Circulating structure for drawing-blowing forming machine

A cycle structure and forming machine technology, applied in the field of conveying devices, can solve problems such as low operating efficiency and limited preforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

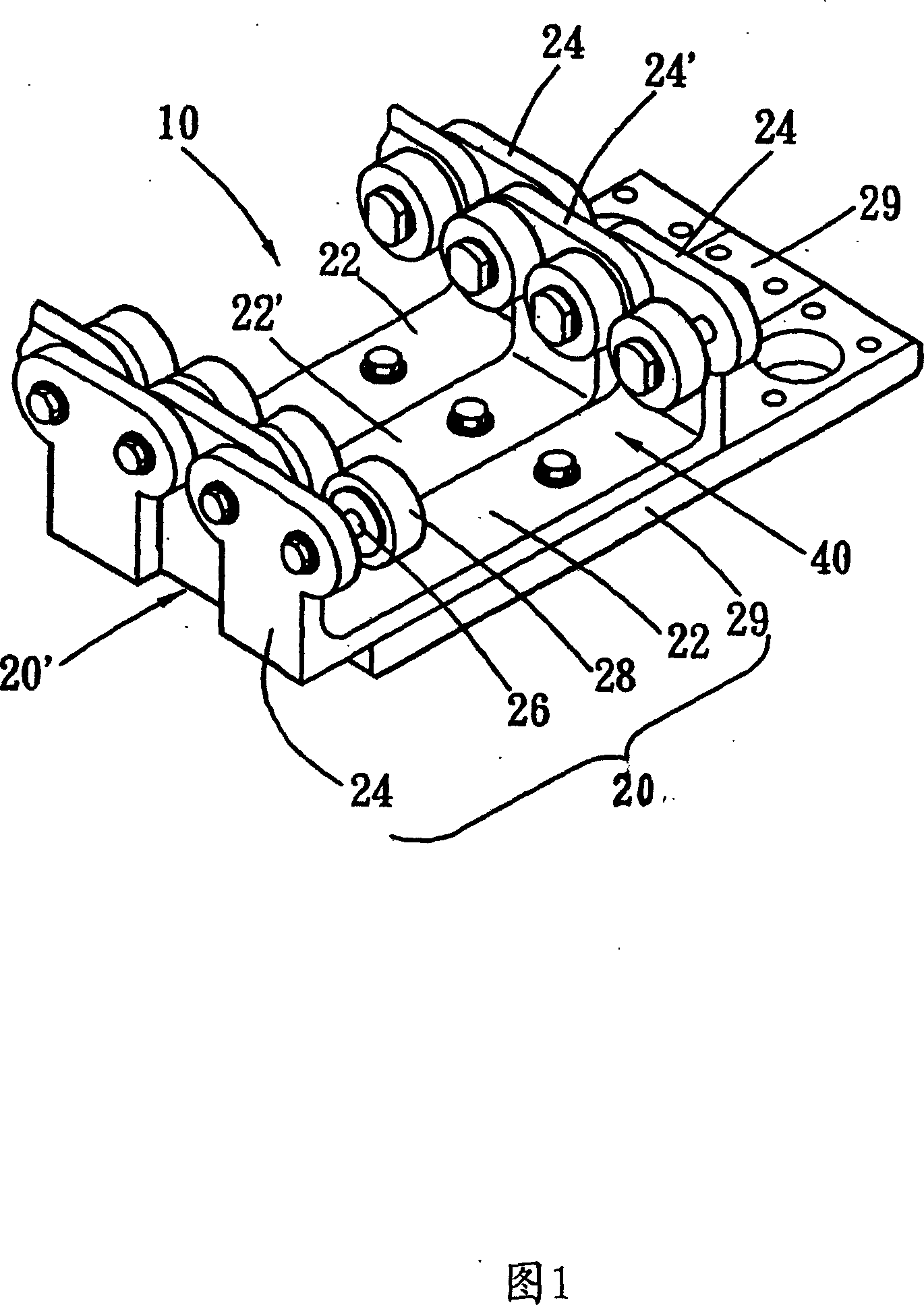

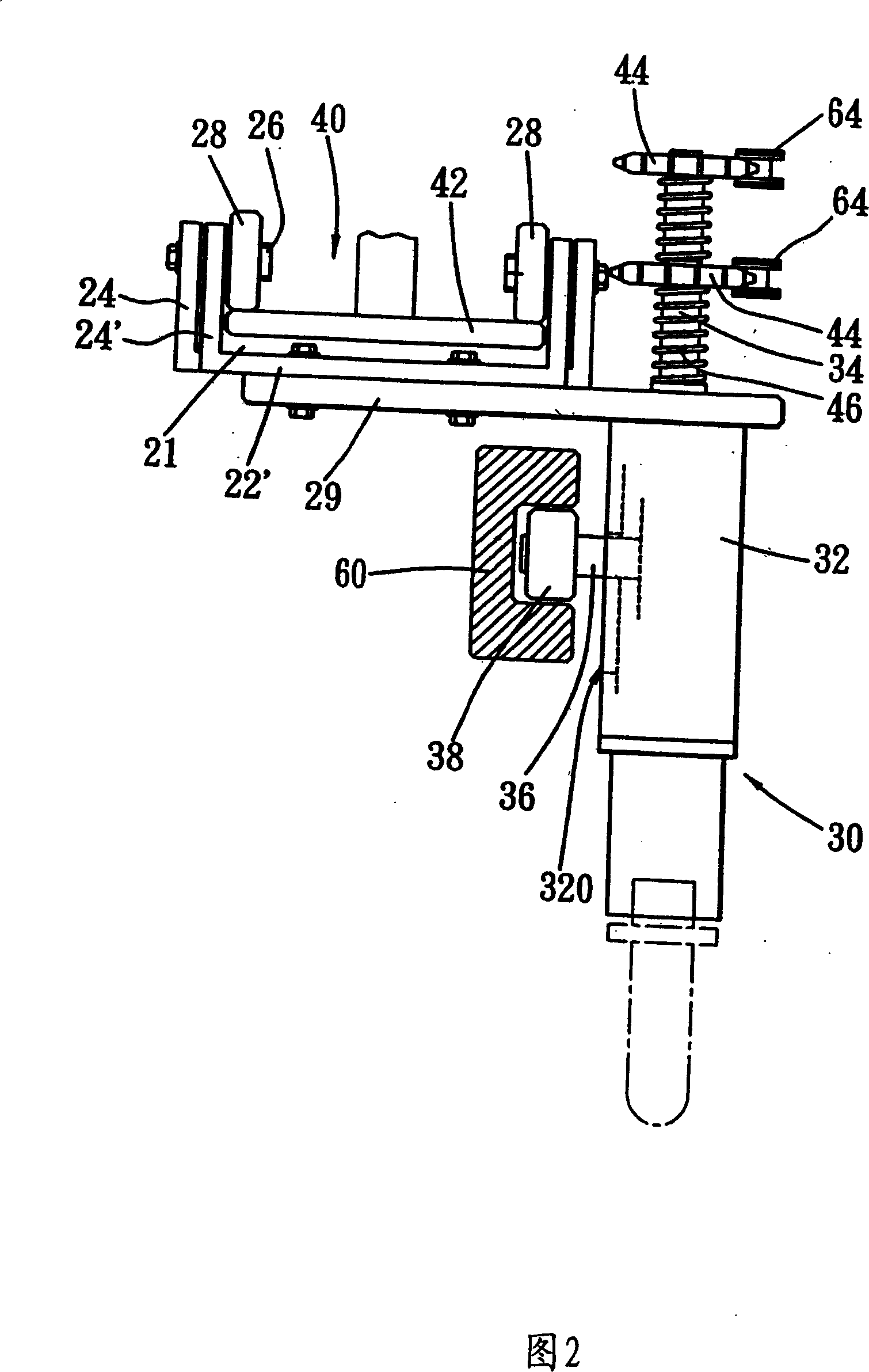

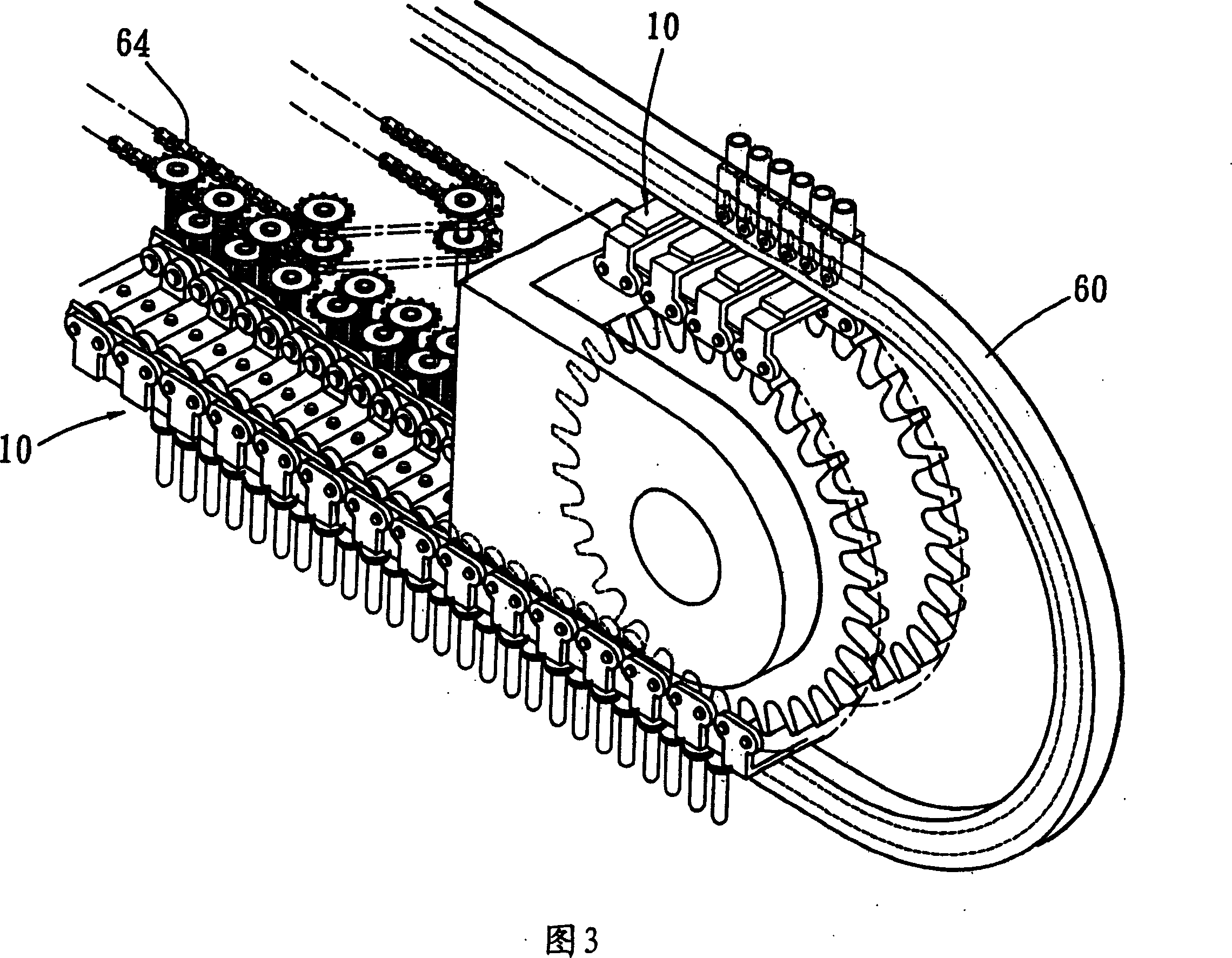

[0019] Please refer to Fig. 1 to Fig. 5 at the same time, the circulation structure of the stretch-blow molding machine disclosed by the present invention mainly consists of a conveyer belt 10 which can circulate along a predetermined conveying path and more than one bottles arranged on the conveyer belt 10 Composed of 30 germ seats.

[0020] The conveyor belt 10 is formed by pivoting two or more adjacent first chain links 20 and second chain links 20'.

[0021] Each first chain link 20 has: a bridging portion 22 having a certain length, and its long axis direction is perpendicular to the extending direction of the conveying path; a pair of connecting portions 24 are slightly T-shaped, and are respectively protruding from the bridging portion 22 The two ends of each bridging portion 22 ( 22 ′) and the connecting portion 24 ( 24 ′) jointly enclose an accommodating space 40 .

[0022] The shape of each second chain link 20' is almost the same as that of the first chain link 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com