Method for producing a coupling segment of a flexible coupling

A technology of coupling and fan piece, applied in elastic coupling, chemical instrument and method, coupling and other directions, can solve the problem of high cost, and achieve the effect of economical manufacturing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

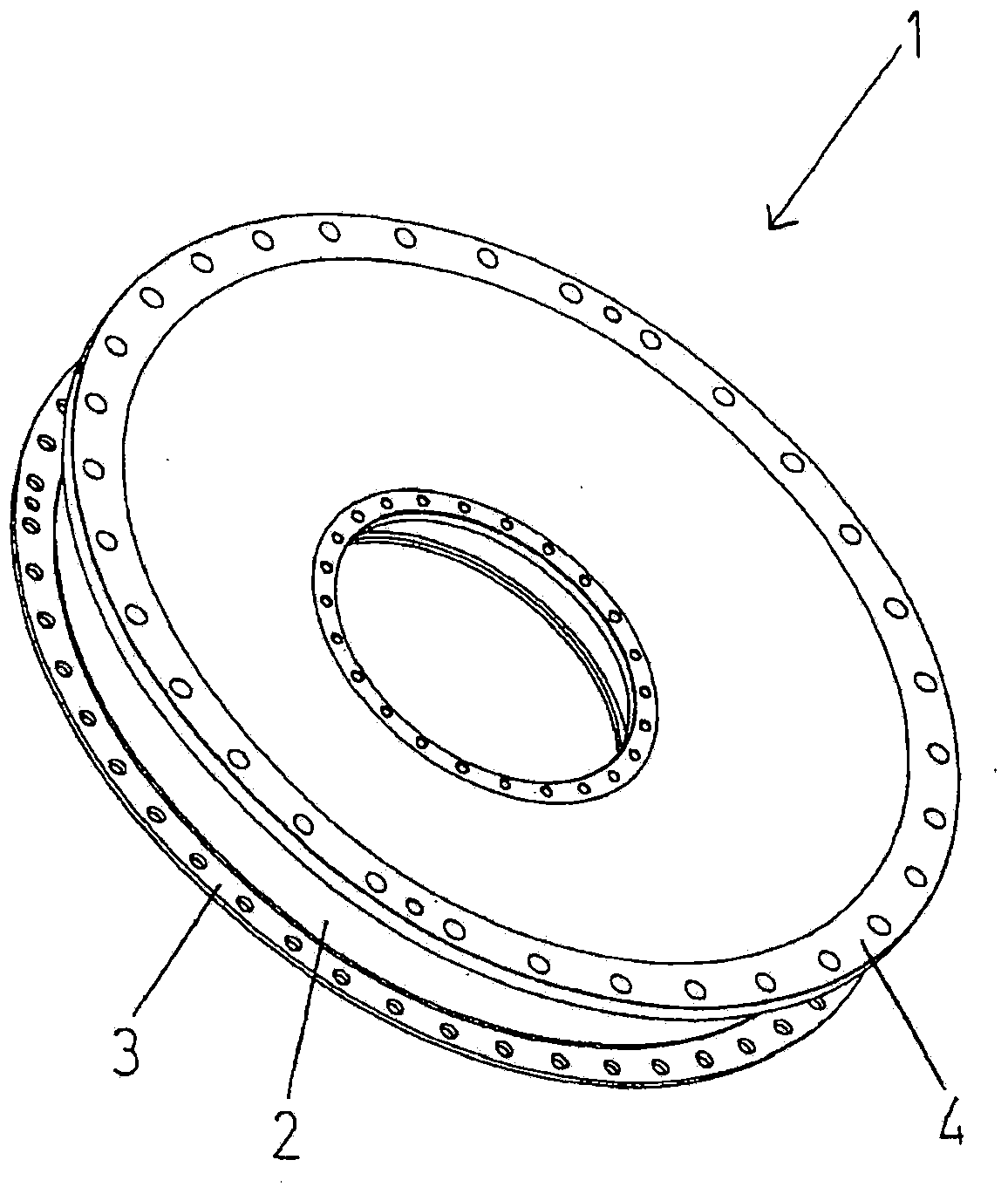

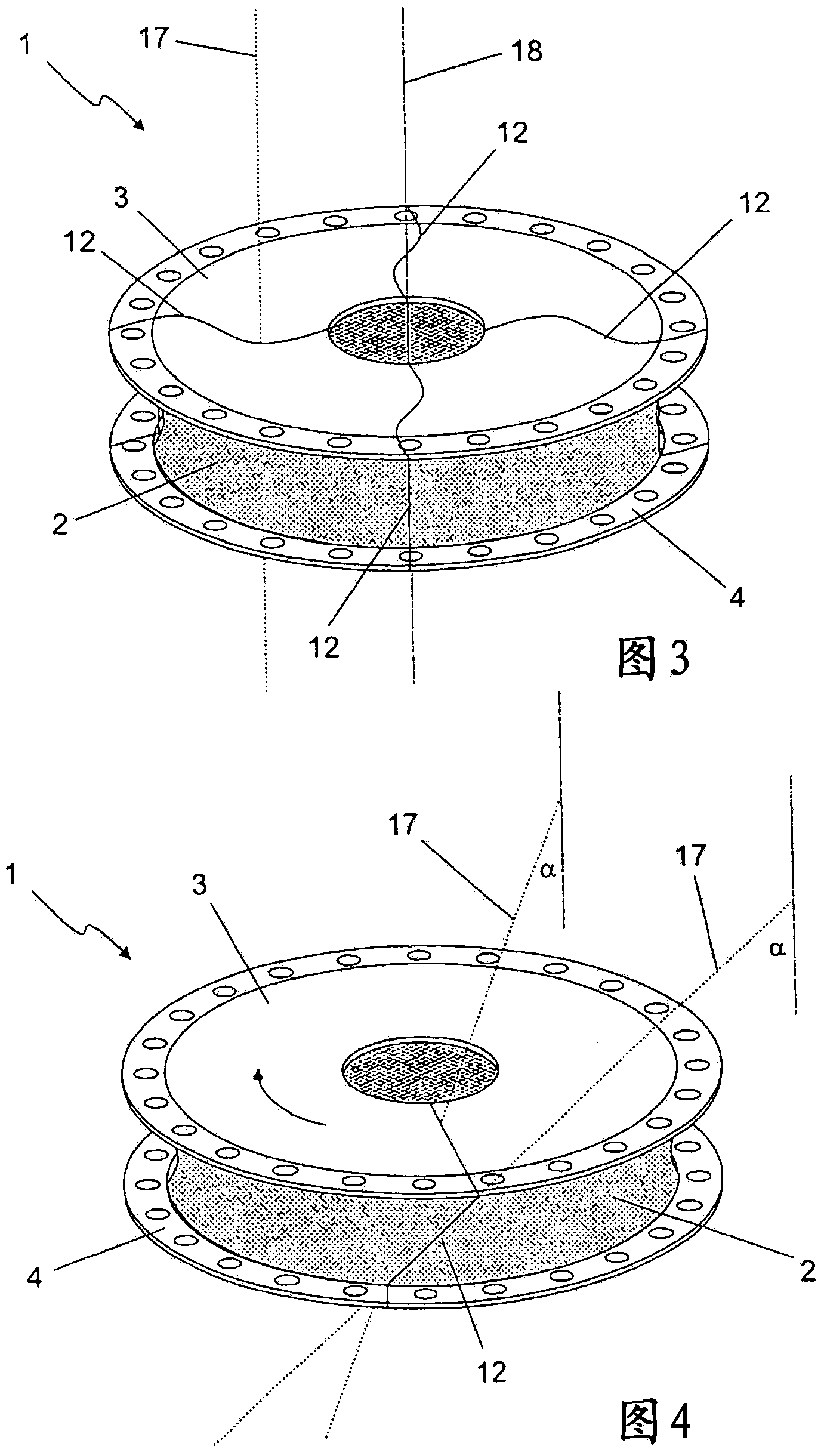

[0030] figure 1A perspective view of an exemplary embodiment of a coupling body 1 of a conventionally produced, torsionally elastic coupling in the form of an annular coupling is shown. The coupling body 1 has an annular elastomer body 2 which is arranged between two annular metallic connecting flanges 3 and 4 . The elastomer body 2 and the two connecting flanges 3 and 4 are aligned coaxially with one another. The metallic connecting flanges 3 and 4 are previously produced by casting. The elastomer body 2 is connected to the connecting flanges 3 and 4 in a form-fitting and torque-transmittable manner by means of vulcanized material.

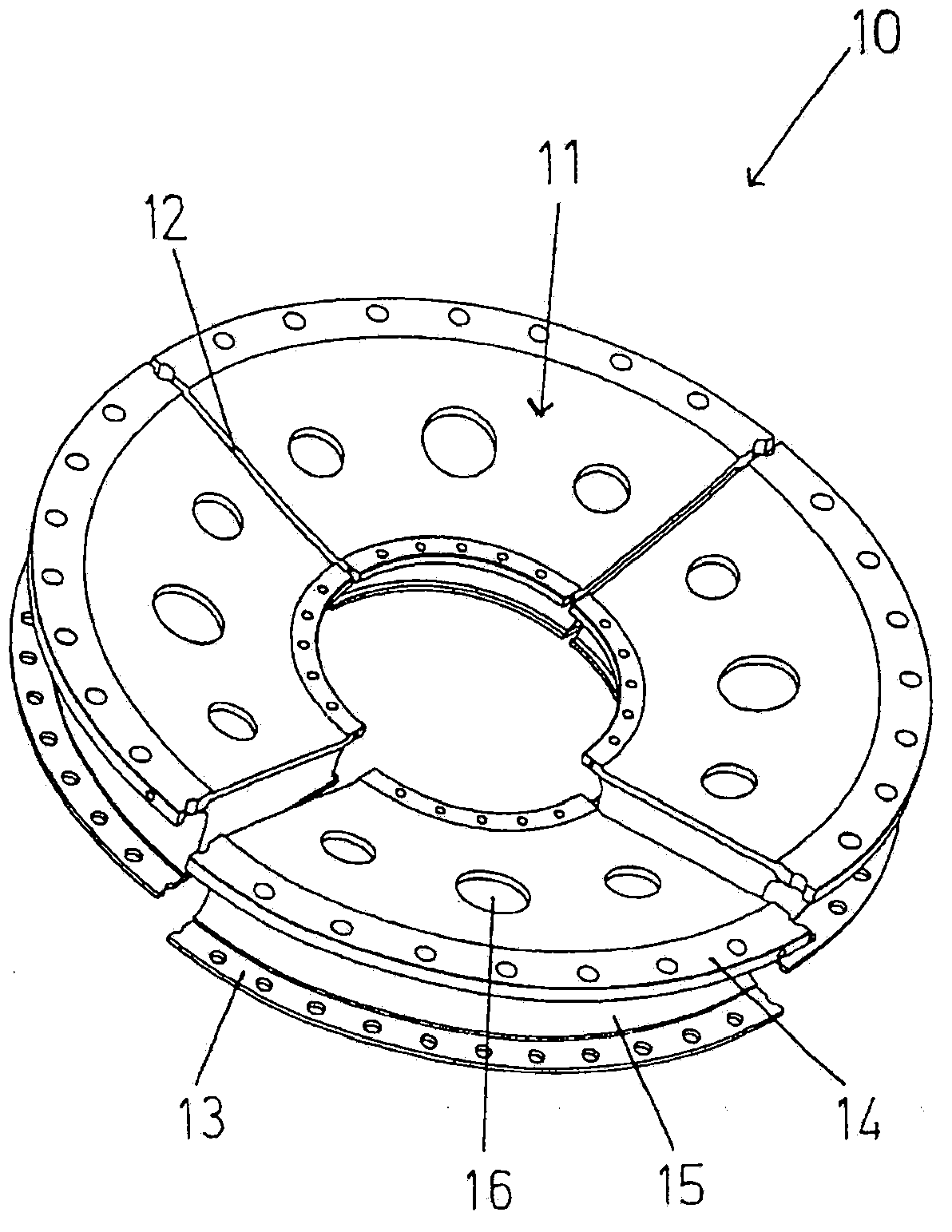

[0031] figure 2 shows that obtained in the implementation of the method according to the invention figure 1 The coupling body 1 shown in , thereby making a segmented elastic coupling 10 with four coupling segments 11 arranged one after the other in the circumferential direction, annularly constituted, and in the form of a rotationally elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com