Preparation method of graphene based reinforced and flame-retarded recycled polyester staple fiber

A technology of recycled polyester and graphene, which is applied in the chemical characteristics of fibers, the manufacture of single-component polyester rayon, and rayon, can solve the problems of poor mechanical properties of recycled polyester fibers, and achieve good spinning and forming The effect of high electron transfer rate and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

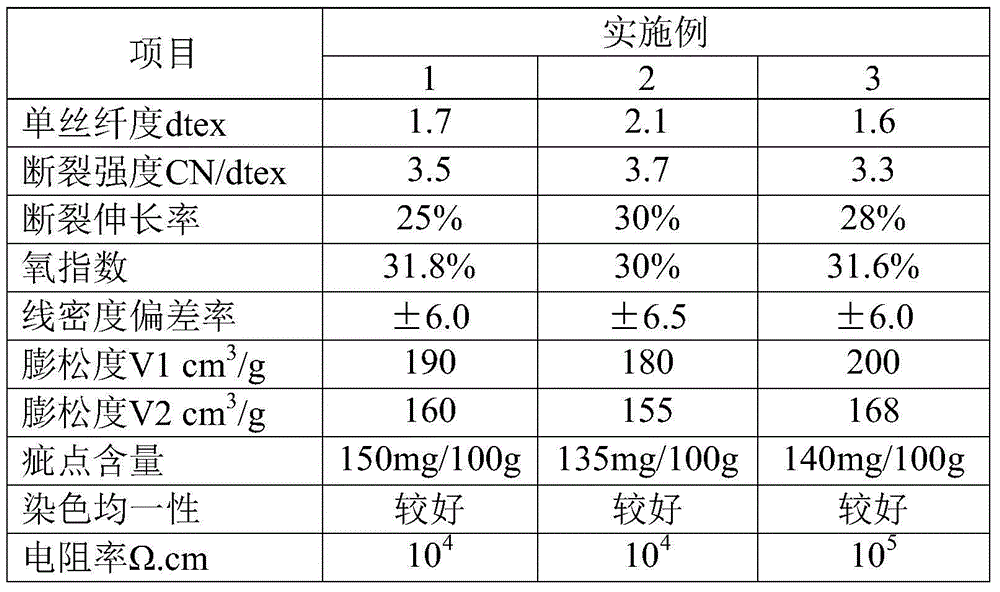

Examples

Embodiment 1

[0036] (1) Preparation of graphene masterbatch

[0037] Graphene is treated with surface sulfonic acid group functionalization, the particle size of graphene is 500nm~1000nm, graphene and polyvinylpyrrolidone are stirred, mixed and dispersed according to the mass ratio of 2:1 to obtain graphene particles; graphene particles are added In the polyester powder, the addition of graphene particles is 10% of the quality of the polyester powder, and the graphene masterbatch is produced by a twin-screw granulation process;

[0038] (2) Preparation of phosphorus-based halogen-free flame-retardant masterbatch

[0039] The mixture of N-methylolpropionamide methyl phosphonate and dimethyl methyl phosphonate with a particle size of 0.1 ~ 8um is mixed with polyester powder at high speed, and then the phosphorus-containing particles are produced through a screw granulation process. The phosphorus content of the flame retardant masterbatch is 60000ppm;

[0040] (3) According to the mass per...

Embodiment 2

[0046] (1) Preparation of graphene masterbatch

[0047] Graphene is functionalized with surface sulfonic acid groups, and the particle size of graphene is 500nm to 1000nm. According to the mass ratio of 5:1, graphene and tetracyanodimethylbenzoquinone are stirred, mixed and dispersed to obtain graphene particles; Graphene particles are added in the polyester powder, the addition of graphene particles is 15% of the quality of the polyester powder, and the graphene masterbatch is obtained by a twin-screw granulation process;

[0048] (2) Preparation of phosphorus-based halogen-free flame-retardant masterbatch

[0049] Mix hydroxyethylphenylphosphinic acid with a particle size of 0.1-8um and polyester powder at high speed to produce phosphorus-containing particles through a screw granulation process. The phosphorus content of the flame-retardant masterbatch is 100,000ppm;

[0050] (3) According to the mass percentage, take 2% graphene masterbatch, 8% phosphorus-based halogen-fre...

Embodiment 3

[0056] (1) Preparation of graphene masterbatch

[0057] Graphene is treated with surface sulfonic acid group functionalization, the particle size of graphene is 500nm~1000nm, graphene and polyvinyl alcohol are stirred, mixed and dispersed according to the mass ratio of 1:1 to obtain graphene particles; graphene particles are added to In the polyester powder, the addition of graphene particles is 20% of the quality of the polyester powder, and the graphene masterbatch is produced by a twin-screw granulation process;

[0058] (2) Preparation of phosphorus-based halogen-free flame-retardant masterbatch

[0059] Phosphorus-containing granules are produced by mixing reactive phosphorus-based halogen-free flame retardants with polyester powder at high speed, and the phosphorus content of the flame-retardant masterbatch is 80,000ppm;

[0060] (3) Mix and dry graphene masterbatch and phosphorus-based halogen-free flame-retardant masterbatch with recycled polyester raw materials accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com