Method for assembling, repairing and setting test parameters of vertical probe card device

An assembly method and probe card technology, which are applied in the field of probe cards, can solve problems such as poor contact, damage to test devices, and affect pad contact, and achieve the effects of clear needle marks, good contact, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

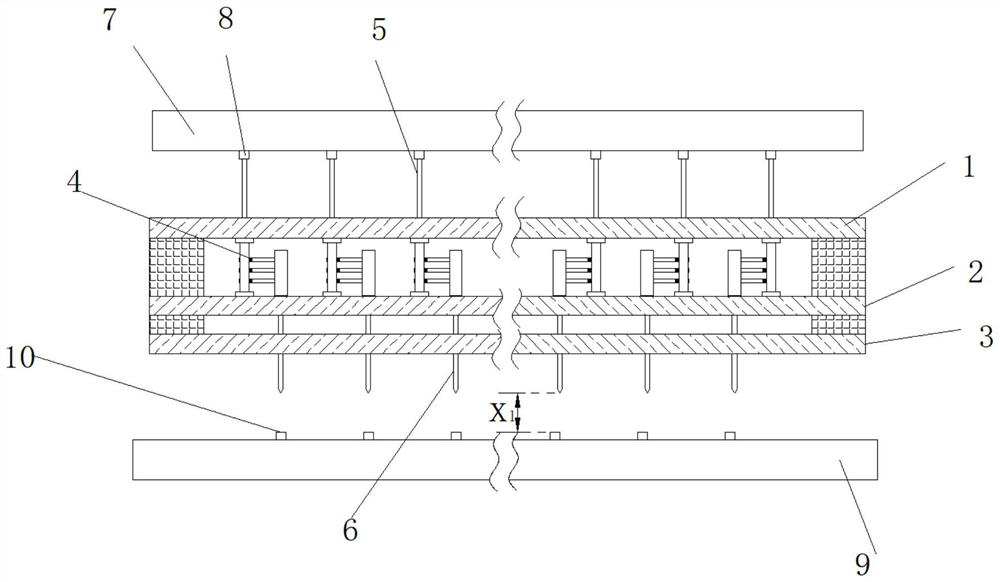

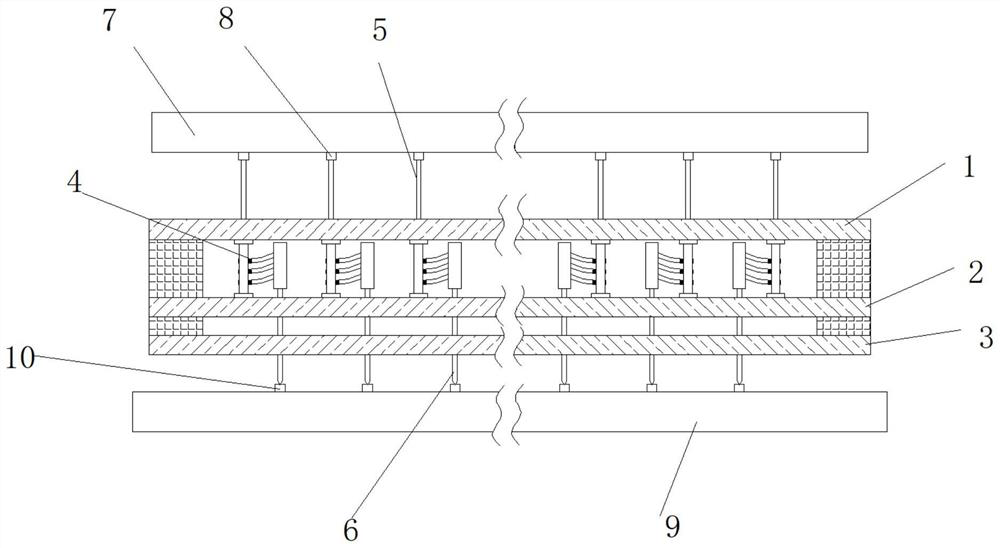

[0083] This embodiment is an embodiment of a vertical probe card device.

[0084] Such as Figure 1-10 As shown, a vertical probe card device disclosed in this embodiment includes an upper guide plate 1, a middle guide plate 2, a lower guide plate 3, a deformation connection device 4, a first probe 5, a second probe 6, a circuit board 7, The first welding pad 8; the upper guide plate 1, the middle guide plate 2 and the lower guide plate 3 are respectively provided with a plurality of vertical limit through holes, and a plurality of deformation connection devices are arranged in an array between the upper guide plate 1 and the middle guide plate 2 4. One end of the plurality of first probes 5 passes through the vertical limiting through hole of the upper guide plate 1 and is electrically connected to one end of the corresponding deformation connection device 4, and the other end is connected to the corresponding first solder joint on the circuit board 7. Pads 8 are connected, ...

specific Embodiment approach 2

[0118] This embodiment is an embodiment of a vertical probe card device.

[0119] A test parameter setting method for a vertical probe card device disclosed in this embodiment includes the following steps:

[0120] Step a, assumed length,

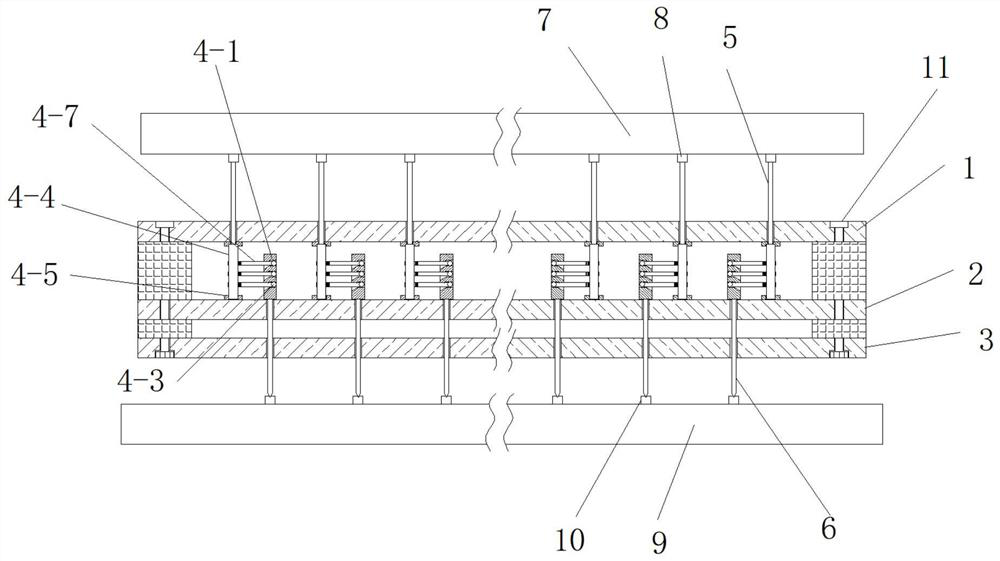

[0121] First assemble some vertical probe card devices to be tested. During the assembly process, the length of the elastic pins 4-7 arrayed on the side wall of the stabilizer 4-4 will be adjusted through the screw thread, and the effective length of the elastic pins 4-7 will be adjusted. , and the effective length of the elastic pins 4-7 is preliminarily set as S, and then the vertical probe card device is assembled;

[0122] Step b. Plane test

[0123] The assembled vertical probe card to be tested is installed on the bearing platform of the test probe station, and the contact flatness test is carried out one by one, and the difference between the highest point and the lowest point of the second probe 6 tip on the vertical probe card is...

specific Embodiment approach 3

[0142] This embodiment is an embodiment of a vertical probe card device.

[0143] A method for calculating the displacement of a probe of a vertical probe card device, comprising the following steps:

[0144] Step a, measure elastic modulus E and moment of inertia I of elastic needle 4-7;

[0145] Step b. Force analysis calculates the concentrated load acting on one end of the elastic needle 4-7 by the limiting member 4-1 through the limiting bead 4-3. When the number of elastic needles is n, calculate the concentrated load acting on the elastic needle 4. The concentrated load of the spacer beads 4-3 at one end of -7 is

[0146] Step c. Draw concentrated load The bending moment diagram when acting on the limit bead 4-3 and on the elastic pin 4-7, that is, M P picture;

[0147] Step d. Draw the unit load The bending moment diagram when acting on the limit bead 4-3 and on the elastic pin 4-7, that is, M 1 picture;

[0148] Step e, calculate the longitudinal displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com