A water chamber welding platform

A welding platform and water chamber technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as sealing performance failure, welding deformation, etc., to ensure welding gap, reduce usage, and ensure welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

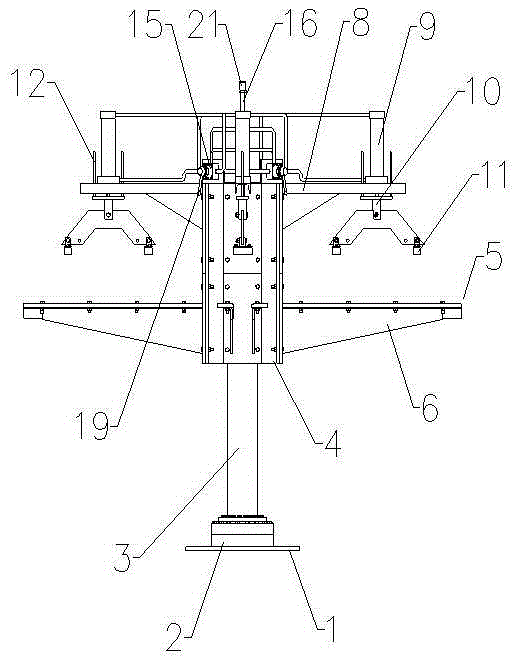

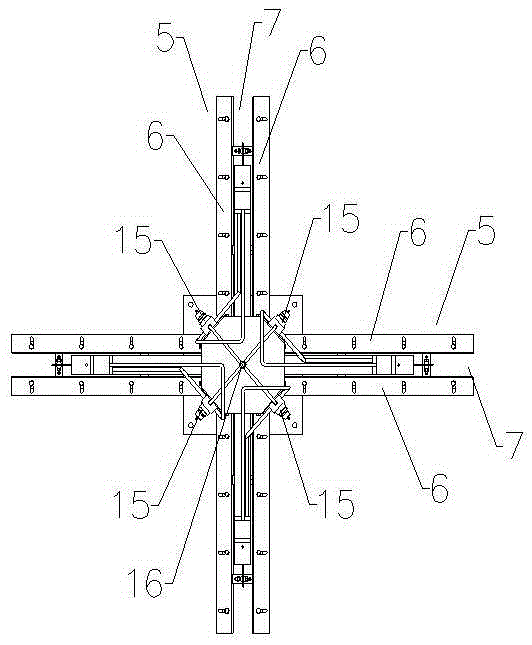

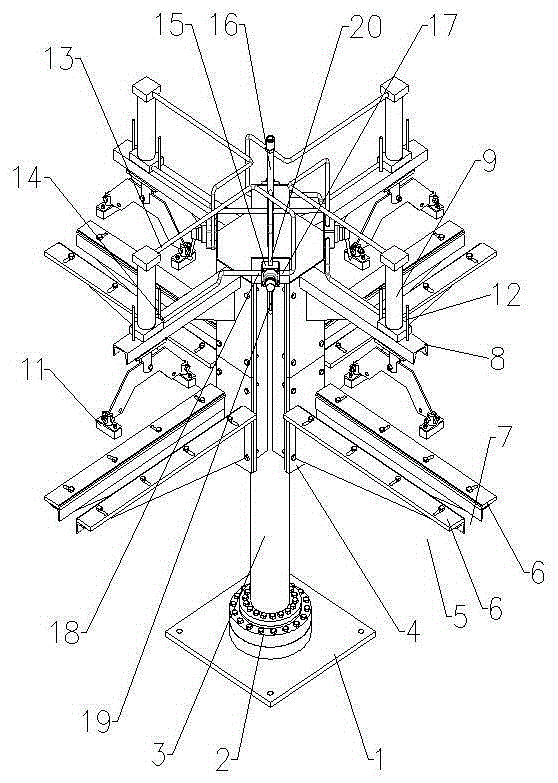

[0039] Examples such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a water chamber welding platform includes a base 1, a slewing support 2 is provided on the base 1, a column 3 is fixed on the slewing support 2, and several sets of clamping devices for fixing the radiator core are provided on the column 3 , the clamping device includes a fixed plate 4 arranged on the column 3, and a bracket 5 for supporting the radiator core is horizontally arranged on the fixed plate 4. The bracket 5 includes two supporting plates 6 on the same horizontal plane, two The upper surface of the supporting plate 6 is even, and there is a main slot 7 for accommodating the core of the radiator between the two supporting plates 6. The supporting plate 6, the bracket 8 and the fixing plate 4 can be adjusted and connected respectively, and the fixing plate above the bracket 5 4 is provided with a bracket 8, the bracket 8 is provided with a cylinder 9, the piston rod 10 of the cylinder 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com