Combined shrunk-enhanced plastic manhole

A plastic inspection well, enhanced technology, applied in waterway systems, drainage structures, water supply devices, etc., to achieve the effects of preventing leakage, increasing strength, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

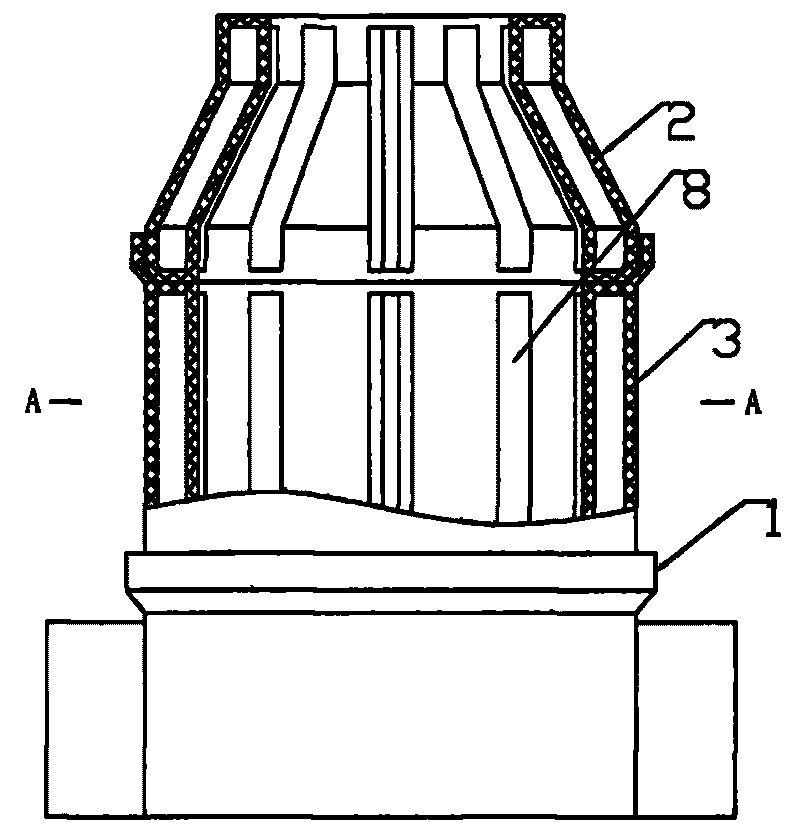

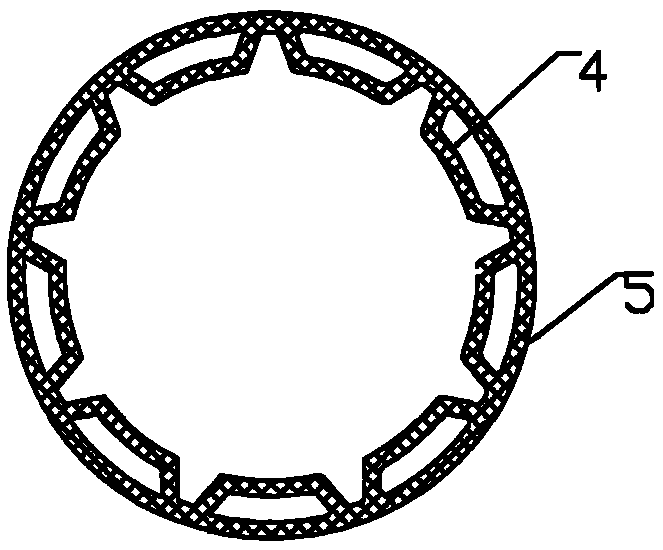

[0046] A combined closed mouth reinforced plastic inspection well, including a well body and a well base 1, wherein the well body includes a closed well body 2 and a straight well body 3 connected to the closed well body 2, and the well body has a two-layer structure, including an inner layer The well body 4 and the outer well body 5, the cross section of the outer well body 5 is circular, the cross section of the inner well body 4 is a longitudinal convex structure and connected with the outer well body 5, which can be molded Well body and well seat 1.

[0047] In the present invention, the inner well body 4 includes a plurality of evenly distributed convex lines, both sides of the convex lines are fixedly connected with the outer well body 5, and the space between the convex lines and the outer well body 5 is a hollow structure. Reinforcing ribs 8 can be arranged on the outer well body 5 .

Embodiment 2

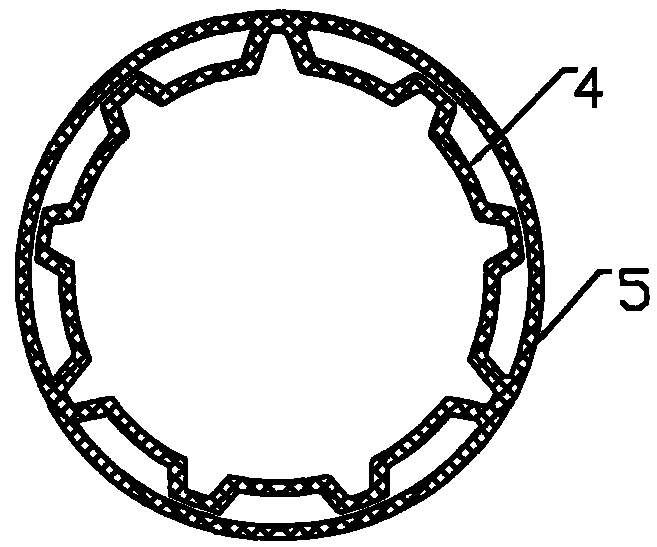

[0049] A combined closed mouth reinforced plastic inspection well, including a well body and a well base 1, wherein the well body includes a closed well body 2 and a straight well body 3 connected to the closed well body 2, and the well body has a two-layer structure, including an inner layer The well body 4 and the outer well body 5 , the cross section of the outer well body 5 is circular, and the cross section of the inner well body 4 is a longitudinal convex structure and is connected with the outer well body 5 .

[0050] In the present invention, the inner well body 4 includes a plurality of evenly distributed convex lines, and the two sides of the plurality of convex lines are connected laterally, among which there are six horizontal joints of the convex lines fixedly connected with the outer well body 5, and the fixed joints Evenly distributed on the circumference of the inner well body, a hollow structure is formed between the convex strip and the outer well body 5 .

Embodiment 3

[0052] A combined closed mouth reinforced plastic inspection well, including a well body and a well base 1, wherein the well body includes a closed well body 2 and a straight well body 3 connected to the closed well body 2, and the well body has a two-layer structure, including an inner layer The well body 4 and the outer well body 5 , the cross section of the outer well body 5 is circular, and the cross section of the inner well body 4 is a longitudinal convex structure and is connected with the outer well body 5 .

[0053] In the present invention, the inner well body 4 includes a plurality of evenly distributed convex lines, both sides of the convex lines are fixedly connected with the outer well body 5, and the space between the convex lines and the outer well body 5 is a hollow structure.

[0054] In the present invention, a connector 6 is provided at the joint between the well body and the well base 1, and the connector 6 is in the shape of an "H". There are seals 7 on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com