Fin tube type heat exchanger

A technology of tubular heat exchangers and heat exchange tubes, applied in the direction of heat exchanger shells, indirect heat exchangers, heat exchanger types, etc., can solve the problems of copper tube deformation, difficulty in meeting, poor consistency, etc., and achieve solder filling Fullness, extended working life, uniform welding gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

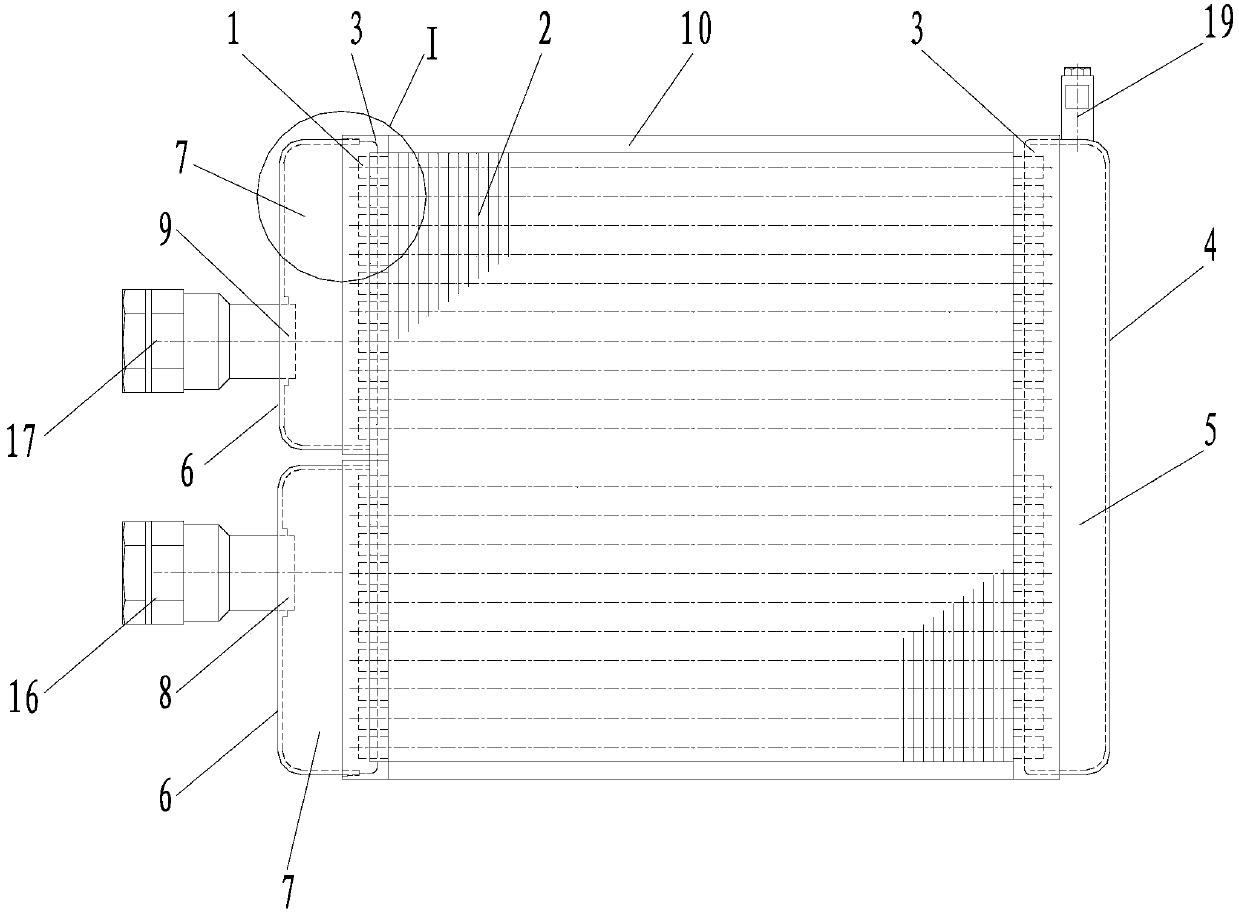

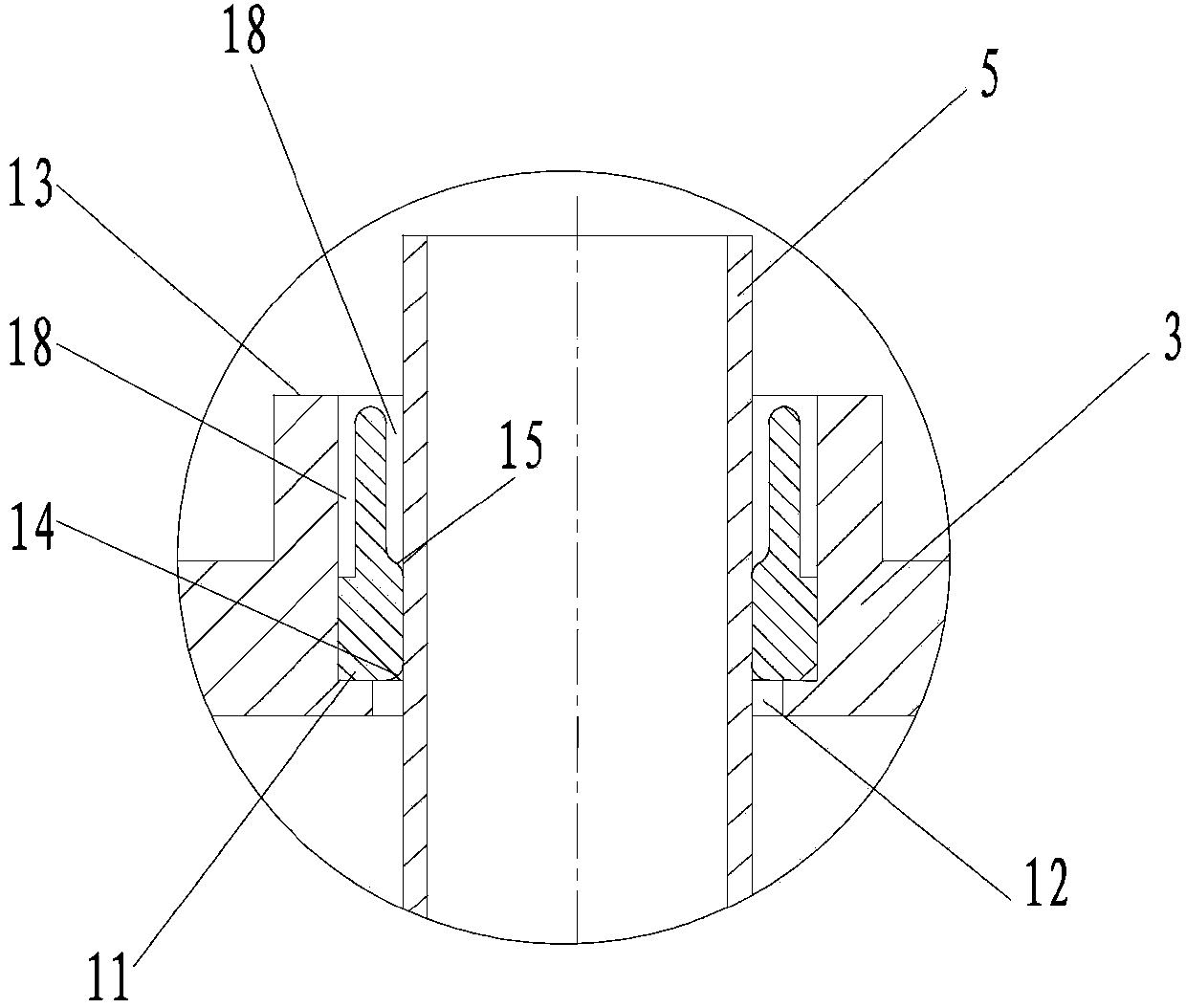

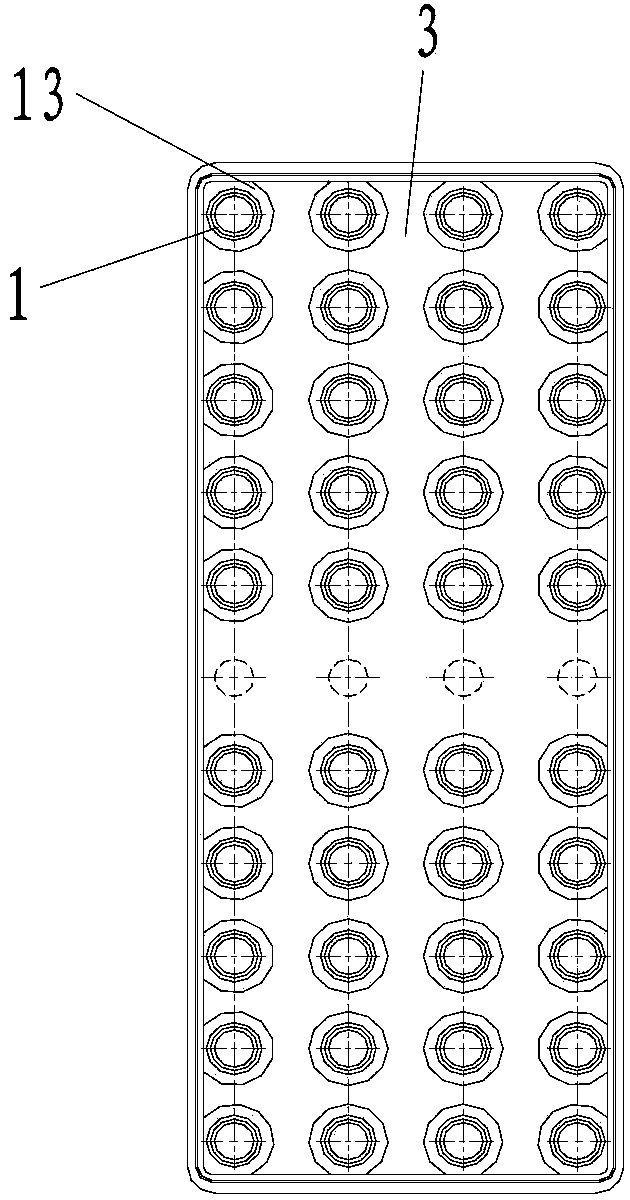

[0020] Attached below Figure 1-5 An embodiment of the present invention is described.

[0021] The finned tube heat exchanger includes a heat exchange tube 1 and a heat dissipation fin 2 on it. The fin 2 is closely matched with the outer diameter of the heat exchange tube 1 to ensure the heat transfer effect. The heat exchange tube 1 is preferably a copper tube. It also includes tube sheets 3, large end caps 4, and small end caps 6 respectively located at both ends of the fins 2, and oil storage chambers I5 and The oil storage chamber II7, wherein the small end cover 6 is provided with a liquid inlet 16 and a liquid outlet 17, specifically, the large end cover 4 and the tube plate 3 are welded together to form an oil storage chamber I5, and the small end cover 6 is formed by a small The end cap A and the small end cap B are composed of the small end cap A and the small end cap B, which are welded together with the tube sheet 3 to form two independent oil storage chambers II7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com