High-strength self-repairing waterborne polyurethane composite material and preparation method thereof

A technology of water-based polyurethane and composite materials, which is applied in the fields of polymer synthesis and intelligent polymer materials, and achieves the effects of good coordination interaction, improved tensile strength, and increased glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

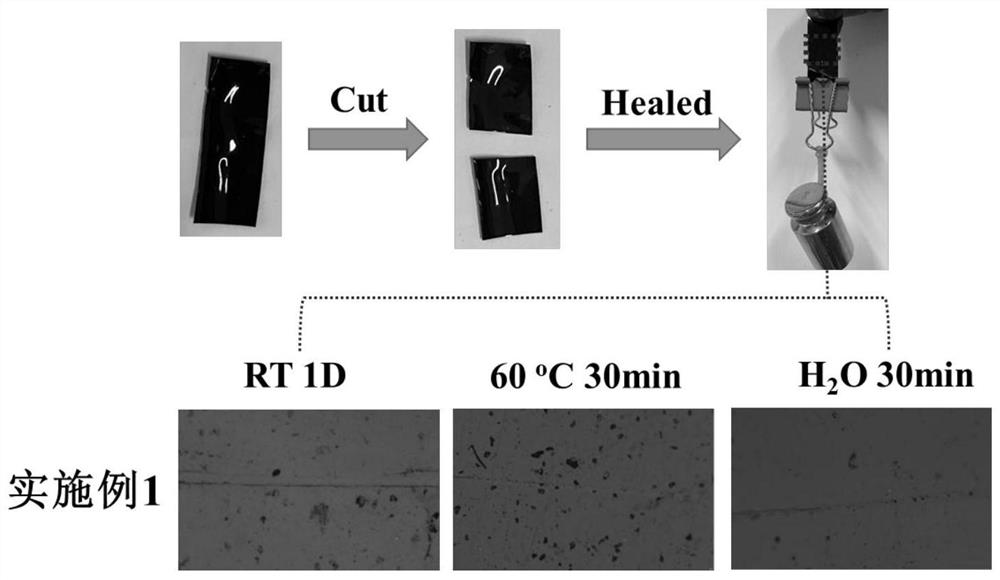

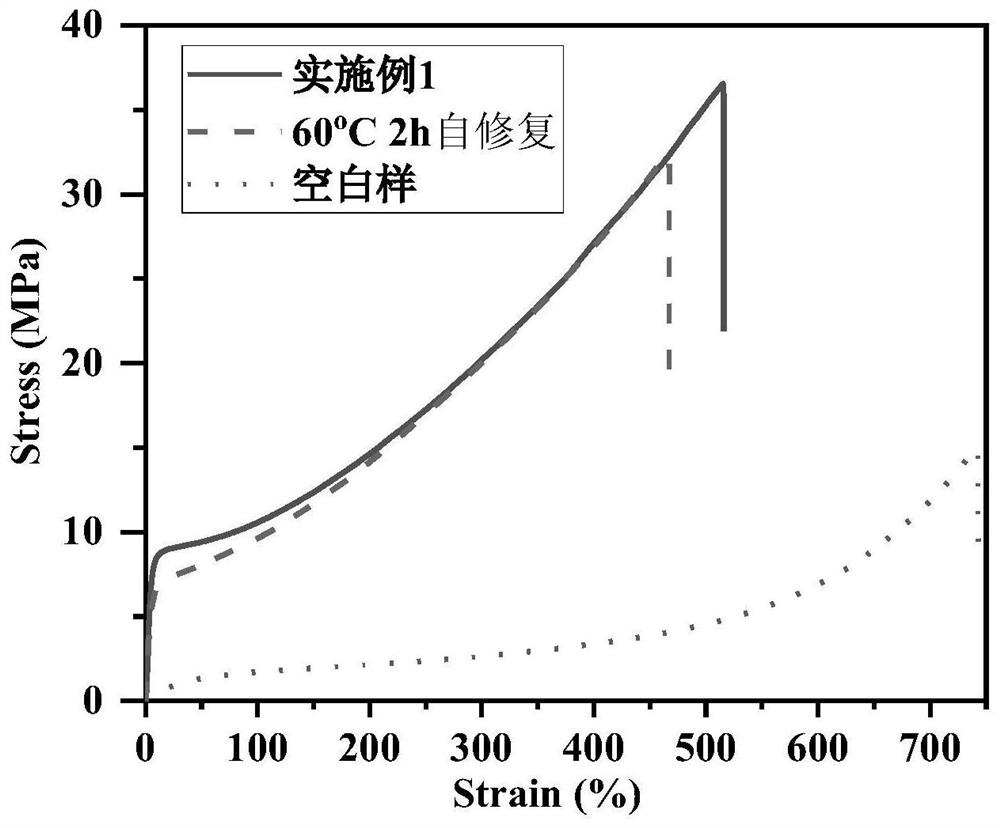

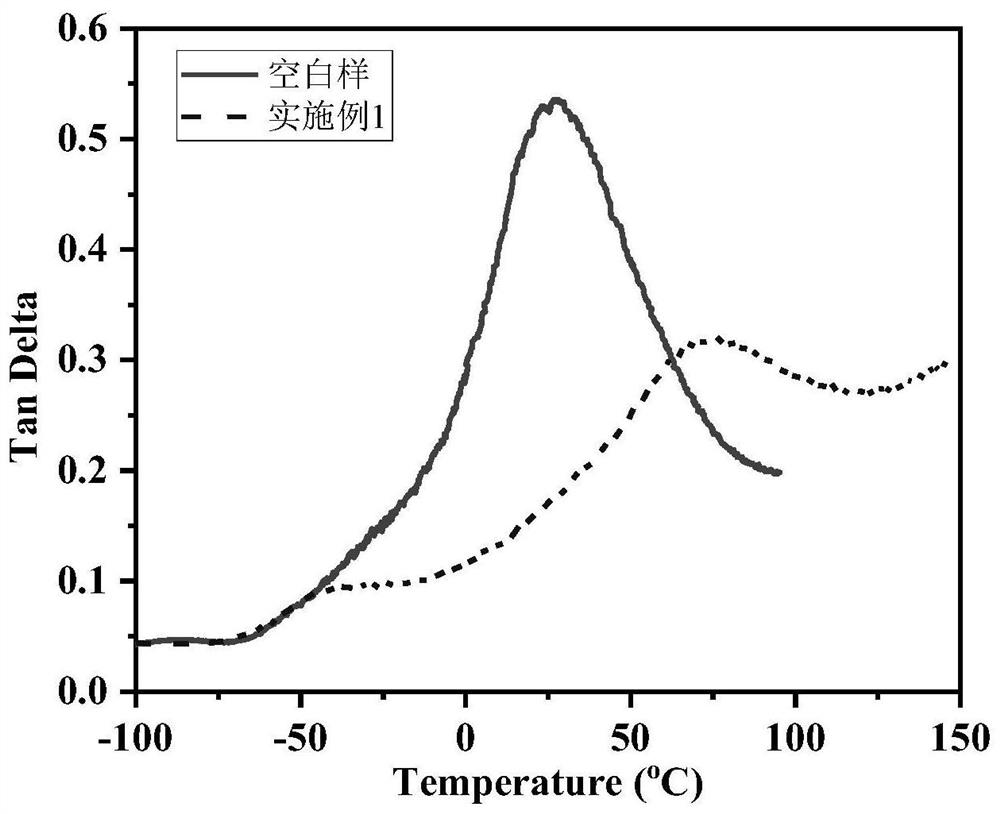

Embodiment 1

[0044] A method for enhancing the mechanical properties and thermomechanical properties of self-healing water-based polyurethane by using ferroferric oxide, the specific steps are as follows:

[0045] 1. Preparation of oleic acid-modified ferroferric oxide magnetic nanoparticles

[0046] 42mL of cyclohexane, 24mL of absolute ethanol and 18mL of water were placed in a three-necked flask (volume ratio 7:4:3), and nitrogen gas was continuously passed for 30min to remove dissolved oxygen. Then weigh 2.16g FeCl 3 ·6H 2 O, 0.79g FeCl 2 4H 2 O, 4.87g of C 18 h 33 o 2 Na and 1.12g NaOH were sequentially added to the above mixed solution, and the mixture was mechanically stirred under a nitrogen atmosphere, and refluxed at 68° C. for 4 h. After the reflux, the flask was removed from the oil bath and cooled to room temperature. After the product was precipitated with ethanol and magnetically separated, the supernatant liquid was decanted, then ultrasonically dispersed with deioni...

Embodiment 2

[0054] A method for enhancing the mechanical properties and thermomechanical properties of self-healing water-based polyurethane by using ferroferric oxide, the specific steps are as follows:

[0055] 1. Preparation of oleic acid-modified ferroferric oxide magnetic nanoparticles

[0056] 42mL of cyclohexane, 24mL of absolute ethanol and 18mL of water were placed in a three-necked flask (volume ratio 7:4:3), and nitrogen gas was continuously passed for 30min to remove dissolved oxygen. Then weigh 2.16g FeCl 3 ·6H 2 O, 0.79g FeCl 2 4H 2 O, 4.87g of C 18 h 33 o 2 Na and 1.12g NaOH were sequentially added to the above mixed solution, and the mixture was mechanically stirred under a nitrogen atmosphere, and refluxed at 68° C. for 4 h. After the reflux, the flask was removed from the oil bath and cooled to room temperature. After the product was precipitated with ethanol and magnetically separated, the supernatant liquid was decanted, then ultrasonically dispersed with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com