Patents

Literature

100results about How to "Enhanced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

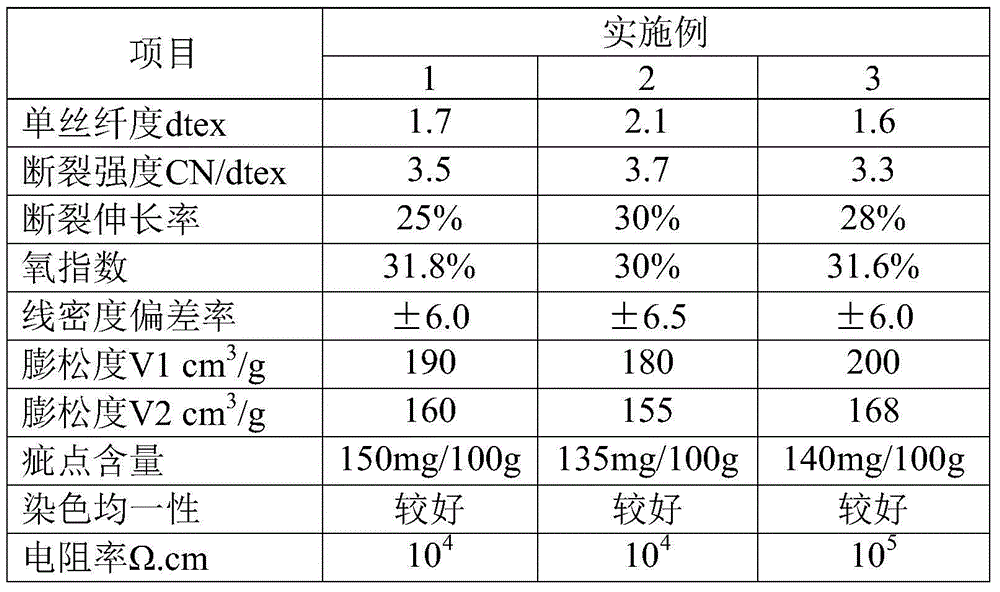

Preparation method of graphene based reinforced and flame-retarded recycled polyester staple fiber

ActiveCN104630928ASpin wellImprove qualityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides a preparation method of a graphene based reinforced and flame-retarded recycled polyester staple fiber. The method comprises the following steps: preparing graphene master batch; preparing phosphate based halogen-free flame retardant master batch; weighing the graphene master batch and the phosphate based halogen-free flame retardant master batch, mixing with a recycled polyester raw material, drying, feeding molten dried raw materials into an impurity removal stirrer under the action of a screw extruder by a melt pump for carrying out homogenization impurity-removal treatment, feeding a homogenized and impurity-removal polyester melt into a secondary filter by the melt pump, enabling a filtered melt to pass through a mixed melt on a pipeline to enter a spinning manifold, carrying out drafting processing on a spun fiber to obtain the reinforced and flame-retarded recycled polyester fiber, cutting off bundles and packaging. The reinforced and flame-retarded recycled polyester chip has the good spinning forming property, the fiber quality is high, the using amount of a fire retardant can be effectively reduced under the synergistic effect of grapheme and the phosphate based flame retardant, the cost is reduced, the reinforcement effect can be achieved and the mechanical property of the fiber is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

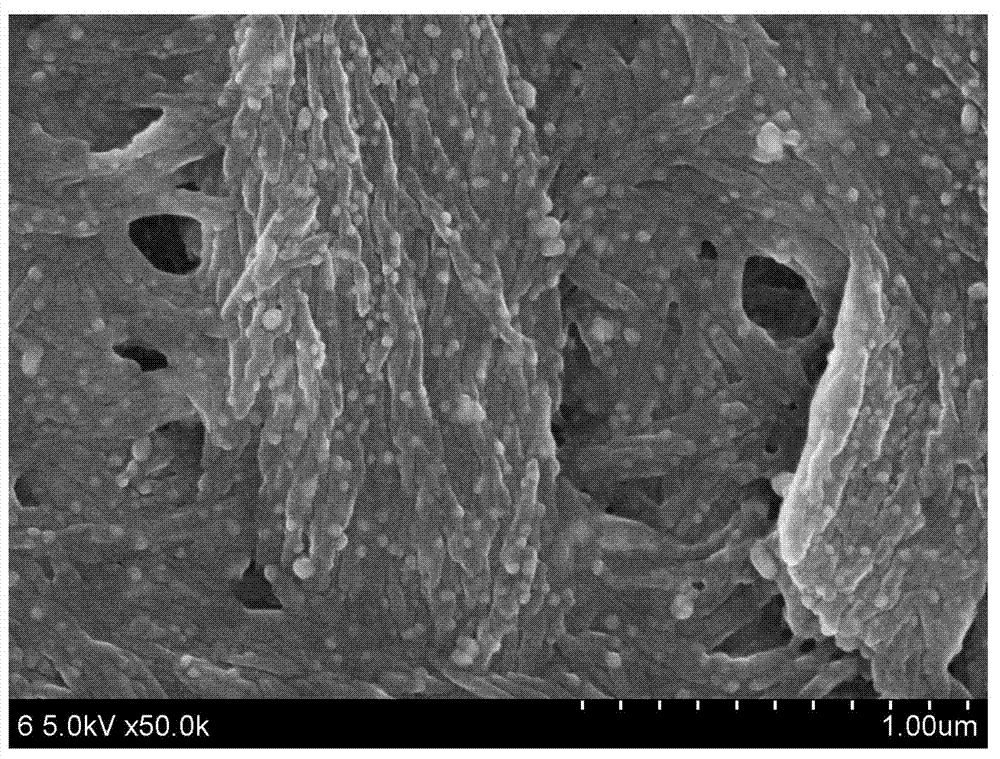

Preparation method for nano-sliver/cellulose nanocrystalline composite particle

InactiveCN102775643AIncrease loadDoes not destroy the glycosidic ring structureNanotechnologyCelluloseFree cooling

The invention relates to a preparation method for a nano-sliver / cellulose nanocrystalline composite particle. The preparation method comprises the following steps of: (1) adding a cellulose raw material into an acid-mixed solution and reacting at the temperature of 50-90DEG C for 1-20 hours; after the reaction is ended, washing a reaction product with deionized water to neutral and obtaining aldehyde cellulose nanocrystalline; and (2) adding the aldehyde cellulose nanocrystalline into a silver nitrate solution; reacting at the temperature of 60-105DEG C for 10-60 minutes; and after naturally cooling, diluting a reaction product with the deionized water, centrifuging and then carrying out free drying or vacuum drying to obtain a nano-silver / CNC (Cellulose Nanocrystalline) composite material. The preparation method disclosed by the invention is simple and convenient in process, easy in operation and environment friendly and can be used for shortening the preparation period; the prepared CNC / nano-silver has the advantages of small size, easy adjustment, large specific area, firmness in combination of the CNC and the nano-silver, durable antibacterial effect, antibacterial and enhancing functions and broad application prospect.

Owner:DONGHUA UNIV

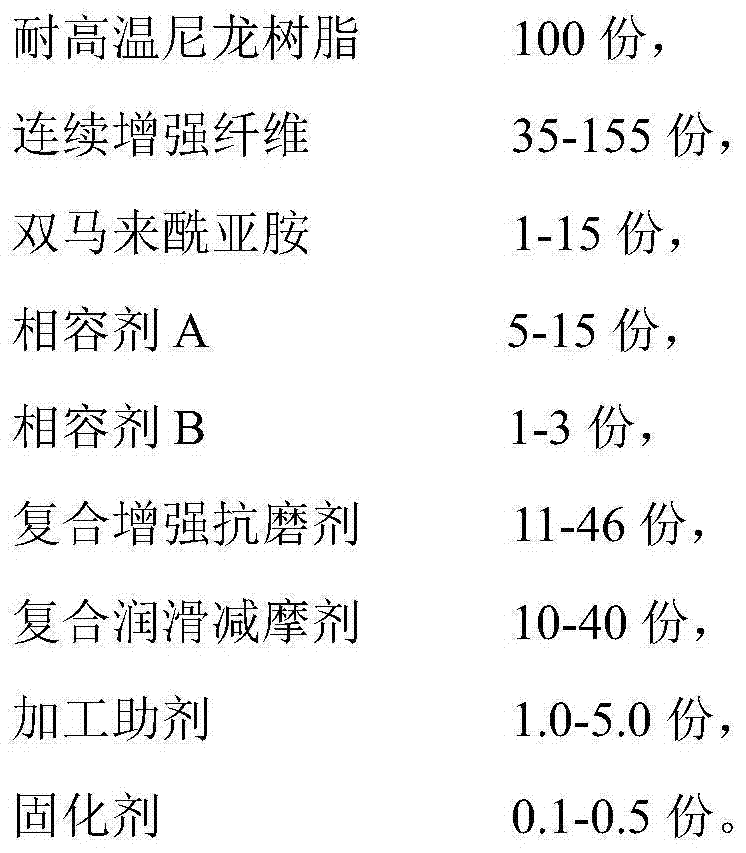

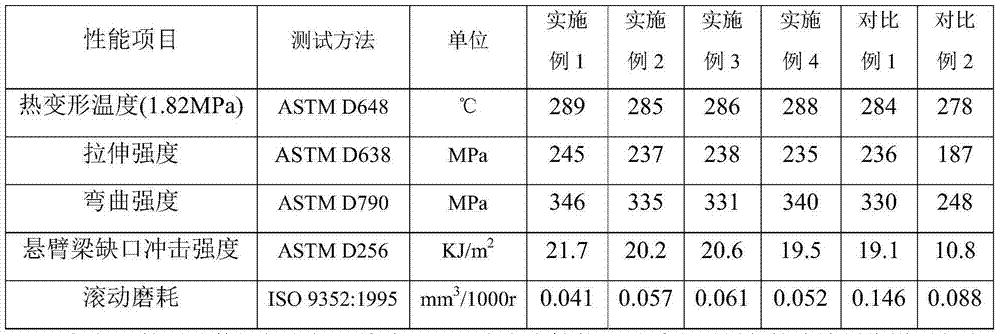

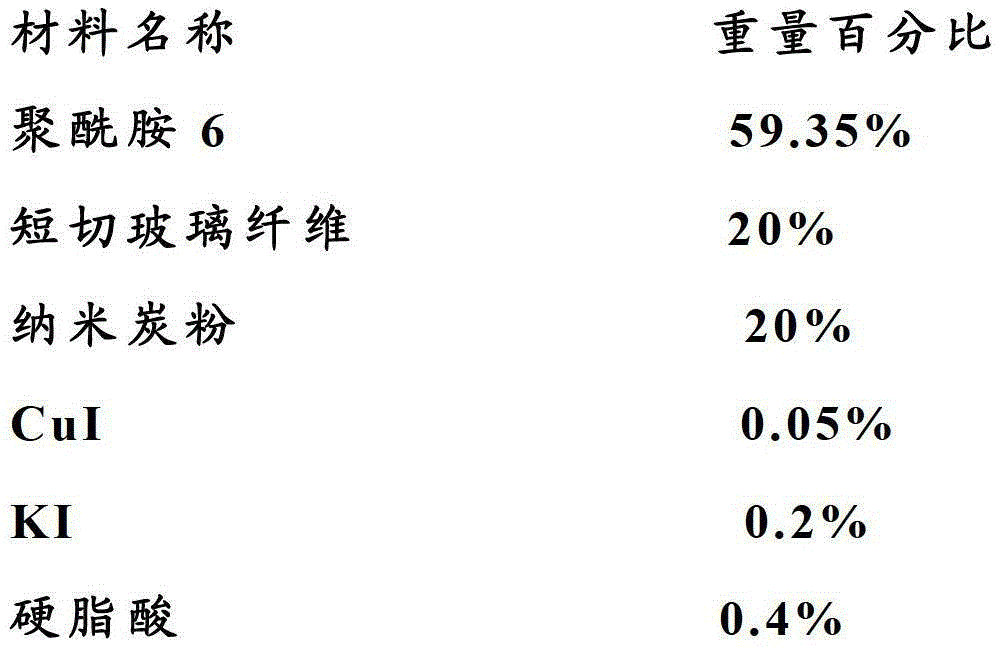

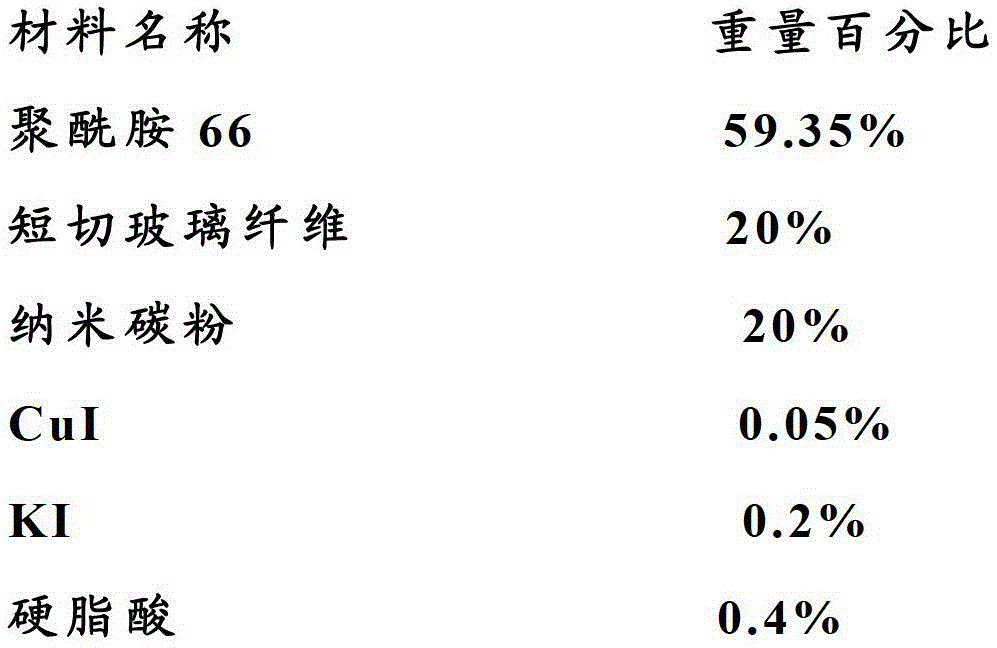

High wear resistant and high self-lubrication continuous long fiber reinforced high temperature resistant nylon composite material and preparation method thereof

InactiveCN104744926AImprove the lubrication effectImprove wear resistanceWear resistantTemperature resistance

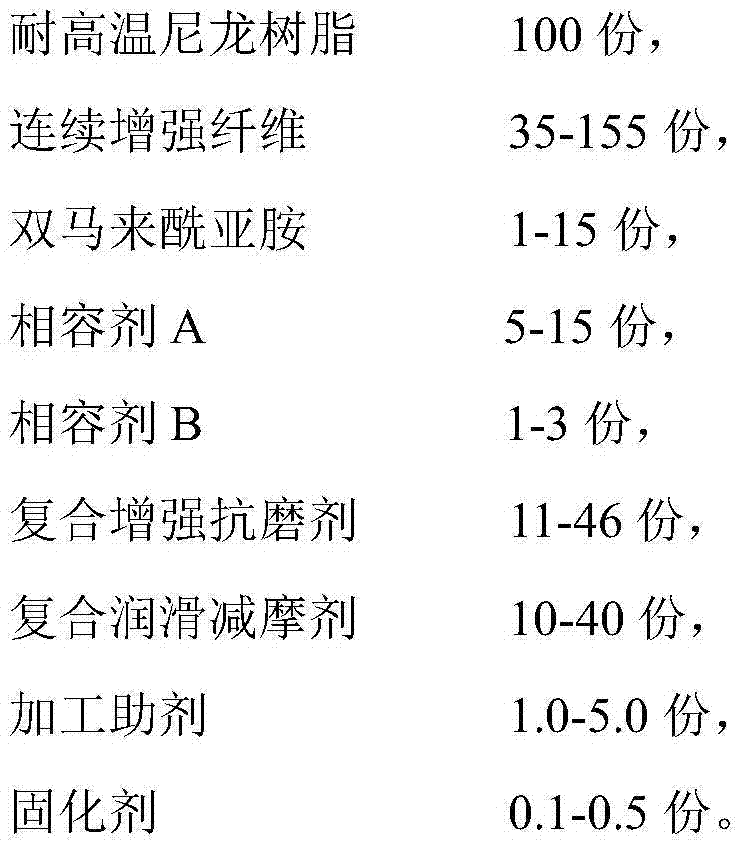

The invention belongs to the high temperature resistant nylon composite material field, and relates to a continuous long fiber reinforced high temperature resistant nylon composite material including the following components by weight: 100 parts of high temperature resistant nylon resin, 35-155 parts of continuous reinforced fiber, 1-15 parts of bismaleimide, 5-15 parts of a compatible agent A, 1-3 parts of a compatible agent B, 11-46 parts of a composite reinforced antiwear agent, 10-40 parts of a composite lubrication antifriction agent, 1.0-5.0 parts of a processing aid and 0.1-0.5 part of a curing agent. The high wear resistant and high self-lubrication continuous long fiber reinforced high temperature resistant nylon composite material has enough wear resistance, self lubrication property, mechanical properties, high temperature resistance and dimensional stability, and can be used in the manufacture of sliding parts such as gears, turbines, cam and other transmission parts and bearings, bushings, guide rails, pistons and other wear resistant, antifriction and self self-lubrication parts and general structural parts working in the high temperature environment.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

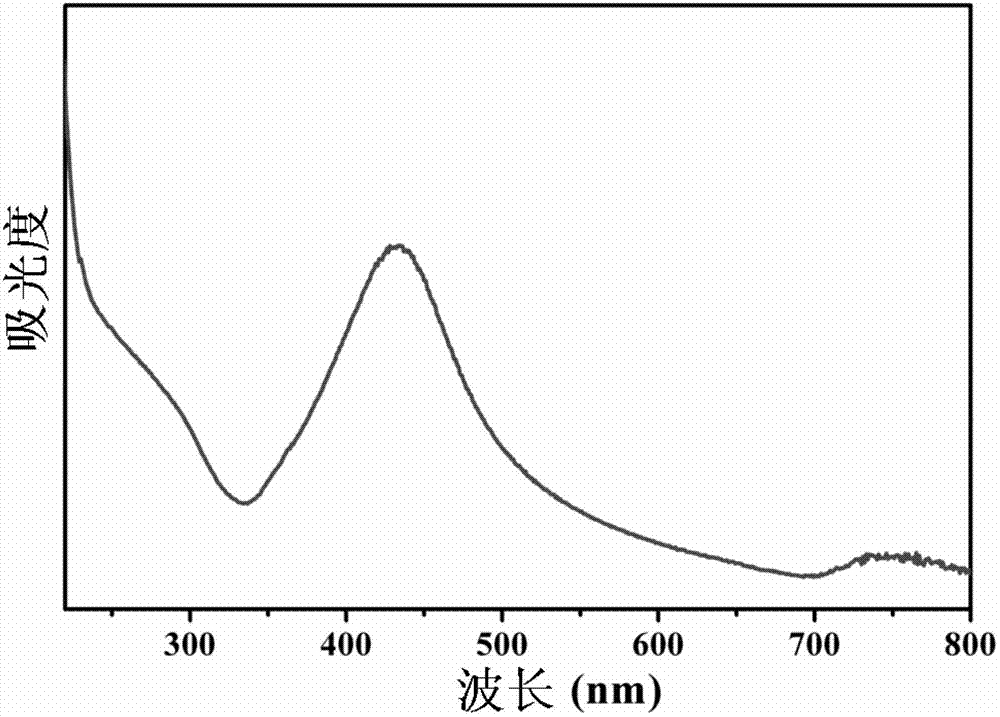

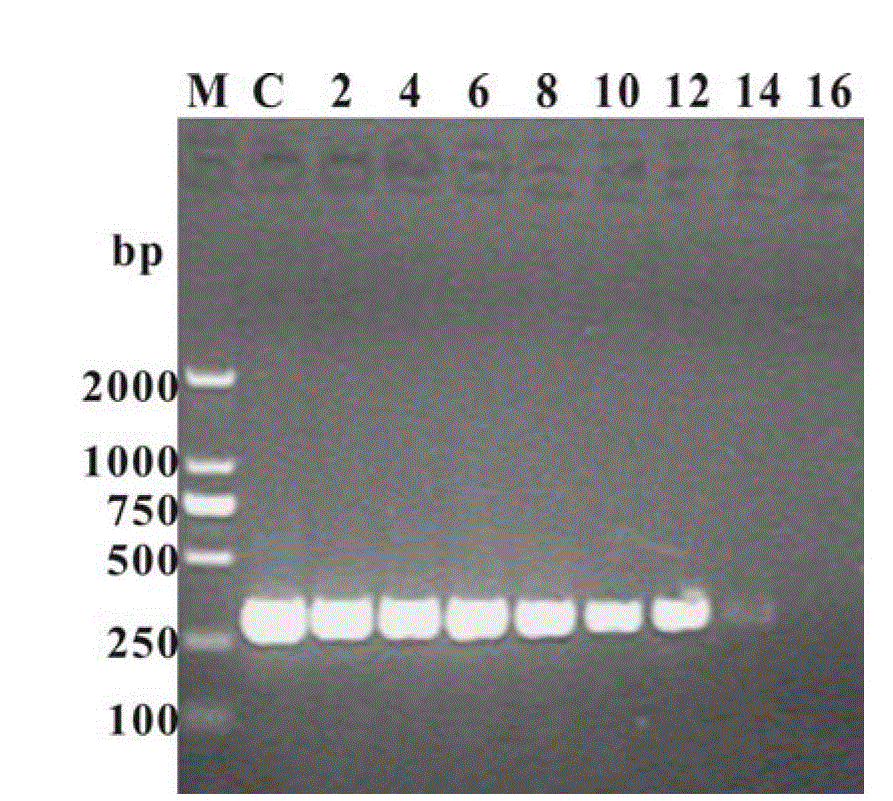

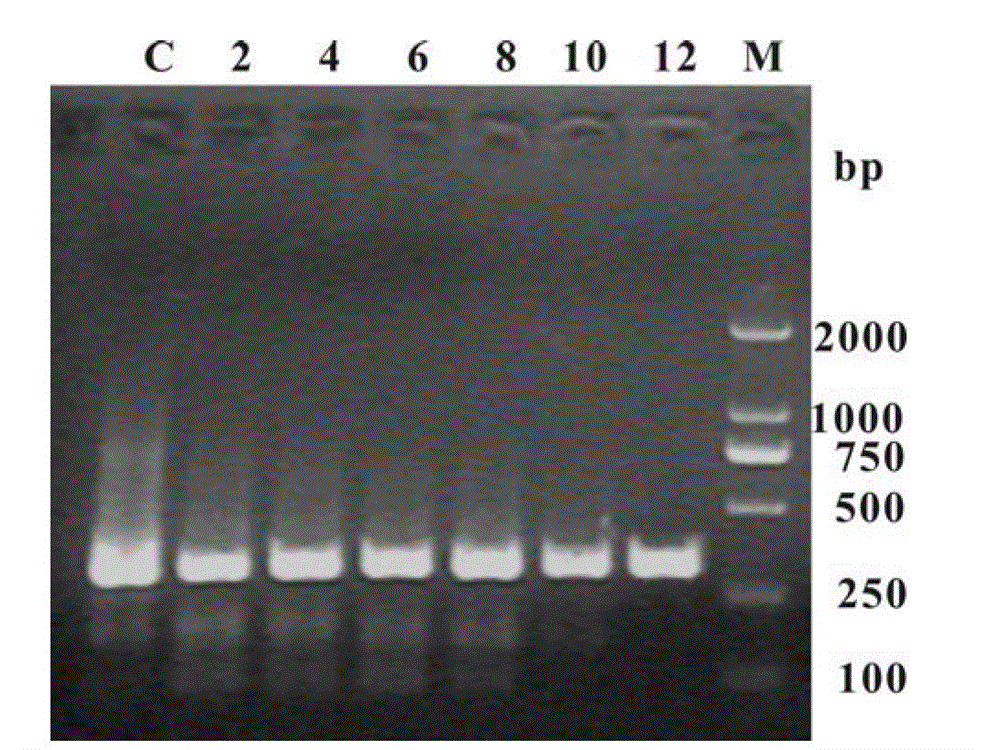

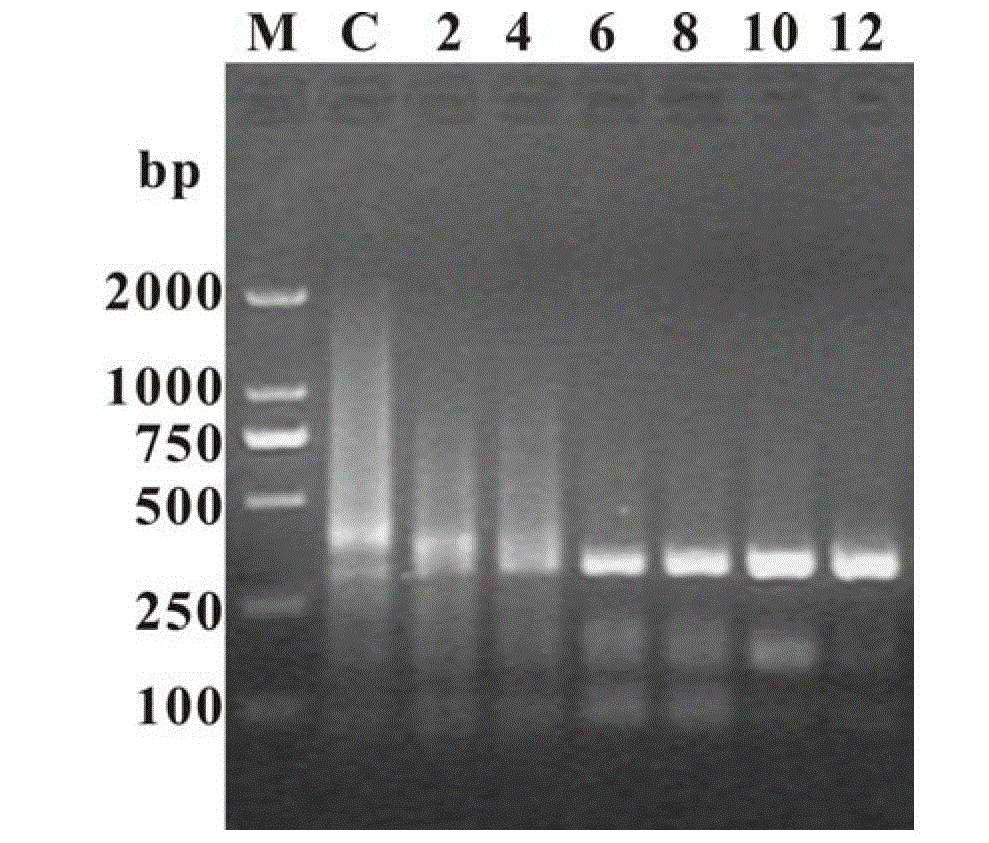

Application of graphene in polymerase chain reaction as reinforcing agent

An application of graphene in polymerase chain reaction as a reinforcing agent relates to a graphene material. An improved Hummers method is utilized to synthesize graphite oxide, and hydrazine hydrate is utilized to synthesize graphene. A plasmid is used as a template to carry out polymerase chain reaction and multi-round polymerase chain reaction, the graphene can increase the specificity of the polymerase chain reaction within 14 mu gmL-1, and a target product with strong specificity can even be obtained through 8-round polymerase chain reaction. A clinical blood sample deoxyribonucleic acid (DNA) is taken as a template to carry out the polymerase chain reaction, and a polymerase chain reaction (PCR) reaction system which is added with the graphene can obtain a product with single specificity and can still obtain the target product with the strong specificity within a scope between 25 DEG C and primer annealing temperature. The amplification products which are added with the graphene do not influence the primer sequence and length through sequencing tests, and the graphene can be used as a polymerase chain reaction reinforcing agent with good performance for polymerase chain reaction.

Owner:XIAMEN UNIV

Preparation method for high performance butadiene-styrene-isoprene powder polymer

The invention adopts a direct coagulation method for preparation of a high performance butadiene-styrene-isoprene powder polymer. The method comprises the following steps: dispersion of a carbon nanotube: a step of adding the carbon nanotube and water into a high-speed disperser and carrying out stirring to allow the carbon nanotube to be uniformly dispersed; preparation of graft latex: a step of successively adding water, styrene-butadiene latex, an emulsifier and a molecular weight regulator into a polymerization kettle, carrying out nitrogen displacement, adding isoprene, carrying out stirring and heating, adding an initiator and carrying out polymerization to prepare the graft latex; and coagulation for formation of powder: a step of successively adding the graft latex, water and the carbon nanotube into a coagulation kettle, carrying out stirring and heating, adding a release agent, a flocculating agent and a coagulating agent and carrying out curing, washing, dehydration and drying to obtain the powder polymer. The prepared powder polymer has the following performances: a powder particle size of 0.5 to 0.8 mm; isoprene content in PSBIR of 20 to 40%; Mooney viscosity ML(1+4)<100 DEG C> of 50 to 70; 300% stress at definite elongation of 18 to 25 MPa; tensile strength of no less than 27.0 MPa; elongation at break of no less than 560%; antistatic resistance of 106 to 109 omega; and electrization voltage of less than 100V.

Owner:PETROCHINA CO LTD

Modified nanometer zinc oxide

ActiveCN107265494AGood dispersionImproved surface structure propertiesZinc oxides/hydroxidesNanotechnologyZno nanoparticlesSurface modification

The invention discloses a modified nanometer zinc oxide. The nanometer zinc oxide is activated, and then a coupling reagent is used for modifying the surface of the activated nanometer zinc oxide and the nanometer zinc oxide is covered by bismuth oxide. According to the invention, after the nanometer zinc oxide is modified, the nanometer zinc oxide used in the coating can obviously promote the hardness and adhesive force of the coating film.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

Preparation method of fire retardant coating

ActiveCN102618162ASmall sizeGood dispersionFireproof paintsPolyurea/polyurethane coatingsHydrogen halide1,4-Butanediol

The invention relates to a preparation method of a fire retardant coating. The preparation method comprises the following steps of: firstly, mixing polyalcohol, ammonium polyphosphate and montmorillonite for stirring; adding diisocyanate, dimethylolpropionic acid and a catalyst into the obtained mixture; after reaction, obtaining a prepolymer; adding 1, 4-butanediol into the prepolymer, carrying out reaction and obtaining a neutral body; cooling the neutral body and then adding triethylamine into the cooled neutral body for reaction; adding nano-microcrystalline cellulose water solution treated by dispersion into the reaction product, stirring and obtaining emulsion; and transferring the emulsion into a template, molding and obtaining the fire retardant coating. According to the method, polyurethane is taken as a film forming matter, the nano-microcrystalline cellulose is taken as a carbonizing agent, the ammonium polyphosphate is taken as an acid source and a gas source, and the montmorillonite has the reinforcement function. The fire retardant coating prepared by the invention is free from pollution, is safe and reliable, is good in mechanical performance, and does not emit corrosive gases such as hydrogen halide and the like when being decomposed by heating.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

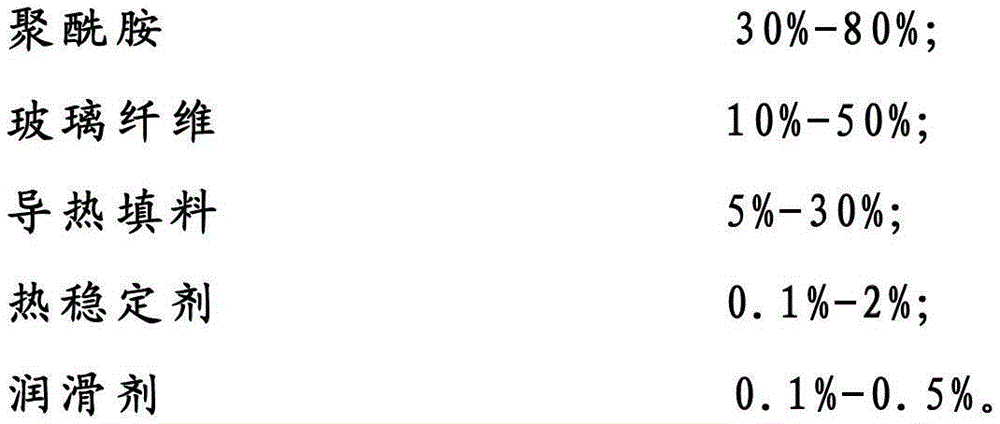

Polyamide composite material as well as preparation method and use thereof

The invention discloses a polyamide composite material. The polyamide composite material comprises the following components in percentage by weight: 30%-80% of polyamide, 10%-50% of glass fiber, 5%-30% of heat-conducting filler, 0.1%-2% of a heat stabilizer and 0.1%-0.5% of a lubricant. A special screw assembly design on a twin-screw extruder is adopted, so that the powder can be well dispersed without adding a coupling agent, and the comprehensive performances are still better. In the composite material, the nanometer heat conducting filler is added, so that the heat conducting performance of the composite material is improved under the condition that the mechanical performance is not reduced, the using temperature of the composite material is increased to 180 DEG C and the service life of the composite material is prolonged.

Owner:大河宝利材料科技(苏州)有限公司

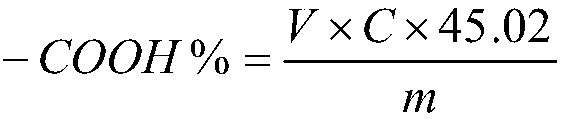

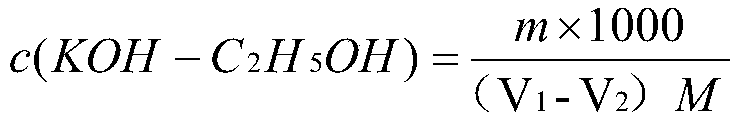

Carboxyl-terminated liquid fluororubber/solid fluororubber blending elastomer material and preparation method thereof

Embodiments of the invention relate to rubber materials, and specifically relate to a carboxyl-terminated liquid fluororubber / solid fluororubber blending elastomer material and a preparation method thereof. The material is prepared from the following raw materials: fluororubber, carboxyl-terminated liquid fluororubber and an acid absorbent. Through the utilization of the toughening effect of the carboxyl-terminated liquid fluororubber and the enhancement effect of the ionic crosslinking formed by a terminal carboxyl group in the carboxyl-terminated liquid fluororubber and the acid absorbent, the hardness of the material can be kept without significant enhancement, while the intensity and toughness can be simultaneously and obviously increased, and good comprehensive properties can be achieved; the material has good high and low temperature resistance, oil resistance and chemical medium resistance; and the preparation method is simple, and easy industrialization can be realized.

Owner:BEIJING UNIV OF CHEM TECH

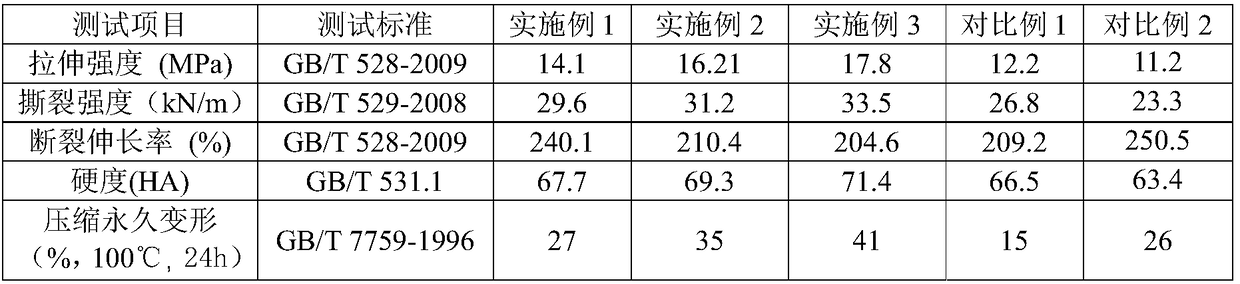

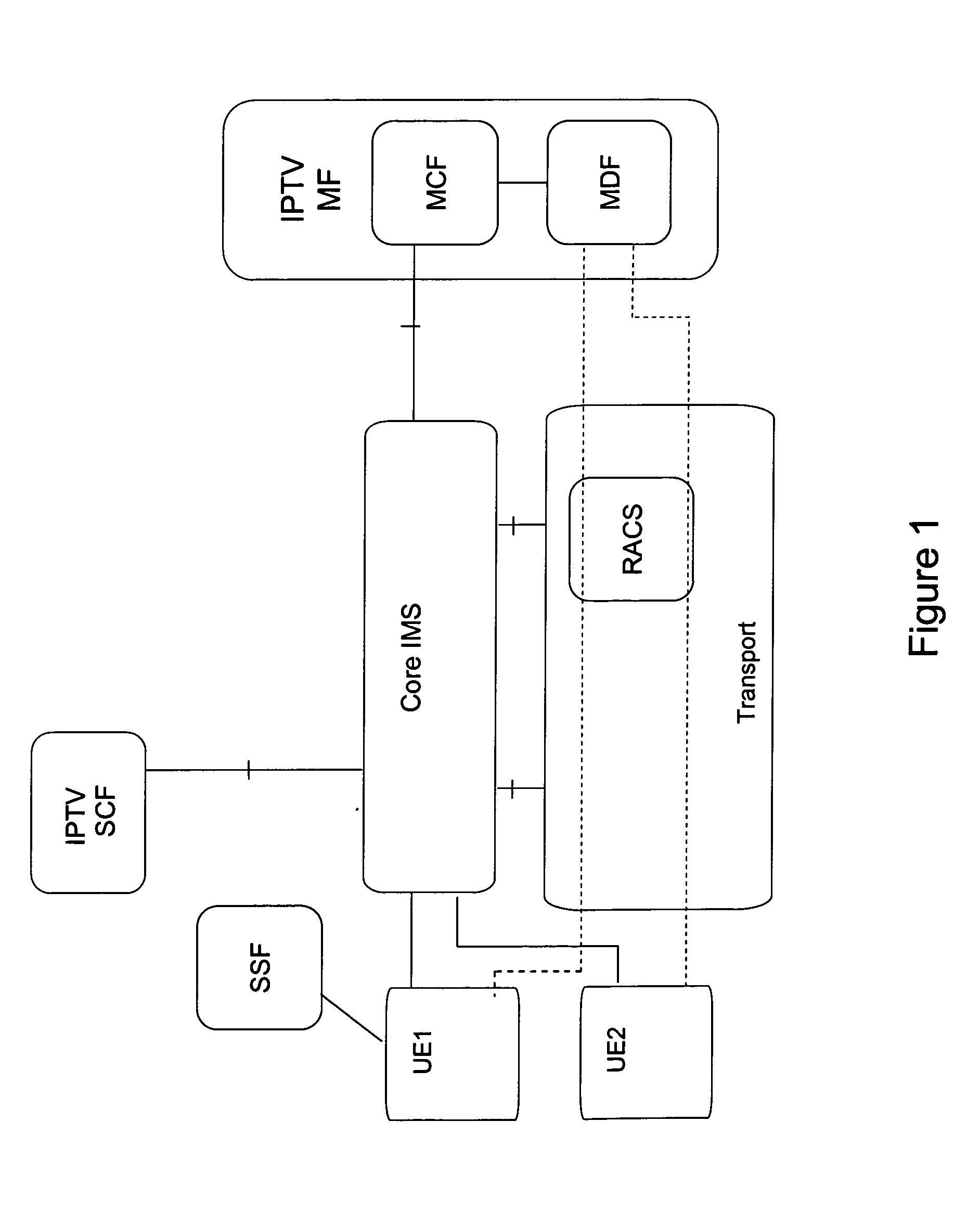

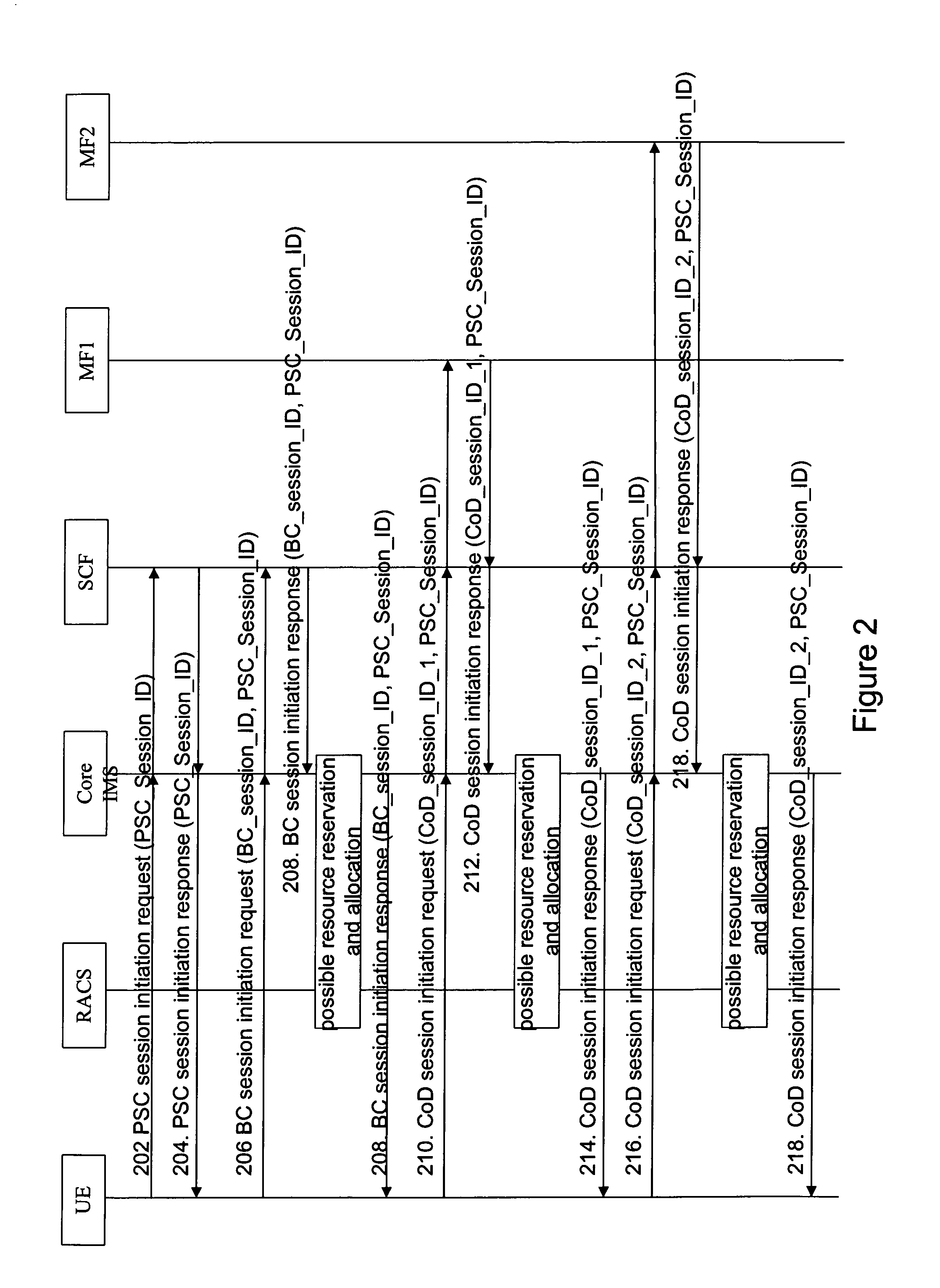

Managing Associated Sessions in a Network

ActiveUS20110276705A1EnhancedEasy to useMultiple digital computer combinationsTransmissionNetwork elementUser equipment

A method and a system for managing associated sessions in a network is described, wherein the network comprises a network element configured for managing associated sessions between the network and user equipment. The method comprises the steps of providing a composition session identifier for associating sessions in a network; exchanging the composition session identifier between a user equipment and the network element; and associating two or more sessions with the composition session identifier by exchanging the composition session identifier.

Owner:KONINK KPN NV

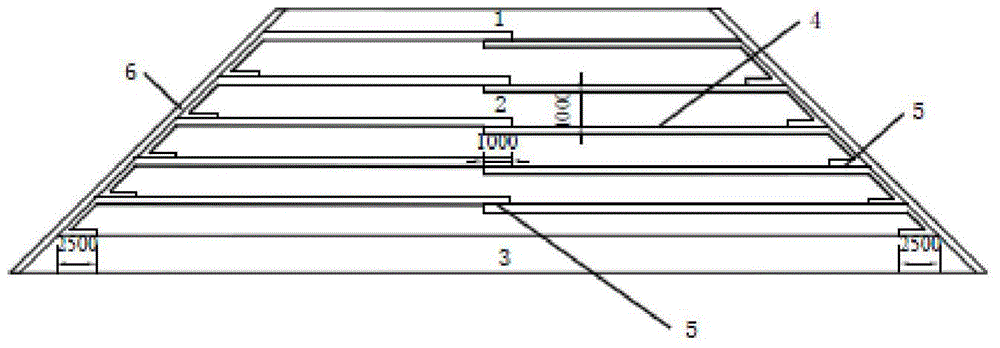

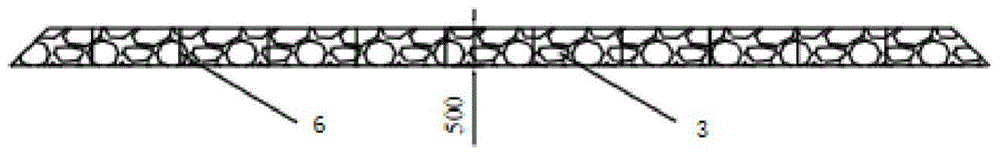

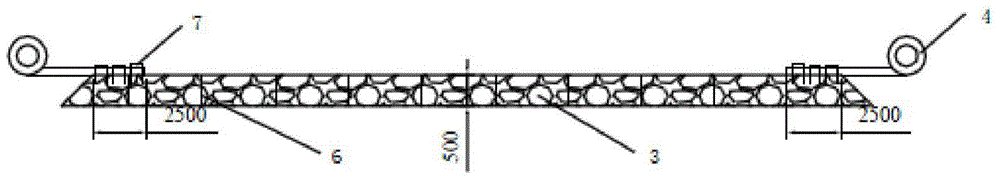

Structure and method for processing black cotton soil embankment with impervious geotextiles

The invention provides a structure and a method for processing a black cotton soil embankment with impervious geotextiles. The embankment structure comprises a geogrid gravelly soil base course, impervious geotextile edging and interlayer seepage-proofing layers, a black cotton soil fill stratum and a non-expansive clay top seal layer. The method comprises the following steps: (1) clearing a foundation; (2) setting out; (3) paving three layers of geogrid gravelly soil with the total thickness being 50cm; (4) spreading the impervious geotextiles on two sides of the road foundation, lapping the impervious geotextiles with filled soil by 250cm, turning up the impervious geotextiles on the slope of the road foundation, lapping the impervious geotextiles on the two sides in the middle of an embankment by 100cm after turning up, and bonding by using emulsified asphalt, wherein the lapping width of the adjacent impervious geotextiles is100cm and the impervious geotextiles are bonded by virtue of the emulsified asphalt; (5) spreading the soil and carrying out rolling construction; and (6) filling and rolling the top seal layer. The structure and the method disclosed by the invention are conducive to the stabilization of the embankment and are capable of preventing the embankment from deformation.

Owner:SOUTHEAST UNIV

Alcohol-base foundry coating for green sand mold and preparation method of alcohol-base foundry coating

InactiveCN104801658AGood suspensionImprove permeabilityFoundry mouldsFoundry coresPolyvinyl butyralFoundry

The invention discloses an alcohol-base foundry coating for a green sand mold and a preparation method of the alcohol-base foundry coating. The coating comprises components in percentage by weight as follows: 44%-55% of 400-600-mesh refractory powder, 1.30%-1.45% of sodium bentonite, 0.45%-0.60% of water, 0.5%-0.7% of polyvinyl butyral, 1.4%-1.6% of thermoplastic phenolic resin and 41%-52% of ethanol. The preparation method comprises steps as follows: 1), raw materials are weighed in proportion; 2), sodium bentonite and water are ground and preprocessed to form paste; 3), the 400-600-mesh refractory powder, the thermoplastic phenolic resin and the polyvinyl butyral are mixed with the paste obtained in the step 2), the ethanol accounting for 25% of total weight of ethanol is added for mixing grinding, and a pasty coating is obtained; 4), the remained ethanol is added and stirred to obtain the coating. The alcohol-base foundry coating has high suspension rate and high permeability, the surface strength of the sand mold can be enhanced, the coating breathability is good and avoids cracking and peeling, and casting is not stuck with sand.

Owner:HUBEI UNIV OF TECH

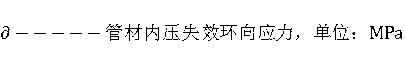

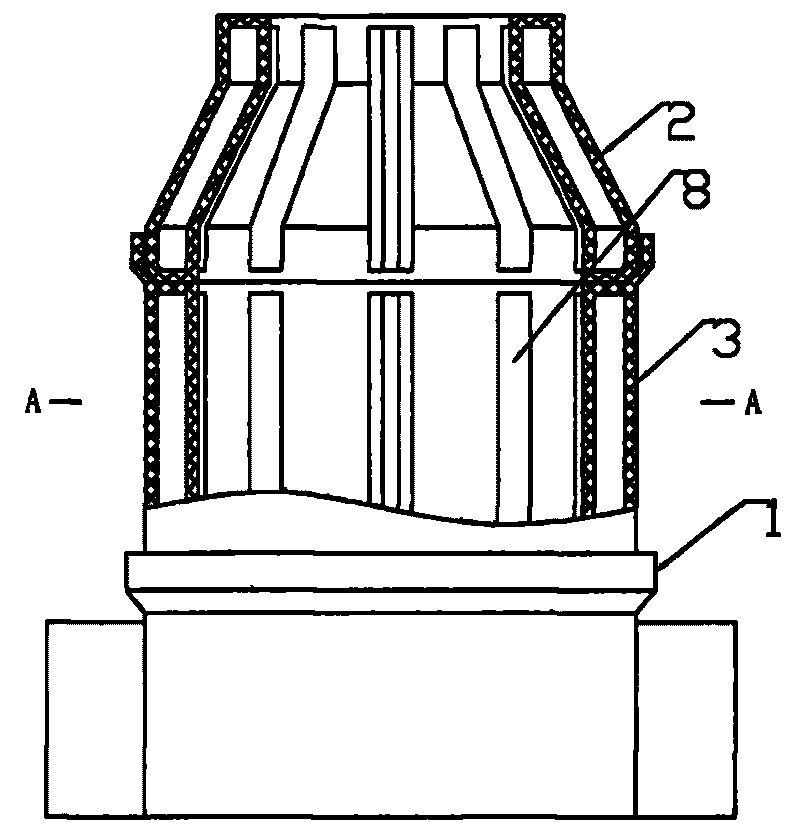

Anti-static flame-retardant steel skeleton fiber reinforced resin pipe and preparation technology thereof

ActiveCN103104754AGood mechanical propertiesReduce dosageRigid pipesTubular articlesEpoxyFine structure

The invention belongs to the technical field of mine conveying pipe bodies, and discloses an anti-static flame-retardant steel skeleton fiber reinforced resin pipe and a preparation technology of the anti-static flame-retardant steel skeleton fiber reinforced resin pipe. The anti-static flame-retardant steel skeleton fiber reinforced resin pipe is technically characterized in that the anti-static flame-retardant steel skeleton fiber reinforced resin pipe comprises a pipe body which comprises a seepage-proof flame-retardant conductive inner lining layer and a pressure-bearing flame-retardant conductive structural layer from inside to outside, wherein the seepage-proof flame-retardant conductive inner lining layer comprises glass fiber solidified on an inner base body, and the pressure-bearing flame-retardant conductive structural layer comprises an outer base body which is synchronously provided with a zinc-coated steel wire and glass fiber direct roving in a winding mode, wherein epoxy resin is coated on the outer surface of the zinc-coated steel wire. According to the anti-static flame-retardant steel skeleton fiber reinforced resin pipe, matching among all layers of fiber is reasonable, mechanical property is strengthened, meanwhile, weight of the tube body is lightened, multi-wall carbon nanotubes and nanometer aluminium hydroxide are filled, fine structures of all layers are changed, meanwhile, bending resistant strength and shock resistance capability are enhanced, wear-resisting property and conductivity are largely improved, service life is prolonged, and cost is reduced.

Owner:河北拓安管业有限公司

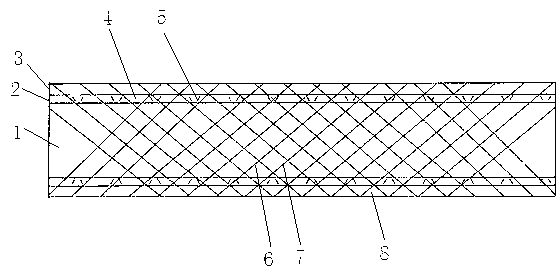

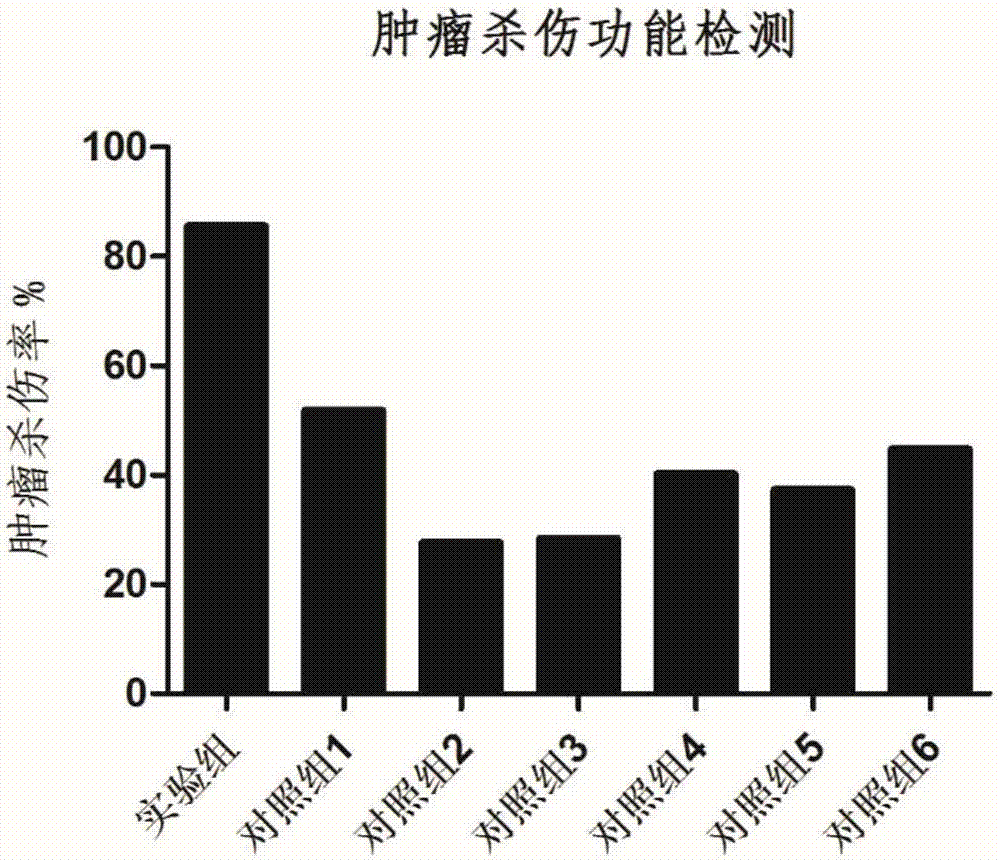

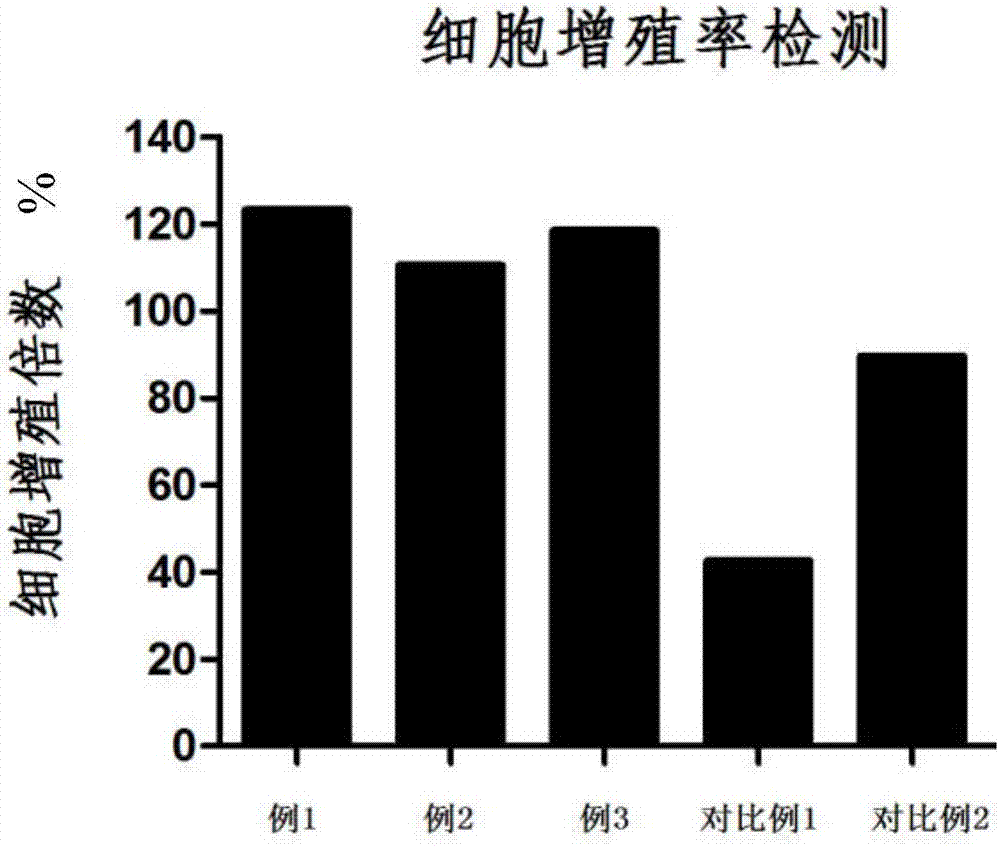

Culture medium for human-derived T lymphocytes and preparation method and application thereof

ActiveCN107151654AReasonable and efficient formulaGood tumor killing functionCell dissociation methodsCulture processT lymphocyteCulture mediums

The invention provides a culture medium for human-derived T lymphocytes. Each 1L of the culture medium comprises the following components: 80-120 mL of human AB serum, 7-15 mL of an MEM vitamin solution, 7-12 mM of N-acetyl-L-cysteine, 1.6-2.5 mM of glutamine or a derivative, 0.8-1.2 mM of sodium pyruvate, 15-25 mM of 4-hydroxyethyl piperazine sodium esilate, 4-6 mu g of IL-7, 6-9 mu g of IL-15 or heterodimer thereof, and the balance of X-VIVO basic culture medium, wherein the glutamine or the derivative thereof comprises glutamine or L-alanyl-L-glutamine. The culture medium can be used for culturing antigen specific T lymphocytes, the cell proliferation rate of the antigen specific T lymphocytes can be increased, and the tumor killing ability can be high. The invention further provides a preparation method and application of the culture medium.

Owner:SHENZHEN BINDEBIOTECH CO LTD

Preparation method of bi-color artificial quartz stone slate

InactiveCN107601966AReduce usageOvercome the defect of low strengthCeramic shaping apparatusGlass particleHardness

The invention discloses a preparation method of a bi-color artificial quartz stone slate. The method comprises steps as follows: (1) raw materials are weighed in proportion and stored separately; (2)an antibacterial agent is added to resin and stirred and mixed in vacuum; pigments, a coupling agent, glass particles, artificial quartz particles, natural quartz sand and quartz powder are stirred and mixed in vacuum; finally, a curing agent is added and stirred and mixed in vacuum, and a mixture is obtained; (3) the mixture is uniformly spread on a template; (4) the template is sent into a vacuum vibration forming press for vibratory pressing forming; (5) primary curing and secondary curing are performed sequentially after vibratory pressing forming. The mechanical properties such as hardness, toughness and the like of the artificial quartz stone slate are effectively improved through optimization and improvement of a raw material formula, matching of different raw materials and improvement of the preparation method, the artificial quartz stone slate has high anti-bacterial ability and lasting anti-bacterial action, and the comprehensive performance of the artificial quartz stone slate is improved.

Owner:佛山市欧泊石业有限公司

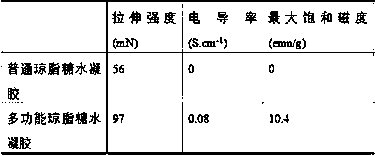

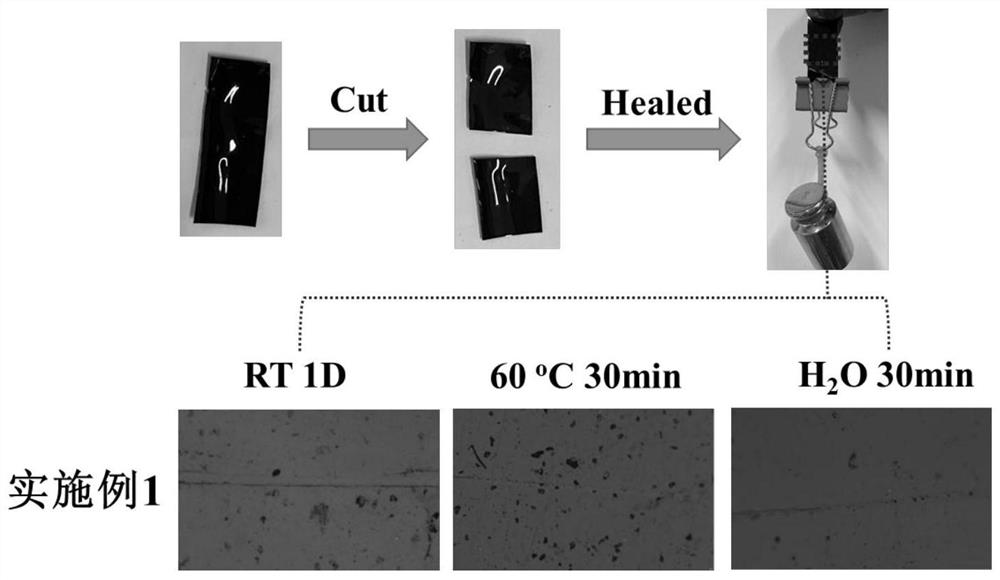

High-strength self-repair conductive magnetic electronic skin material and preparation method thereof

The invention belongs to the field of biotechnology, and concretely relates to a high-strength self-repair conductive magnetic electronic skin material and a preparation method thereof. The method ischaracterized in that the surface of nano cellulose is coated with polypyrrole, Fe3O4 magnetic particles are immobilized, the materials are added in an agarose aqueous solution for uniform mixing, andthe high-strength self-repair conductive magnetic electronic skin material is prepared. A nano cellulose / polypyrrole / Fe3O4 compound is used so that an agarose hydrogel has intensity, conductivity andmagnetic performance, three disadvantages of low intensity, no conductivity and non magnetic performance of the common agarose hydrogel are improved, and the high-strength self-repair conductive magnetic electronic skin material can be taken as a novel multifunctional electronic skin material.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing single-piece talcum powder

The invention provides a method for preparing single-piece talcum powder. The method for preparing the single-piece talcum powder by collaborative foaming expansion shear tensile specifically comprises the following steps: firstly, preprocessing the talcum powder by a swelling agent to increase an interval between talcum powder layers so as to enable a foaming agent to be dipped between the talcum powder layers, and enabling the talcum powder layers to relatively slide; utilizing a multistage millstone type mixing mill for shearing and peeling to enable the talcum powder layers to be peeled, and forming the talcum powder of a single-layer laminated structure. The talcum powder prepared with the method is the single-layer laminated talcum powder and has the advantages of high preparation efficiency and high additional value, and the layer structure of the talcum powder is not damaged. The talcum powder is used for composite materials, has a high enhancement function, has transparency, can be widely added into products including plastics, high-class coatings and the like, is suitable for scale production and has an obvious market application value.

Owner:桂林龙胜正大粉体科技有限公司

Fibrillar silicate-reinforced super thermal-insulation heat-preserving paint and preparation method thereof

The invention provides a fibrillar silicate-reinforced super thermal-insulation heat-preserving paint. The paint is prepared from the following raw materials by weight: 34 to 38 parts of ethyl orthosilicate, a proper amount of hydrochloric acid, a proper amount of ammonia water, a proper amount of ethanol, a proper amount of deionized water, 1 to 2 parts of vinyltrimethoxy silane, 2.5 to 3 parts of dimethyldiethoxylsilane, 0.8 to 1.2 parts of 3-aminopropyltrihydroxysilane, 0.5 to 0.8 part of phenolic resin, 0.2 to 0.4 part of nanometer calcium carbonate, 0.6 to 0.9 part of fibrillar silicate, 70 to 75 parts of epoxy resin E-12, 9 to 12 parts of ethylene glycol diglycidylether and 7 to 7.5 parts of triethanolamine. According to the invention, through hydrophobic modification of aerogel, the phenomenon of fragmentation of the aerogel due to moisture absorption is reduced; and through hydrophilic modification, bonding strength between the aerogel and a film forming agent is improved.

Owner:DANGTU COUNTY KEHUI TRADING

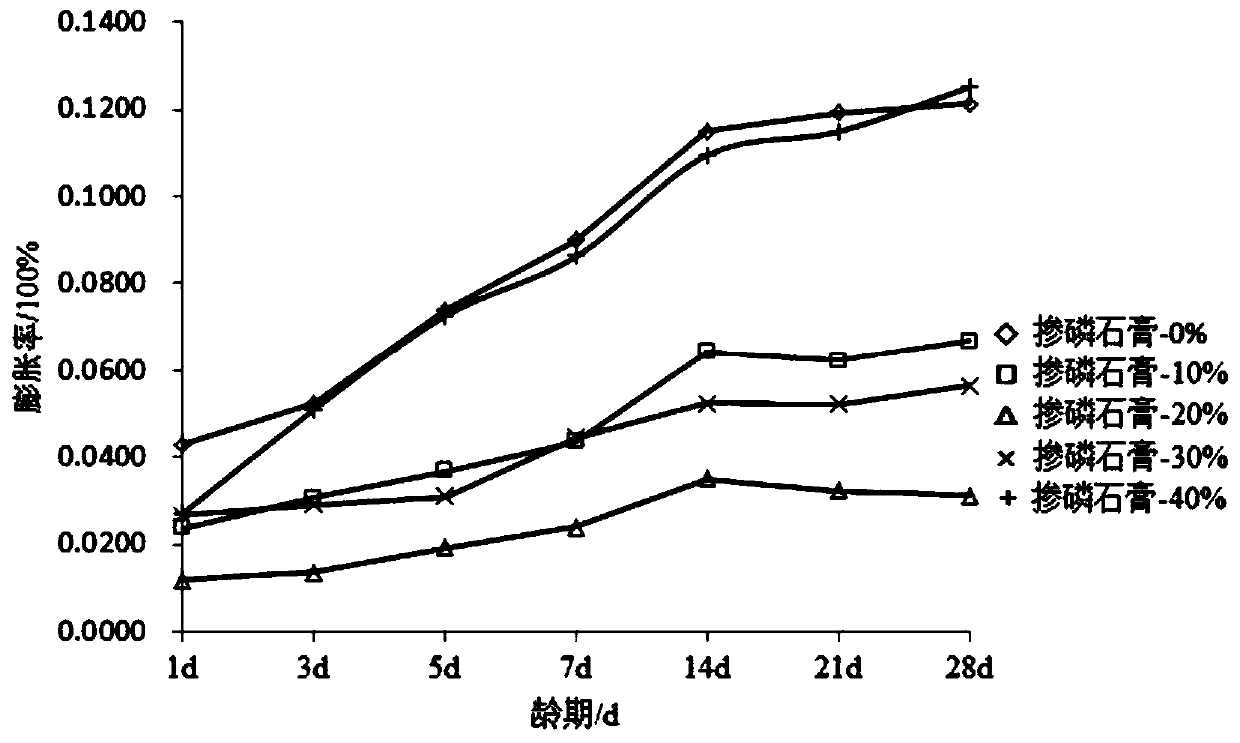

Phosphogypsum-doped quick-setting and quick-hardening cement matrix, concrete canvas prepared from cement matrix and construction method of concrete canvas

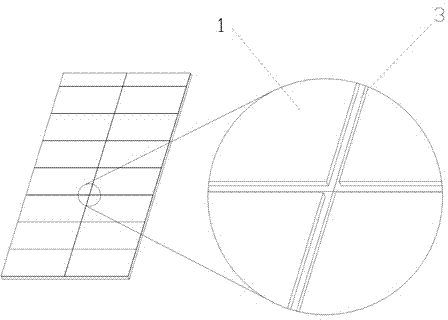

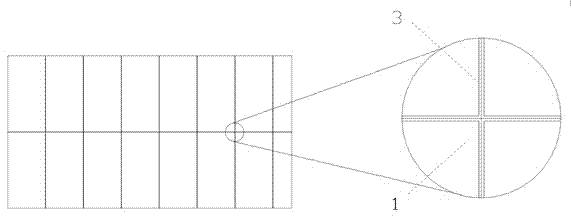

ActiveCN110577375AHigh strengthSolve the problem of accumulating and occupying land and polluting groundwater qualityFilm/foil adhesivesFibre typesFiberPhosphogypsum

The invention relates to a phosphogypsum-doped quick-setting and quick-hardening cement matrix, concrete canvas prepared from the cement matrix and a construction method of the concrete canvas. The raw materials of the cement matrix are composed of the following components in parts by weight: 700 to 800 parts of sulphoaluminate cement and 200 to 300 parts of acid-pickled phosphogypsum. A three-dimensional spacer fabric is filled with the phosphogypsum-doped quick-setting and quick-hardening cement matrix, and an adhesive sealing layer is arranged above the three-dimensional spacer fabric; thethree-dimensional spacer fabric comprises an upper woven fabric layer, a cellosilk layer and a lower woven fabric layer, and the cellosilk layer is composed of cellosilk distributed in a three-dimensional mode. The invention provides the novel cement matrix for the concrete canvas, the strength can be remarkably improved by doping phosphogypsum into the cement matrix system, so that excellent performance is obtained, and a feasible solving method can be provided for solving the current phosphogypsum problem by doping phosphogypsum.

Owner:CHINA THREE GORGES UNIV

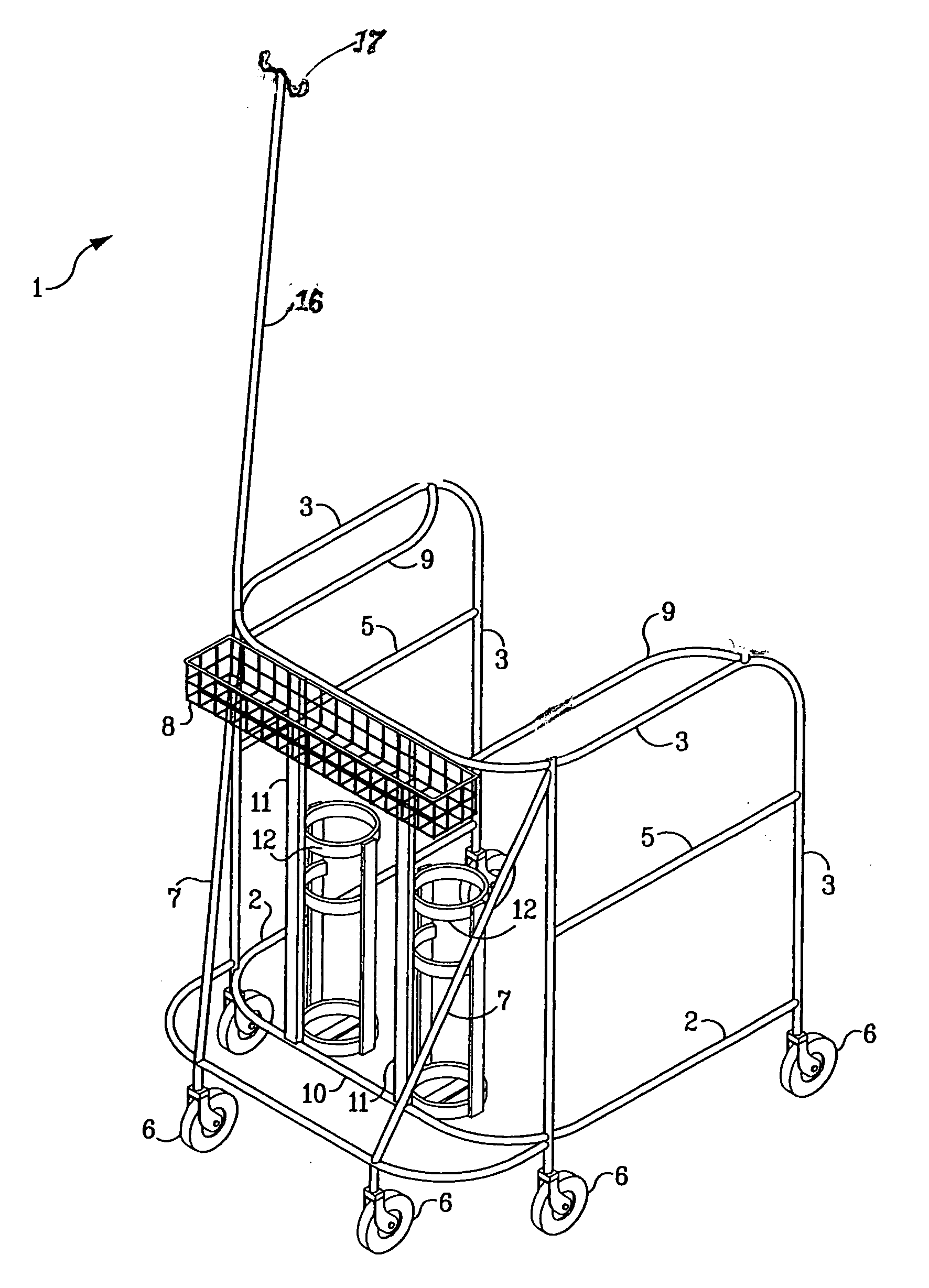

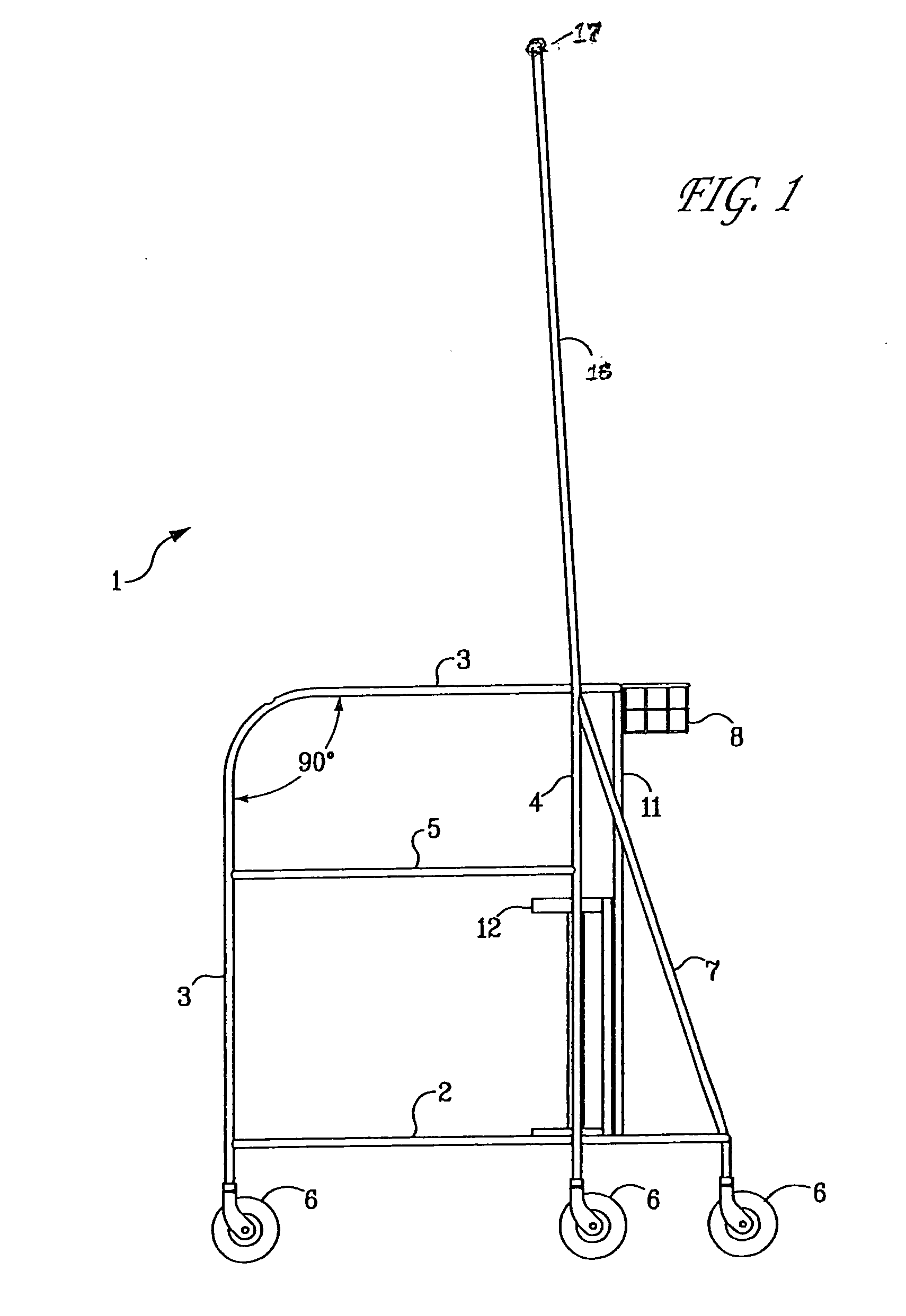

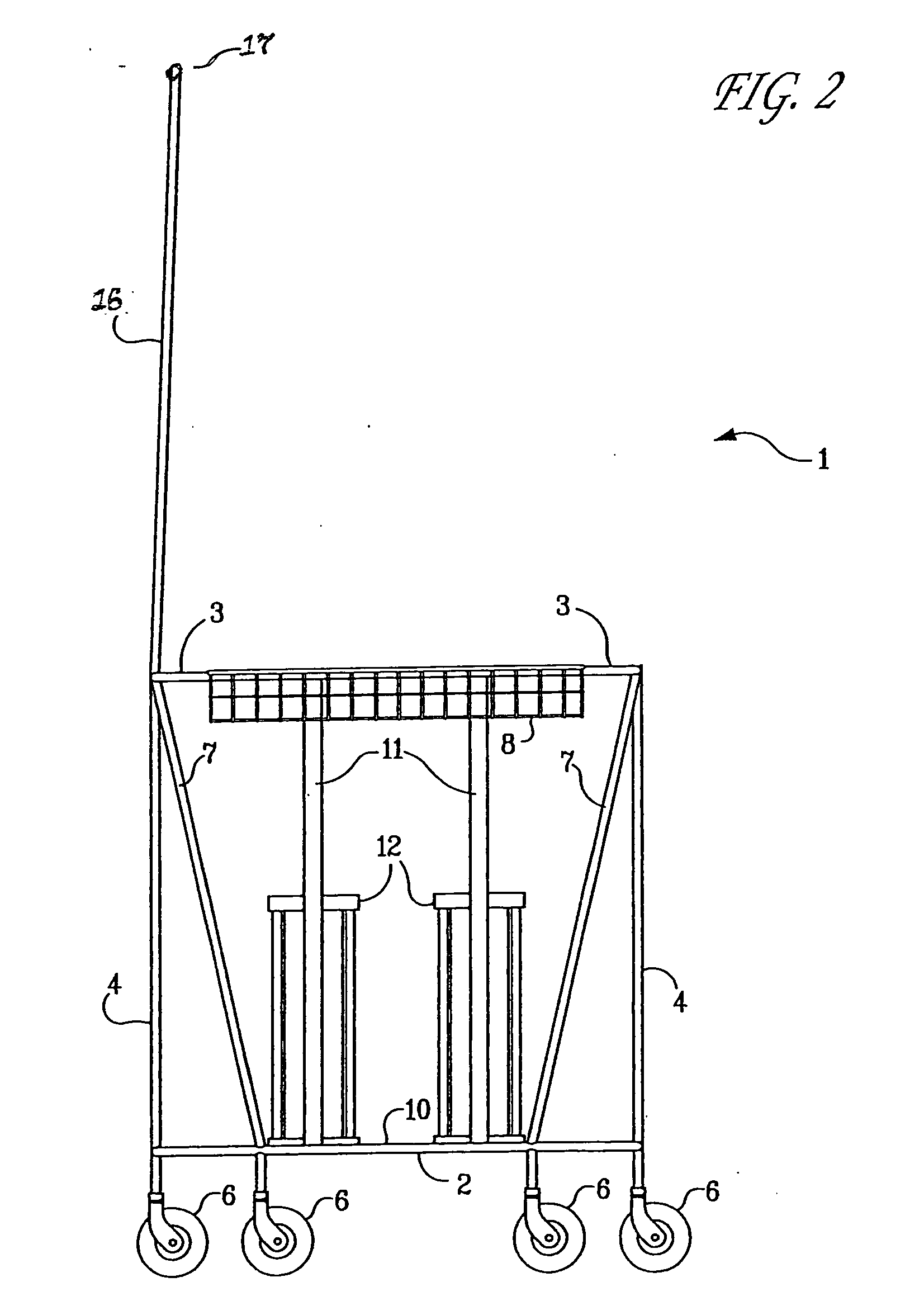

Enhanced Patient Mobility Apparatus

InactiveUS20100212708A1EnhancedImprove mobilityWalking sticksPassenger cyclesAmbulation DevicesIntravenous use

The invention is an Enhanced Patient Mobility Apparatus for use by ambulatory or recovering patients. The Enhanced Mobility Apparatus is fabricated from sturdy tubular material and has a lower U-shaped base frame member mounted on casters with an upwardly extending mid frame member and two vertical supports attached thereto and each also attached at its lower extremity to the lower U-shaped base frame member. The U-shaped base frame member, the mid frame member and the two vertical supports define a walking space for the patient with provision for the possibility of the patient also being able to move about with oxygen tanks, a patient intravenous drip apparatus and other medical devices and apparatus which must be transported by an ambulatory patient.

Owner:TURNER DAVID B +1

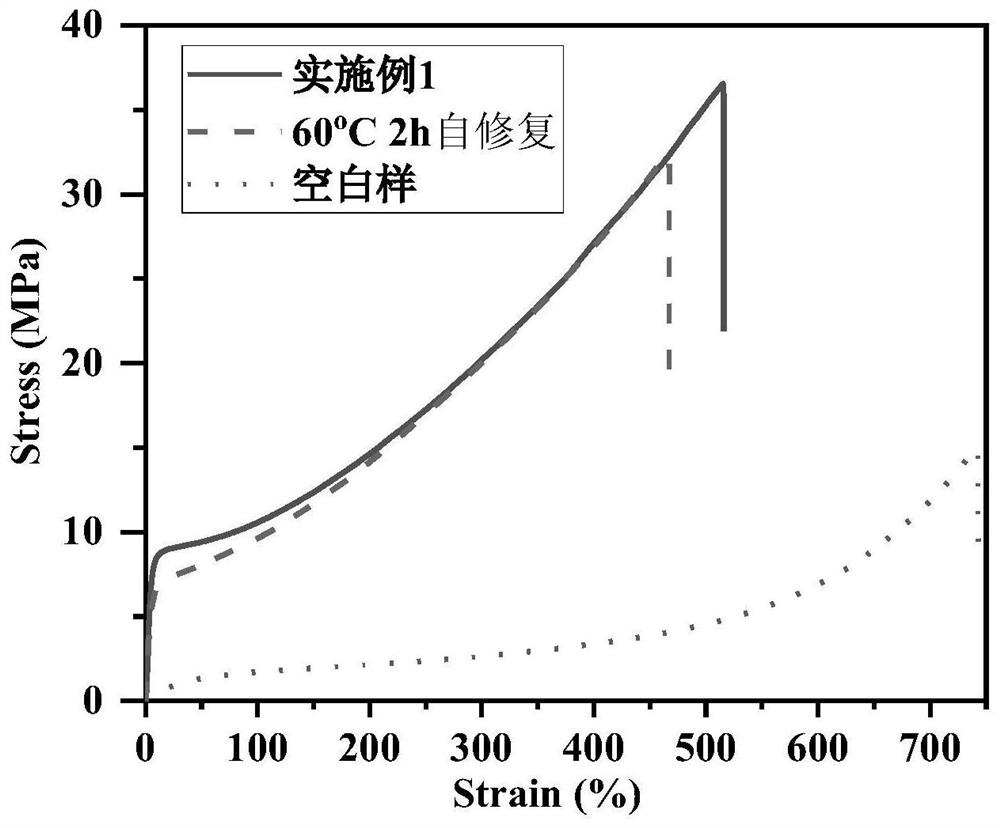

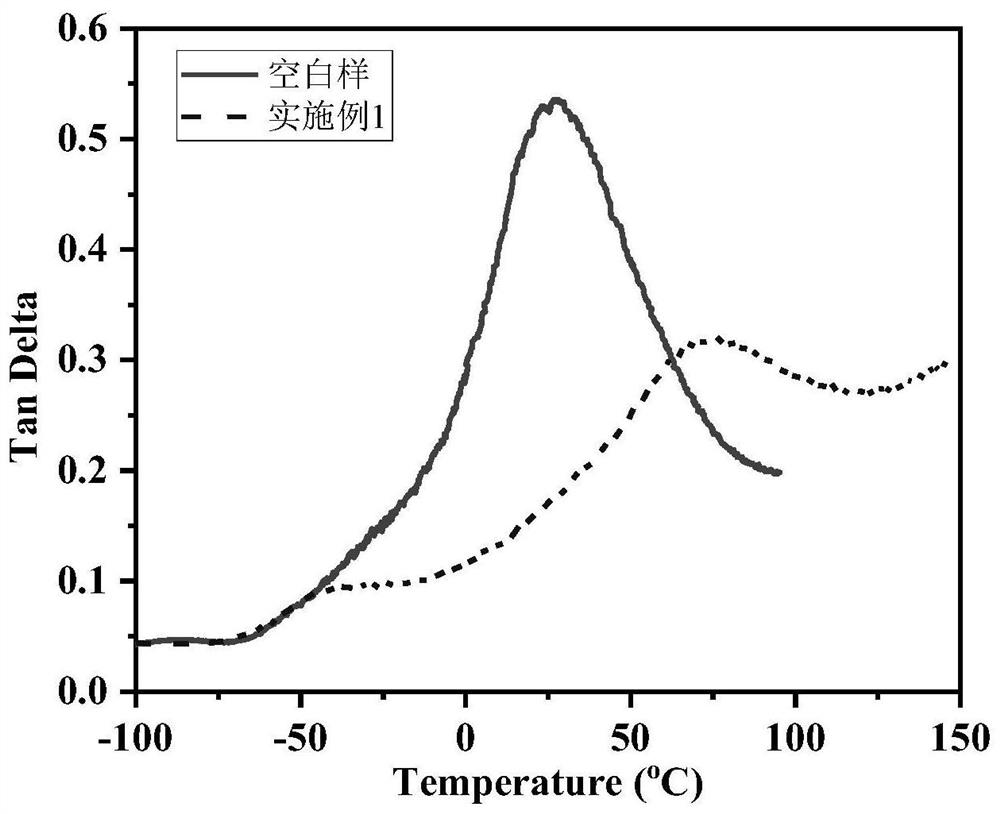

High-strength self-repairing waterborne polyurethane composite material and preparation method thereof

ActiveCN112876690AHigh tensile strengthHigh glass transition temperaturePolymer scienceMolecular materials

The invention relates to a green and environment-friendly waterborne polyurethane material capable of realizing high strength and self-repairing performance based on a metal organic coordination bond and a preparation method of the green and environment-friendly waterborne polyurethane material, and belongs to the field of polymer synthesis and intelligent polymer materials. The invention provides a high-strength self-repairing waterborne polyurethane composite material. The composite material is prepared from catechol-terminated waterborne polyurethane and a metal oxide through a coordination reaction. According to the invention, metal oxides such as ferroferric oxide nanoparticles and the like are selected as reinforcing fillers, and the characteristics of excellent self-repairing and stimulation response of metal-organic ligand coordinate bonds are utilized, so that the high-strength rapid self-repairing waterborne polyurethane composite material is obtained.

Owner:SICHUAN UNIV

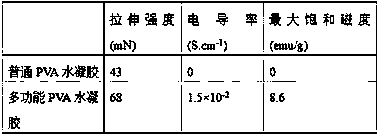

High-strength self-repairing conductive magnetic PVA (Polyvinyl Alcohol) hydrogel and preparation method thereof

The invention belongs to the technical field of functional polymer materials, and particularly relates to high-strength self-repairing conductive magnetic PVA (Polyvinyl Alcohol) hydrogel and a preparation method thereof. The method comprises the steps of wrapping polyaniline into the surface of nano-crystalline cellulose, immobilizing MnFe2O4 magnetic particles, then adding into a PVA water solution, uniformly mixing, and preparing the high-strength self-repairing conductive magnetic PVA hydrogel. A nano-crystalline cellulose / polyaniline / MnFe2O4 compound is utilized, so that the PVA hydrogelhas high strength, electrical conductivity and magnetic performance at the same time, three defects of low strength, no electrical conductivity and no magnetism of common PVA hydrogel are overcome, and the PVA hydrogel has a higher application value.

Owner:FUJIAN AGRI & FORESTRY UNIV

Tile surface material composite plate and novel construction method thereof

ActiveCN104775589AReduce the stringent requirements of the technical level of the installationImprove performanceCovering/liningsBuilding material handlingComposite materialCeramic tiles

The invention relates to a tile surface material composite plate and a novel construction method thereof. The construction method comprises the following steps: (1) sticking the tile surface material on a base plate to form a tile surface material spliced plate; (2) cleaning the tile surface material spliced plate; (3) forming straight-line-shaped cutting grooves on connecting seams of the tile surface material spliced plate in batches; (4) filling the cutting grooves with a crack-sealer, then curing to obtain the tile surface material composite plate and finishing the construction. The cutting grooves are formed in the modularized tile surface material composite plate in the construction method; the construction efficiency of the tile surface material composite plate can be improved, the labor intensity of the construction staff is reduced, the technological dependence of the construction staff is reduced; in addition, the butt seam precision of the tile is greatly improved, and the attractive effect of the buildings appearance is improved.

Owner:GUANGZHOU HONLLEY COMPOSITE MATERIAL

Flame-retardant polyurethane foam plastic and preparation method thereof

ActiveCN109232847APromote degradationMeet the requirements of green economic developmentPolyolToluene

The invention provides a flame-retardant polyurethane foam plastic. The foam plastic is prepared from the following components in parts by mass: 35-50 parts of toluene diisocynate, 52-65 parts of polyether polyol, 1.5-2.5 parts of water, 0.24-0.4 part of triethanolamine, 0.4-0.45 part of dibutyltin dilaurate, 0.45-0.5 part of methylsilicone oil 201 type and 20-30 parts of flame retardant. The flame-retardant polyurethane foam plastic is prepared by adopting a one-step foaming process, is simple in process operation, excellent in controllability and low in cost, and is easy to realize industrial production.

Owner:湖南科旺科技有限公司

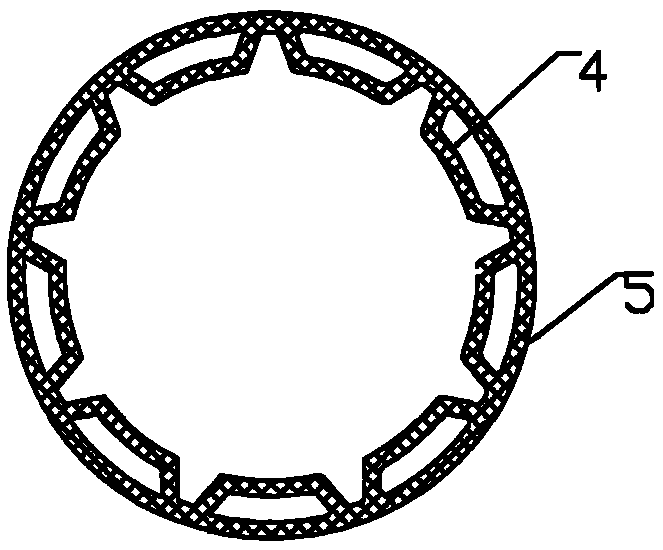

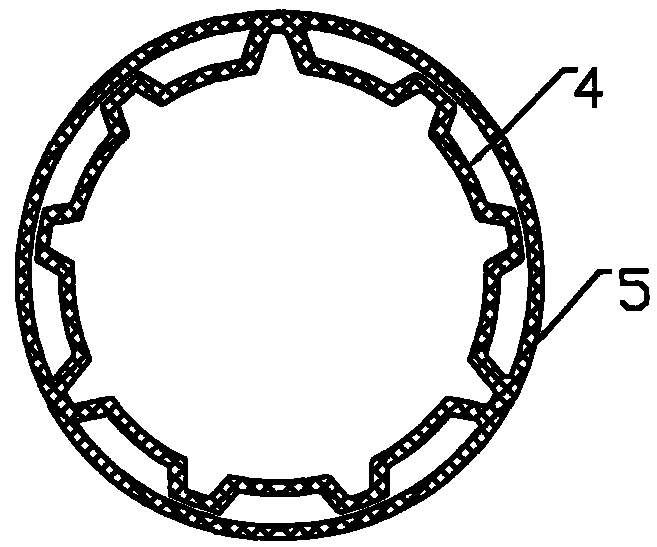

Combined shrunk-enhanced plastic manhole

InactiveCN101694107AWon't separateImprove protectionSewerage structuresUltimate tensile strengthLine structure

The invention discloses a combined shrunk-enhanced plastic manhole comprising a well body and a well block. The well body comprises a shrunk well body and a cylindrical well body connected with the shrunk well body; the well body is in two-layered structure and comprises an inner well body and an outer well body; the outer well body has a round cross section; and the inner well body has a cross section in a longitudinal raised-line structure and is connected with the outer well body. The invention adopts a combined structure, has high connection strength and reliable sealing, not only saves molding materials, but also ensures the manhole strength and solves the problems of sealing, transportation, cost and strength of the manhole.

Owner:四川天鑫塑胶管业有限公司

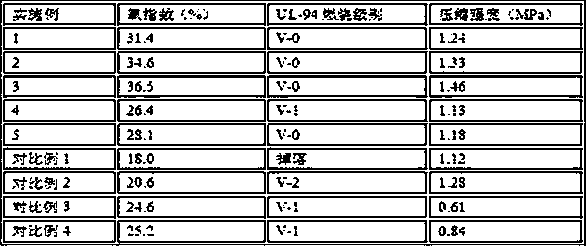

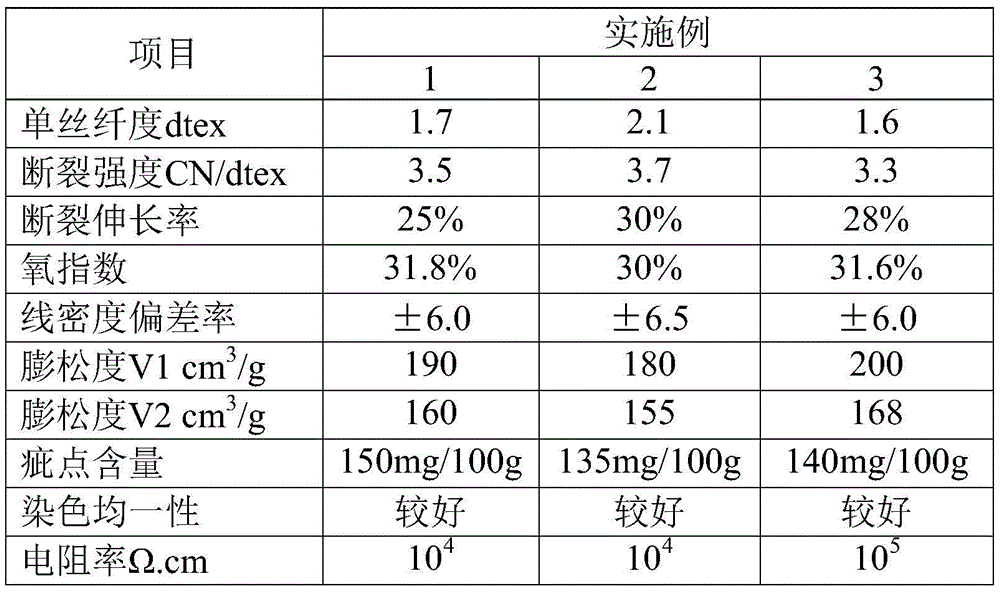

A preparation method based on graphene-enhanced flame-retardant recycled polyester staple fiber

ActiveCN104630928BSpin wellImprove qualityMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides a preparation method of a graphene based reinforced and flame-retarded recycled polyester staple fiber. The method comprises the following steps: preparing graphene master batch; preparing phosphate based halogen-free flame retardant master batch; weighing the graphene master batch and the phosphate based halogen-free flame retardant master batch, mixing with a recycled polyester raw material, drying, feeding molten dried raw materials into an impurity removal stirrer under the action of a screw extruder by a melt pump for carrying out homogenization impurity-removal treatment, feeding a homogenized and impurity-removal polyester melt into a secondary filter by the melt pump, enabling a filtered melt to pass through a mixed melt on a pipeline to enter a spinning manifold, carrying out drafting processing on a spun fiber to obtain the reinforced and flame-retarded recycled polyester fiber, cutting off bundles and packaging. The reinforced and flame-retarded recycled polyester chip has the good spinning forming property, the fiber quality is high, the using amount of a fire retardant can be effectively reduced under the synergistic effect of grapheme and the phosphate based flame retardant, the cost is reduced, the reinforcement effect can be achieved and the mechanical property of the fiber is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing flame-retardant anti-microbico polypropylene bulked continuous filament

ActiveCN102965754AHas antibacterial propertiesFlame retardantFlame-proof filament manufactureMonocomponent polyolefin artificial filamentPolymer scienceMagnesium salt

The invention discloses a method for preparing a flame-retardant anti-microbico polypropylene bulked continuous filament. The method comprises the following steps: A) evenly mixing magnesium sulfate whisker, basic magnesium chloride whisker, magnesium salt whisker and palygorskite, and then roasting the mixture in a vacuum stove, cooling down the mixture, stirring and dispersing the mixture in absolute ethyl alcohol by sodium hexametaphosphate, then carrying out plasma treatment at normal pressure, and then carrying out ultrasonic dispersion and cleaning in deionized water containing calcium stearate dispersion liquid, filtering the suspended whisker on the upper layer of the solution, taking modified whisker mixture liquid, repeating operation until depuration, and carrying out drying in a vacuum oven after depuration, thus obtaining modified whisker; B) stirring the modified whisker obtained from step A), antimonous oxide, hexabromocyclododecane aluminum, calcium stearate and a PP-g-MAH (maleic anhydride grafted polypropylene) bulking agent in a mixer, and adding isotactic polypropylene powder, so as to obtain flame-retardant anti-microbico isotactic polypropylene after mixing and stirring; and C) drying the flame-retardant anti-microbico isotactic polypropylene obtained from the step B) in a dynamic vacuum oven so that the moisture content is less than or equal to 30 ppm, carrying out direct extrusion through a co-rotating twin-screw melt mixing extruder and spinning, thus obtaining the flame retardant anti-microbico polypropylene bulk continuous filament with improved multiple functions.

Owner:浙江枫翎新材料科技有限公司

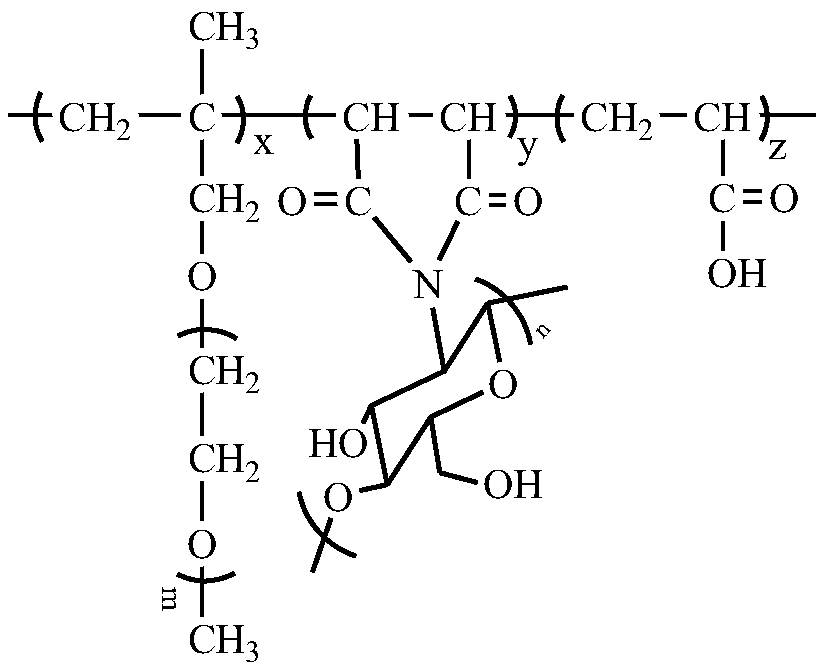

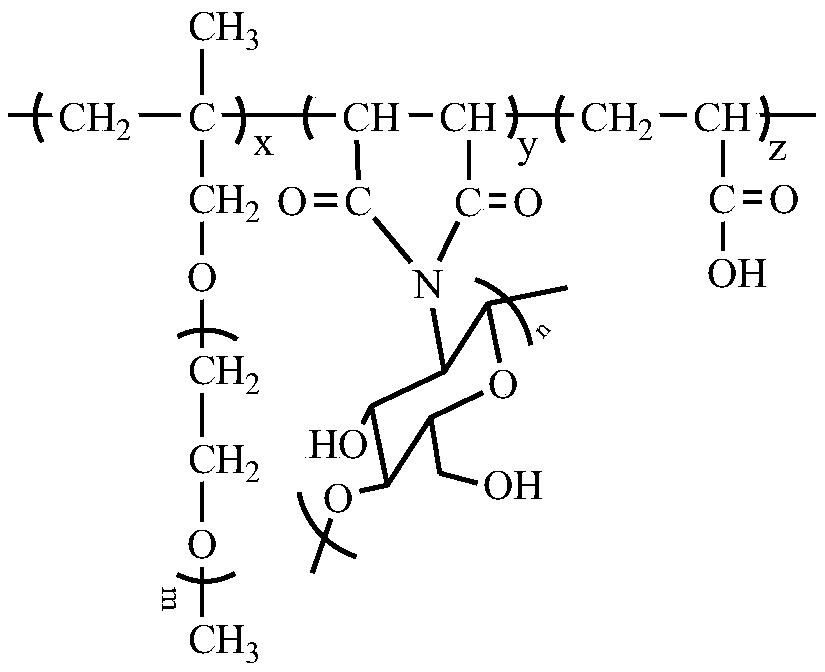

Chitosan oligosaccharide graft modified polycarboxylic acid water reducing agent and preparation method of water reducing agent

The invention discloses a chitosan oligosaccharide graft modified polycarboxylic acid water reducing agent and a preparation method of the water reducing agent. The method comprises the following steps: 1) preparing a chitosan oligosaccharide amidated macro-monomer, placing chitosan oligosaccharide and maleic anhydride in a molar ratio of 1:1.02-1.1 into a polar solvent, adding a catalyst at 85-95DEG C and carrying out a reaction for 3-4 h under stirring, and performing washing and oven-drying to obtain the powdery chitosan oligosaccharide amidated macro-monomer; and 2) preparing the water reducing agent, performing free radical polymerization in an aqueous solution on methyl allyl polyoxyethylene ether and the chitosan oligosaccharide amidated macro-monomer to obtain the chitosan oligosaccharide graft modified polycarboxylic acid water reducing agent. The chitosan oligosaccharide amidated macro-monomer directly participates in polymerization through a carbon-carbon double bond, and has high polymerization activity, and chitosan oligosaccharide side chains can greatly enhance viscosity-increasing water-retention properties of the water reducing agent, and can further enhance dispersion of the water reducing agent. In addition, the chitosan oligosaccharide side chains interacts with polyether long side chains, so that a hydrated film formed on the surface of cement particles ismore stable, and slump-loss is smaller over time.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

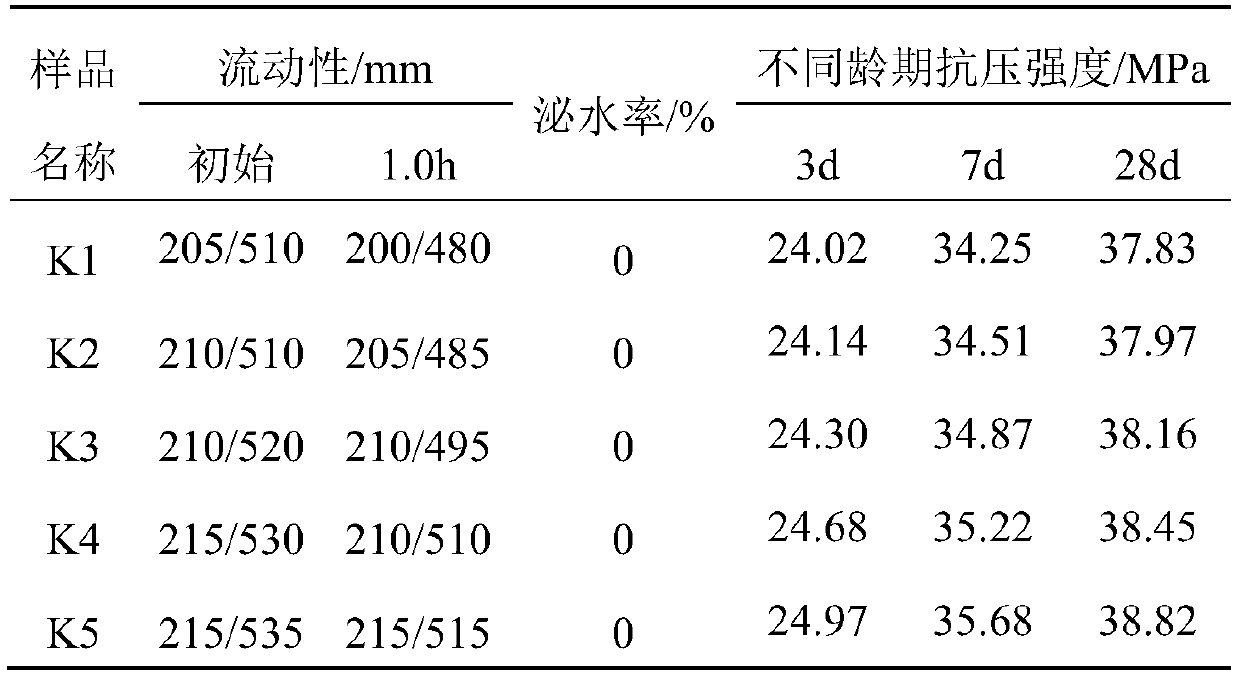

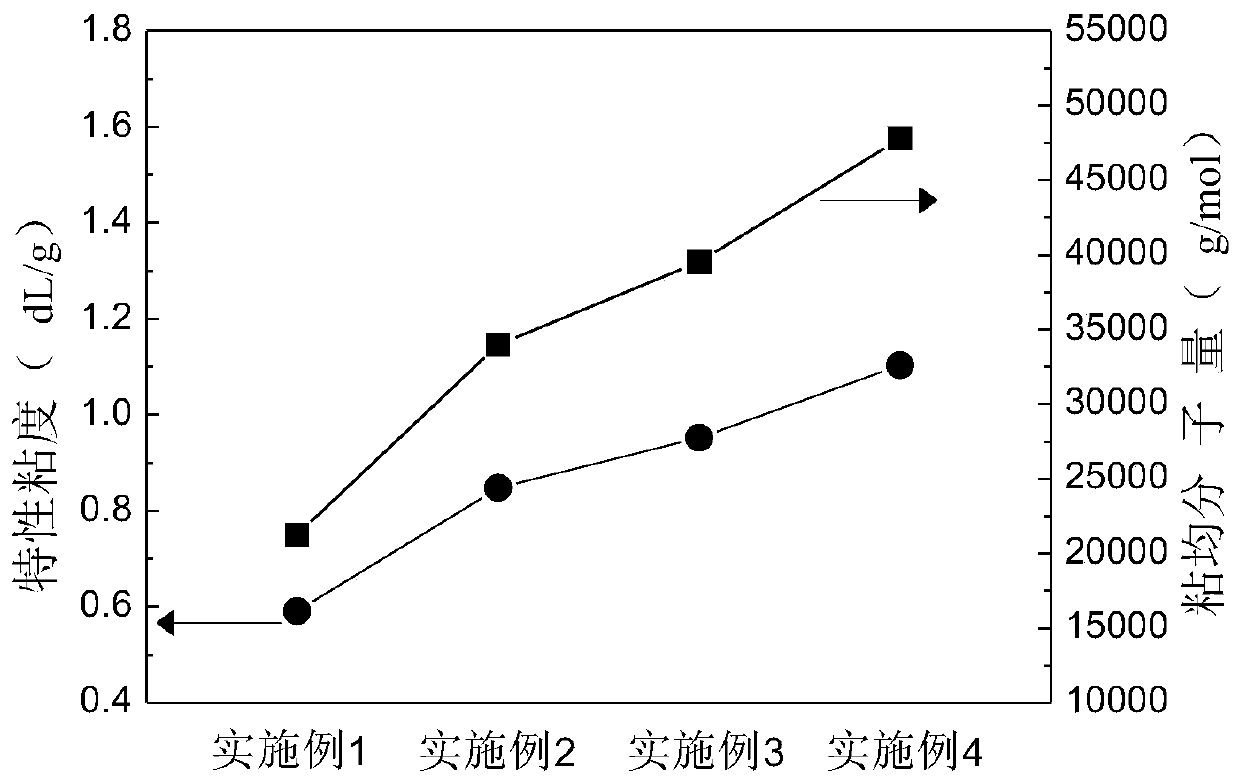

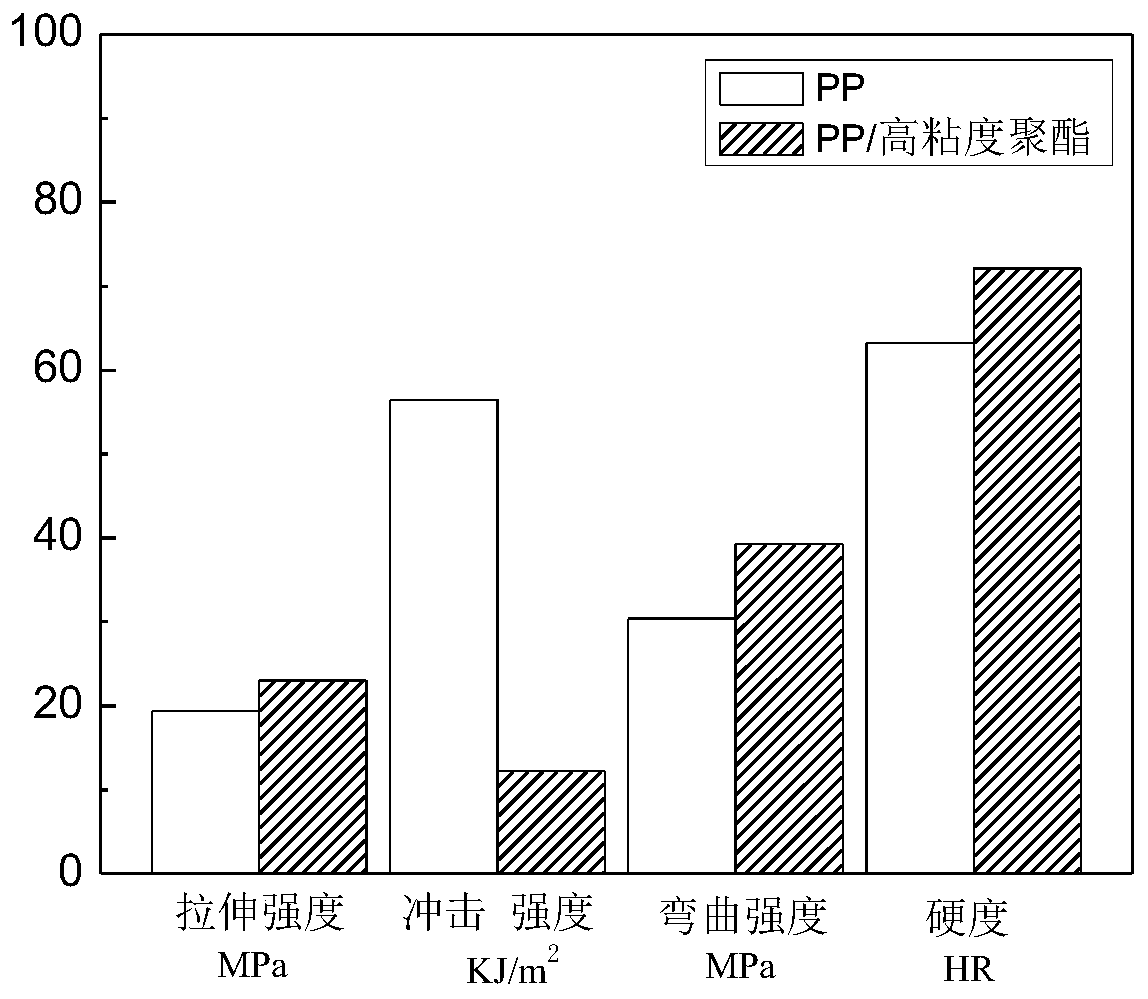

Method for tackifying recycled polyester bottle flake by using chain extender and application thereof

InactiveCN109749070AHigh intrinsic viscosityReduced potentiationPolyesterPolyethylene terephthalate glycol

The invention provides a method for tackifying recycled polyester bottle flakes by using chain extender and applications thereof and belongs to the field of comprehensive utilization of polymer materials recycling. The method for tackifying recycled the polyester bottle flakes by using the chain extender is characterized in that the recycled polyester flakes as adopted as matrix resin, the chain extender is added thereto for chemical chain extension reaction to obtain high viscosity polyester, and the recycled polyester component is polyethylene terephthalate. The method for tackifying recycled the polyester bottle flakes by using the chain extender has the advantages of effectively improving the intrinsic viscosity of r-PET (recycled polyethylene terephthalate) according to r-PET chain extension reaction mechanism and by selecting the suitable chain extender for compounding, enabling modified high-viscosity polyester material to meet the requirements of engineering plastics, playing an important role in expanding the application range of r-PET products, and providing research basis and practical guiding significance for the industrial production of the r-PET products.

Owner:DALIAN POLYTECHNIC UNIVERSITY

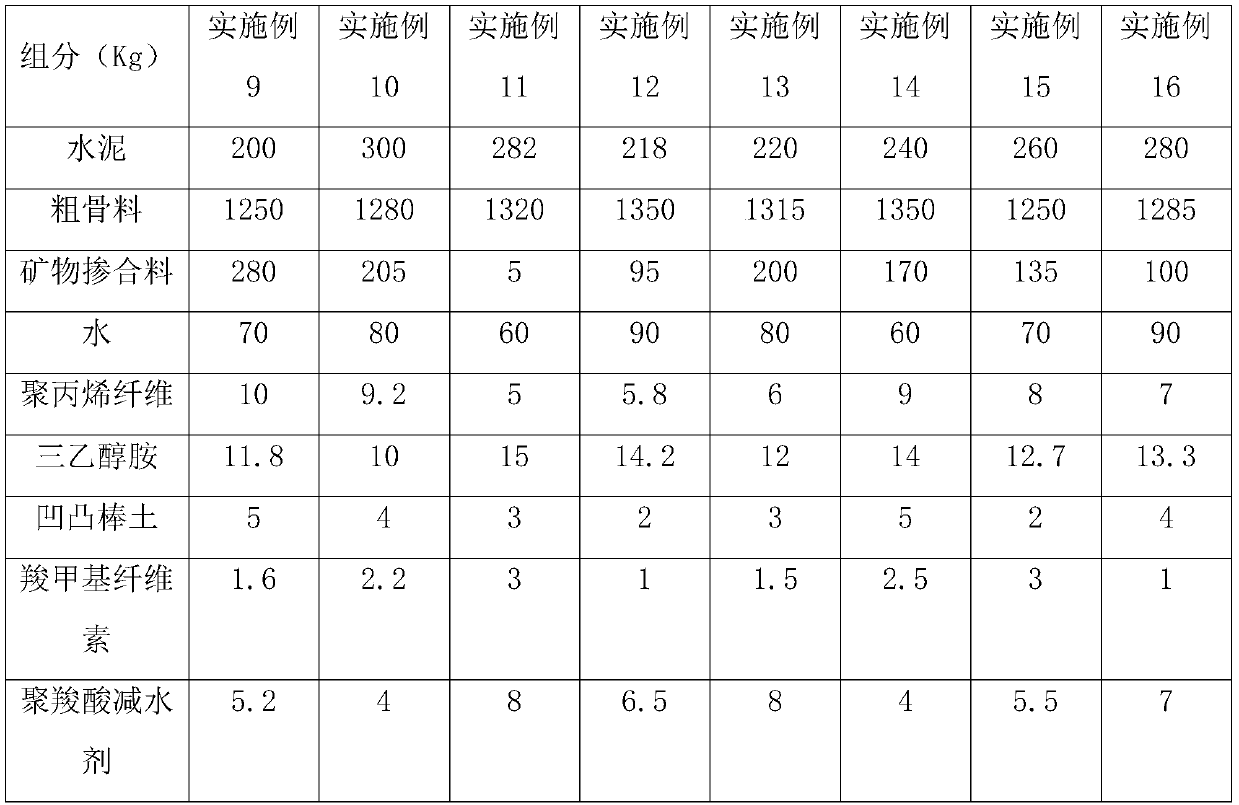

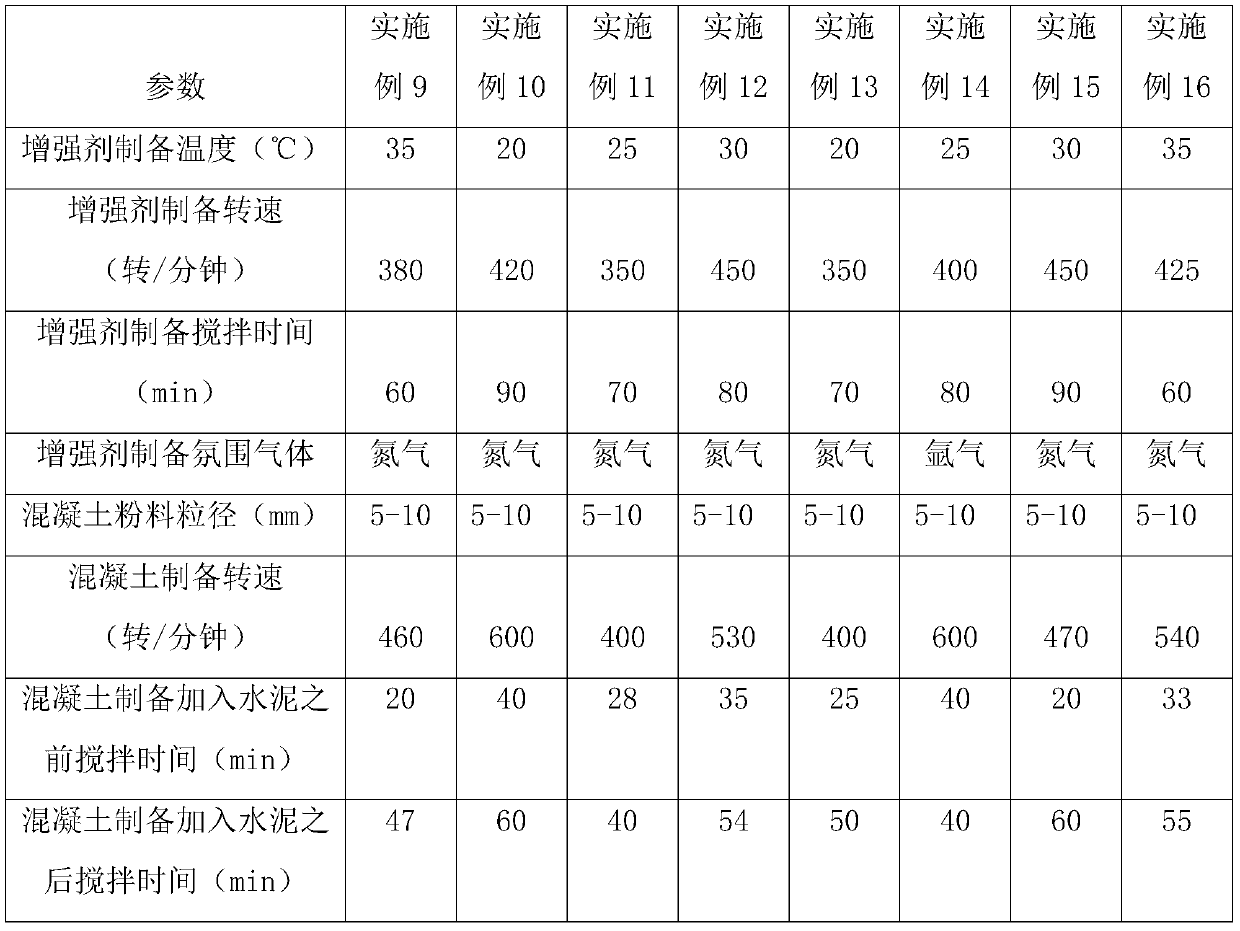

Pervious concrete and construction method thereof

InactiveCN111377685AHigh strengthGood dispersionIn situ pavingsPaving gutters/kerbsTriethanolamineStructural engineering

The invention discloses pervious concrete and a construction method thereof, which relate to the technical field of concrete construction. The pervious concrete is prepared from the following perviousconcrete raw materials in parts by weight: 200 to 300 parts of cement, 1250 to 1350 parts of coarse aggregate, 5 to 280 parts of mineral admixture and 60 to 90 parts of water. The pervious concrete raw material further comprises a surface reinforcing agent, and the surface reinforcing agent is prepared from the following reinforcing agent raw materials in parts by weight: 5-10 parts of polypropylene fiber and 10-15 parts of triethanolamine. The anti-pressure performance is good. The construction method of the pervious concrete comprises the following steps of reinforcing agent preparation, mixing, concrete preparation, pavement pouring and the like. The construction method of the pervious concrete has the advantage that the dispersity of the reinforcing agent is conveniently improved.

Owner:陕西隆生建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com