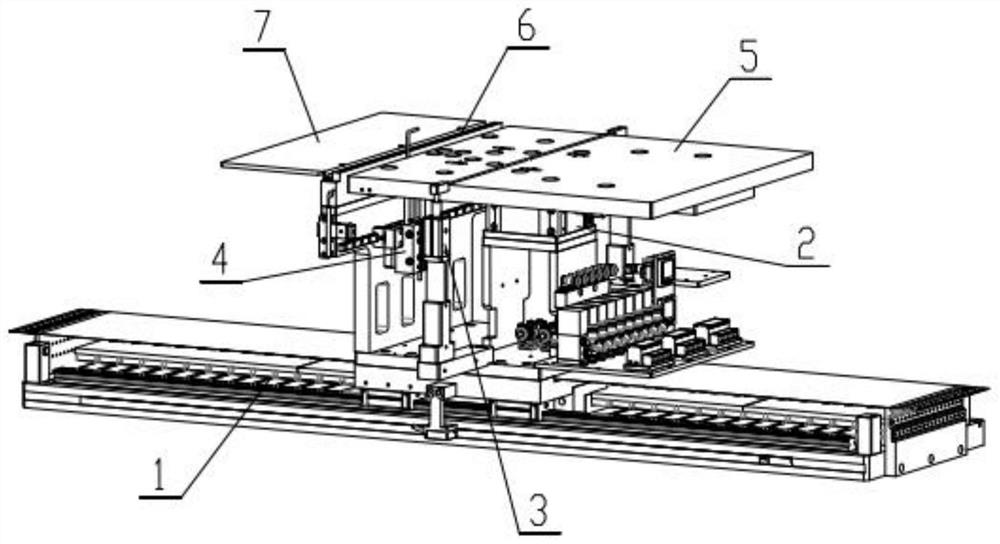

[0049] The platform assembly 101 has a plasma membrane placement platform 5 and a Y-axis drive mechanism 1 installed on the bottom plate 100. The Y-axis drive mechanism 1 is provided with a first slider assembly for Y-axis movement. The top surface of the slider assembly is respectively equipped with a Z-axis mechanism 2 for adjusting the height of the plasma membrane placement platform 5 in the Z direction, 2 stripping lever mechanisms 3 arranged on both sides of the Z-axis mechanism 2, and an adjustable thimble Separation mechanism 4;

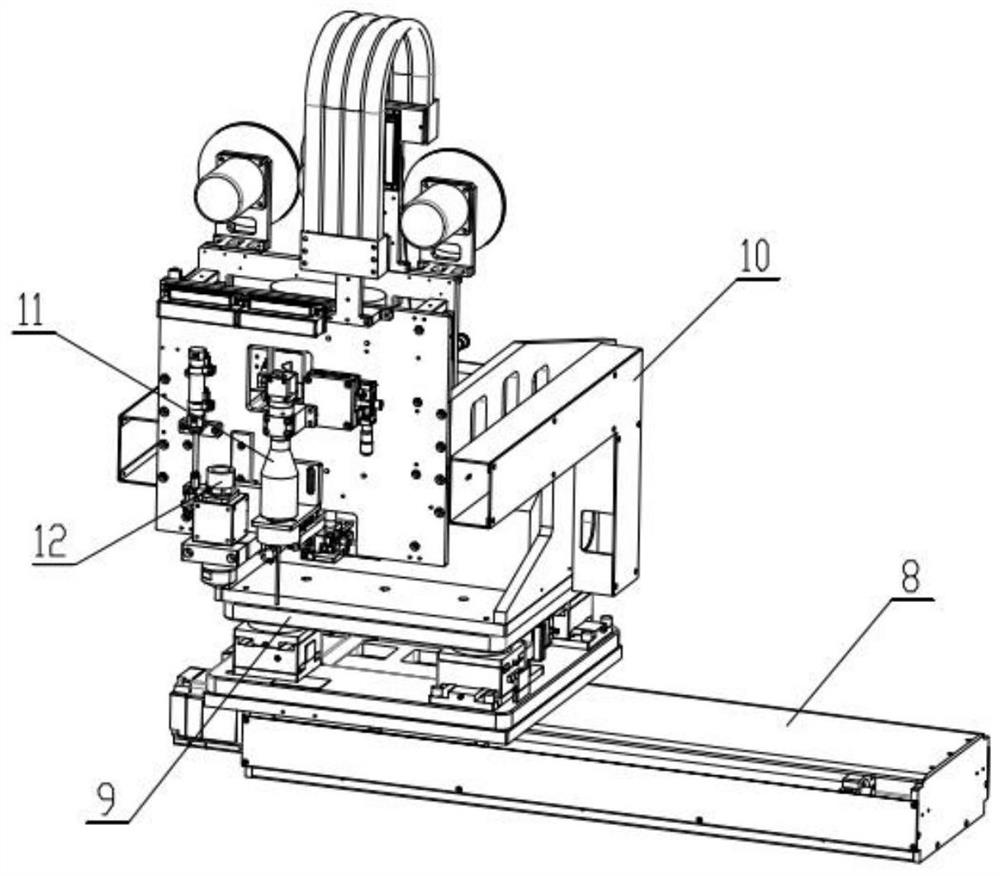

[0050] The cleaning and attaching assembly 102 has an X-axis driving mechanism 8 installed on the base plate 100 and vertically arranged with the Y-axis driving mechanism 1. The X-axis d...

Embodiment 2

[0077] The working principle of the combined mechanism of plasma cleaning of T-FOF and attachment of ACF of the present invention:

[0078] The product to be cleaned and attached with ACF glue is placed on the plasma membrane placement platform 5, the vacuum on the main platform is turned on, and the Panel is adsorbed. According to the position of the T-FPC, the adjustable thimble separation mechanism 4 automatically adjusts the position, and pushes the T-FPC upwards. After separation, the peeling rod mechanism 3 on both sides automatically peels off according to the shape of the product, and the Y-axis drive mechanism 1 drives the plasma membrane placement platform 5 to move, and the product runs to the bottom of the Plasma cleaning machine [that is, the above-mentioned cleaning device 12], and the paste The attached position is cleaned and then ACF is attached, and then the ACF attachment accuracy is detected by a high-precision camera, and the platform components are returne...

Embodiment 3

[0080] The combination mechanism of Plasma cleaning and ACF attachment of T-FOF of the present invention is used for cleaning and ACF glue attachment before binding of T-FPC and M-FPC, and is also used for cleaning and attachment of FPC and Panel on various planes. attach. Due to the complex structure of the special-shaped T-FPC and M-FPC, and the special binding position, the T-FPC needs to be automatically peeled off to facilitate cleaning and ACF attachment. For this purpose, a shared use of Plasma cleaning and ACF attachment is set up. Place the platform mechanism. Plasma cleaning and ACF attachment placement platform mechanism adopts anti-static vacuum suction nozzle for Panel placement, ACF attachment support back drag can automatically adjust the vacuum adsorption and peeling rod according to different positions of the product, and the attachment back drag is made of high-quality stainless steel 440C material, the flatness of the supporting surface of the back drag is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com