Engine

A technology for engines and driven shafts, which is applied to engine components, machines/engines, motor vehicles, etc., and can solve problems such as difficult maintenance of driving gears and lengthening of crankshafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

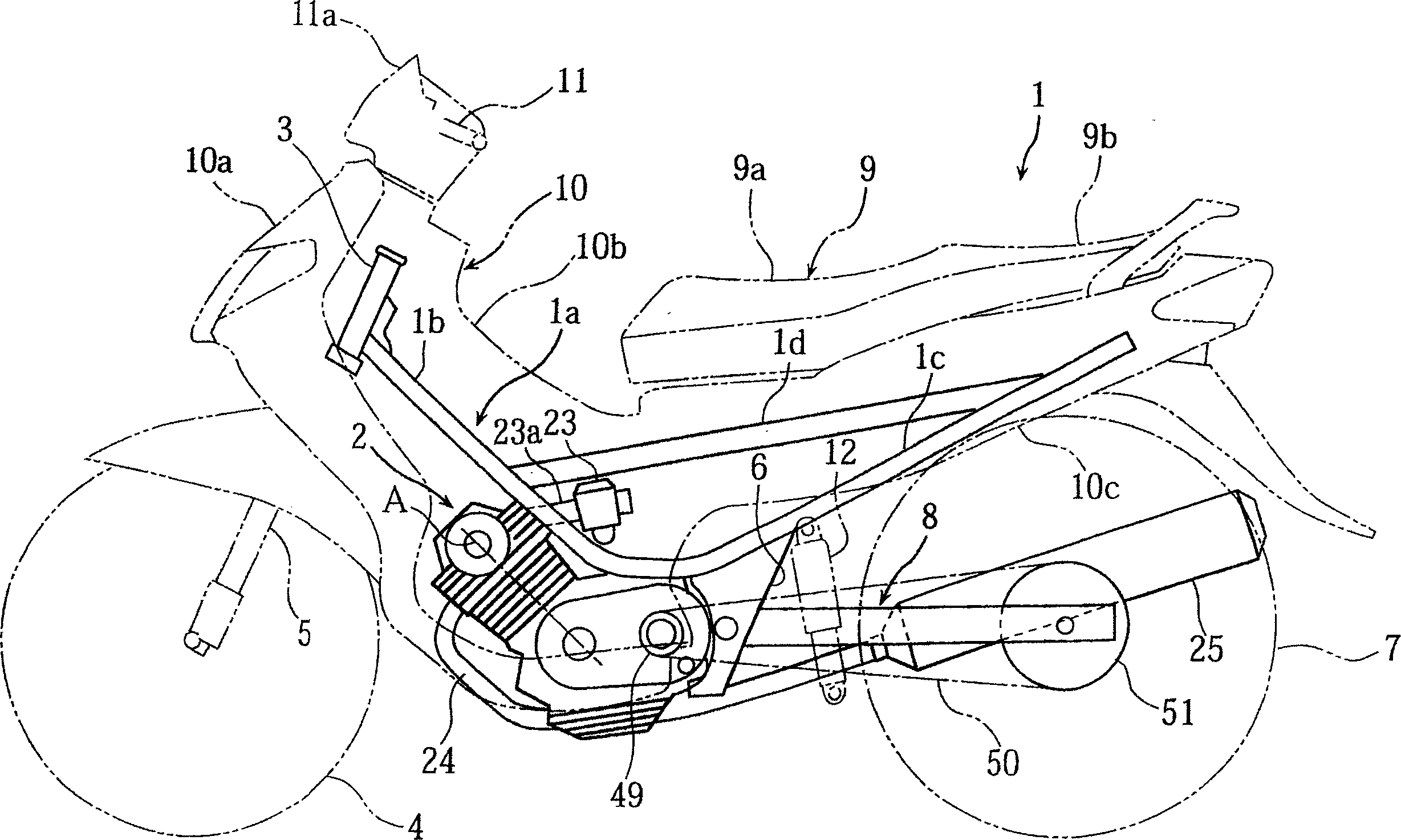

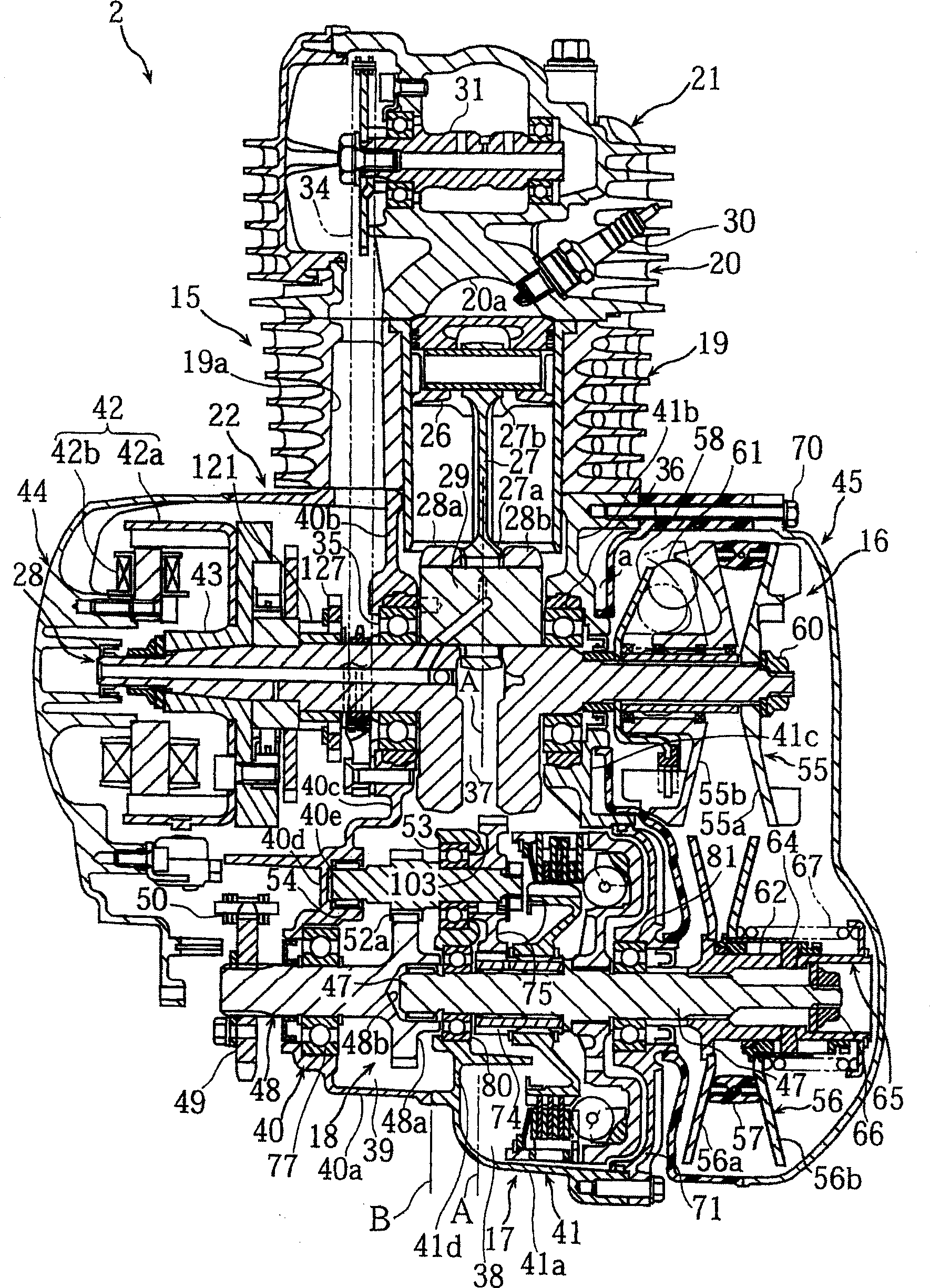

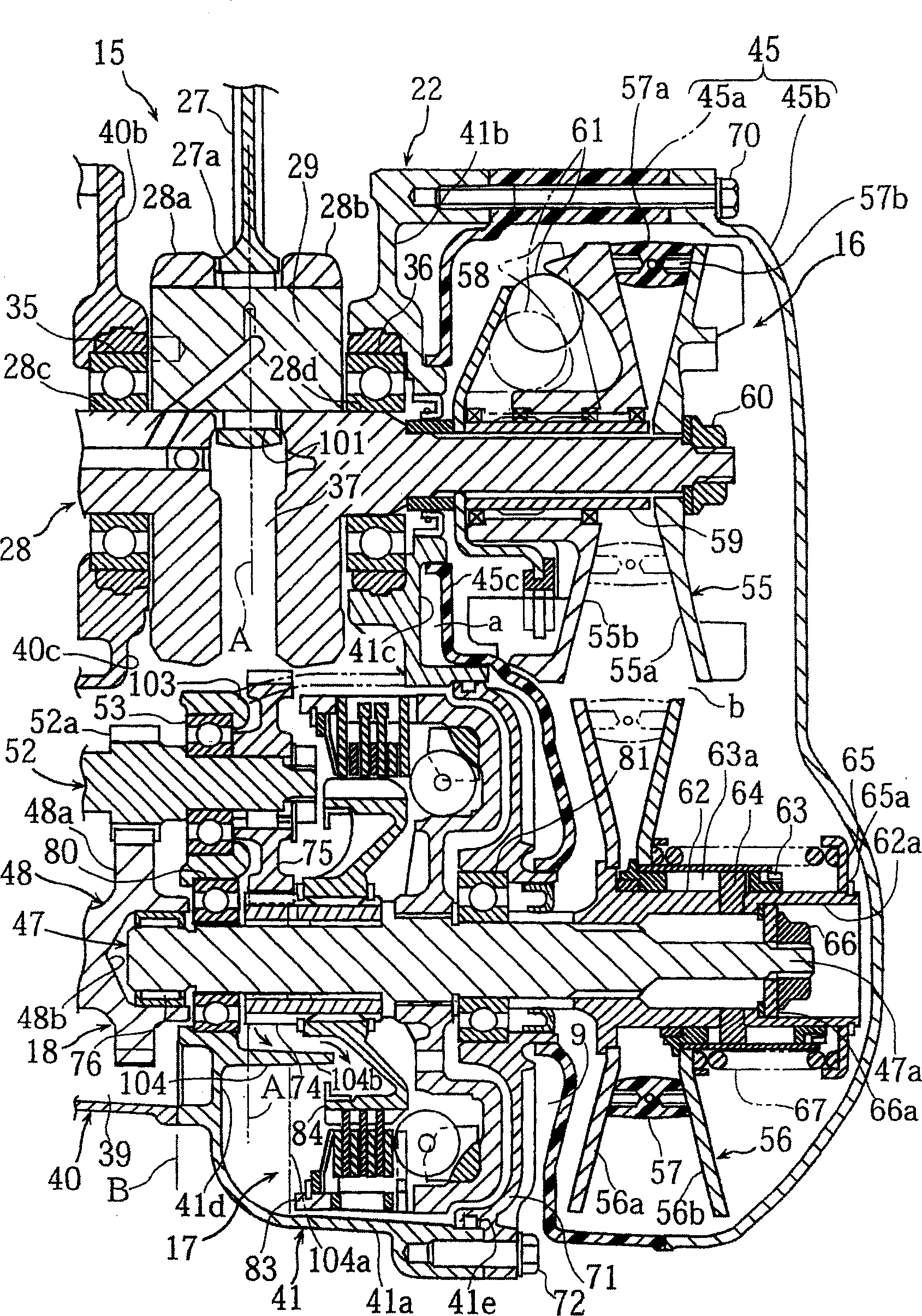

[0031] Embodiments of the present invention will be described below based on the drawings.

[0032] Figure 1 to Figure 15 is a diagram for explaining a motorcycle engine according to an embodiment of the present invention, figure 1 It is the left side view of the motorcycle equipped with the engine of this embodiment, figure 2 It is a sectional top view showing the engine in the unfolded state ( Figure 6 II-II line profile), image 3 It is a cross-sectional top view of the continuously variable transmission mechanism and the centrifugal clutch mechanism of the engine, Figure 4 , Figure 5 are the right side view and left side view of the engine, Figure 6 It is a right side view with the engine's continuously variable transmission mechanism and centrifugal clutch mechanism removed, Figure 7 is the right side view of the crankcase, Figure 8 is the sectional top view of the crankcase ( Figure 5 VIII-VIII line profile), Figure 9 It is a cross-sectional top view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com