High-strength self-repair conductive magnetic electronic skin material and preparation method thereof

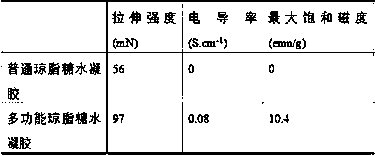

An electronic skin and self-repairing technology, applied in the biological field, can solve the problem of single functionality of electronic skin, and achieve the effect of increasing strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of polypyrrole-coated nanocellulose:

[0022] Weigh 10 g of 1% nanocellulose aqueous suspension and place it in a water bath at 4°C for stirring. Weigh 0.01mol pyrrole and drop into the nanocellulose. Weigh 0.01mol ferric chloride dissolved in 10ml water, and slowly drop into the nanocellulose. The polymerization reaction was stirred for 24 hours in an ice-water bath at 4°C, and the nanocellulose / polypyrrole composite was obtained after centrifugation.

[0023] (2) Nanocellulose / polypyrrole composite immobilized Fe 3 o 4 Preparation of magnetic particles:

[0024] Weigh the nanocellulose / polypyrrole composite with a mass concentration of 5% and heat it to 65°C, then weigh 0.001mol FeCl 2 and 0.002mol FeCl 3 Dissolve in 5ml of distilled water, and add to the cellulose / polypyrrole composite, add ammonia water dropwise until the pH value of the solution is 11, then fully stir and react for 10 minutes, then centrifuge to obtain the nanocellulose / polypy...

Embodiment 2

[0028] (1) Preparation of polypyrrole-coated nanocellulose:

[0029] Weigh 10g of 1% nanocellulose aqueous suspension by mass fraction and place it in a water bath at 4°C for stirring. Weigh 0.02mol of pyrrole and drop into the nanocellulose. Weigh 0.02mol ferric chloride dissolved in 10ml water, and slowly drop into the nanocellulose. The polymerization reaction was stirred for 24 hours in an ice-water bath at 4°C, and the nanocellulose / polypyrrole composite was obtained after centrifugation.

[0030] (2) Nanocellulose / polypyrrole composite immobilized Fe 3 o 4 Preparation of magnetic particles:

[0031] Weigh the nanocellulose / polypyrrole composite with a mass concentration of 5% and heat it to 65°C, then weigh 0.002mol FeCl 2 and 0.004mol FeCl 3 Dissolve in 5ml of distilled water, and add to the cellulose / polypyrrole composite, add ammonia water dropwise until the pH value of the solution is 11, then fully stir and react for 10 minutes, then centrifuge to obtain the n...

Embodiment 3

[0035] (1) Preparation of polypyrrole-coated nanocellulose:

[0036] Weigh 10g of 1% nanocellulose aqueous suspension by mass fraction and place it in a water bath at 4°C for stirring. Weigh 0.03mol pyrrole and drop into the nanocellulose. Weigh 0.03mol ferric chloride dissolved in 10ml water, and slowly drop into the nanocellulose. The polymerization reaction was stirred for 24 hours in an ice-water bath at 4°C, and the nanocellulose / polypyrrole composite was obtained after centrifugation.

[0037] (2) Nanocellulose / polypyrrole composite immobilized Fe 3 o 4 Preparation of magnetic particles:

[0038] Weigh the nanocellulose / polypyrrole composite with a mass concentration of 5% and heat it to 65°C, then weigh 0.003mol FeCl 2 and 0.006mol FeCl 3 Dissolve in 5ml of distilled water, and add to the cellulose / polypyrrole composite, add ammonia water dropwise until the pH value of the solution is 11, then fully stir and react for 10 minutes, then centrifuge to obtain the nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com