Welding deformation control method of large thick-wall box body component

A technology of welding deformation and control method, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problem of outward bending of the box plate, improve the welding gap, reduce the shrinkage of the welding seam, and control the welding deformation. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

[0023] The specific process implemented according to the present invention will now be described in detail, including the following five steps.

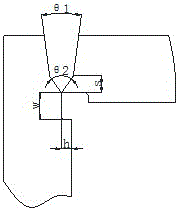

[0024] (1) Before welding, according to the warping and wall thickness distribution of the entire length of the plate welding edge and the load-bearing requirements of the weld seam, an assembly reference platform is prefabricated on the plate welding edge, such as figure 1 The h×w platform shown. Among them, h and w are the depth and width of the assembly reference platform, respectively. After the plate is prefabricated and assembled on the reference platform, the influence of plate welding edge warpage or uneven wall thickness on the welding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com