Laser information positioning transfer paper and preparation method thereof

A technology for information positioning and transfer of paper, applied in paper, papermaking, packaging paper, etc., can solve problems such as poor ability to distinguish authenticity, loss of reputation of production enterprises, damage to consumer interests, etc., and achieve strong ink absorption and wide market. The effect of sex, distinctive brand visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

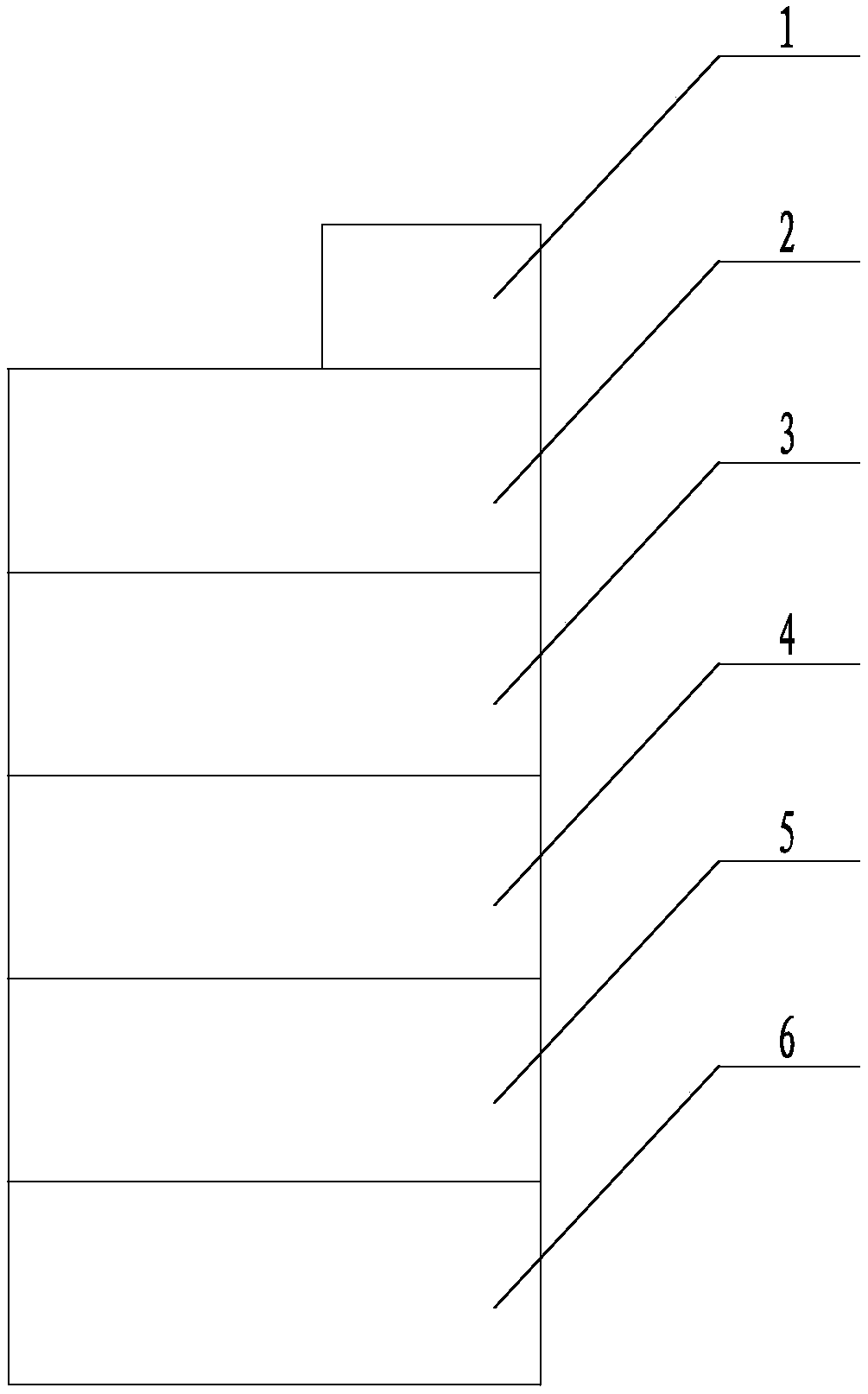

Image

Examples

Embodiment 1

[0052] Customer order (100,000 meters)

[0053] (1) PET with a thickness of 14 μm is selected as the carrier, and the transfer layer is coated by a slit coating method. The drying tunnel temperature is 110°C, and the vehicle speed is 70 m / min. Coating solution ratio: 8kg color layer (WHL-25) + 2.5kg ethanol + 0.5kg water

[0054] (2) Molding: Adopt laser holographic anti-counterfeiting positioning laser molding technology.

[0055] Firstly, the position of holographic anti-counterfeiting laser printing is calculated before plate making, and the anti-counterfeiting pattern is implanted in a specific position in the laser mold plate, and then the laser positioning molding is carried out.

[0056] Thoroughly clean the plate shaft, rubber shaft and cold cylinder, and heat up the plate shaft to 50°C. The board pressure is 18kg / cm 2 . Pack the production version 1 and the production version 2 on the version shaft and center them, and rotate and adjust according to the direction...

Embodiment 2

[0061] Customer orders (200,000 meters)

[0062] (1) PET with a thickness of 18 μm is selected as the carrier, and the transfer layer is coated by a slit coating method. The temperature of the drying tunnel is 150°C, the speed of the vehicle is 80 m / min, and the ratio of the coating solution: 8 kg of color layer (WHL-25) + 2.5 kg of ethanol + 0.5 kg of water

[0063] (2) Molding: Adopt laser holographic anti-counterfeiting positioning laser molding technology.

[0064] Firstly, the position of holographic anti-counterfeiting laser printing is calculated before plate making, and the anti-counterfeiting pattern is implanted in a specific position in the laser mold pressing plate, and then the laser positioning molding is carried out.

[0065] Clean the plate shaft, rubber shaft and cold cylinder, and heat up the plate shaft to 55°C. Adjust the board pressure to 19kg / cm 2 . Pack the production version 1 and the production version 2 on the version shaft and center them, and ro...

Embodiment 3

[0070] Customer orders (300,000 meters)

[0071] (1) PET with a thickness of 20 μm is selected as the carrier, and the transfer layer is coated by a slit coating method. The temperature of the drying tunnel is 180°C, the speed of the vehicle is 90 m / min, and the ratio of the coating solution: 8kg color layer (WHL-25) + 2.5kg ethanol + 0.5kg water

[0072] (2) Molding: Adopt laser holographic anti-counterfeiting positioning laser molding technology.

[0073] Firstly, the position of holographic anti-counterfeiting laser printing is calculated before plate making, and the anti-counterfeiting pattern is implanted in a specific position in the laser mold pressing plate, and then the laser positioning molding is carried out.

[0074] Clean the plate shaft, rubber shaft and cold cylinder, and heat up the plate shaft to 60°C. Adjust the board pressure to 20kg / cm 2 . Pack the production version 1 and the production version 2 on the version shaft and center them, and rotate and adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com