High-strength self-repairing conductive magnetic PVA (Polyvinyl Alcohol) hydrogel and preparation method thereof

A self-healing, high-strength technology applied in the field of functional polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

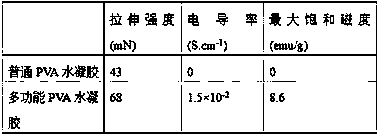

Image

Examples

Embodiment 1

[0019] (1) Preparation of polyaniline-coated nanocellulose:

[0020] First, weigh 20 grams of 1% nanocellulose aqueous suspension in a 100ml beaker, and place it in an ice-water bath at 4°C. 2mmol of phytic acid and 6mmol of aniline were dissolved in 4ml of distilled water, stirred evenly, and added dropwise into the nanocellulose. Weigh 2mmol of ammonium persulfate and dissolve in 4ml of distilled water. Then the ammonium persulfate solution was added dropwise to the nanocellulose to initiate aniline polymerization, and finally the nanocellulose / polyaniline composite was obtained by centrifuging and washing with distilled water for 5 times in a centrifuge at 10,000 rpm.

[0021] (2) Nanocellulose / polyaniline composite dispersed MnFe 2 o 4 Preparation of magnetic nanoparticles:

[0022] Add water to the above-mentioned nanocellulose / polyaniline composite to a concentration of 0.5wt%, and then add 8mmol FeCl 3 and 4 mmol MnSO 4 Stir to dissolve, and heat to 70°C, keep for...

Embodiment 2

[0026] (1) Preparation of polyaniline-wrapped nanocellulose:

[0027] First, weigh 30 grams of 1% nanocellulose in a 100ml beaker and place it in an ice-water bath at about 4°C. 3mmol of phytic acid and 9mmol of aniline were dissolved in 4ml of distilled water, stirred evenly, and added dropwise to the nanocellulose. Weigh 3mmol of ammonium persulfate and dissolve in 4ml of distilled water. Then the ammonium persulfate solution was added dropwise to the nanocellulose to initiate aniline polymerization, and finally the nanocellulose / polyaniline composite was obtained by centrifuging and washing with distilled water for 5 times in a centrifuge at 10,000 rpm.

[0028] (2) Nanocellulose / polyaniline composite dispersed MnFe 2 o 4 Preparation of magnetic nanoparticles:

[0029] Add water to the above nanocellulose / polyaniline composite to a concentration of 0.5wt%, and then add 10mmol FeCl 3 and 5mmolMnSO 4 Stir to dissolve, and heat to 70°C, keep for 5h, add dropwise 6mol / L N...

Embodiment 3

[0033] (1) Preparation of polyaniline-wrapped nanocellulose (nanocellulose):

[0034] First, weigh 40 grams of 1% nanocellulose in a 100ml beaker and place it in an ice-water bath at 4°C. 4mmol of phytic acid and 12mmol of aniline were dissolved in 4ml of distilled water, stirred evenly, and added dropwise into the nanocellulose. Weigh 4mmol of ammonium persulfate and dissolve in 4ml of distilled water. Then the ammonium persulfate solution was added dropwise to the nanocellulose to initiate aniline polymerization, and finally the nanocellulose / polyaniline composite was obtained by centrifuging and washing with distilled water for 5 times in a centrifuge at 10,000 rpm.

[0035] (2) Nanocellulose / polyaniline composite dispersed MnFe 2 o 4 Preparation of magnetic nanoparticles:

[0036] Add water to the above nanocellulose / polyaniline composite to a concentration of 0.5wt%, and then add 10mmol FeCl 3 and 5 mmol MnSO 4 Stir to dissolve, and heat to 70°C, keep for 5h, add drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com