Narrow strip strain weighing sensor, narrow strip array dynamic scale and use method thereof

A technology of load cell and dynamic balance, applied in the detailed information of weighing equipment, instruments, weighing, etc., can solve the problems of poor measurement result accuracy, large bending deformation of the shell, difficult to achieve, etc., to ensure the measurement accuracy , The effect of reducing position error and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

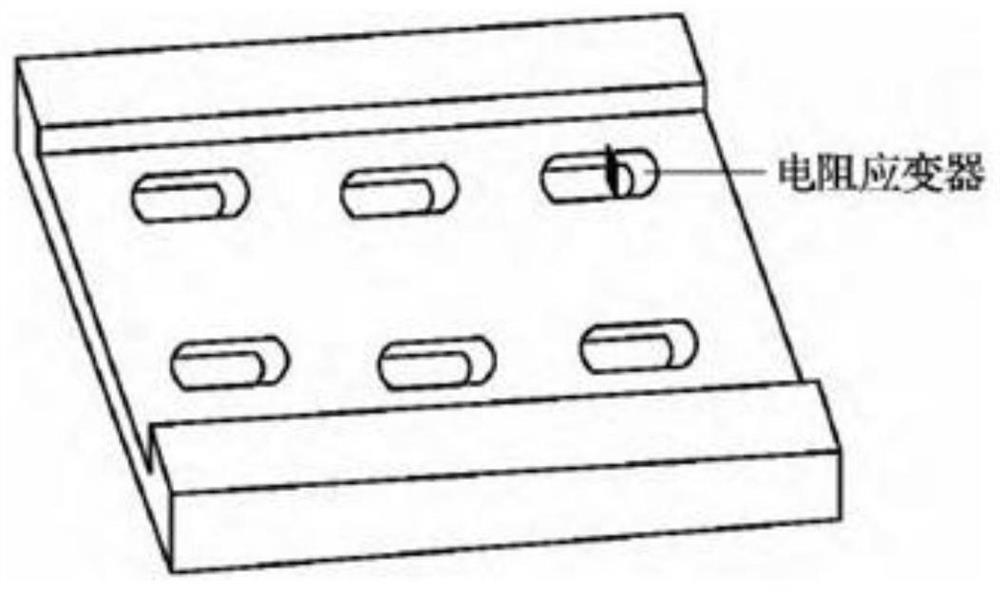

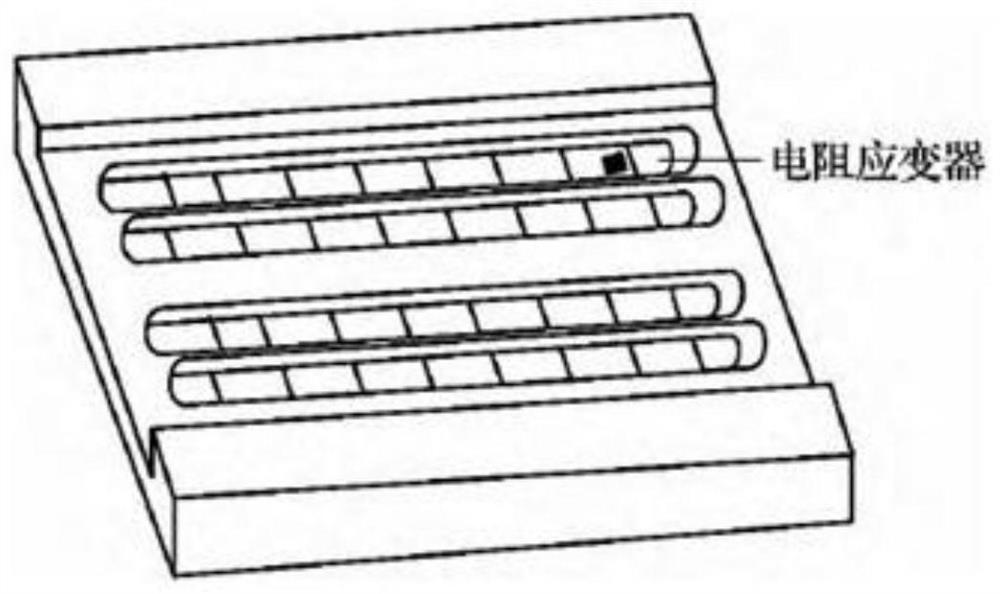

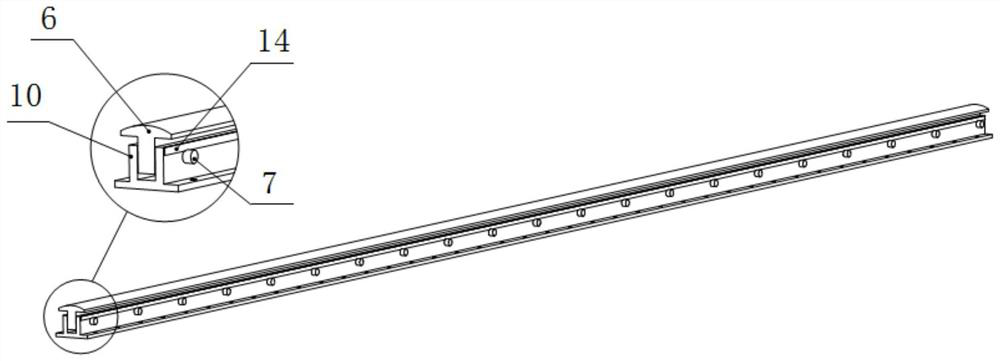

[0043] Such as image 3 , Figure 4 with Figure 5 As shown, the narrow strip strain load cell of the present invention includes a load beam 6, a plurality of pin sensors 7 and a base 8, the pin sensors 7 are horizontally installed on the base 8, and the load beam 6 includes a T arrangement The horizontal plate and the vertical plate, the vertical plate is connected with the pin sensor 7, and the pin sensor 7 is perpendicular to the load beam 6, the side wall of the pin sensor 7 is provided with a counterbore 15, the counterbore The bottom of the hole 15 is a vertical plane, and the bottom of the counterbore 15 is provided with a shear strain gauge 9 .

[0044] The load beam 6 can be made of stainless steel or the like, and is used to transmit the load of the vehicle to the pin sensor 7. The load beam 6 is only connected to the pin sensor 7 and does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com