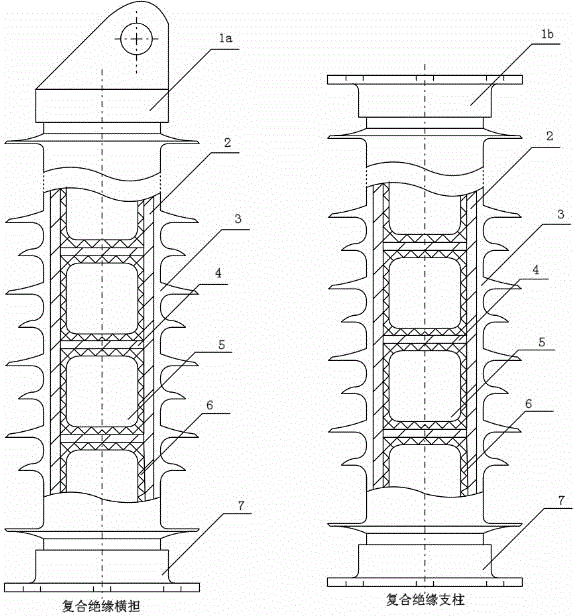

Light composite crossarm and pillar of solid insulators interruptedly filled in epoxy glass fiber tube

An epoxy glass fiber tube and solid insulation technology, which is applied in the field of insulating cross arms and substation insulating pillars, can solve the problems of poor rigidity of solid extruded rods, out-of-round deformation of insulating tubes, and inadequate restoration of fillings, etc., to reduce bending The effect of deformation, product weight reduction, and raw material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

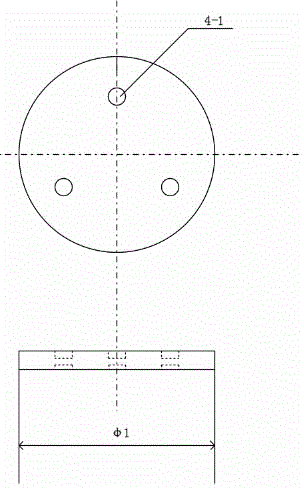

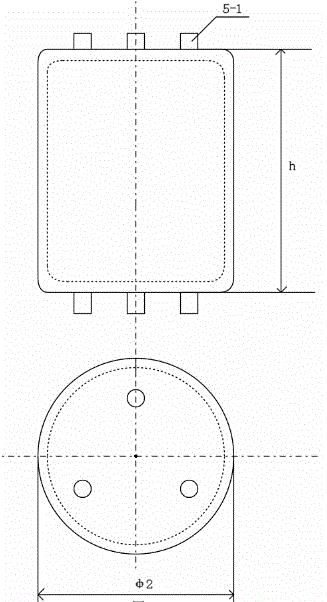

[0011] 1. Refer to the attached figure 2 Production of insulating support plate 4; 2. Refer to the attached image 3 , in a clean environment with a constant temperature of 20°C and a humidity of less than 50%, make an insulating airbag 5 to ensure that the gas in the airbag is clean and dry; 3. Put the epoxy glass fiber tube in a special mold to vulcanize the silicone rubber shed 3; 4. Install the insulating support plate 4 at the lower end of the vertical epoxy glass fiber tube with the shed 3, the positioning holes on the support plate are aligned with the positioning pins at the lower end of the insulating airbag 5, and filled with an appropriate amount of insulating material. The upper end of the insulating air bag 5 is aligned with the positioning pin hole, and another insulating support plate 4 is installed. This is repeated until the insulating support plate 4 and the insulating air bag 5 are installed in the entire epoxy glass fiber tube, and the insulating material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com