Welded joint structure used for automobile brake hose and welding process of welded joint structure

A technology for automobile brake hoses and welded joints, which is applied in the direction of brakes, brake components, manufacturing tools, etc., can solve the problems of weak welding, uneven welding gaps, low pass rate, etc., and achieve good capillary flow performance and welding The effect of uniform gap, improving product stability and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described now in conjunction with accompanying drawing.

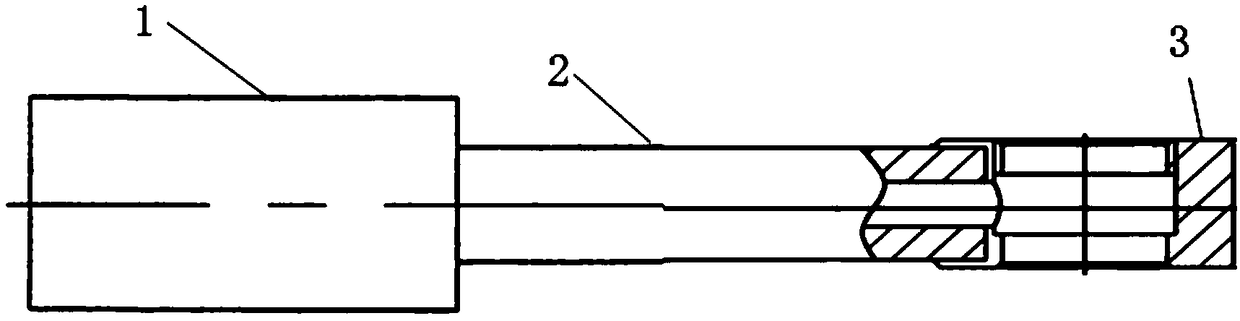

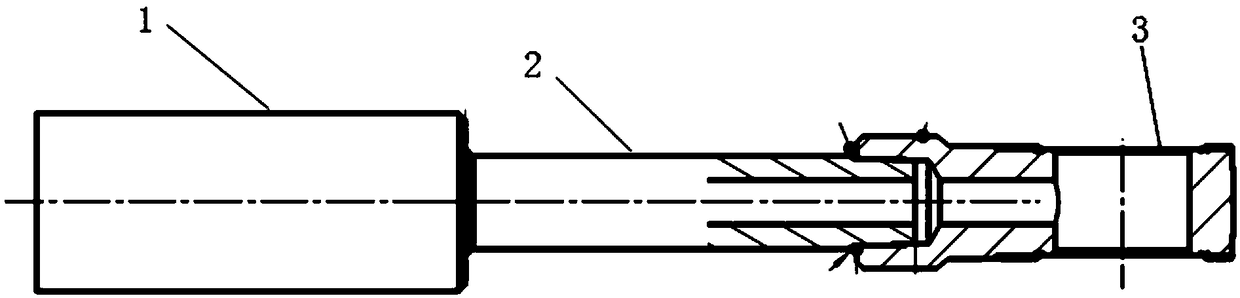

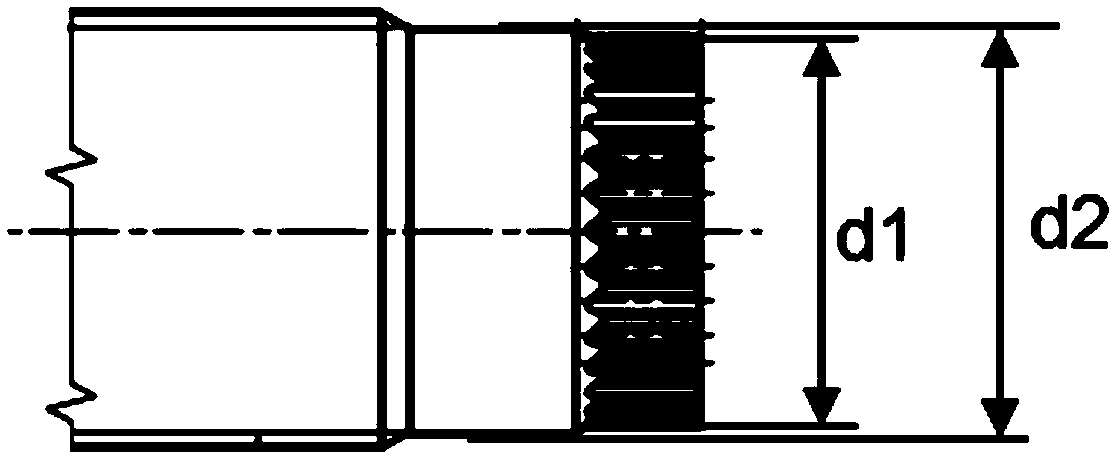

[0019] see Figure 2-Figure 4 , the present invention is a welding joint structure for automobile brake hose, including a pipe body and a joint block, the pipe body and the joint block are welded and formed, and one end of the pipe body 2 is a segmented structure of the pipe body and the flower tooth structure structure, the end of the pipe body is provided with a flower tooth structure, the other end of the pipe body 2 is provided with a fastening sleeve 1, and the end of the joint block 3 is provided with a stepped hole, the stepped hole includes a large diameter hole at the outer end and a small diameter hole at the inner end. Diameter hole, interference fit is adopted between the flower tooth structure and the small diameter hole at the inner end, clearance fit is adopted between the pipe body and the large diameter hole at the outer end, and a copper liquid storage area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com