A collector and exhaust pipe welding fixture

A technology for welding fixtures and exhaust pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of poor mechanical strength at the connection between the collector and the exhaust pipe, and poor uniformity of solder flow on the welding sealing surface , Collector and exhaust pipe vertical difference, etc., to achieve the effect of ensuring consistent welding quality, convenient processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

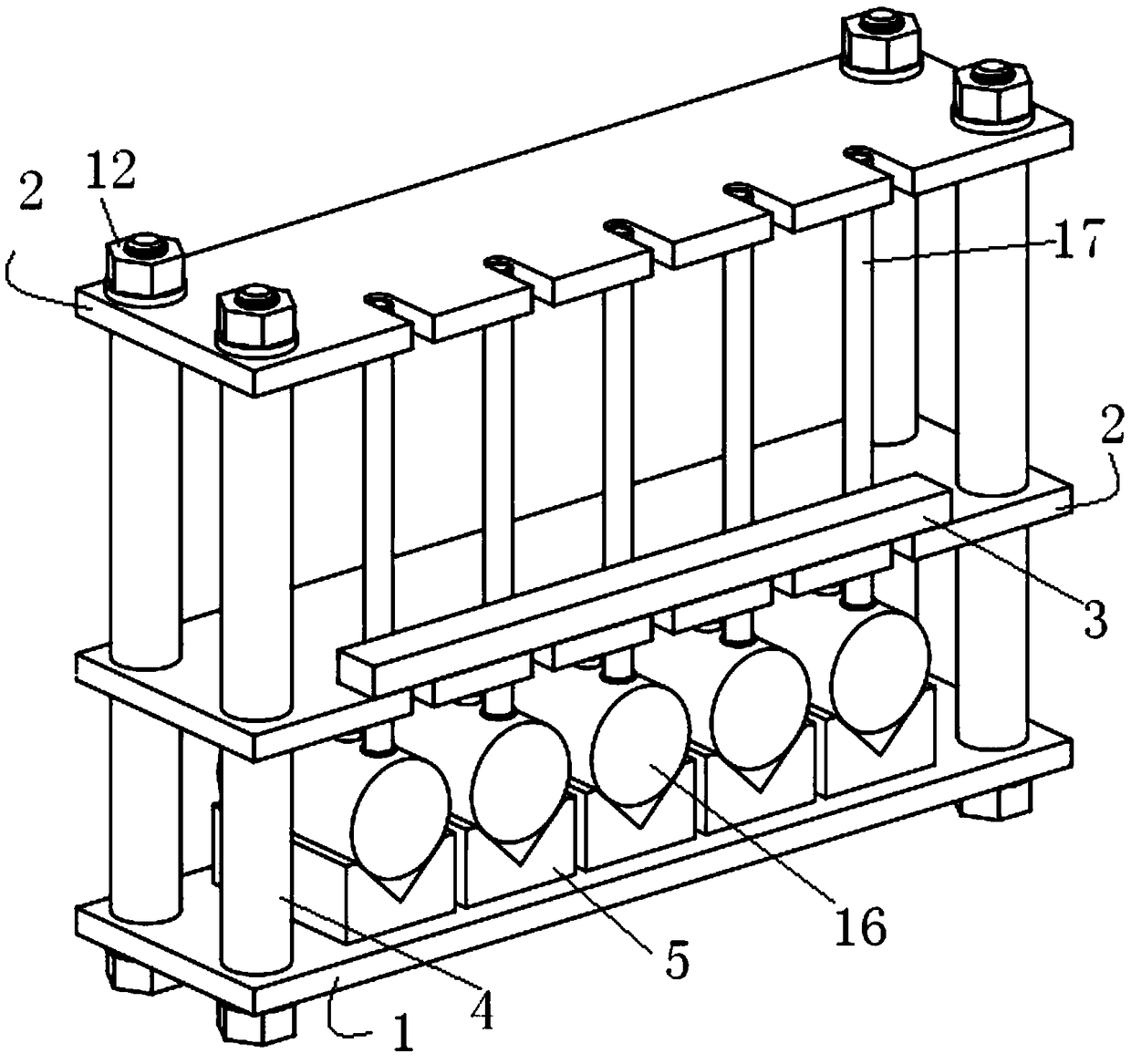

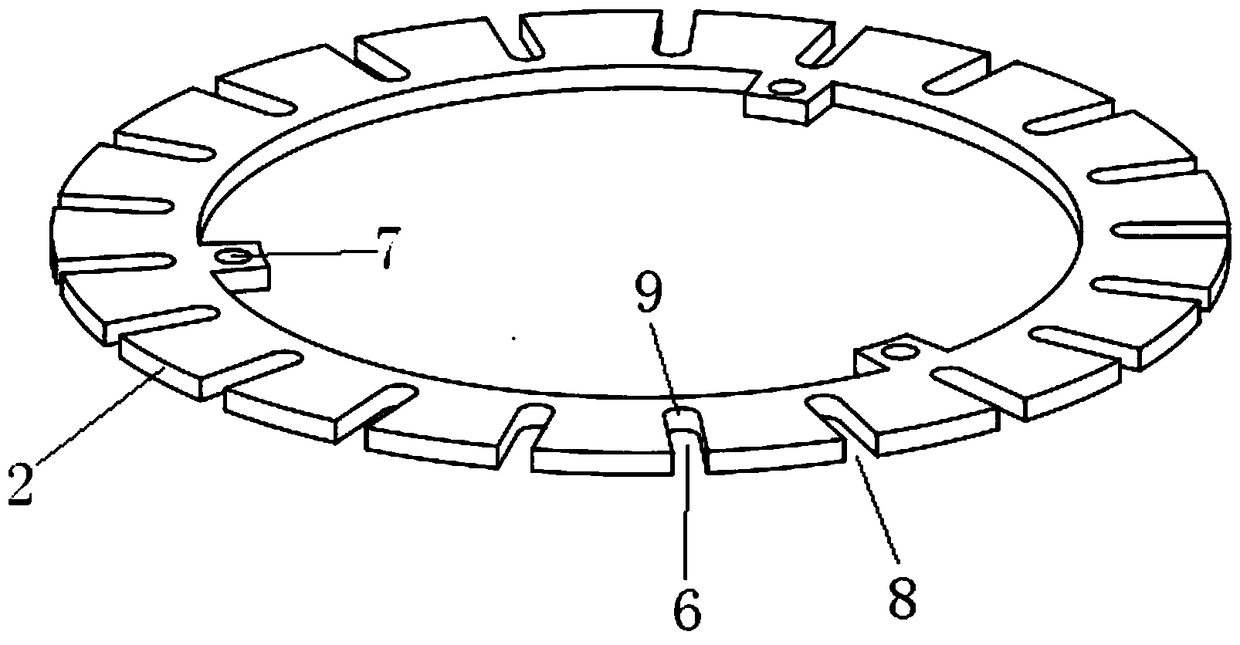

[0025] The collector and exhaust pipe welding fixture in Embodiment 1, the welding fixture includes a base, two positioning seats, a connecting rod and a support for placing the collector to be welded; the base and the positioning seats are connected sequentially from bottom to top The rods are connected and fixed; the base, the positioning seat, the connecting rod and the support are all made of metal materials whose melting point is higher than the melting point of the solder; the described clamp for the collector and exhaust pipe welding machine, the base, The positioning piece and the positioning seat are strip-shaped.

[0026] - The base is provided with a base positioning cylinder for installing the connecting rod and a plane for placing the support, and the base positioning cylinder is coaxial with the connecting rod;

[0027] -The positioning seat is provided with at least one loading and unloading positioning groove for loading and unloading the exhaust pipe to be exh...

Embodiment 2

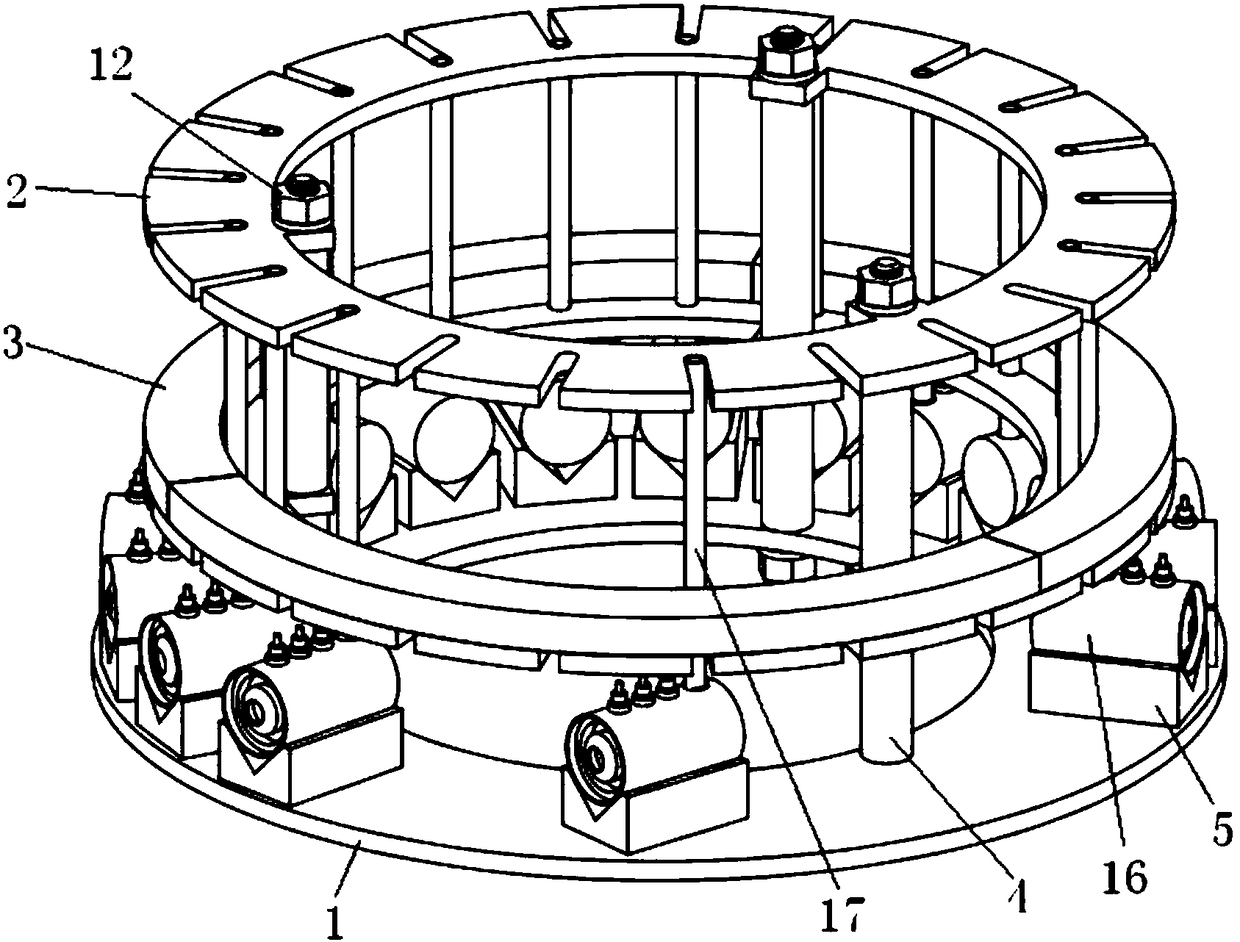

[0031] The collector and exhaust pipe welding fixture in the second embodiment, the welding fixture includes a base, two positioning seats, a connecting rod and a support for placing the collector to be welded; the base and the positioning seats are connected sequentially from bottom to top The rods are connected and fixed; the base, the positioning seat, the connecting rod and the support are all made of metal materials whose melting point is higher than the melting point of the solder; the described clamp for the collector and exhaust pipe welding machine, the base, The positioning piece and the positioning seat are disc-shaped.

[0032] - The base is provided with a base positioning cylinder for installing the connecting rod and a plane for placing the support, and the base positioning cylinder is coaxial with the connecting rod;

[0033] -The positioning seat is provided with at least one loading and unloading positioning groove for loading and unloading the exhaust pipe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com