Multi-line cutting device

A multi-line cutting, cutting roller technology, applied in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of prolonging cutting time, cutting line breakage, increasing the degree of cutting line wear, etc., to ensure integrity, Avoid the effect of lengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

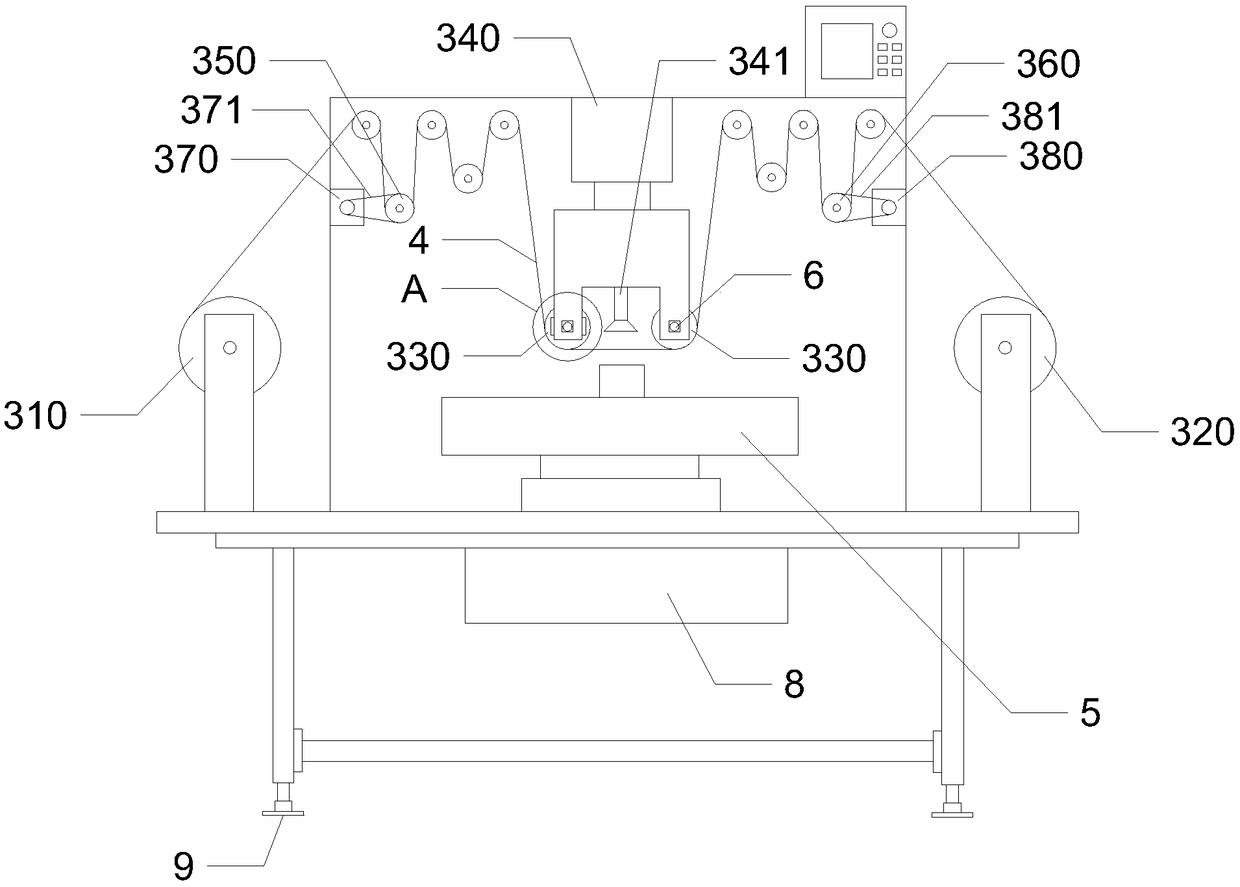

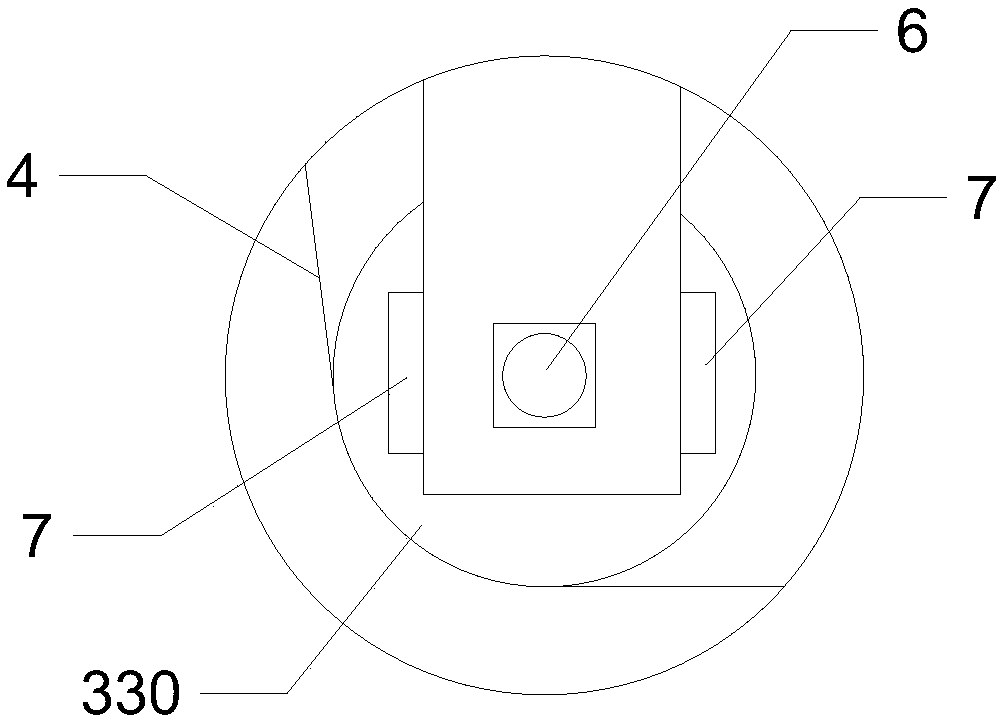

[0019] see Figure 1-3 , a kind of multi-wire cutting device, it comprises: workbench 1, and this workbench 1 is provided with installation board 2, and described installation board 2 is provided with roller assembly 3, and described roller assembly 3 comprises pay-off roller 310 , a take-up roller 320, two cutting rollers 330 and a lift assembly 340 for driving the two cutting rollers 330 to move up and down, and multiple groups of cutting wires 4 are wound on the pay-off roller 310, the two cutting rollers 330 and the take-up roller 320 to form a cutting line net, and the workbench 1 is also provided with a workpiece clamper 5 .

[0020] Wherein, an encoder 6 is also provided on the mounting plate 2, and the encoder 6 is used to detect the rotation speed values of the two cutting rollers 330; A brake 7 is also provided, and the brake 7 is used to slow down the rotation speed of the cutting roller 330 .

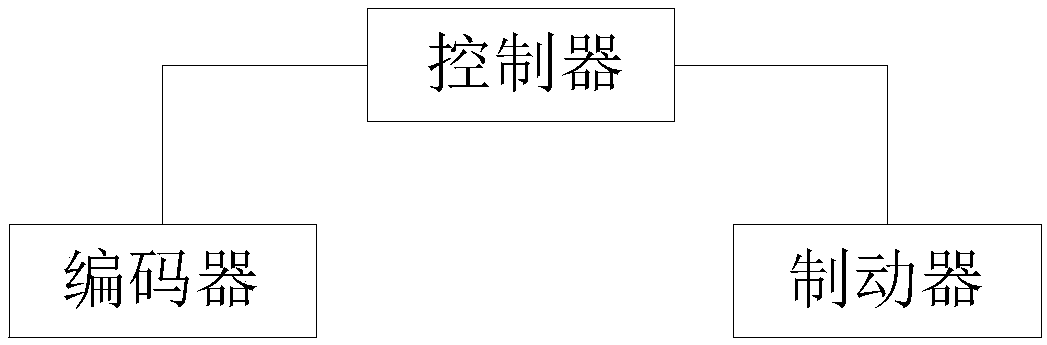

[0021] The multi-wire cutting device also includes a controller, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com