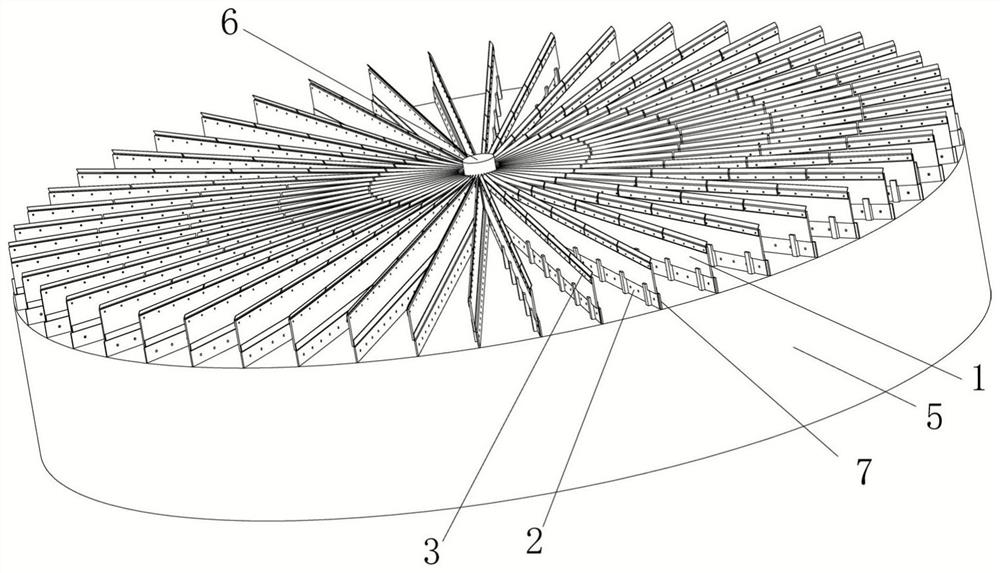

Novel non-deformation constant-air-leakage-rate sealing device for air pre-heater

A sealing device and air preheater technology, applied in the direction of heat exchanger shell, indirect carbon dioxide emission reduction, combustion method, etc., can solve the problems of losing the swing limit of the floating plate, hidden danger of operation, and high maintenance cost, and can eliminate the installation and welding process. , to ensure the flexibility of activities, to simplify the effect of the sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

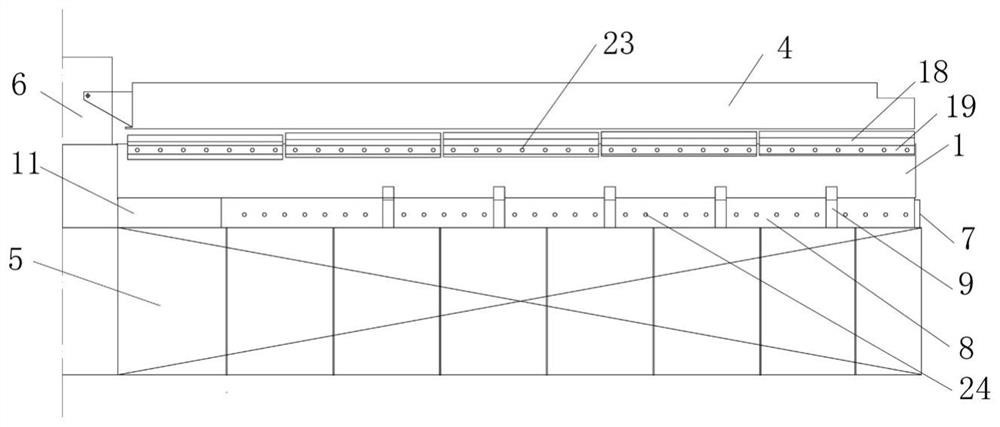

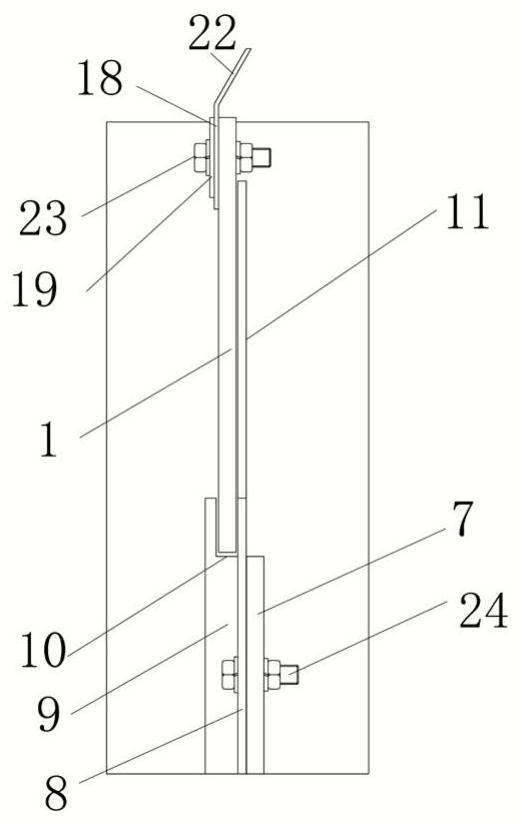

[0062] When installing, first place the limit plate 8 of the limit mechanism 2 on the rotor 5 and pre-attach it to the rear side of the storage grid plate 7 in the direction of rotation. Then, after aligning the fastening connection hole 16 of the limit plate 8 with the fastening hole 15 at the bottom of the compartment panel 7, use the fastener 24 to pass through the fastening connection. The hole 16 and the fastening hole 15 lock and fix the limiting plate 8 on the compartment grid plate 7, and the installation of the limiting mechanism 2 is completed.

[0063] After the installation of the limit mechanism 2 is completed, the rear end of the floating plate 1 is first placed in the limit groove 10 of the limit mechanism 2, and the horizontal section 13 of the limit support hook 9 arranged at five consecutive equal distances will float The plate 1 is stably supported and supported to facilitate the subsequent installation of the floating plate 1, and plays a role in the radial...

Embodiment 2

[0068] This embodiment is similar to Embodiment 1, the difference is that the vertical section 12 of the present embodiment is provided with a support reinforcement plate 14 outside, and the vertical section 12 is used to improve the position-limiting effect of the floating plate 1 through the support reinforcement plate 14, effectively extending the The service life of the limit mechanism 2 ensures long-term safe and stable operation of the non-deformable and constant air leakage rate sealing device of the present invention. The height of the limiting plate 8 of the present embodiment is 15 mm higher than the height of the compartment grid plate 7, and the floating plate 1 and the inner walls of the limiting groove 10 both sides have a movable gap of 1 mm, which can ensure the flexibility of the floating plate 1 while ensuring the limit. The position mechanism 2 has sufficient position swinging effect on the floating plate 1.

Embodiment 3

[0070] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, according to the thermal deformation of the air preheater rotor 5, the distance between the upper end of the flexible sealing plate 18 and the lower end surface of the sector plate is sequentially set from back to front 13mm, 10mm, 6mm, 3mm, 2mm, after the rotor 5 is heated and bent downward, the gap distance between the top of the flexible sealing plate 18 and the bottom of the fan-shaped plate 4 remains stable, effectively improving the rotation balance of the rotor 5 during rotation, Reduce the occurrence of abnormal swing conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com