Double-clutch-type automatic gearbox transmission mechanism

A technology of automatic transmission and transmission mechanism, applied in the direction of transmission elements, transmission devices, vehicle gearboxes, etc., can solve the problems of accelerated wear of support bearings, influence of reverse power transmission, shortened service life of support bearings, etc. Well-arranged, large-scale design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

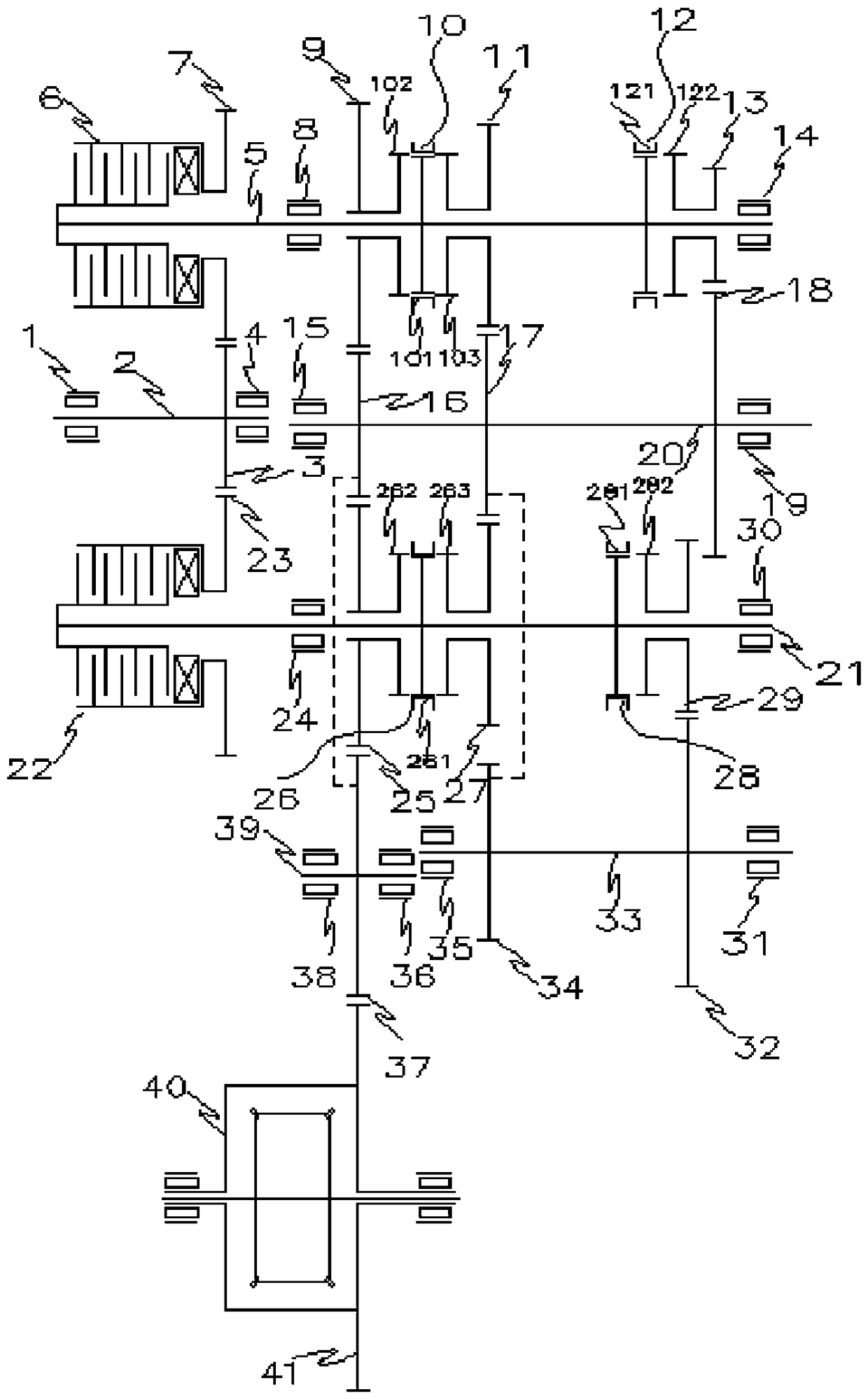

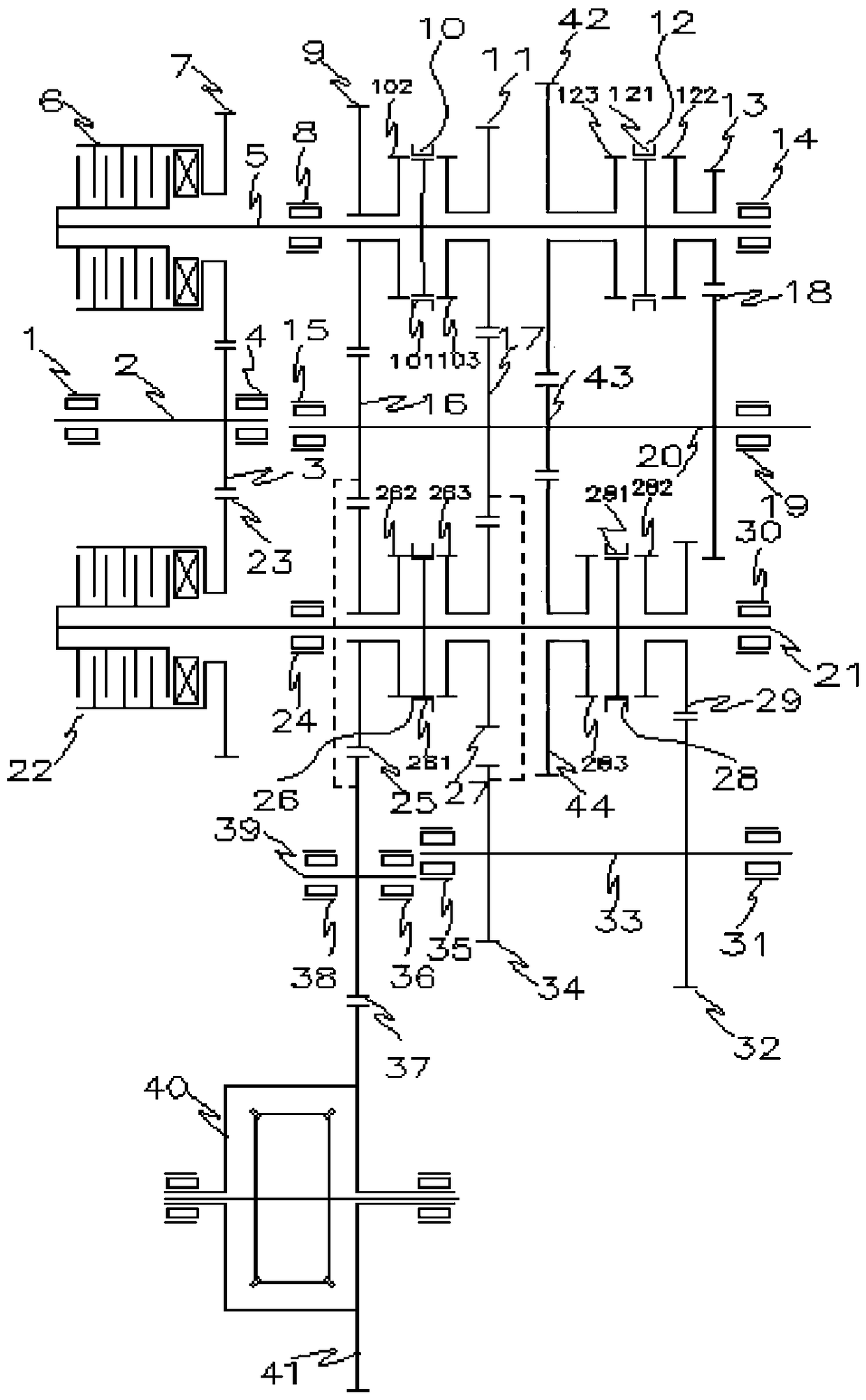

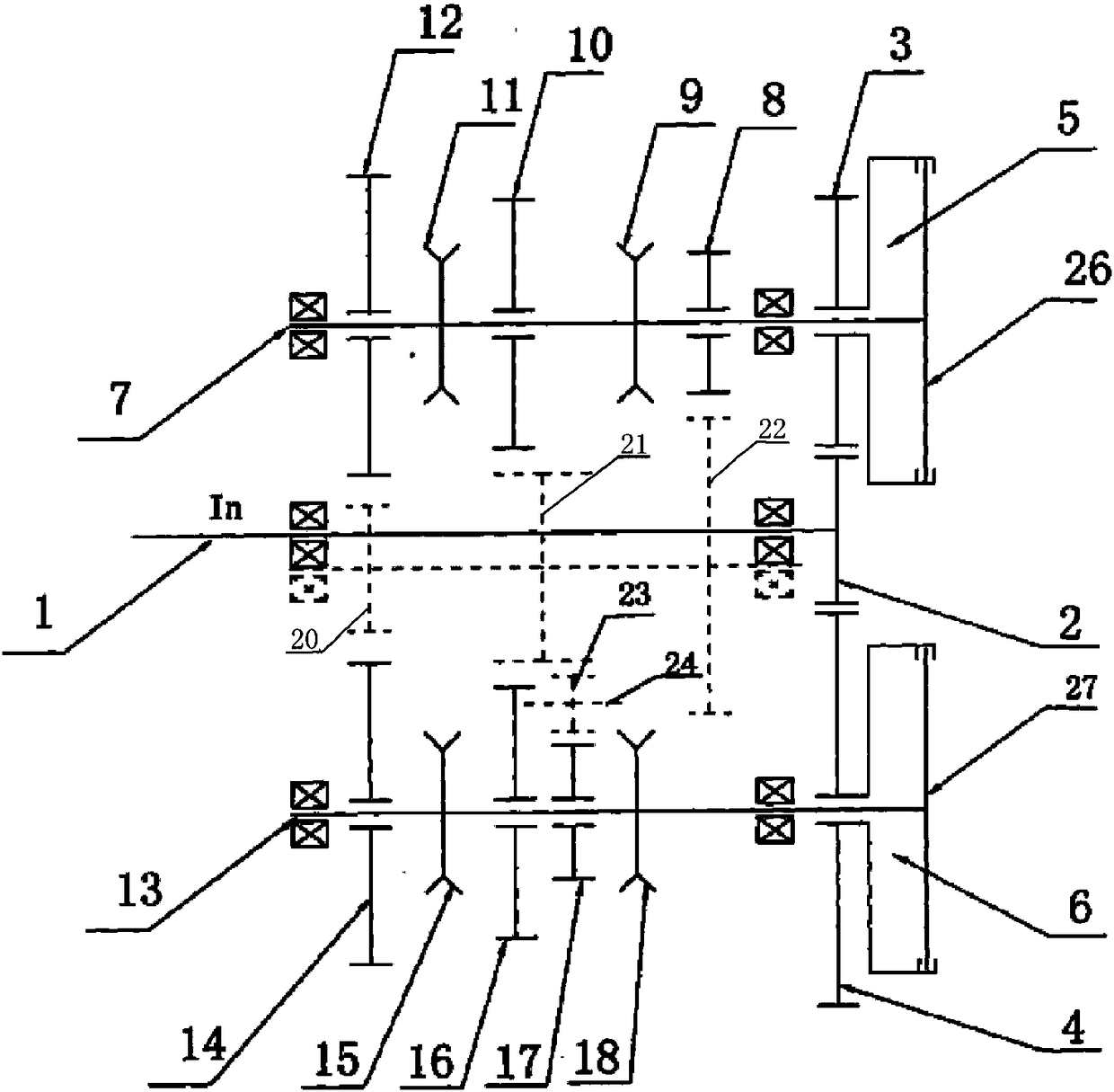

[0024] see Figure 1 to Figure 2 , a dual-clutch automatic transmission transmission mechanism, including an input shaft 2, a first countershaft 5, a second countershaft 21, and an intermediate shaft 20 supported by bearings and arranged in parallel, and the bearings supported are all arranged in the case of the transmission superior. The input shaft 2 meshes with the first clutch gear 7 and the second clutch gear 23 through a fixed input shaft gear 3, and the left end of the first countershaft 5 and the driven disc of the first clutch 6 are circumferentially fixed by splines connected, the left end of the second countershaft 21 is fixedly connected with the driven disk of the second clutch 22 through splines in the circumferential direction. The first clutch gear 7 and the second clutch gear 23 can be axially fixed and hollowly sleeved on the transmission case respectively. Or the first clutch gear 7 is axially and fixedly vacantly sleeved on the first countershaft 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com