Equipment for quickly cooling aluminum material

A rapid cooling, aluminum technology, applied in the field of equipment for rapid cooling of aluminum, can solve the problems of insufficient heat exchange between cold air and aluminum, unable to meet technical requirements, and mutual interference of cold air, achieving novel structure and unique design. , The effect of improving the quality of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention utilizes the technical characteristics of combining air cooling and water cooling to design an aluminum material cooling device, which can achieve a good cooling effect at a low cost.

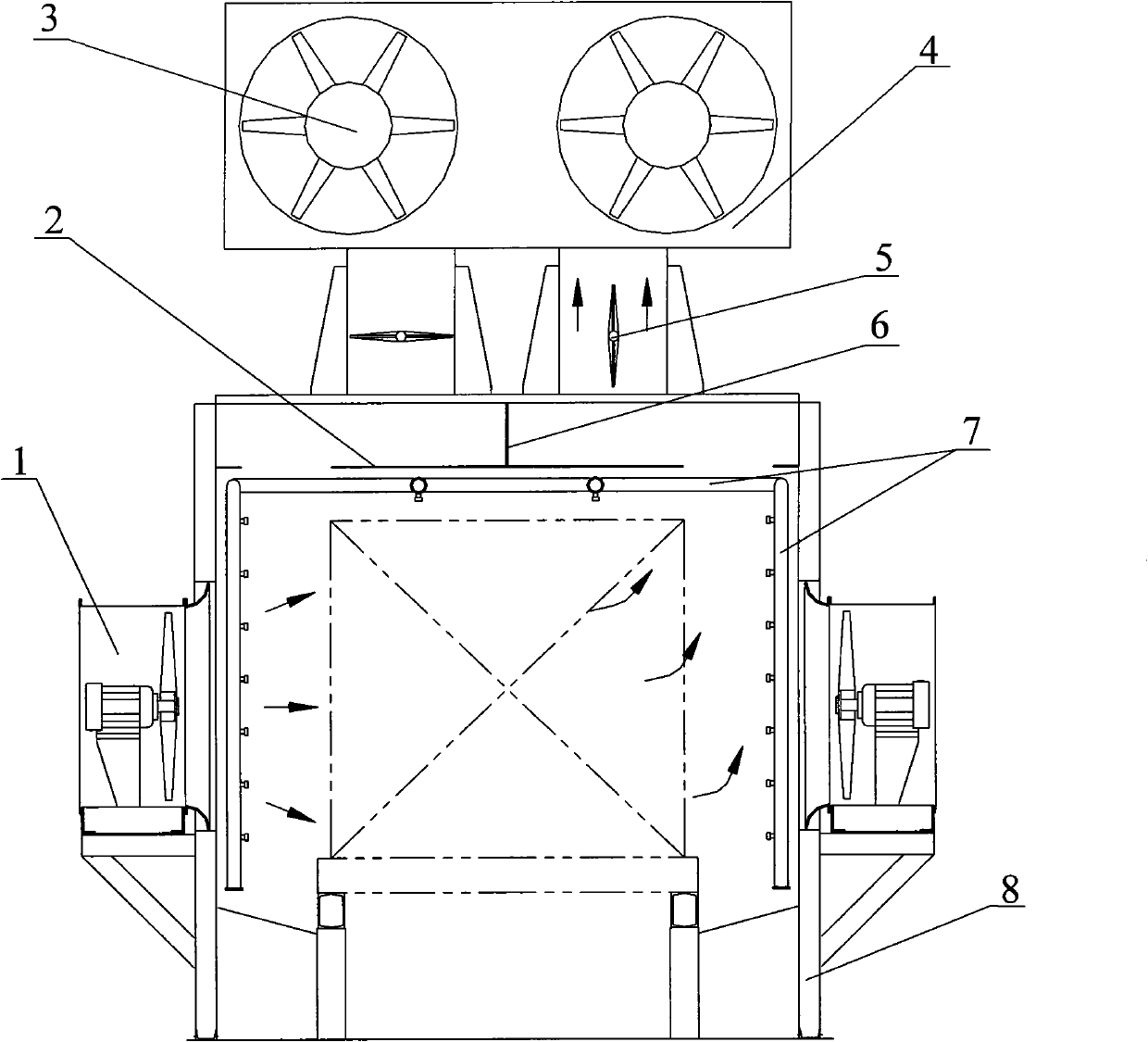

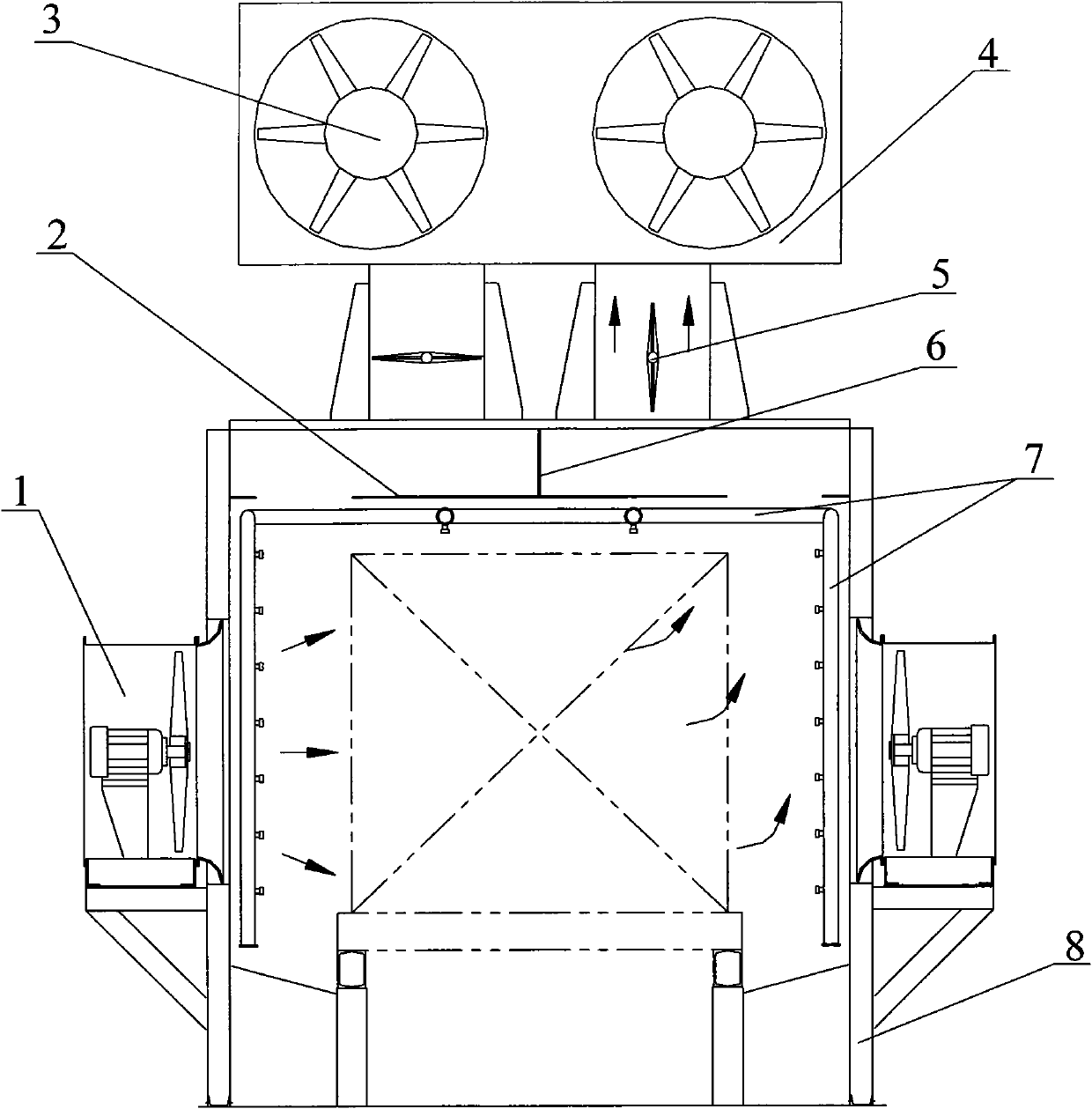

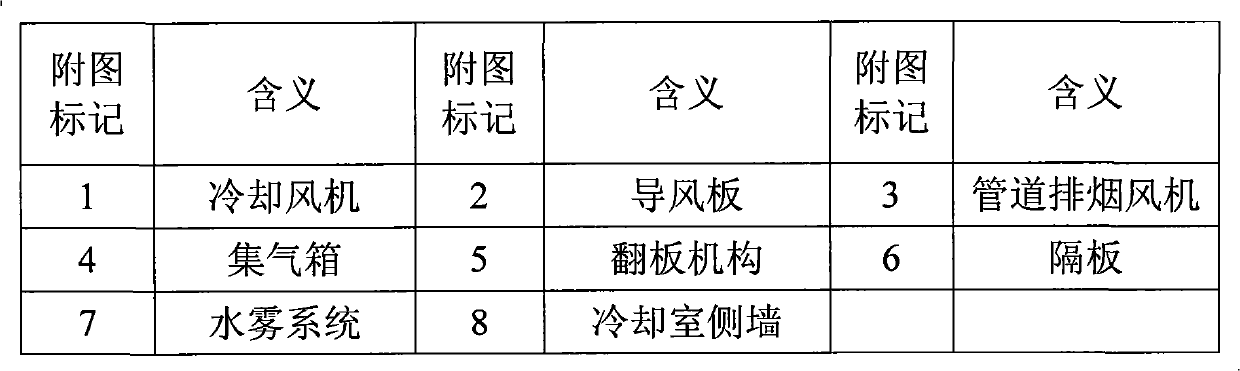

[0016] Such as figure 1 As shown, the aluminum cooling device mainly includes a cooling chamber, a cooling fan 1 and a water mist system 7, a cooling fan 1 is installed on the side wall 8 of the cooling chamber, and an air deflector 2 is arranged on the upper part of the cooling chamber. 2 There are vents on both sides, and an upright partition 6 is set between the air deflector 2 and the top wall of the cooling chamber. The partition 6 is located in the center, and there are two air outlets on the top wall of the cooling chamber, one on the left and one on the left. , distributed symmetrically; each air outlet is connected to a smoke exhaust pipe, and a flap mechanism 5 is installed in each smoke exhaust pipe, and a gas collection box 4 is arranged above the two smoke exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com