Welding method for carriage side plate of self-dumper

A welding method and dump truck technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of large bending deformation of the side plate of the carriage, and achieve the effect of reducing the deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

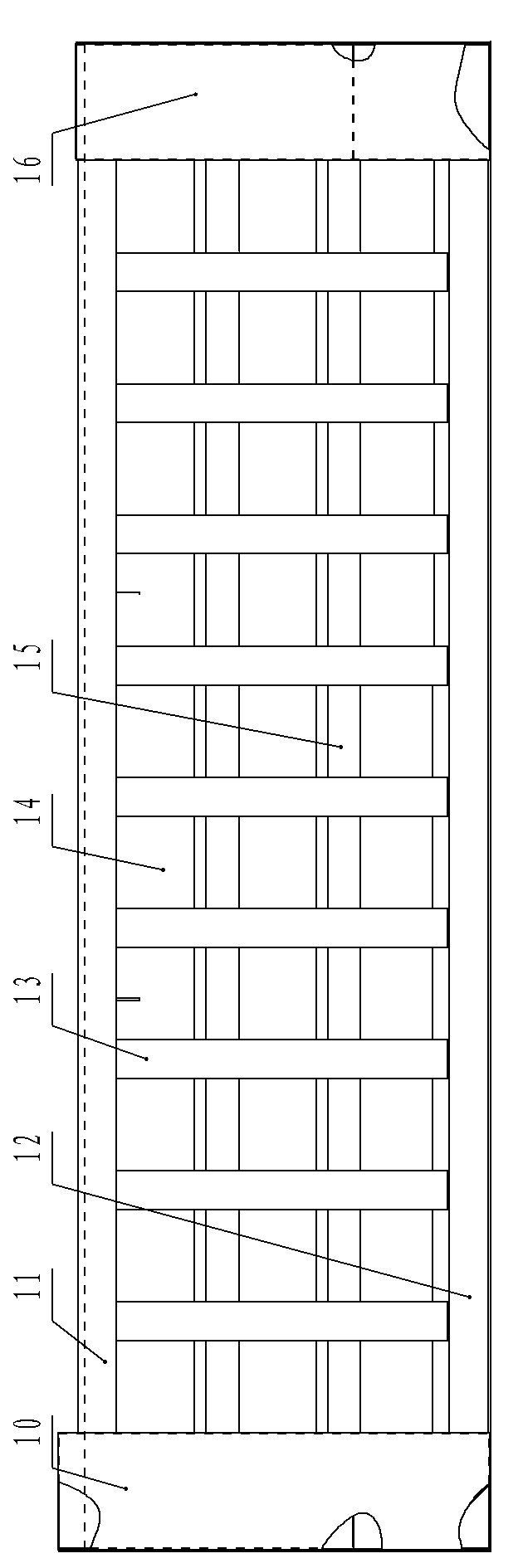

[0031] Such as figure 1 Shown is the dump truck side plate of the embodiment of the present invention, and the method for welding the side plate of the dump truck comprises the following steps:

[0032] A. Hoist the tailor-welded side plate bottom plate 14 onto the platform of the first station, and place the rear large column 16, the side plate frame 11, the side plate lower frame 12, the front large column 10, multiple middle columns 13 and Multiple pieces of middle transverse ribs 15 are respectively spot-welded and fixed on the side plate bottom plate 14 to form the side plate of the carriage. At the short sides of both ends of the side plate, the side plate frame 11 and the side plate lower frame 12 are respectively fixed on the long sides of the side plate bottom plate 14; multiple pieces of central columns 13 and multiple pieces of middle transverse ribs 15 are distributed on the side plate bottom plate at intervals 14 on the board. The spot welding fixing sequence is...

Embodiment 2

[0040] The welds formed by welding the side plate of the carriage in this embodiment are: the welds between the central column 13, the middle transverse rib 15, the lower frame 12 of the side plate, the frame 11 of the side plate and the bottom plate 14 of the side plate are intermittent For fillet welds, the fillet size of the intermittent fillet welds is 6 mm, the length of the welds is 150 mm, and the distance between adjacent welds is 100 mm; The welding seam is a continuous fillet weld, and the fillet size of the continuous fillet weld is 6 mm; other features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com