High wear resistant and high self-lubrication continuous long fiber reinforced high temperature resistant nylon composite material and preparation method thereof

A nylon composite material, high temperature resistant technology, applied in the field of high temperature resistant nylon composite materials, can solve the problems of unused continuous fiber reinforcement, unused high temperature resistant nylon, etc., achieve good mechanical properties, increase affinity, The effect of excellent self-lubrication and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

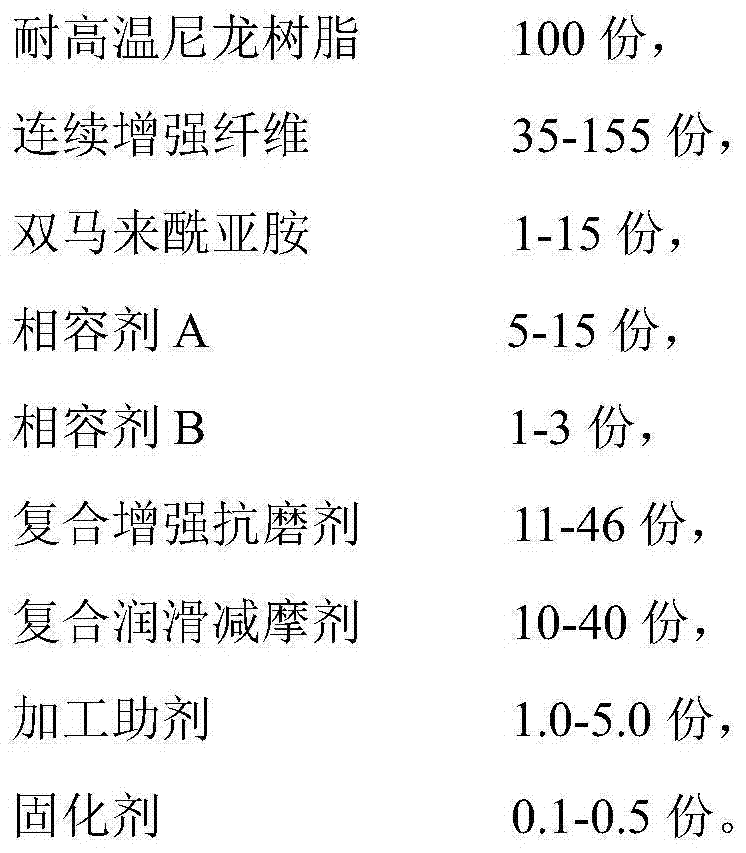

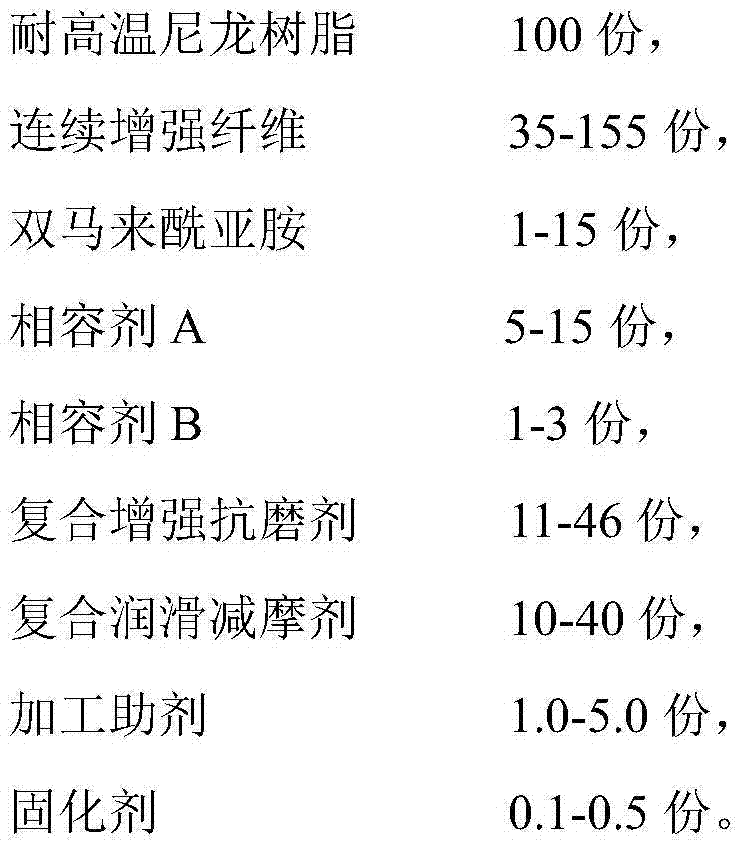

Method used

Image

Examples

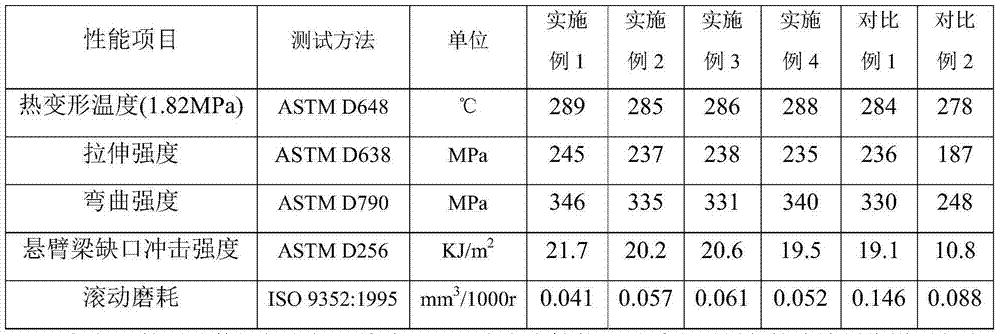

Embodiment 1

[0044] (1) Place polydecanediamide terephthalamide in a drying oven at 110°C and dry for 10 hours; graft high-density polyethylene with maleic anhydride and hollow glass microspheres (with a particle size of 10 μm and a bulk density of 1.6g / cm 3 ), silicon dioxide, potassium titanate whiskers (0.1 μm in diameter, 15 μm in length), polytetrafluoroethylene and ultra-high molecular weight polyethylene with a molecular weight of 2.5 million were placed in a drying oven at 80°C for 4 hours;

[0045] (2) 100 parts of polydecanediamide, 8 parts of diphenylmethane bismaleimide, 15 parts of compatibilizer A high-density polyethylene grafted maleic anhydride, 36 parts of composite reinforced anti-wear agent (15 parts of hollow glass microspheres, 6 parts of nano-silica, 15 parts of potassium titanate whiskers), 40 parts of composite lubricant and friction reducer (15 parts of polytetrafluoroethylene, 25 parts of ultra-high molecular weight polyethylene), 5 parts Parts of processing aid...

Embodiment 2

[0048] (1) Place polyhexamethylene terephthalamide-co-hexamethylene adipamide copolymer in a drying oven at 110°C for 10 hours; graft high-density polyethylene with maleic anhydride, hollow glass Beads (particle size 10 μm, bulk density 1.6 g / cm3), silica, potassium titanate whiskers (diameter 0.1 μm, length 15 μm), polytetrafluoroethylene and ultra-high molecular weight polytetrafluoroethylene with a molecular weight of 2.5 million Put ethylene in an 80°C drying oven and dry for 4 hours;

[0049] (2) 100 parts of polyhexamethylene terephthalamide-co-adipamide copolymer, 8 parts of diphenylmethane bismaleimide, 15 parts of high-density polyethylene grafted with maleic anhydride , 36 parts of composite enhanced anti-wear agent (15 parts of hollow glass microspheres, 6 parts of nano-silicon dioxide, 15 parts of potassium titanate whiskers), 40 parts of composite lubricating antifriction agent (15 parts of polytetrafluoroethylene, 25 parts of super High molecular weight polyethy...

Embodiment 3

[0052] (1) Place polynonanediamine terephthalamide in a drying oven at a temperature of 110°C and dry for 10 hours; graft high-density polyethylene with maleic anhydride and hollow glass microspheres (with a particle size of 10 μm and a bulk density of 1.6g / cm3), silicon dioxide, potassium titanate whiskers (0.1 μm in diameter, 15 μm in length), polytetrafluoroethylene and ultra-high molecular weight polyethylene with a molecular weight of 2.5 million were placed in an 80°C drying oven, Dry for 4 hours;

[0053] (2) 100 parts of polynonanediamine terephthalamide, 8 parts of diphenylmethane bismaleimide, 15 parts of high-density polyethylene grafted maleic anhydride, 36 parts of composite reinforced anti-wear agent (15 parts Hollow glass microspheres, 6 parts of nano-silica, 15 parts of potassium titanate whiskers), 40 parts of composite lubricant and friction reducer (15 parts of polytetrafluoroethylene, 25 parts of ultra-high molecular weight polyethylene), 1.5 parts of proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com