Patents

Literature

34results about How to "Solve Flatness Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

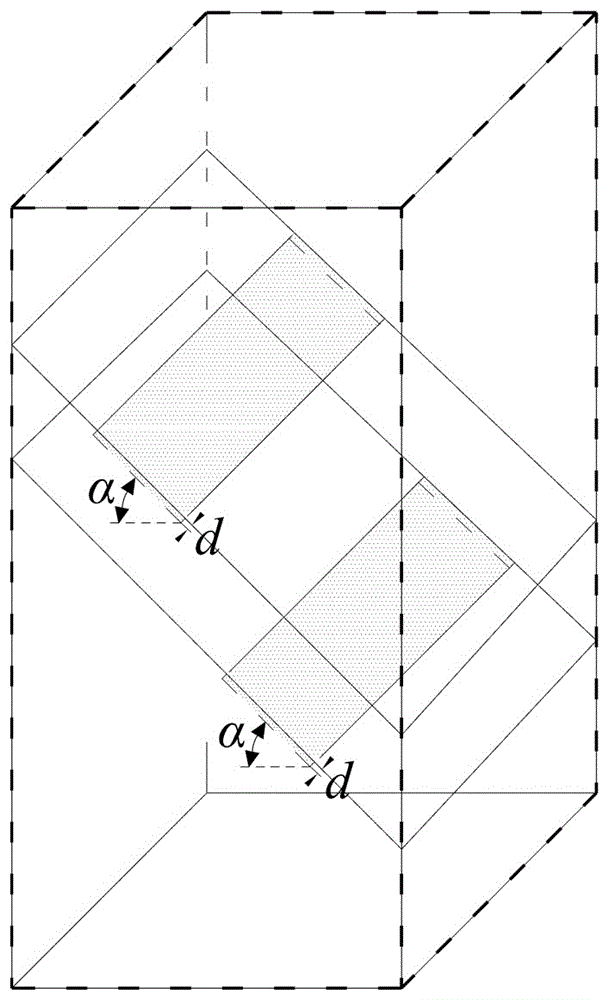

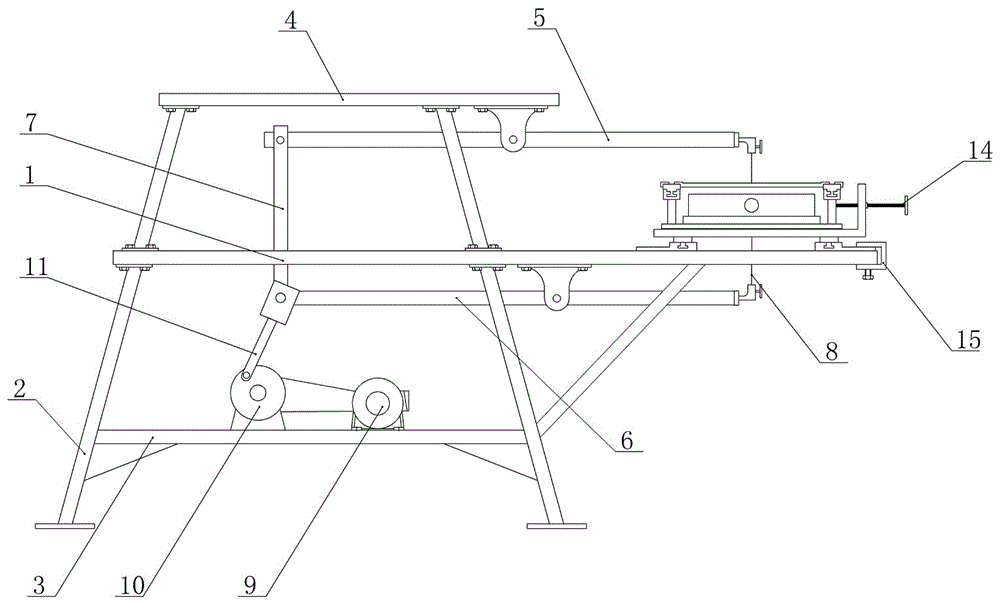

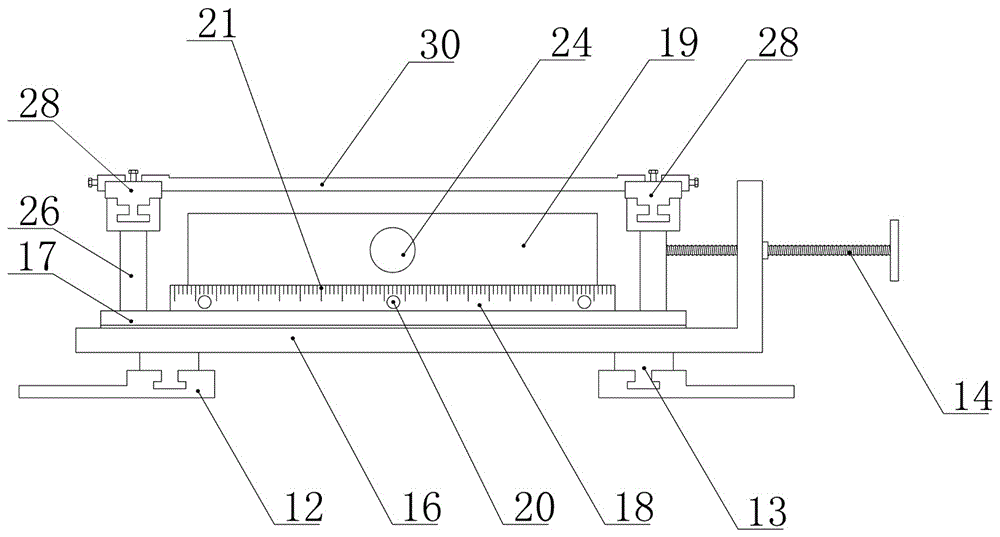

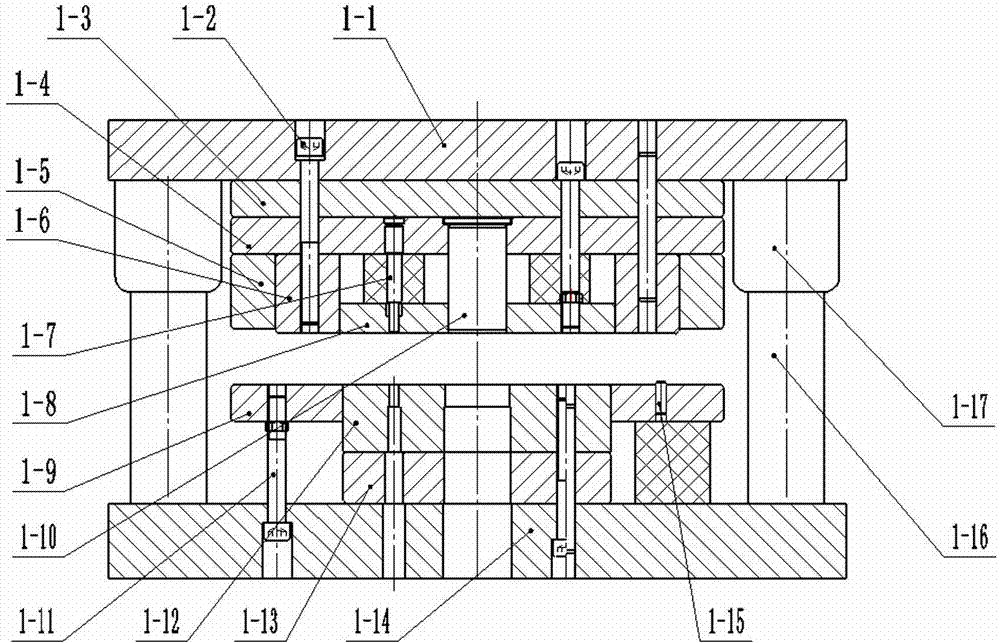

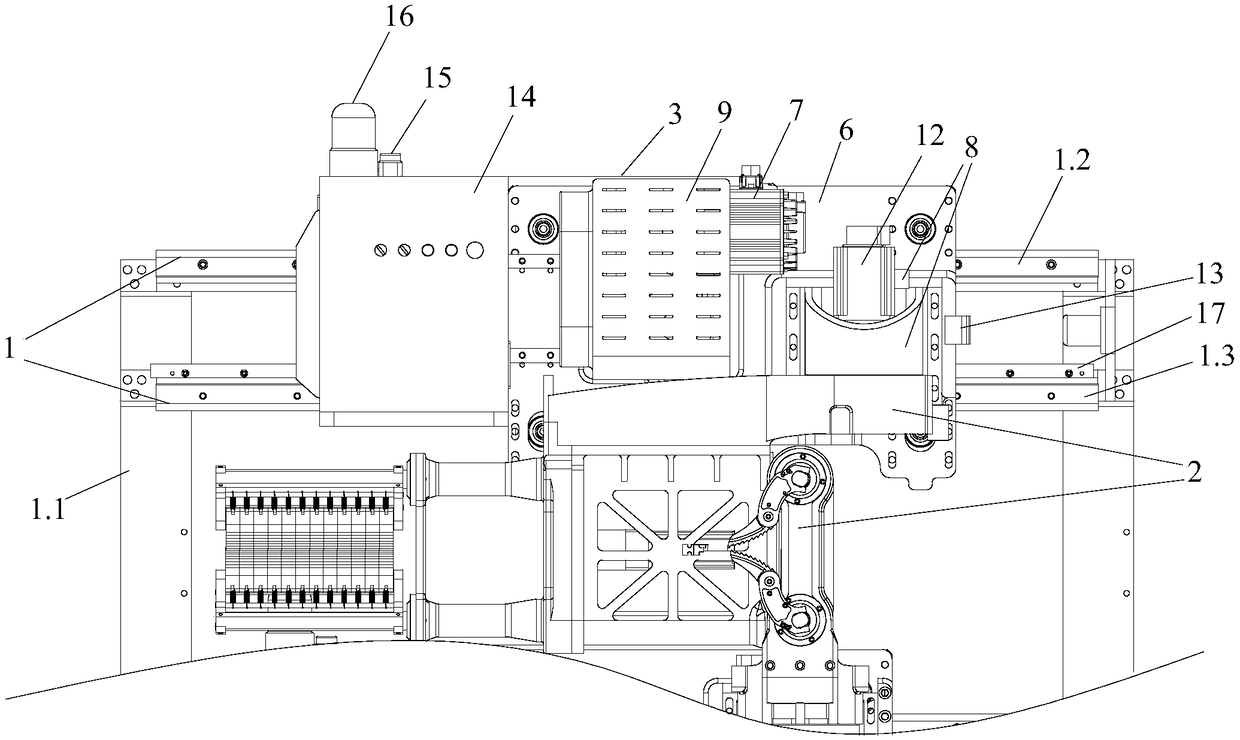

Three-dimensional intermittent cut-through crack production apparatus and method of cuboid rock test sample

ActiveCN106092699AImprove accuracyReflect mechanicsPreparing sample for investigationTest sampleWire cutting

The invention belongs to the technical field of geotechnical engineering, and relates to a three-dimensional intermittent cut-through crack production apparatus and method of a cuboid rock test sample. The three-dimensional intermittent cut-through crack production apparatus comprises a stander, and an electric wire saw assembly, a three-dimensional moving assembly, a test sample fixing assembly and a crack width control assembly which are arranged on the stander. By adopting the three-dimensional moving assembly and the test sample fixing assembly, the multi-azimuth three-dimensional adjustment of the real rock test sample can be realized, and the production requirement of the cut-through crack can be met; meanwhile, the production of different intermittent prefabricated cracks of different dip angles and different widths can be completed by virtue of the cooperation of the electric wire saw assembly and the crack width control assembly; meanwhile, the problem of the manual saw wire cutting that the flatness and smoothness are insufficient and the crack difference of different samples is great can be effectively solved by virtue of the crack width control assembly, a test result can be maximally optimized, the accuracy of the test result can be guaranteed, and the cracking rule of the rock can be actually reflected.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

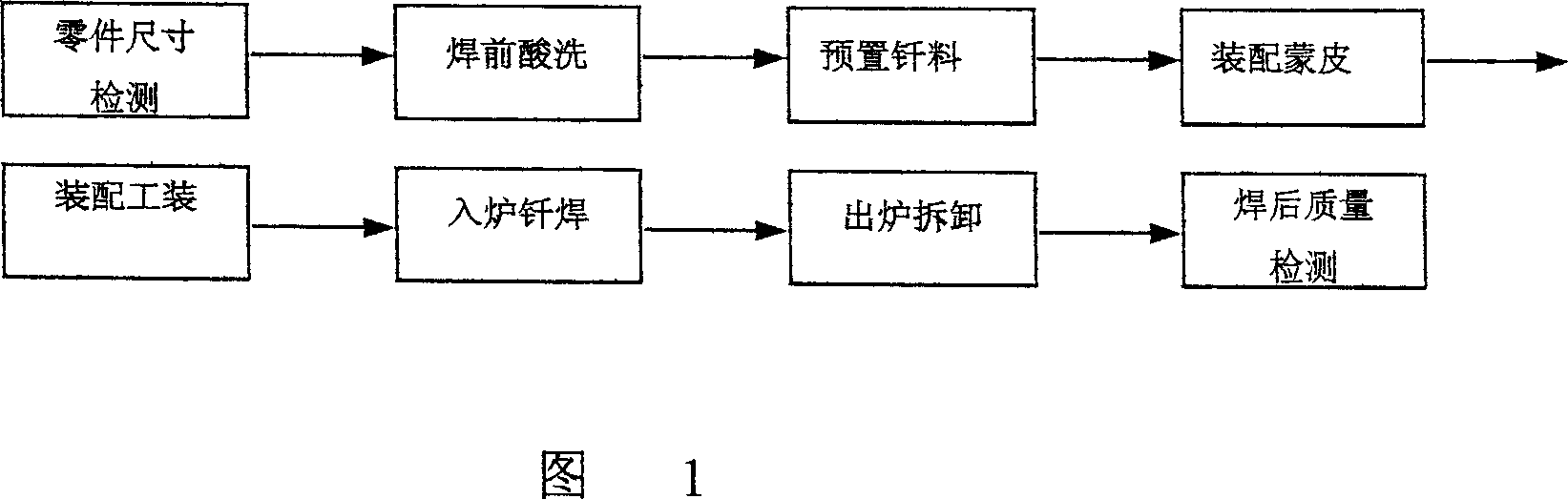

Welding method of titanium alloy framework and covering variable cross-section element

ActiveCN1990149ASolve Flatness ProblemsSolve the technical problem of severe welding deformation of symmetryWelding/cutting auxillary devicesAuxillary welding devicesThermal expansionTreatment use

A titanium alloy frame and covering variable cross-section components welding methods, it presets the titanium alloy foiling solder between the frame and covering to weld surface, uses thermal expansion assembly equipments or face pressurized thermal expansion assembly equipments clamping, heats the overall unit in vacuum environment to melting solder and covering entire surface welding, completes solder welding connection through diffusing treatment after solidifying, it also provides the structural components of face pressurized thermal expansion assembly equipments which can be used below 950 degree C repeatedly, the equipment structure is simple, woke reliable, cost low and easy to use, maintenance and repairs. And it reveals the innovative composite art parameters of high temperature solder welding and diffusing treatment using FTI high strength titanium alloy solder.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

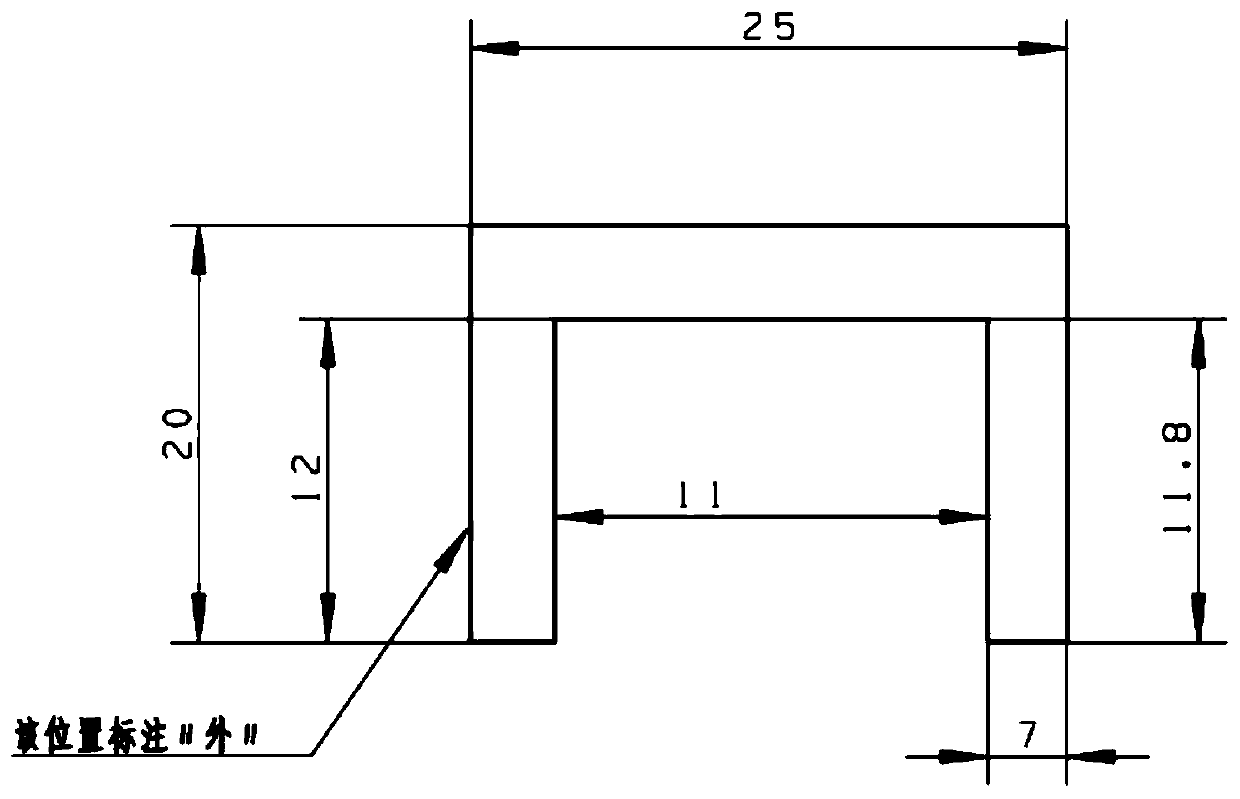

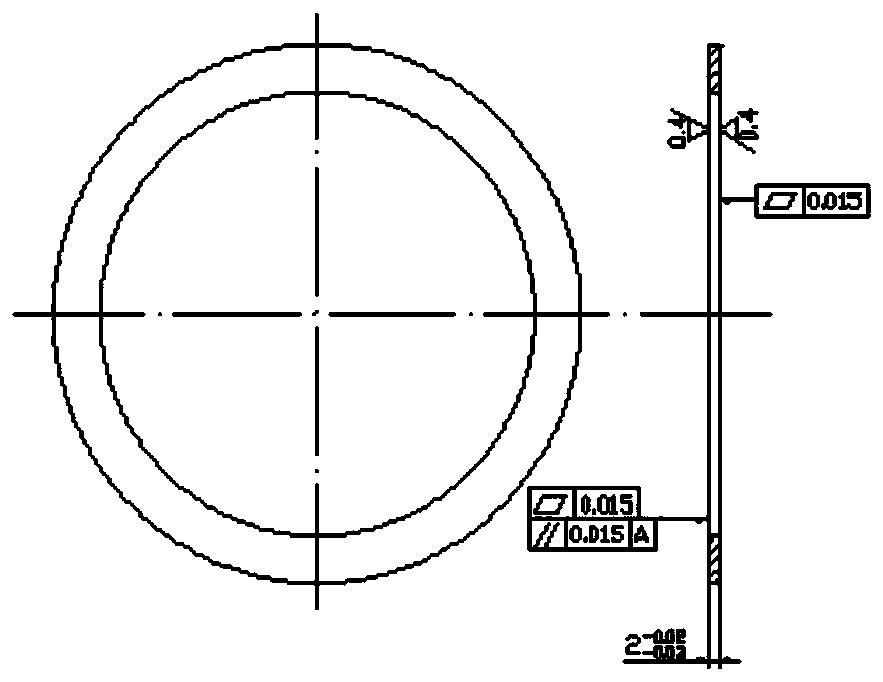

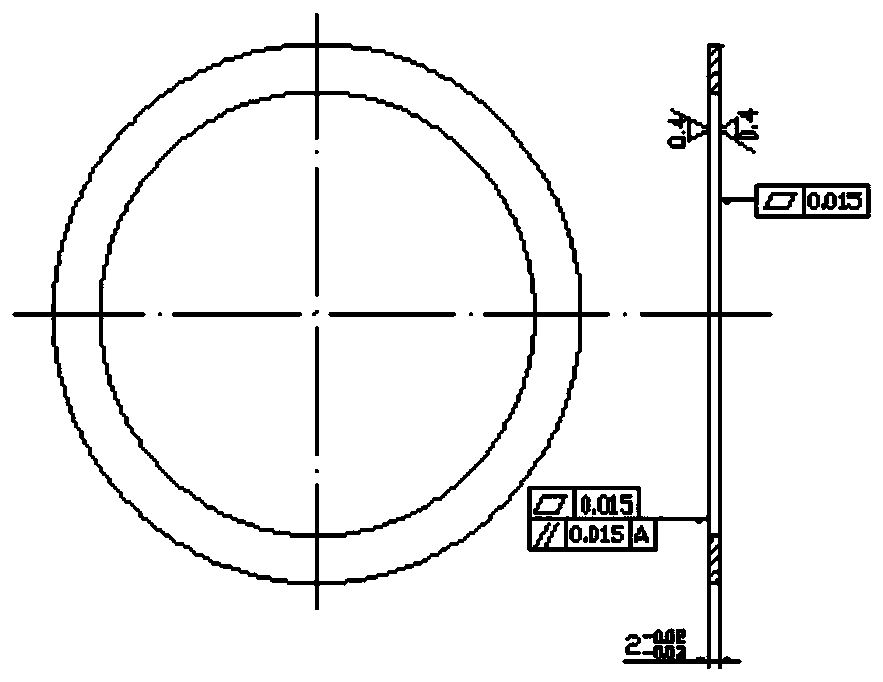

Machining method for stop ring

The invention belongs to the technical field of machining parts and in particular to a machining method for a stop ring. The machining method for the stop ring takes a GCr15 bearing-steel steel pipe as a raw material and the inner and outer diameters of the steel pipe are sizes of the inner and outer diameters of a stop ring blank; and then the steel pipe is cut to obtain the stop ring blank. According to the machining method for the stop ring, provided by the invention, the qualitative transition is realized by abandoning sheet material machining and replacing the sheet material machining with pipe machining, so that the utilization rate of the material is improved and material stress generated by rolling the material for a plurality of times is reduced; a cutting method is used for replacing punching so that punching machining stress of the blank is reduced and a foundation of solving a planeness problem is laid for subsequent machining; a heat treatment method is modified and the material stress, machining stress and heat treatment deformation are controlled to be minimum; and in conclusion, the problems of uncontrollable planeness, poor parallelism, poor thickness and plane roughness in an old method are solved through the machining method provided by the invention and the yield and market credibility of a product are improved.

Owner:WUJIANG SHUANGJING BEARING

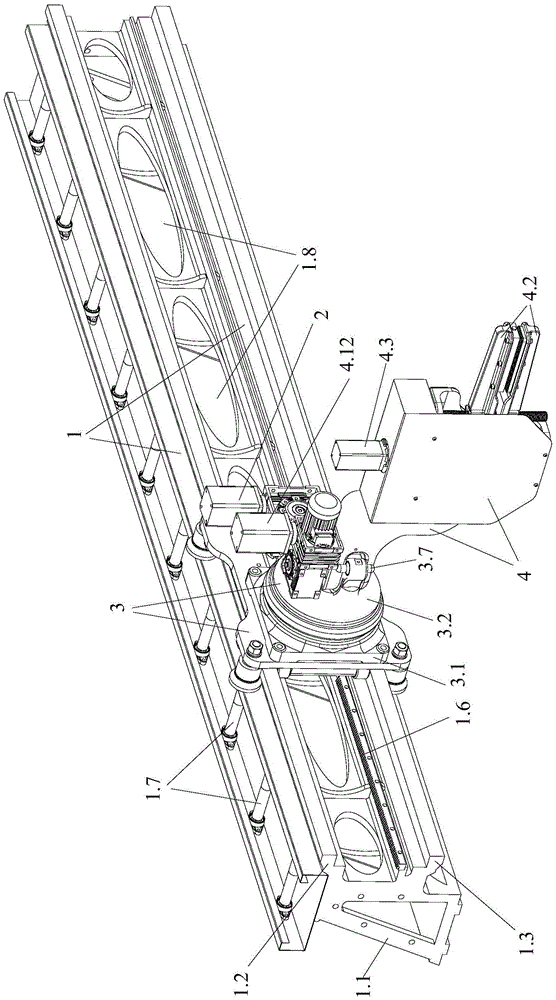

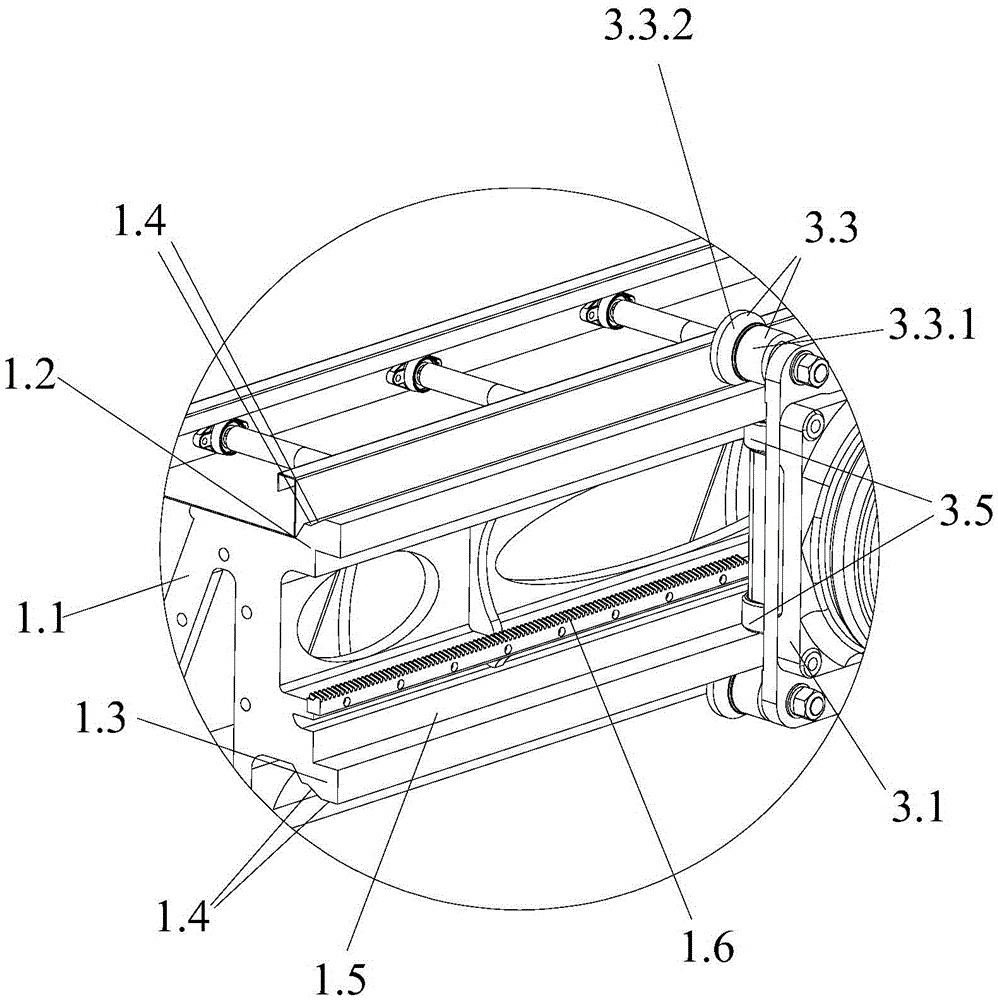

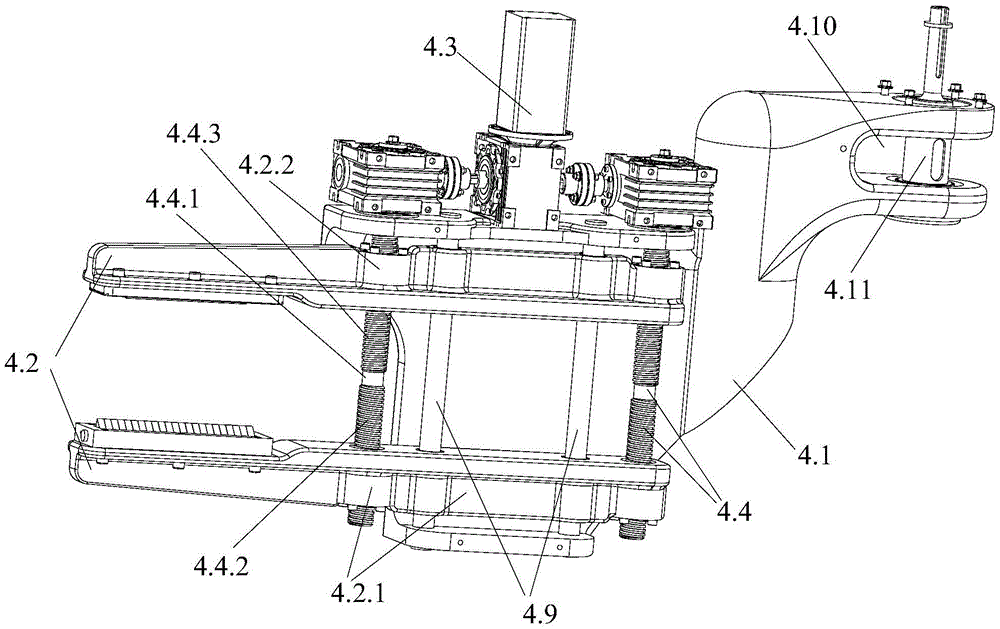

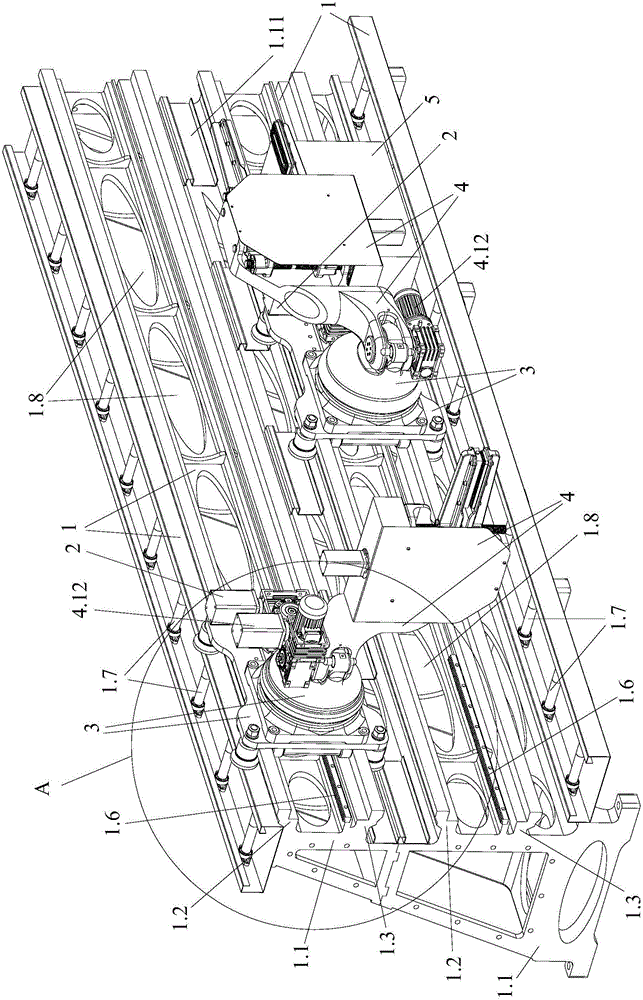

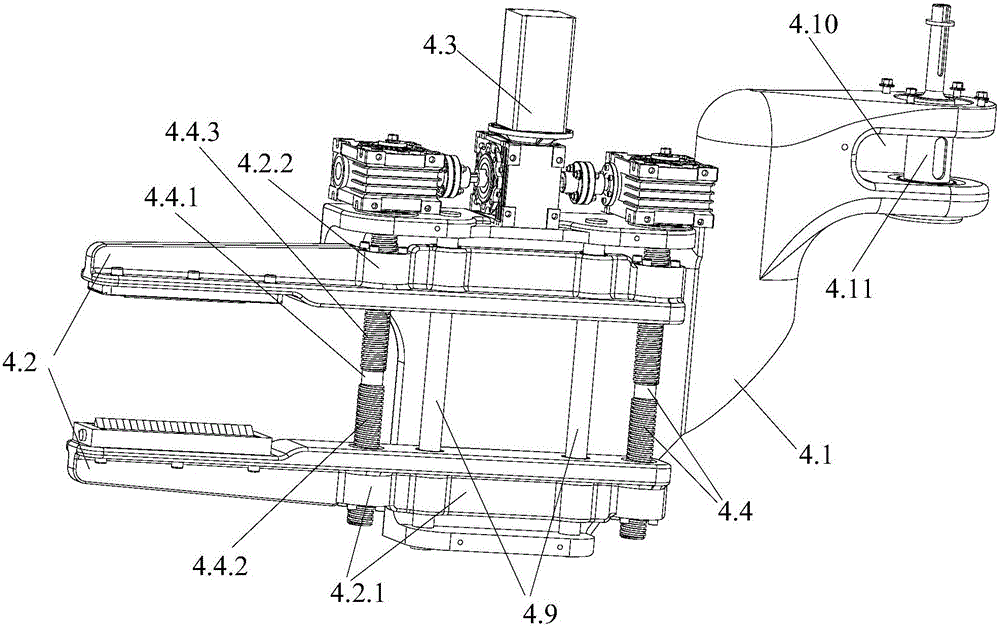

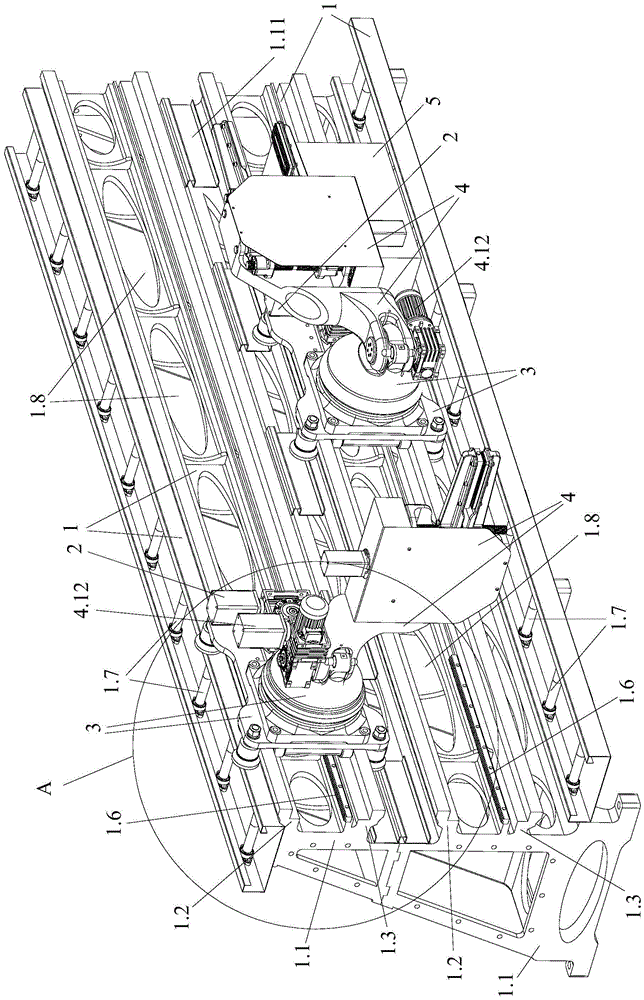

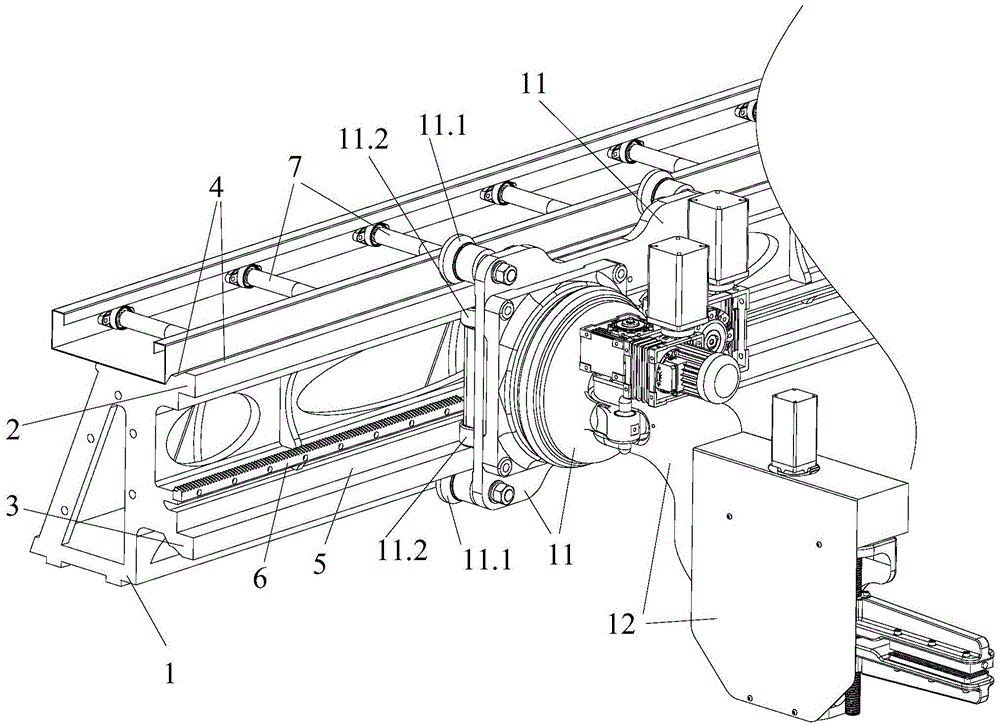

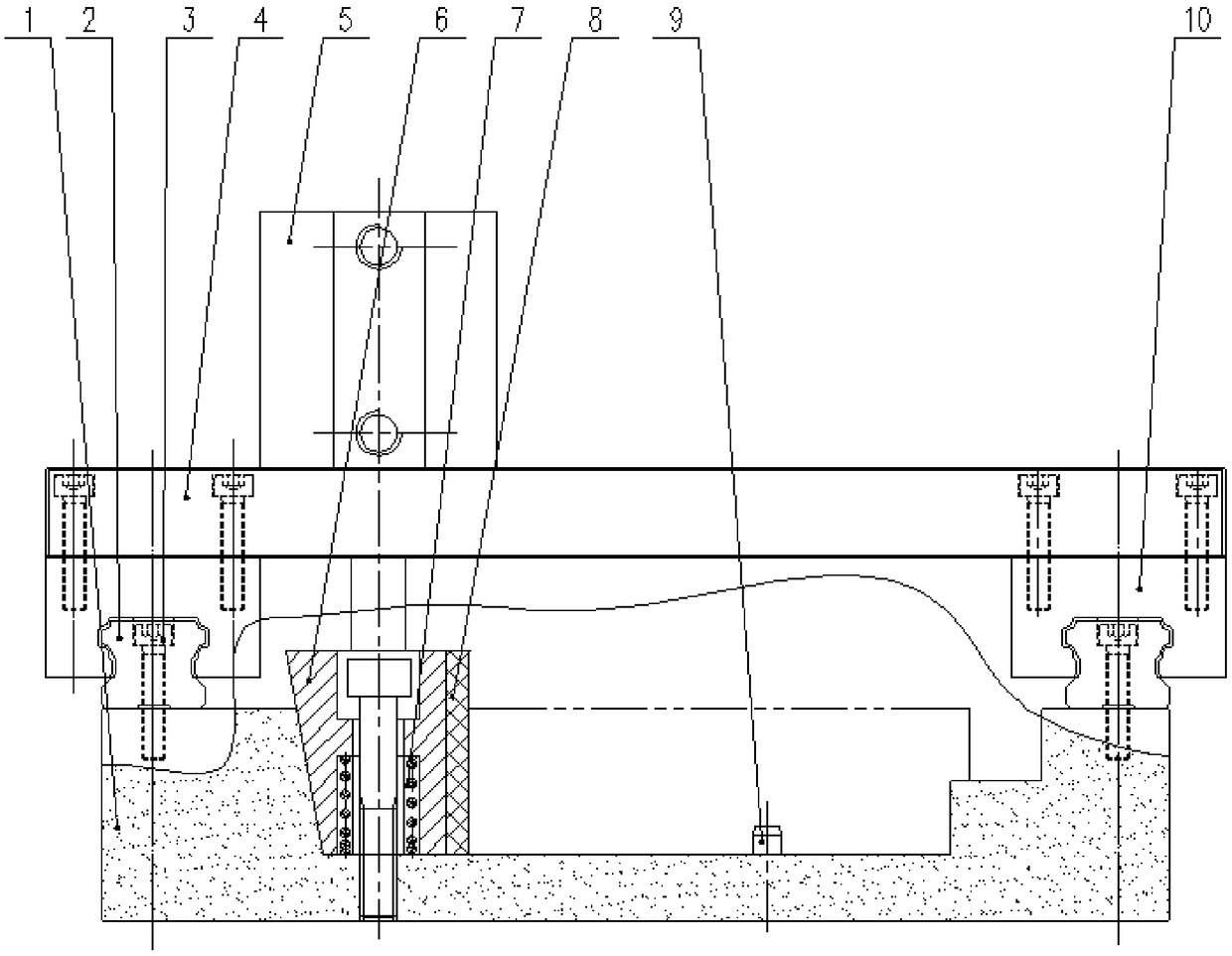

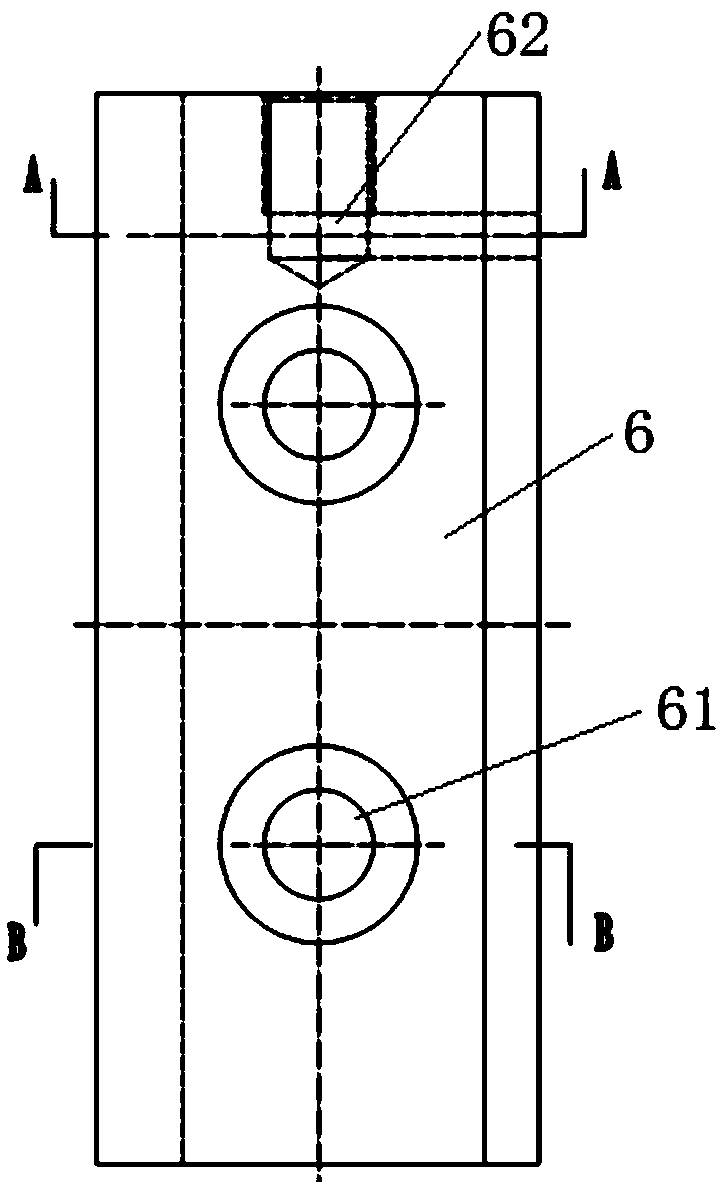

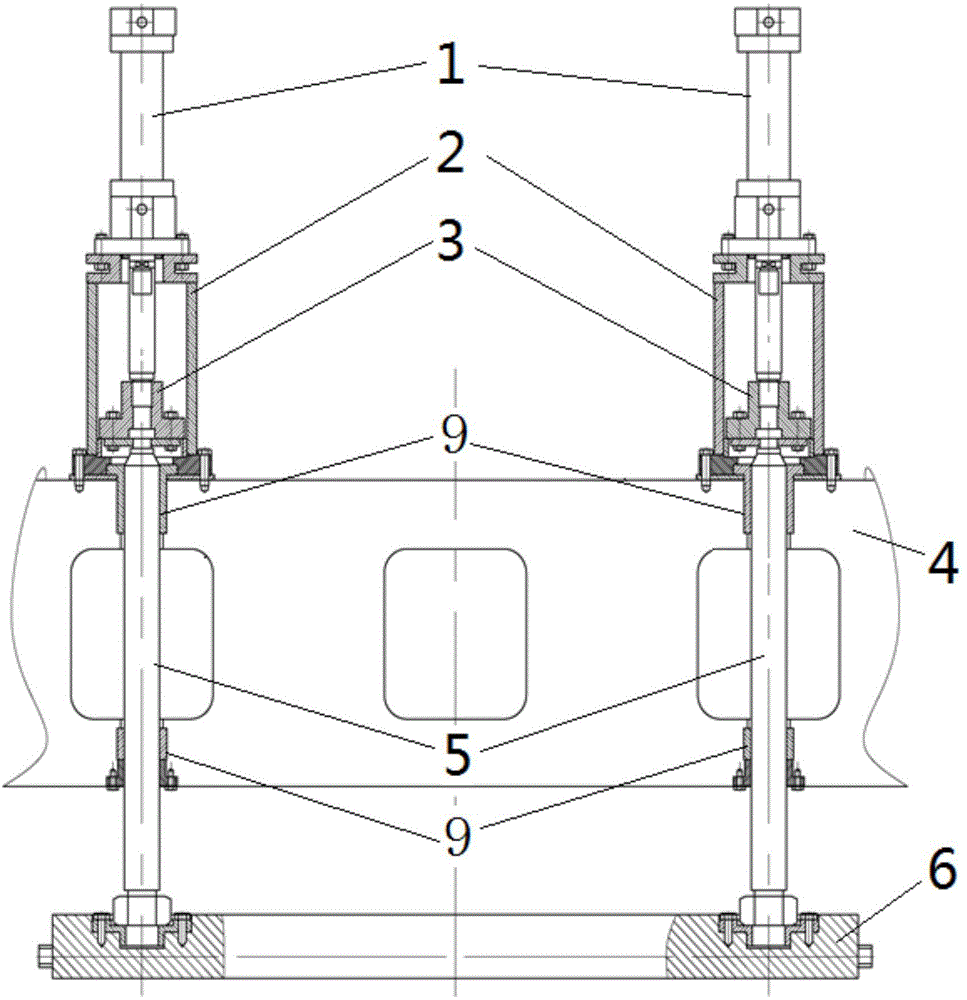

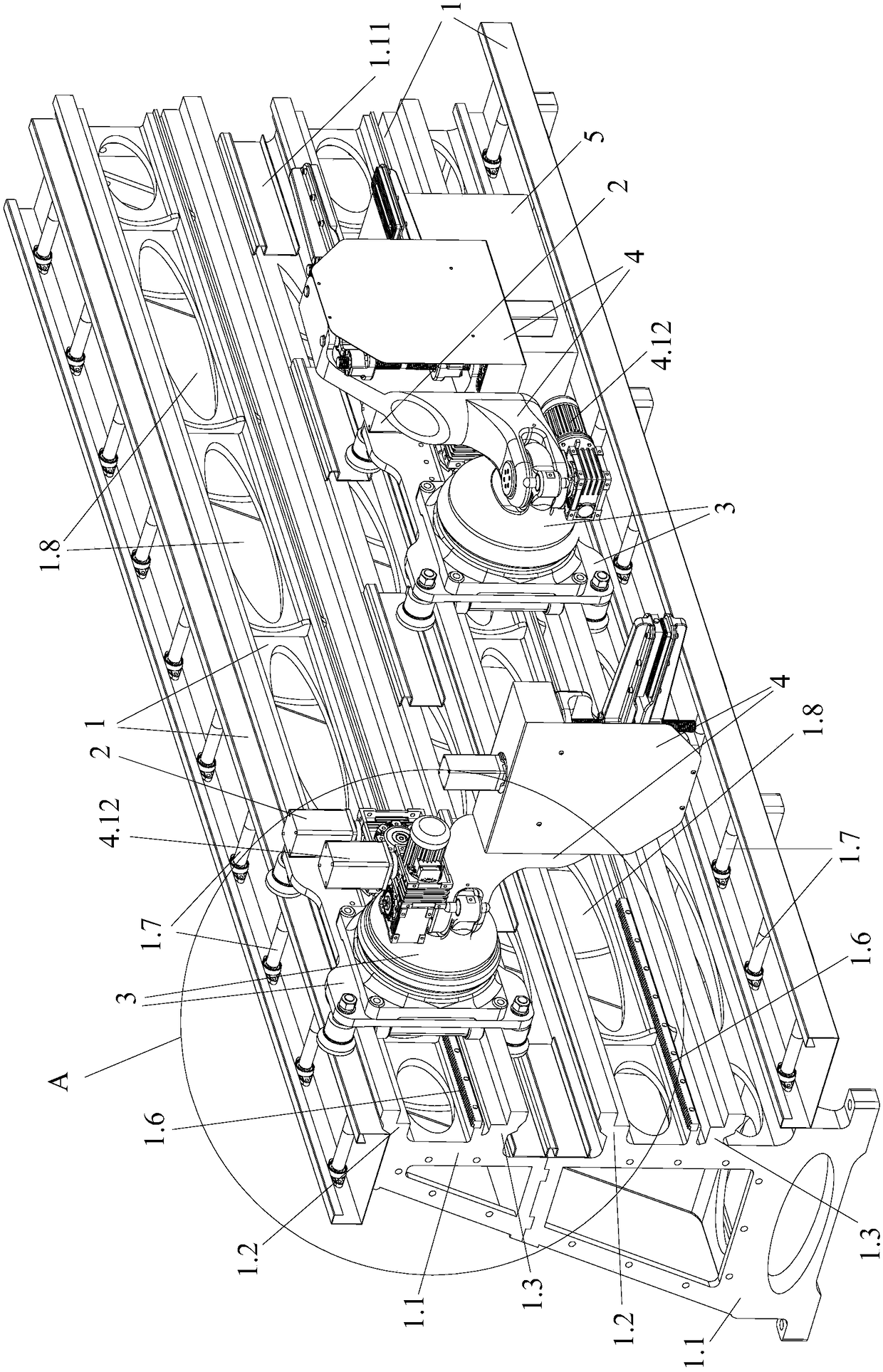

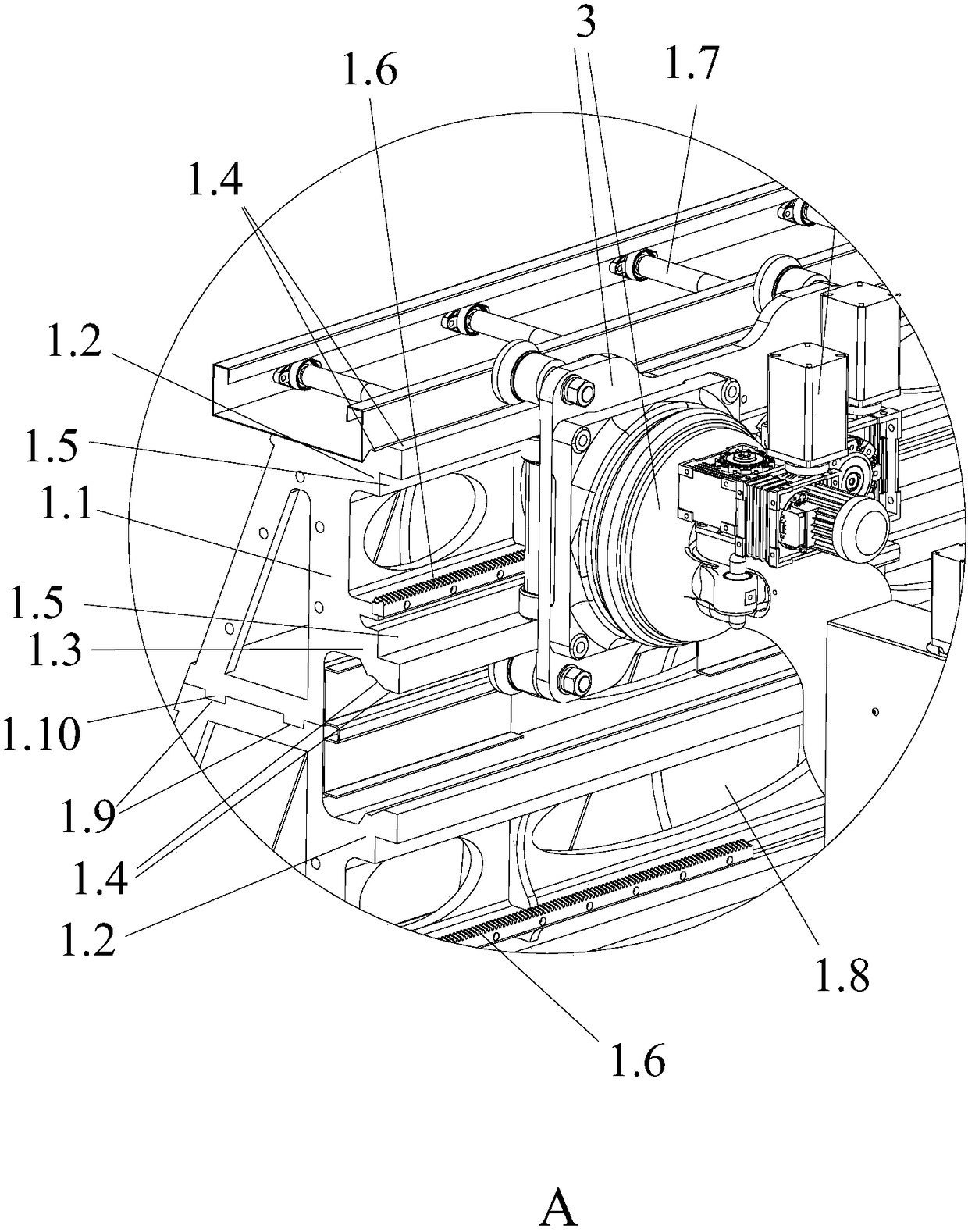

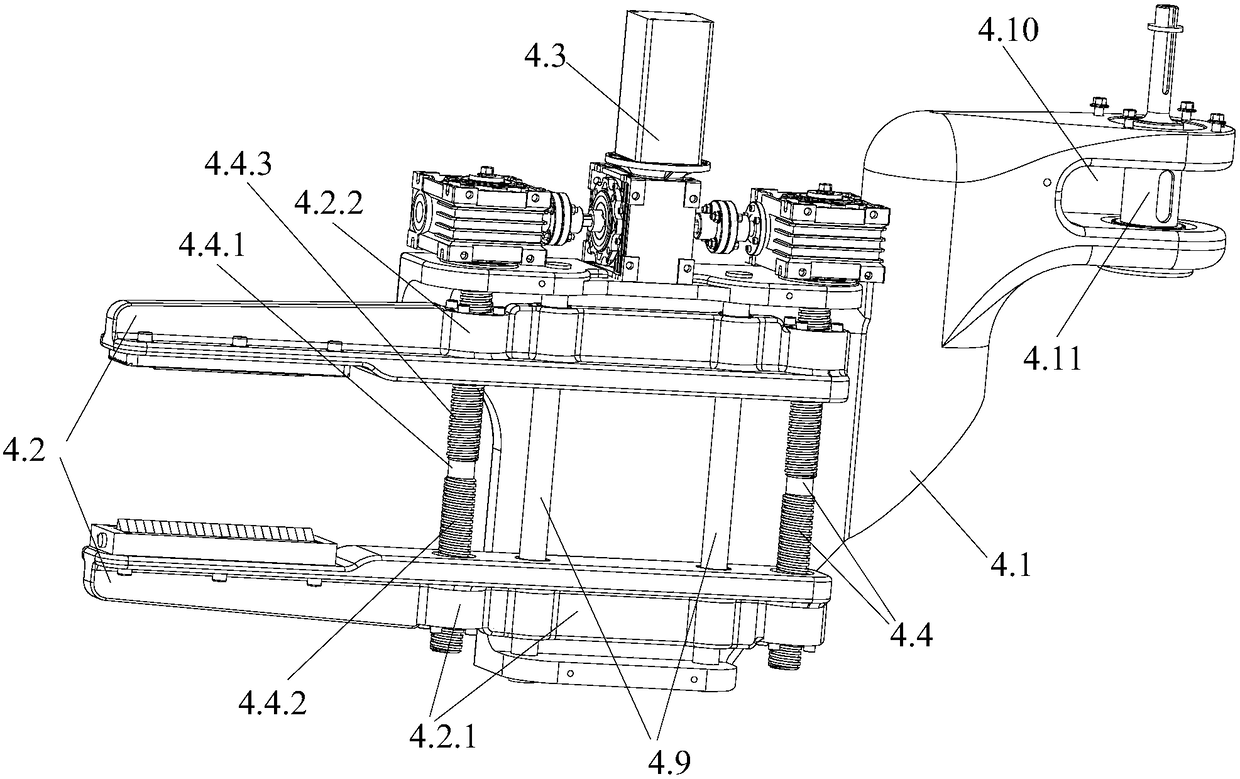

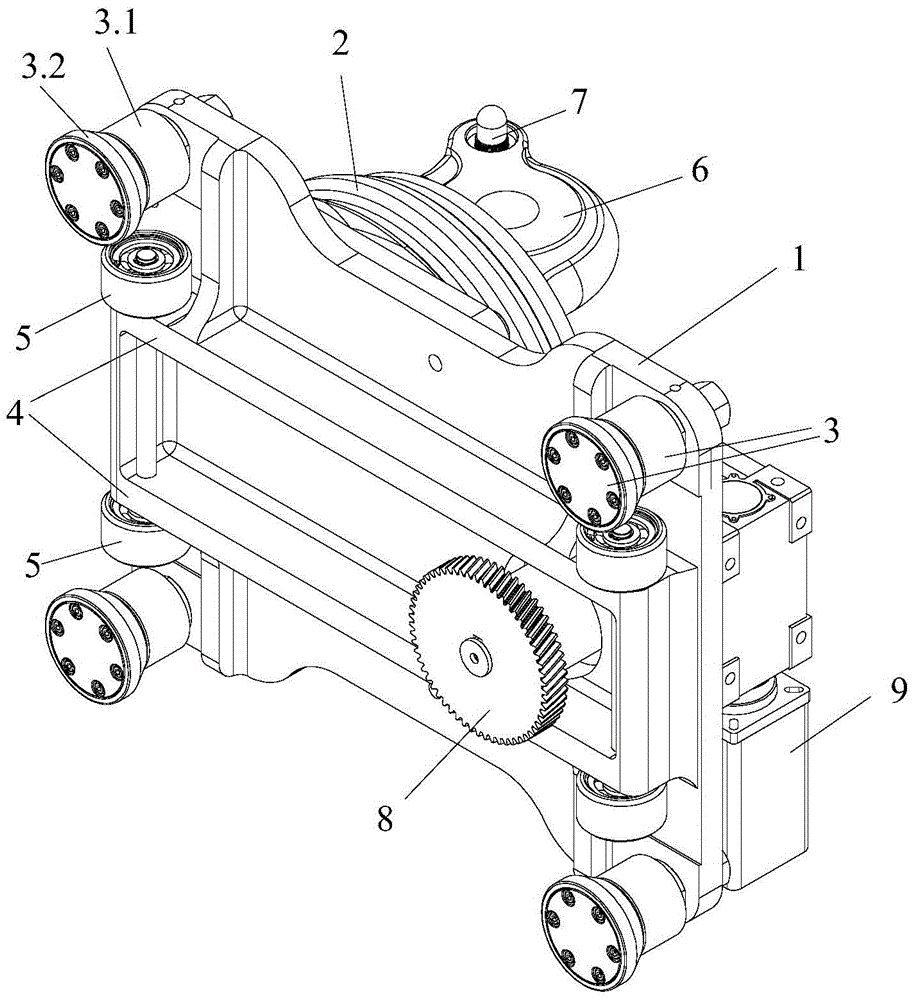

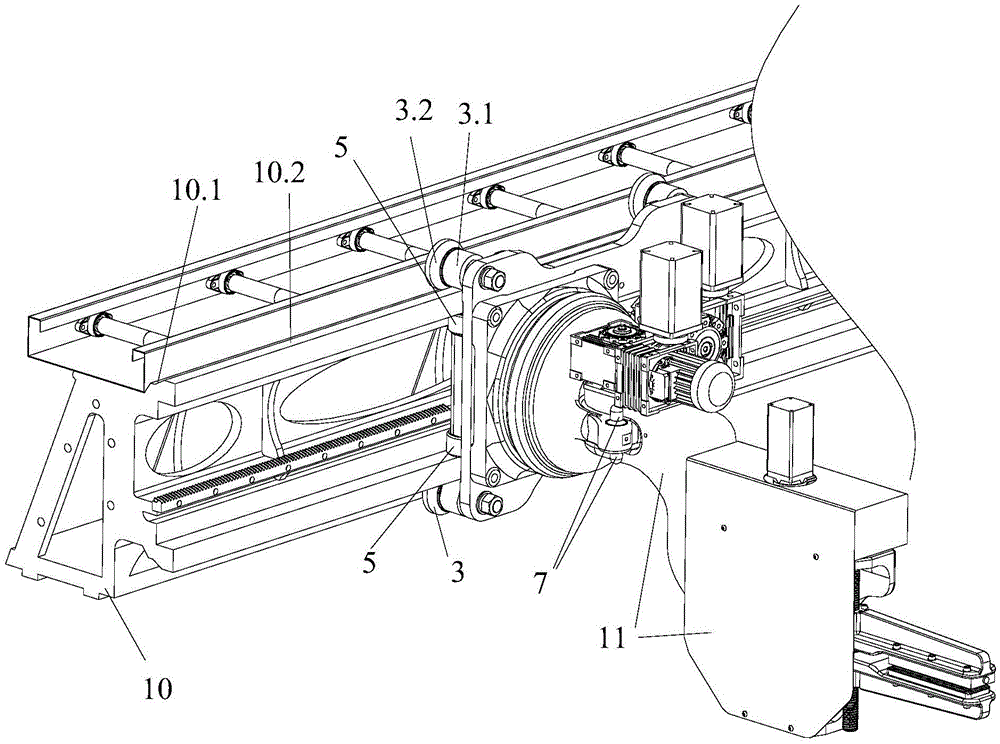

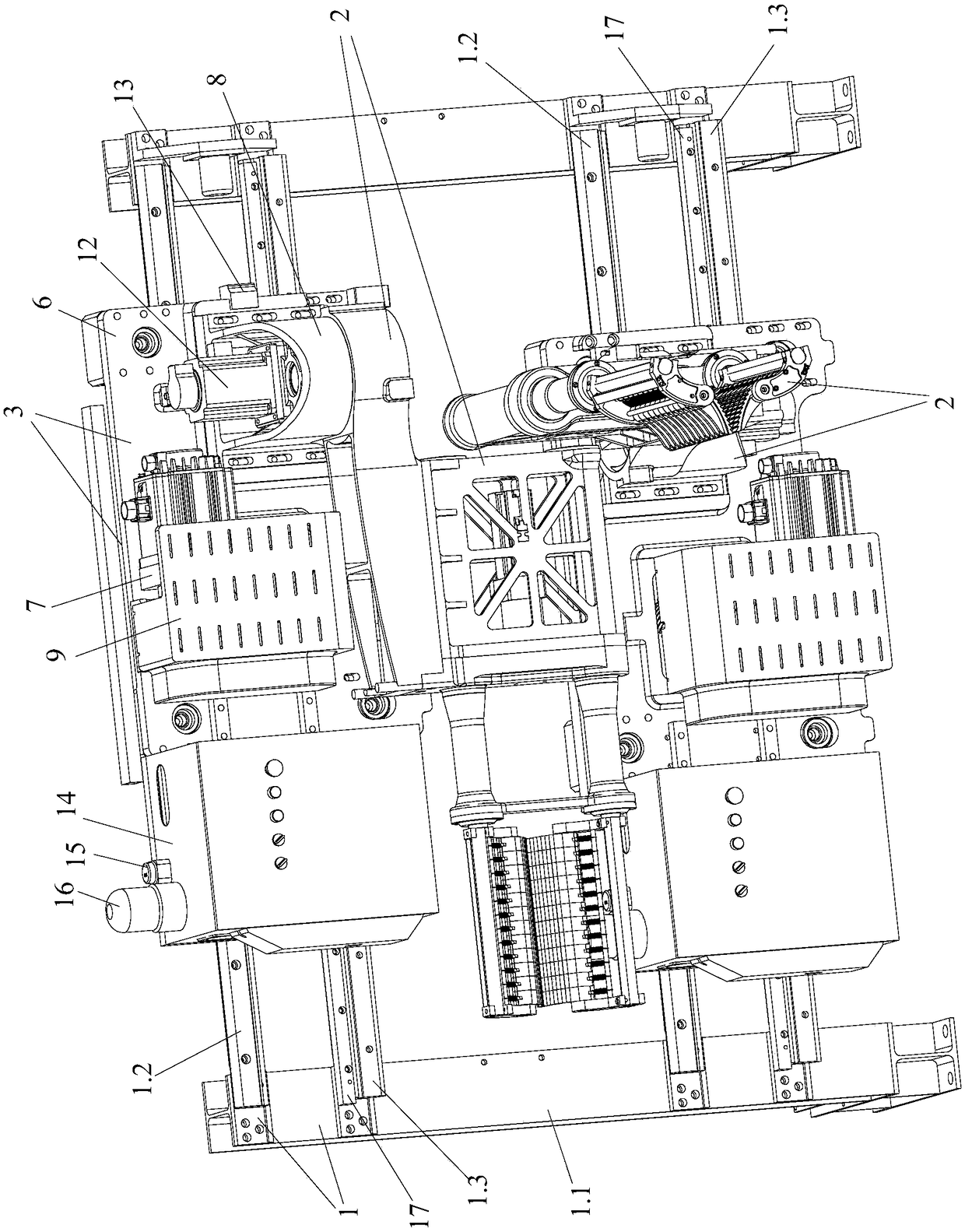

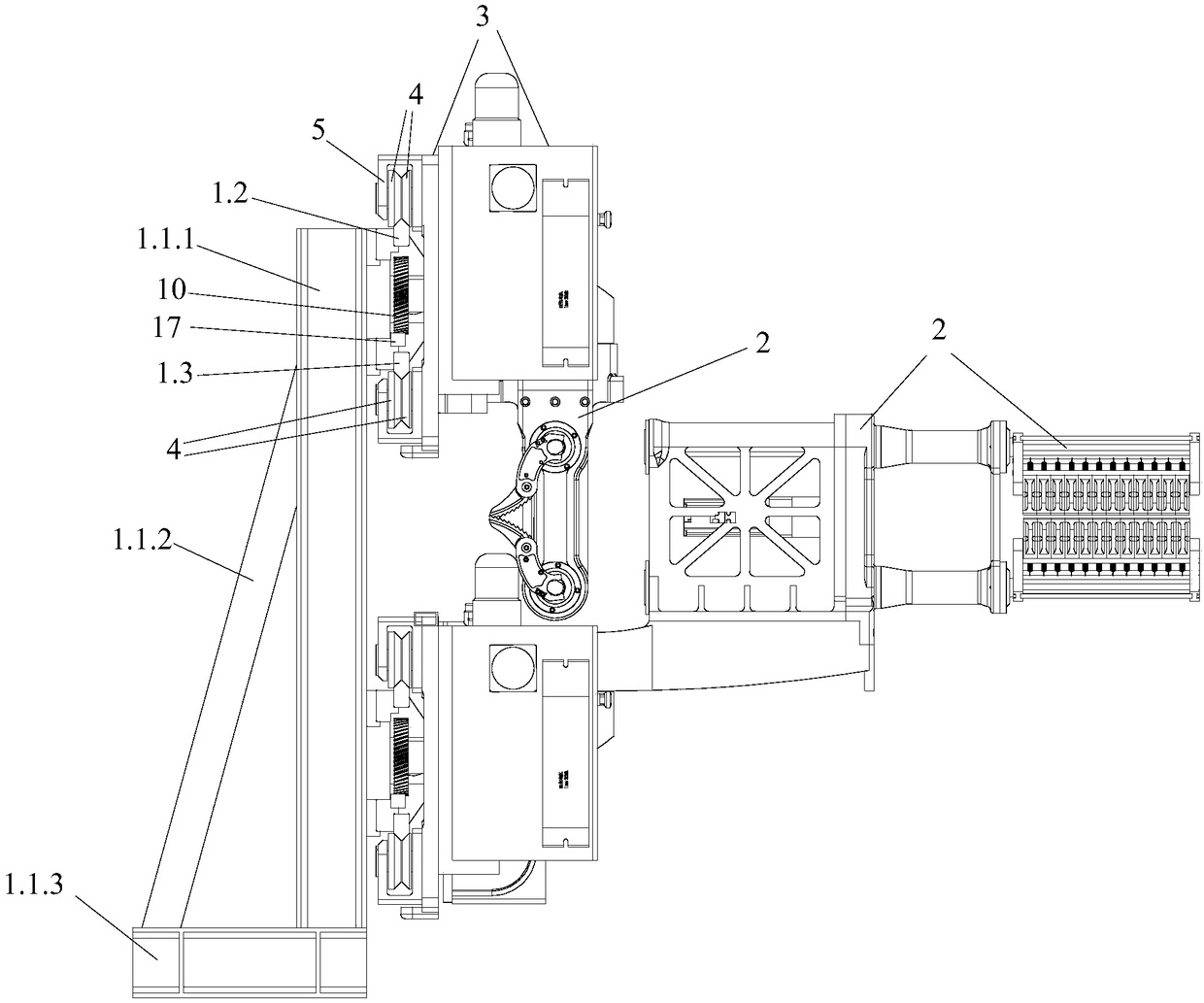

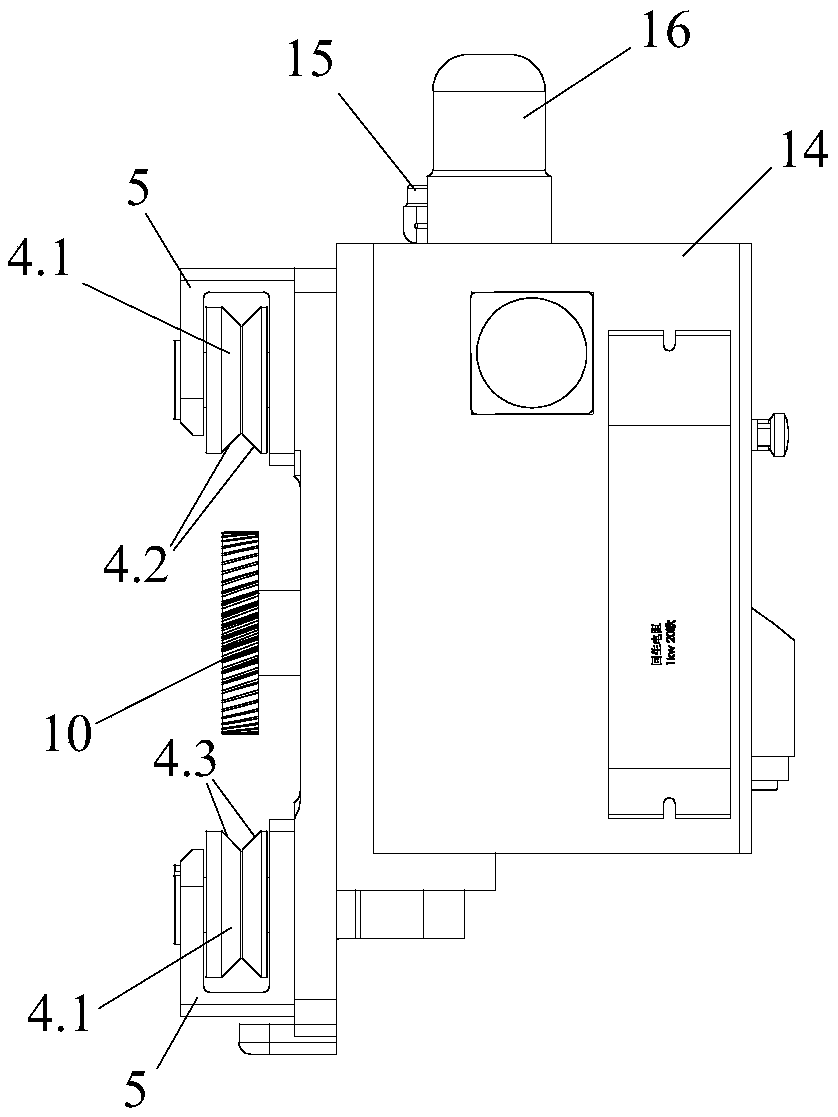

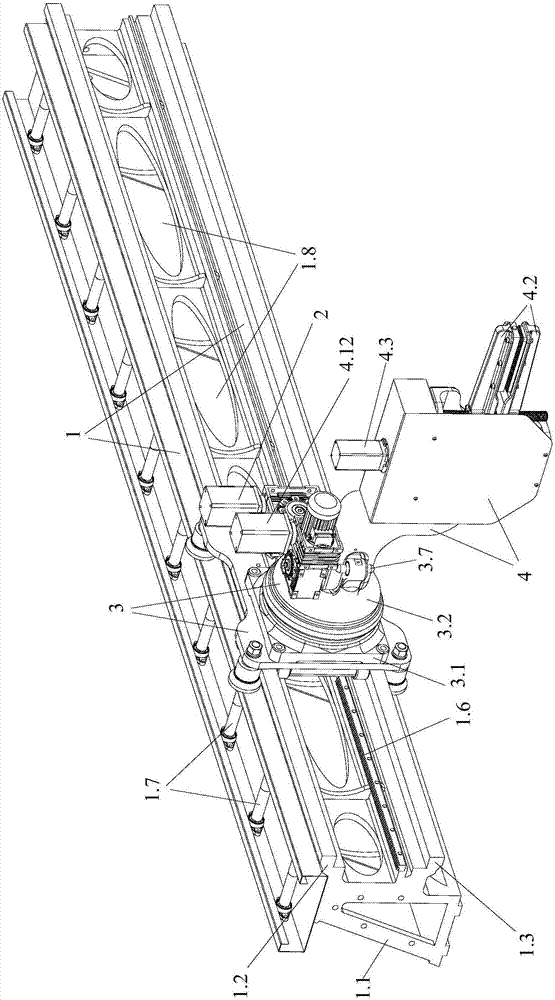

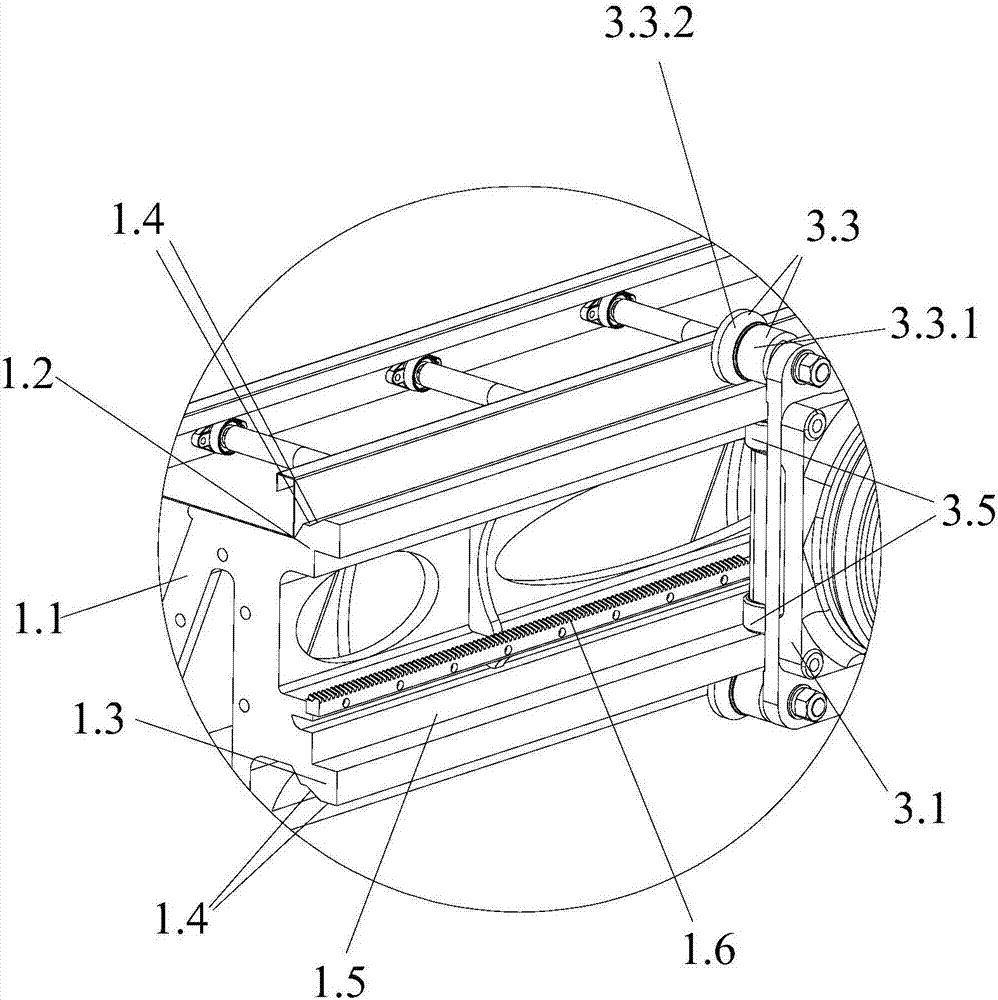

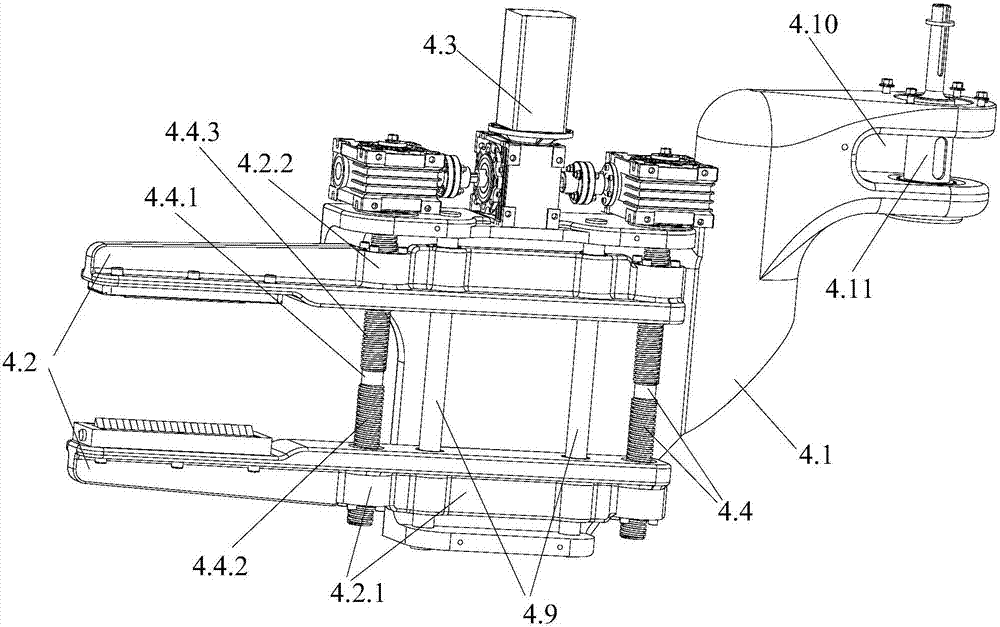

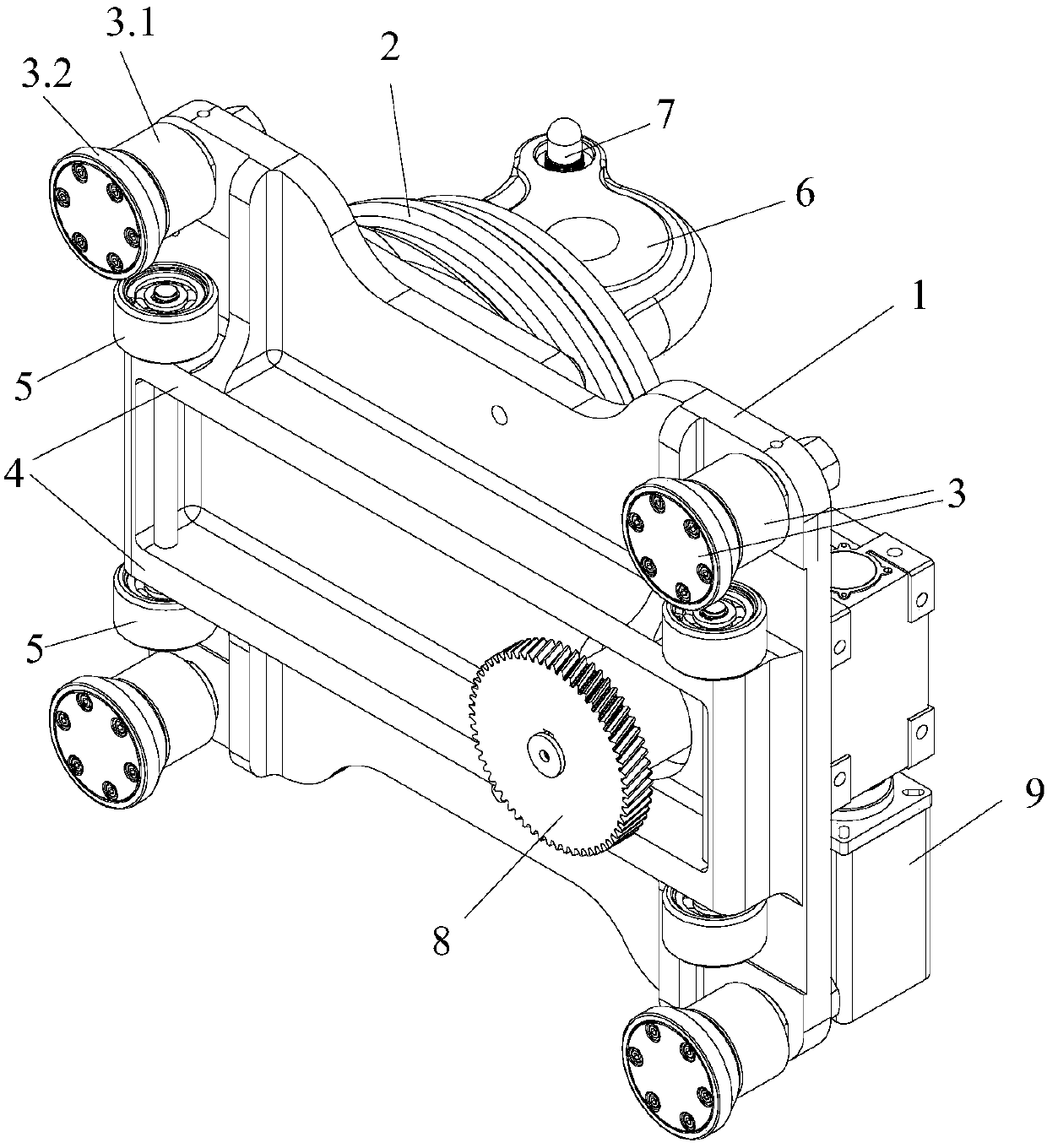

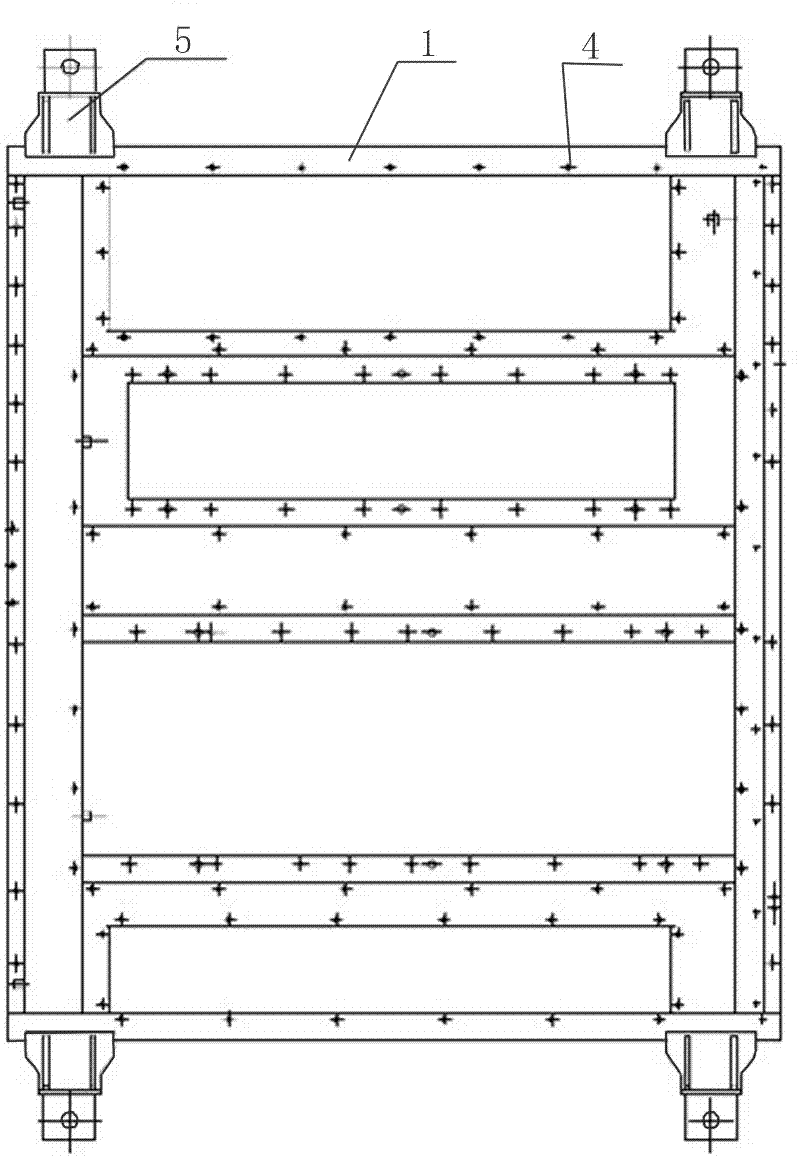

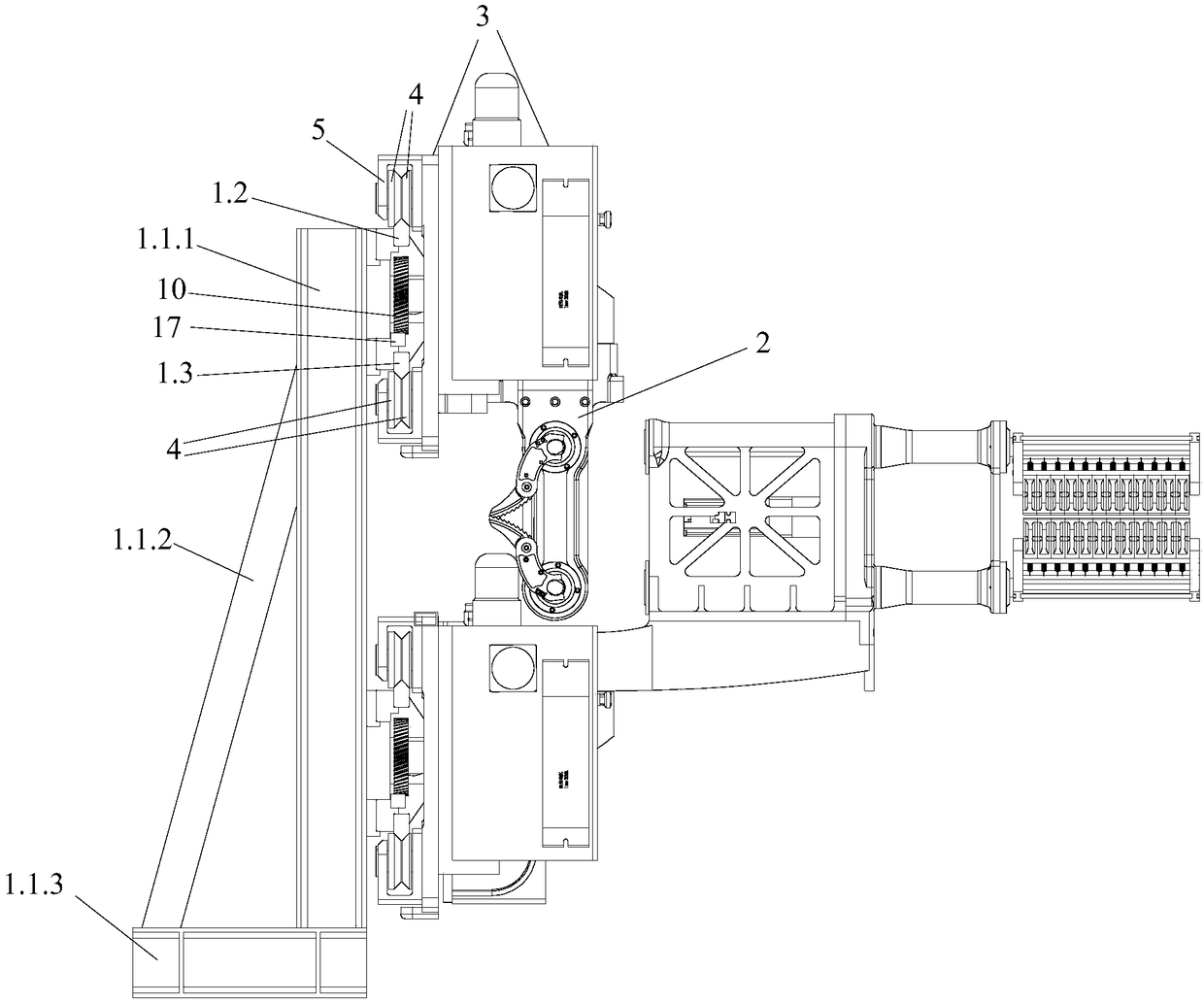

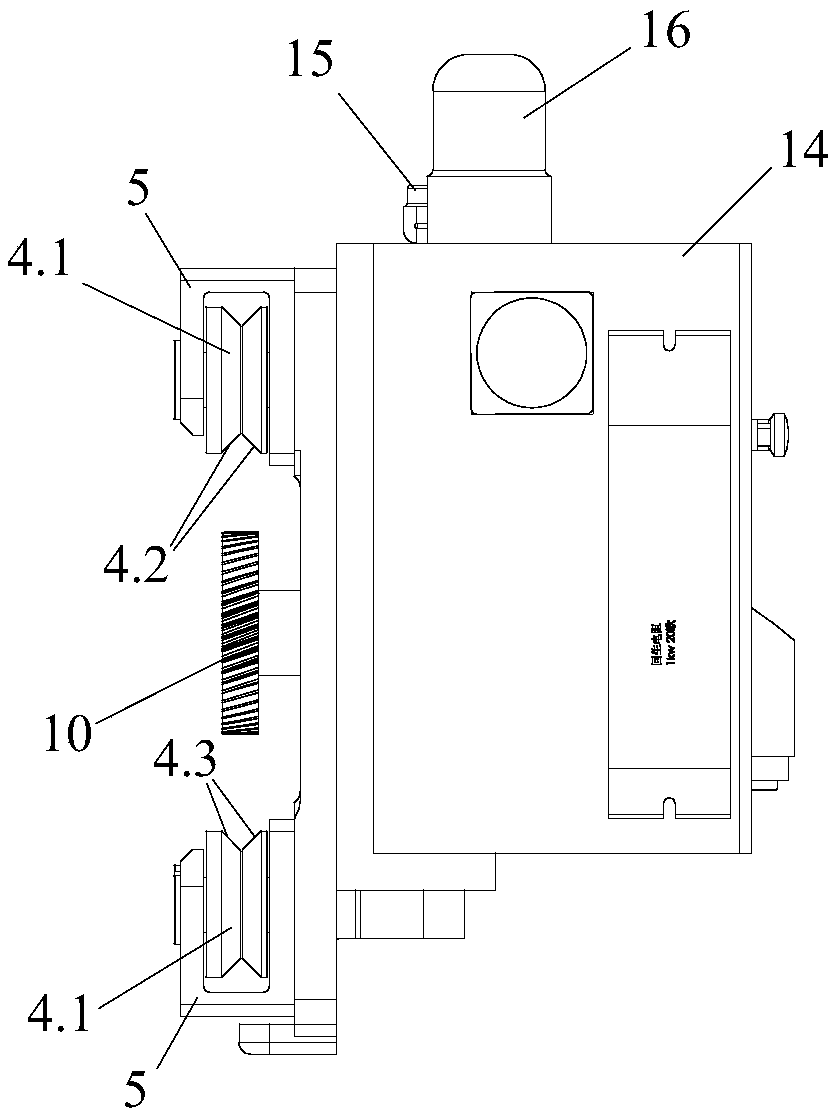

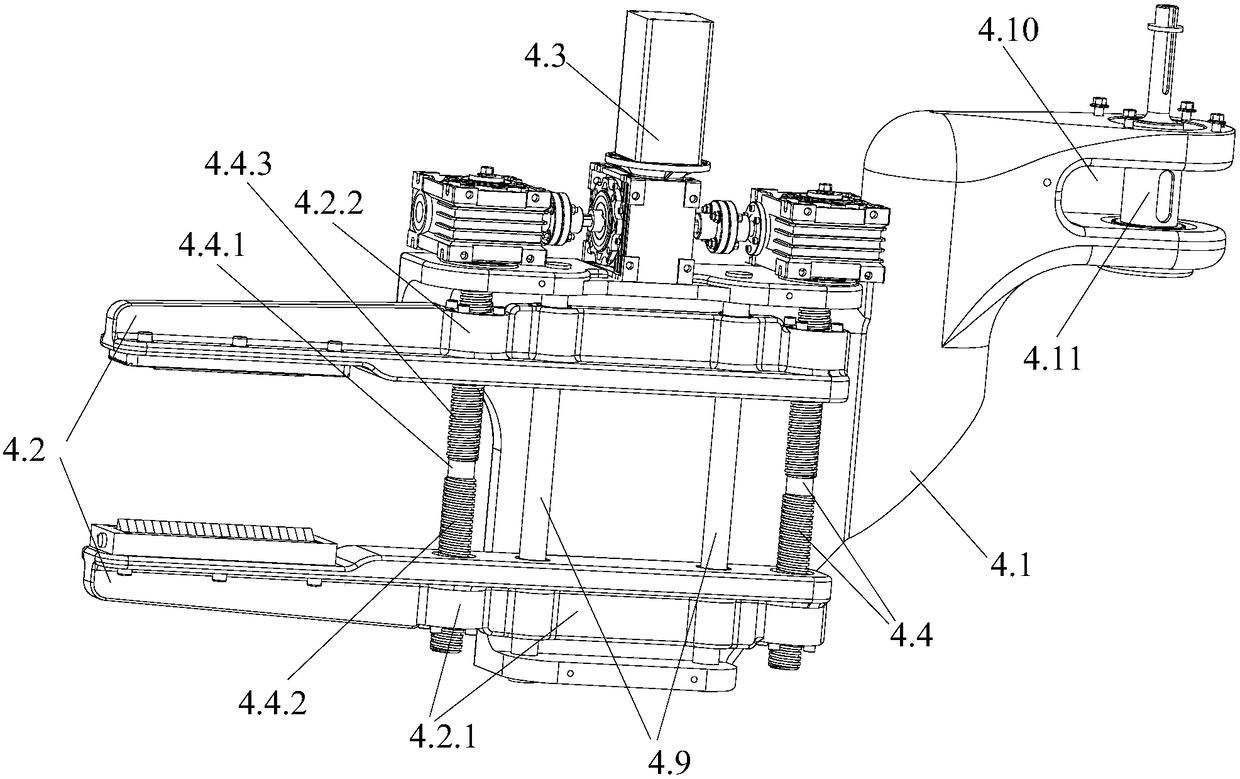

Vertical profile single-rail traction robot

The invention provides a vertical profile single-rail traction robot. The vertical profile single-rail traction robot comprises a vertical walking rail, a mechanical arm for clamping and towing a profile, a transmission mechanism, a driving mechanism for connecting with the transmission mechanism, and a control mechanism; the mechanical arm is buckled on the side surface of the vertical walking rail, and is slidingly connected with the side surface of the vertical walking rail to realize walking movement by hanging on the side surface of the vertical walking rail; the transmission mechanism consists of a transmission device 1 arranged on the mechanical arm and a transmission device 2 arranged on the vertical walking rail; and the control mechanism is respectively in signal connection with the driving mechanism and the mechanical arm. The vertical profile single-rail traction robot adopts the mechanical arm as an actuation mechanism for towing the profile, and is flexible in operation and convenient for control. Meanwhile, the vertical profile single-rail traction robot can shrink the floor area to reduce the production cost, and is not influenced by the ground condition to effectively solve the problem of incapability of guaranteeing the profile towing straightness caused by uneven ground so as to improve the profile towing processing quality.

Owner:广东泰格威机器人科技有限公司

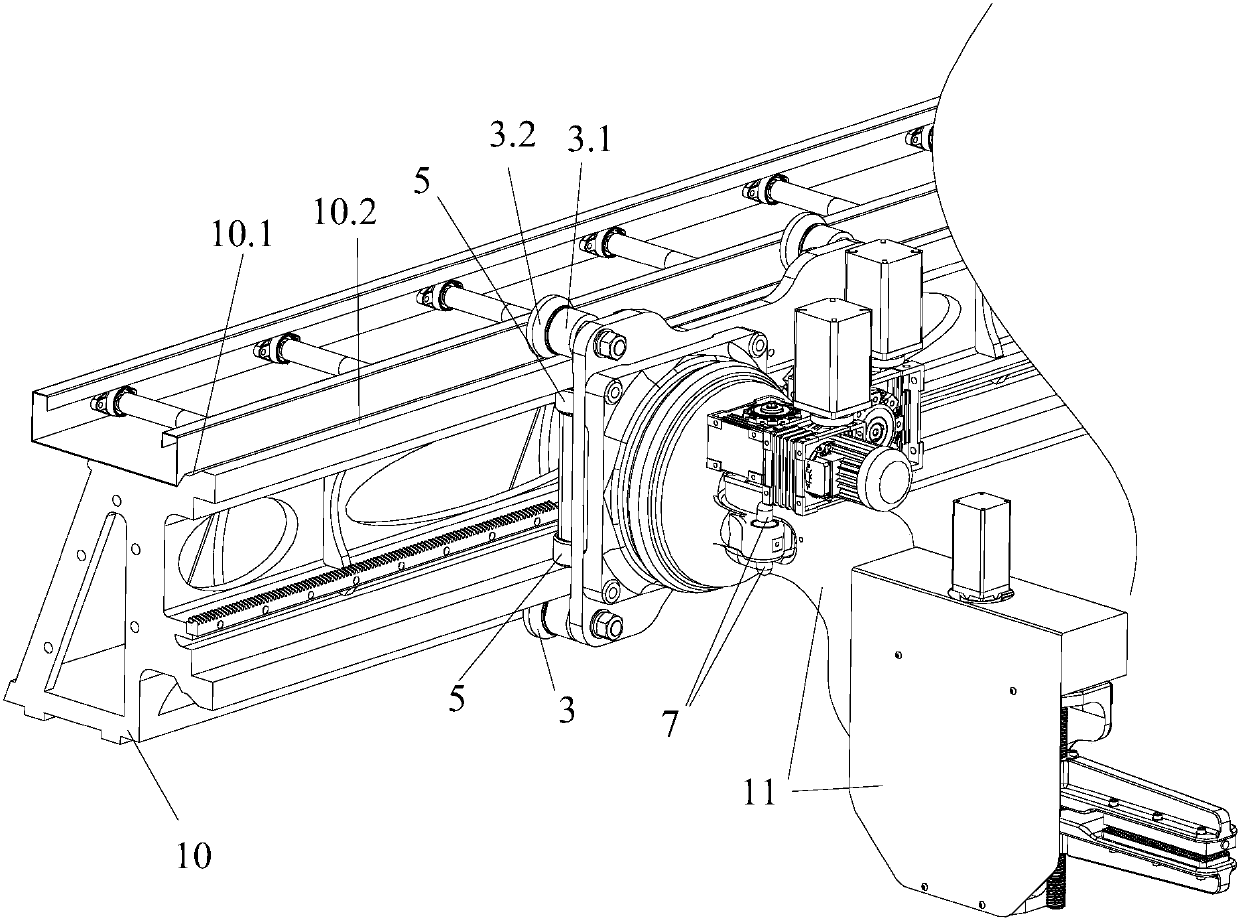

Novel profile pulling method

The invention provides a novel profile pulling method. A vertical pulling robot is used for pulling a profile. The vertical pulling robot is formed by overlapping and splicing M pulling units in the vertical direction. Each pulling unit is provided with a vertical type walking track and a mechanical arm moving on the vertical type walking track. M is a natural number which is greater than or equal to 2. The mechanical arms of every two adjacent pulling units are hung on the vertical type walking tracks and move in a cooperatively alternating and mutual avoiding mode, so that the profile is pulled in a cooperatively alternating mode. According to the novel profile pulling method, the practicality is high, the pulling speed is high, the profile can be fully automatically pulled in a multi-track mode according to production requirements, and therefore the profile pulling efficiency is improved, an efficient and stable pulling effect can be achieved, full-automatic and intelligent profile pulling processing is achieved, and the novel profile pulling method is suitable for large-scale production.

Owner:广东省智行机器人科技有限公司

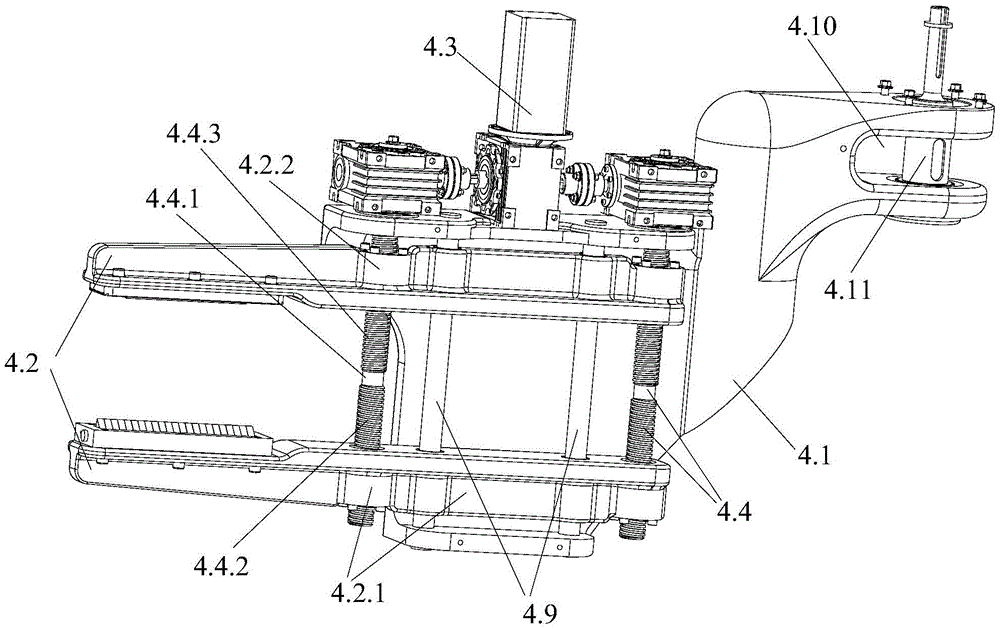

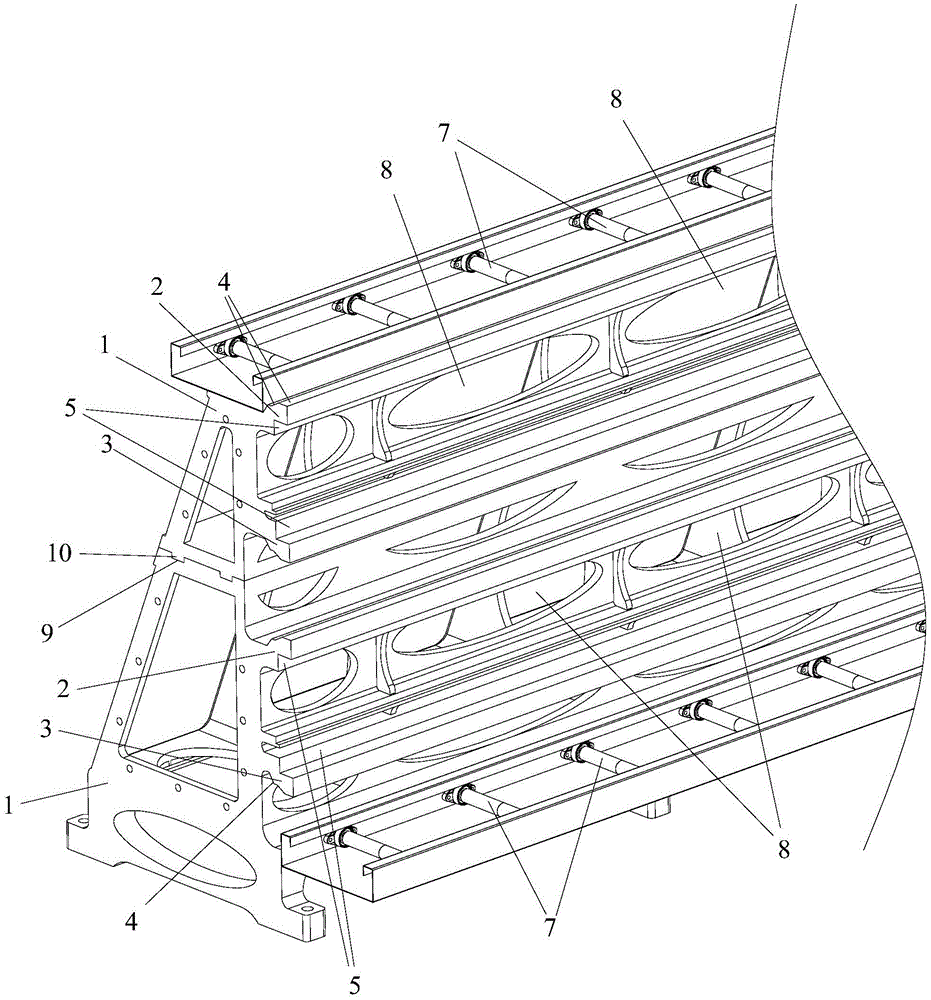

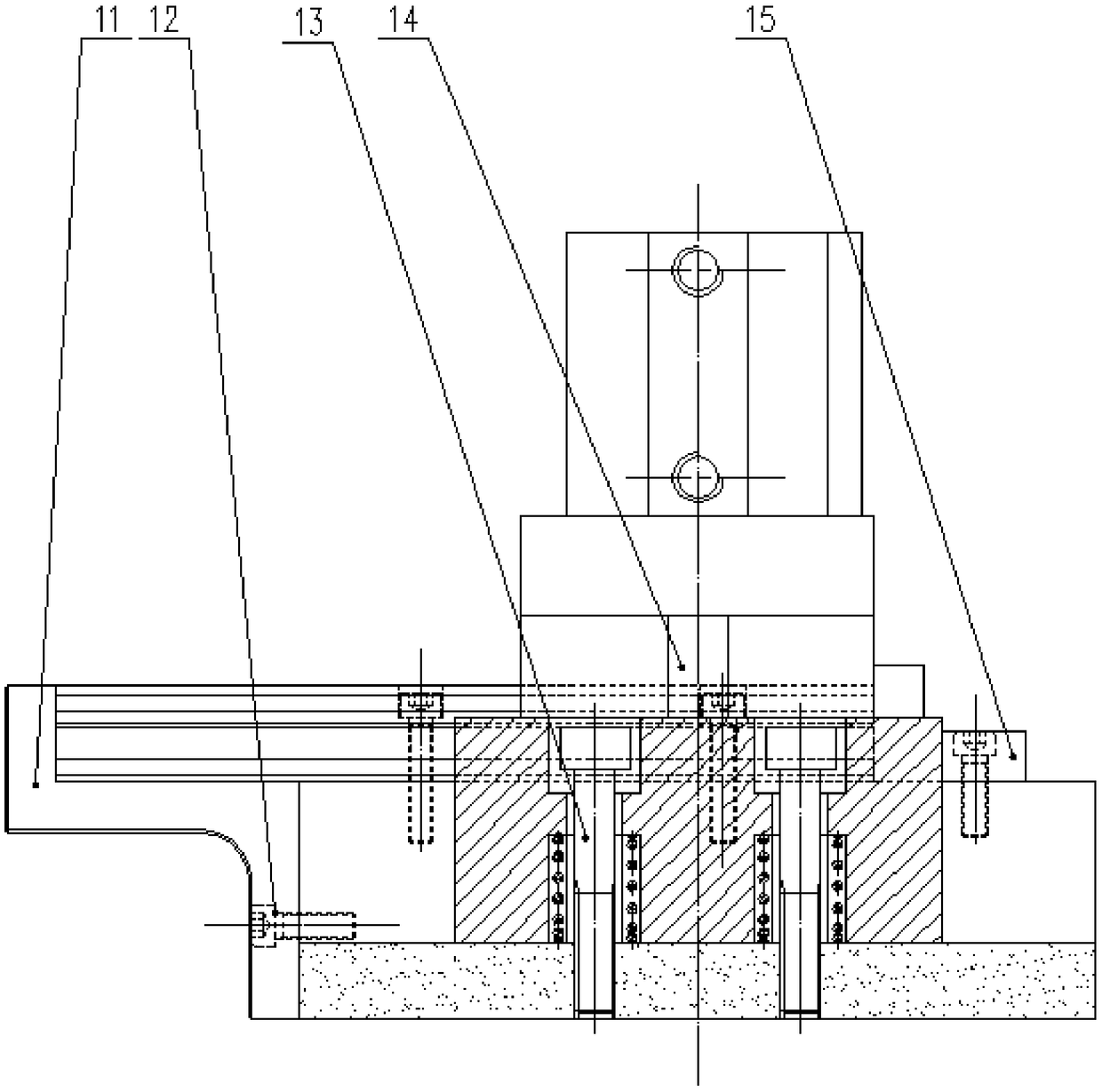

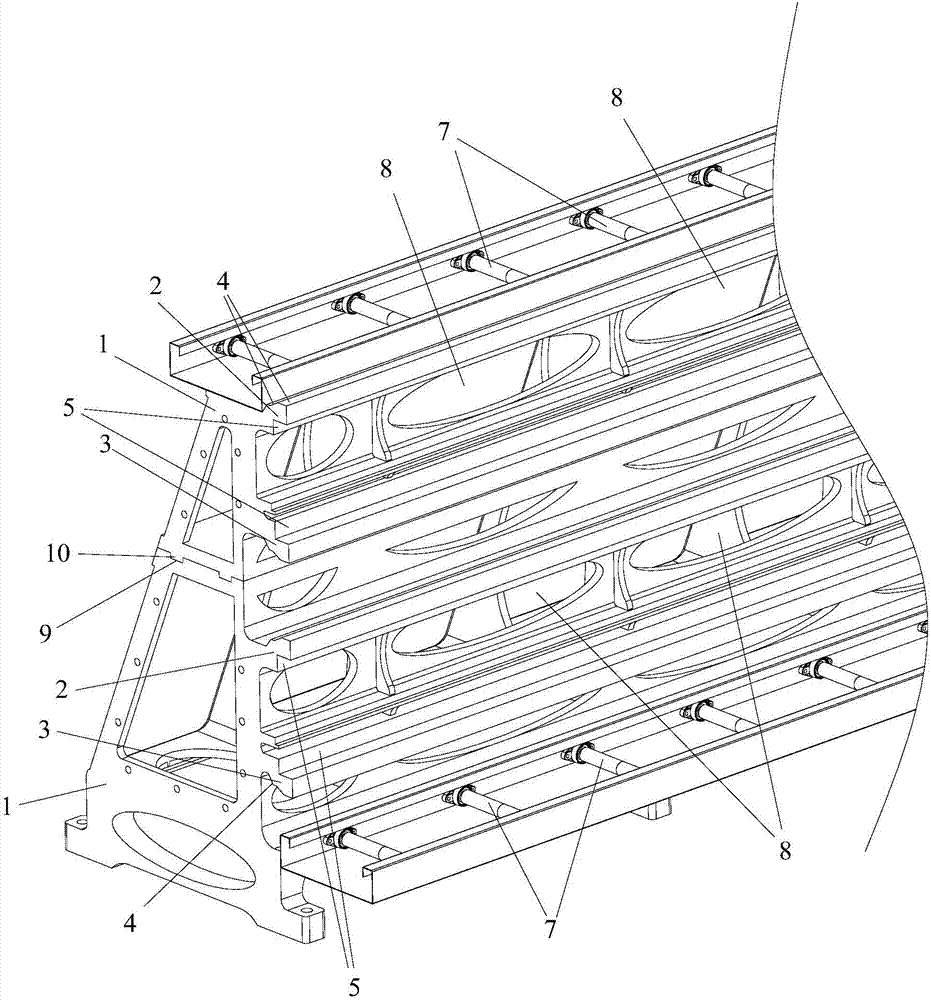

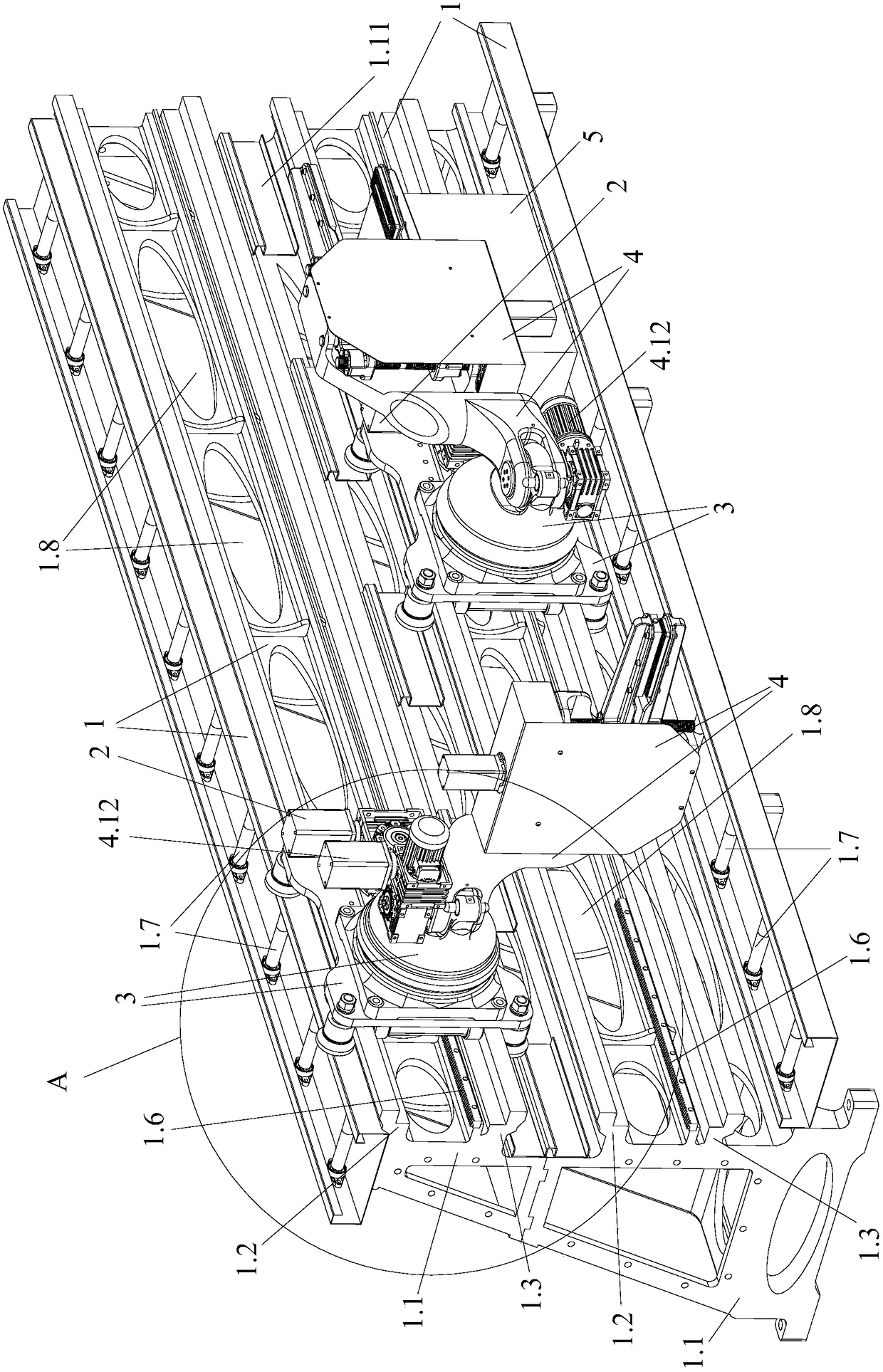

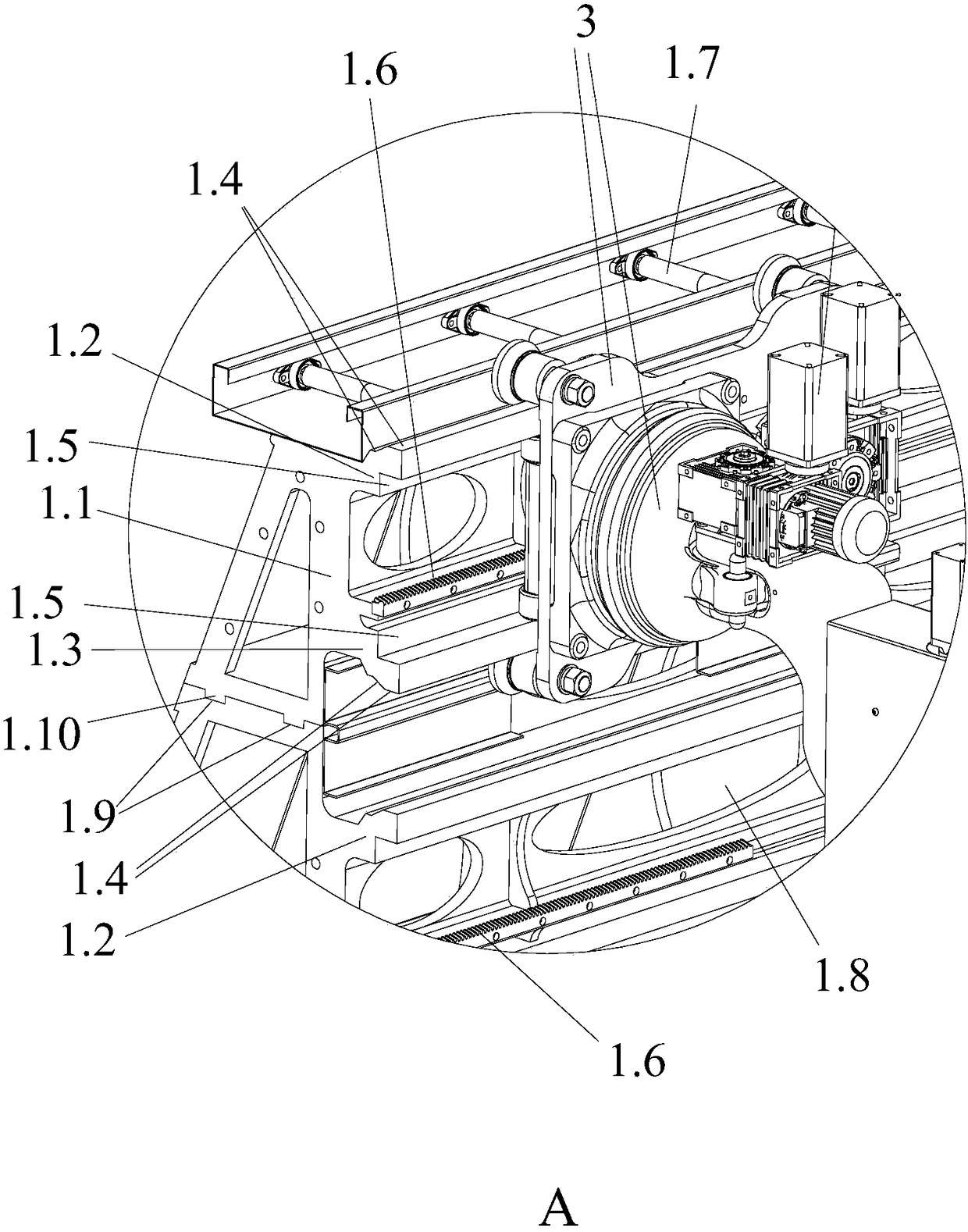

Vertical multi-track pulling robot for section bars

ActiveCN105598942AImprove the efficiency of automatic tractionExpand traction workspaceManipulatorEngineeringElectrical and Electronics engineering

The invention provides a vertical multi-track pulling robot for section bars. The vertical multi-track pulling robot comprises M pulling units and a control mechanism. Each pulling unit comprises a vertical travel track, a mechanical arm, a transmission mechanism and a driving mechanism, the mechanical arms are used for clamping and pulling the section bars, the driving mechanisms are used for being connected with the transmission mechanisms, and the mechanical arms are clipped on the side surfaces of the vertical travel tracks and are slidably connected with the side surfaces of the vertical travel tracks, so that the mechanical arms can be suspended on the side surfaces of the vertical travel tracks and can travel and move; the transmission mechanisms comprise first transmission gears and second transmission gears, the first transmission gears are arranged on the mechanical arms, and the second transmission gears are arranged on the vertical travel tracks; the M pulling units are spliced with one another in an overlapped manner by the aid of the vertical travel tracks, and the mechanical arms of each two adjacent pulling units are suspended on the corresponding vertical travel tracks and can cooperatively alternately travel and move, so that the section bars can be pulled in a cooperative alternative manner. The vertical multi-track pulling robot has the advantages that the section bars can be fully automatically pulled in a multi-track mode according to production requirements, and accordingly the section bar pulling efficiency can be improved.

Owner:广东省智行机器人科技有限公司

Bending forming process and tool for square pipe

The invention belongs to the field of machine manufacturing, and particularly relates to a bending forming process and tool for a square pipe. The bending forming process comprises the following steps of (1) designing and manufacturing the tool: designing and manufacturing the dedicated tool according to the requirement of the bending size of the square pipe, wherein the tool comprises a substrate (1), a plurality of circle forming baffles (2) and a plurality of ejecting and pushing devices (3). The substrate (1) is used as the reference datum plane. The circle forming baffles (2) are fixed on the same surface of the substrate (1). The extension connecting lines of the baffles (2) coincide with the inner circle of a workpiece. The ejecting and pushing devices (3) is arranged along the excircle of the workpiece to provide needed external force for bending of the square pipe; (2) prebending the workpiece; (3) fixing the workpiece; (4) conducting hot straightening on the workpiece; and (5) removing the margin: removing the margin of the square pipe, forming a ring body after a joint is welded, and polishing a welding seam to be smooth. Through implementation of the bending forming process, indexes such as the roundness, the planeness and the appearance quality of the ring body after the square pipe is formed through bending can be effectively improved, the processing residual stress is removed, the structural strength of a product is improved, and compared with a conventional square pipe bending forming technology, the cost is low, the precision is high, and the process and the tool are suitable for popularization.

Owner:XINJIANG YIZHITE MACHINERY EQUIP MFG CO LTD

Method for preparing high-borosilicate anti-explosion glass cover

ActiveCN110117156AImprove tempering effectMeet safety requirementsGlass furnace apparatusElectric furnaceBorosilicate glassRaw material

The invention discloses a method for preparing a high-borosilicate anti-explosion glass cover. The high-borosilicate anti-explosion glass cover is prepared from, by mass, 69.5%-73.5% of SiO2, 12.5%-17.5% of B2O3, 5.5%-9.5% of Na2O, 1.5%-4.5% of Al2O3, 0.01%-0.05% of Li2O, 0.1%-0.6% of K2O, 0.1%-0.6% of BaO, 0.1%-0.5% of ZnO and 0%-0.03% of Fe2O3 in cooperation with high-borosilicate glass raw materials. An electric melting furnace with the highest use temperature of 1800 DEG C is used as founding equipment of the high-borosilicate anti-explosion glass cover, the glass raw materials are converted into glass clear liquid, and the founding process of glass is completed through the processes of silicate forming, clarification, homogenizing and cooling; the finished glass is formed through a forming process and toughening treatment in combination with planeness treatment. The method has the advantages of being capable of meeting the quality requirement and safety requirement of explosion-proof glass and has wide development and application prospects.

Owner:绥中明晖工业技术有限公司

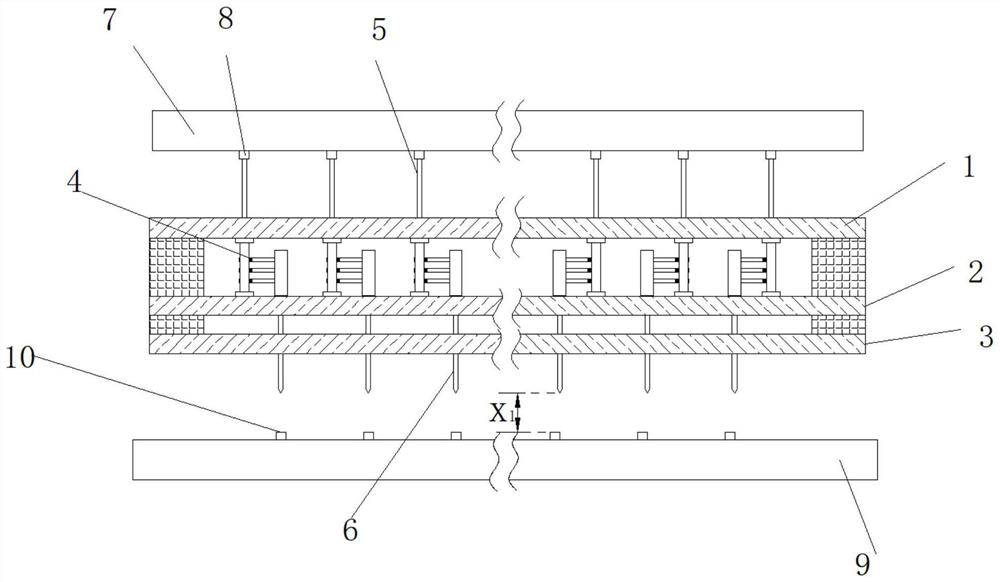

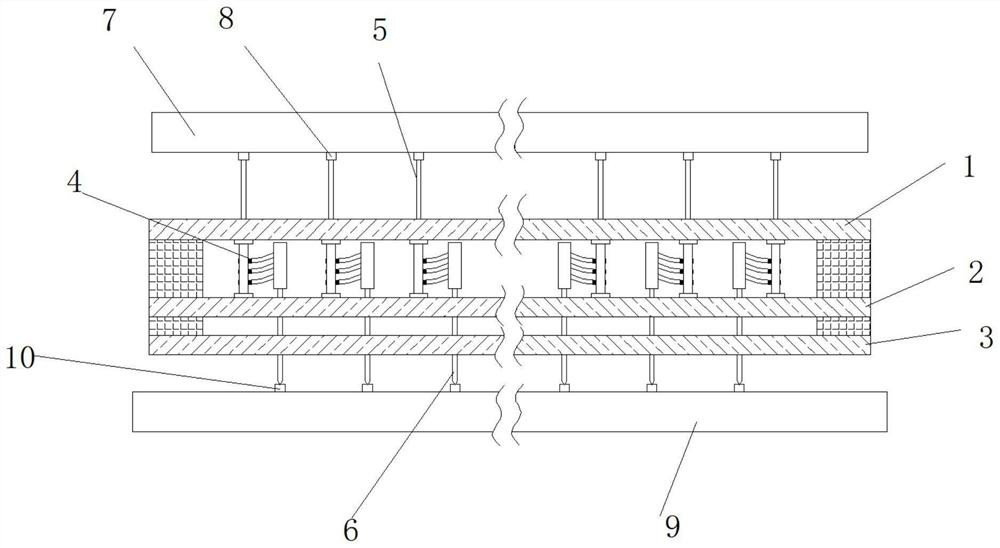

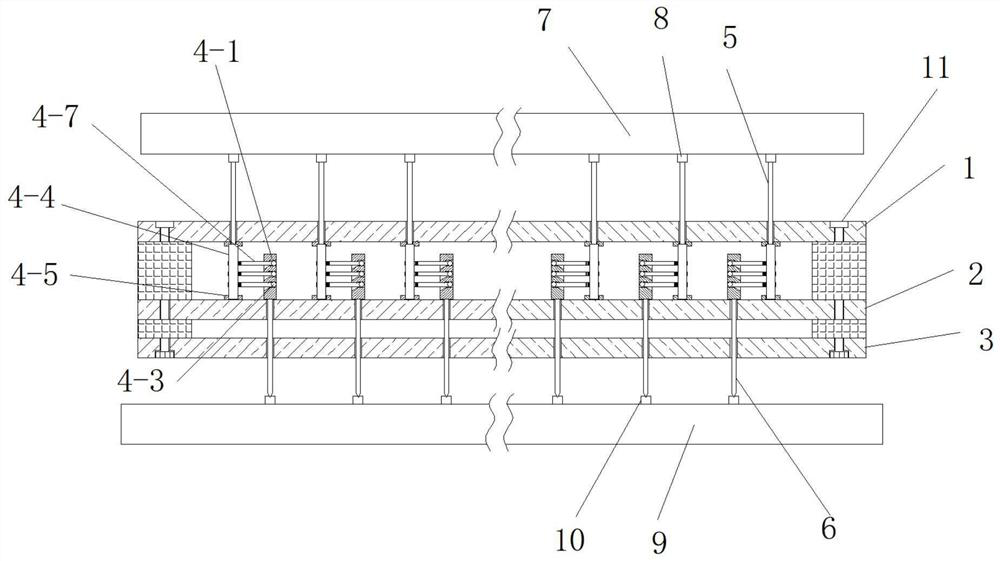

Vertical probe card device and detection method thereof

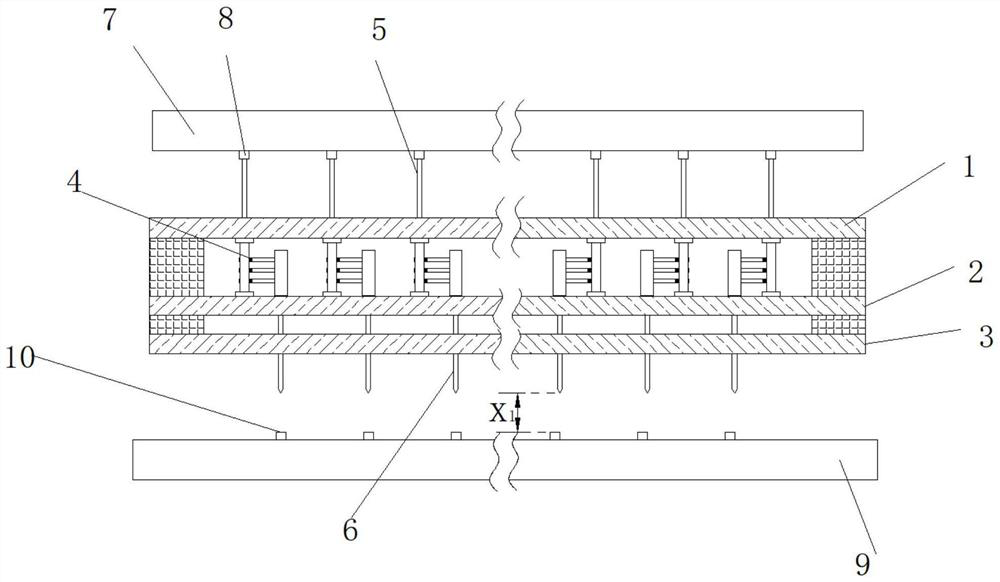

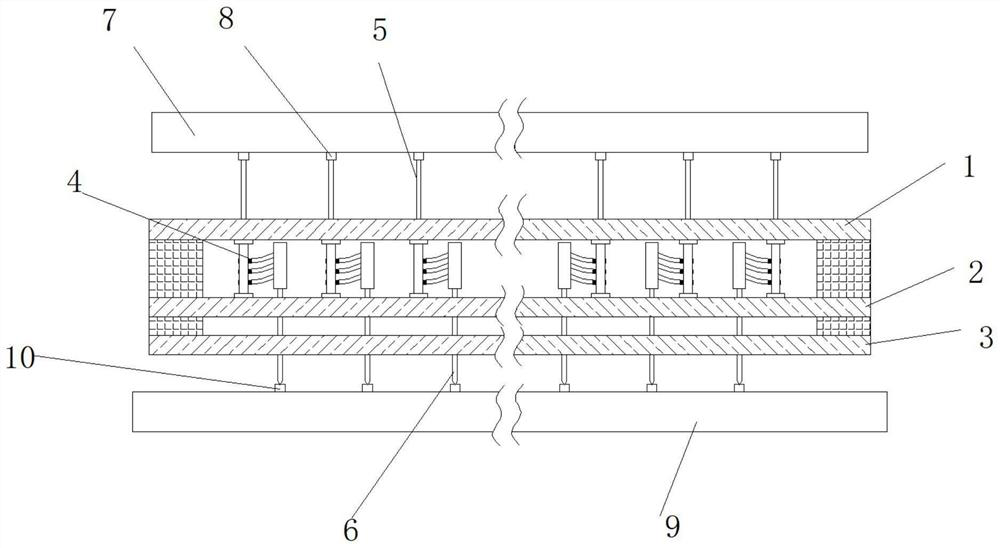

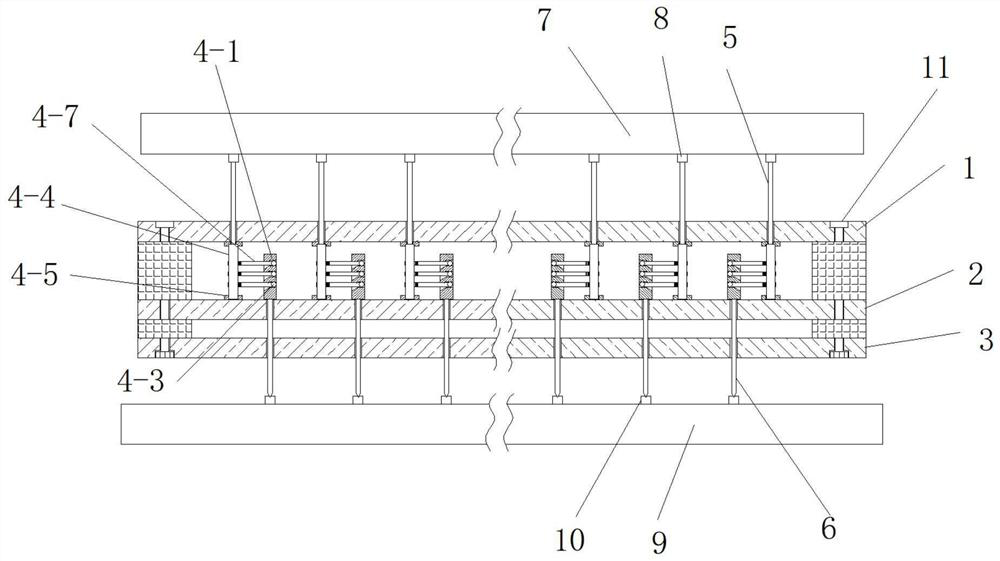

ActiveCN114034894ABending deformation will notBending deformation is not recoverableElectrical measurement instrument detailsElectrical testingProbe cardMechanical engineering

The invention discloses a vertical probe card device and a detection method thereof, and relates to the technical field of probe cards. The vertical probe card device comprises an upper-layer guide plate, a middle-layer guide plate, a lower-layer guide plate, deformation connecting devices, a first probe, a second probe, a circuit board and a first welding pad. The upper-layer guide plate, the middle-layer guide plate and the lower-layer guide plate are respectively and correspondingly provided with a plurality of vertical limiting through holes, a plurality of deformation connecting devices are arranged between the upper-layer guide plate and the middle-layer guide plate in an array mode, and one end of each of the first probes penetrates through the vertical limiting through hole of the upper-layer guide plate to be electrically connected with one end of each of the correspondingly-arranged deformation connecting devices; the detection method of the vertical probe card device sequentially comprises the steps of fixed installation, alignment and positioning, height setting, pressure boosting and closed circuit testing. According to the vertical probe card device and the detection method thereof, the problems of deformation and deviation of the existing probe, contact of the probe and replacement and repair of the probe are solved, so that the effects of good contact, clear probe marks and effective utilization are achieved.

Owner:FTDEVICE TECH (SUZHOU) CO LTD

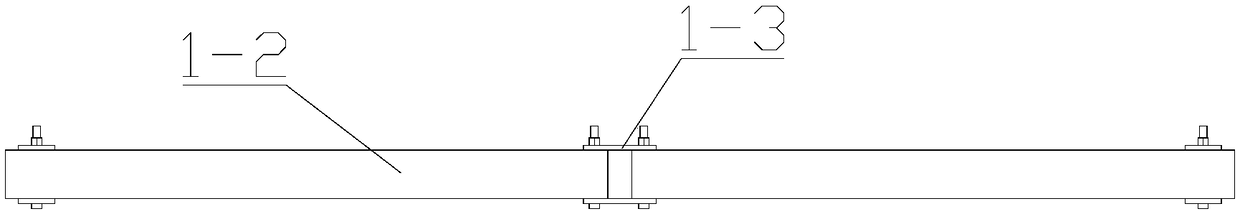

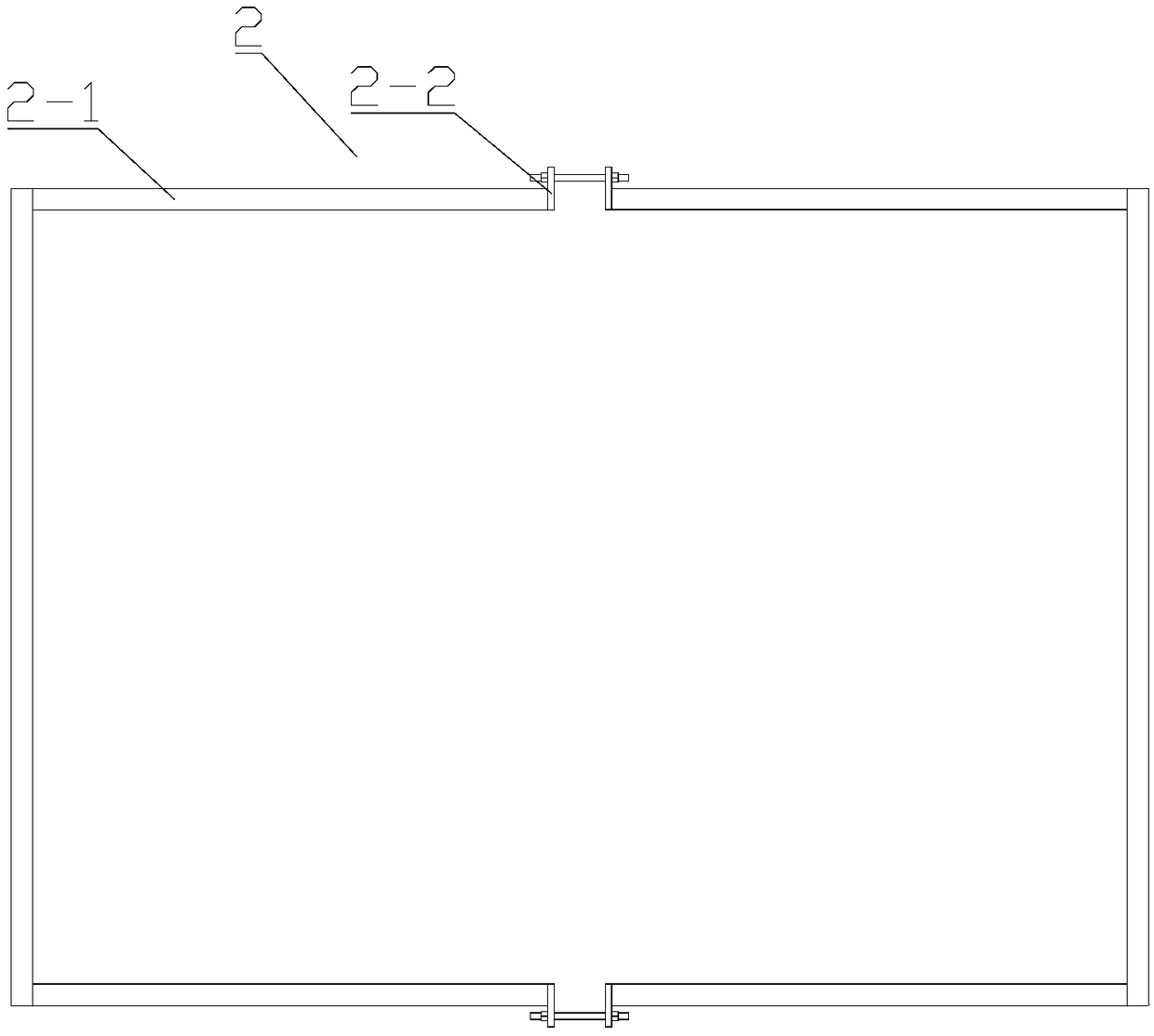

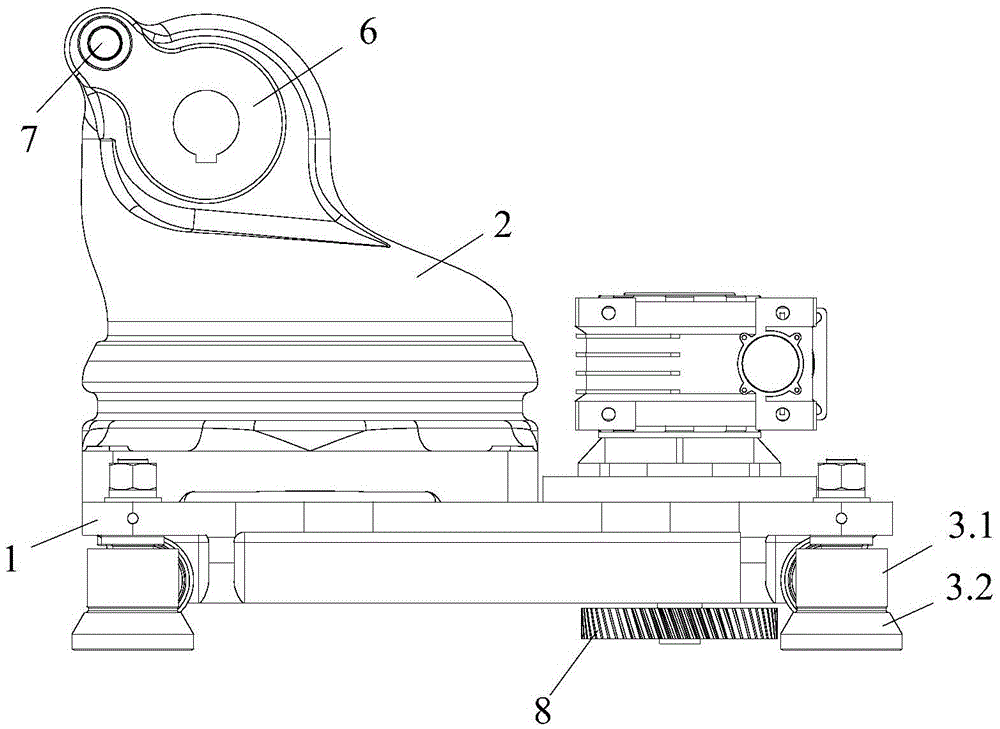

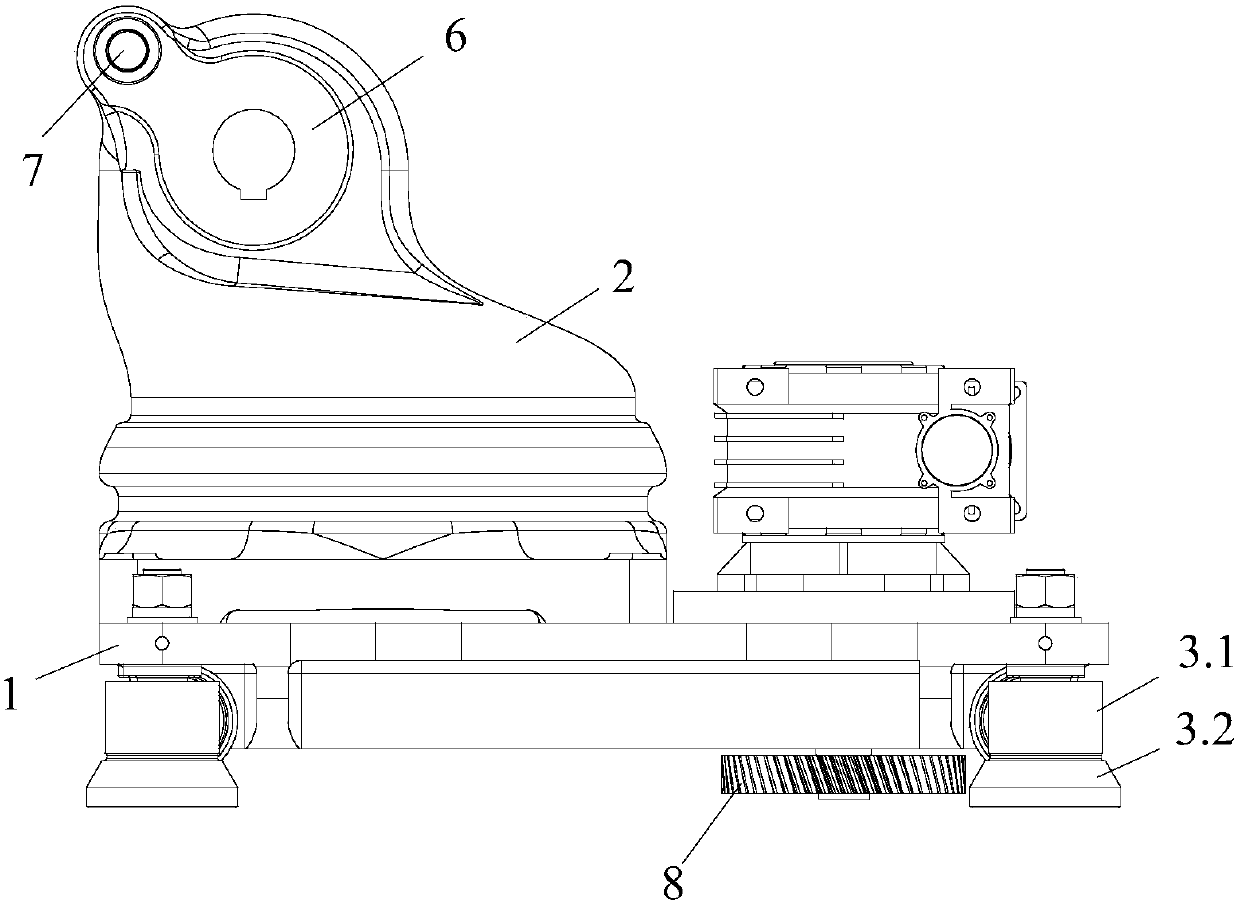

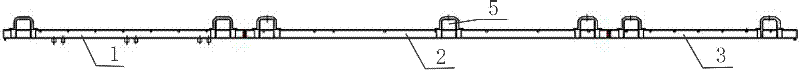

Vertical walking rail

The invention provides a vertical walking rail for slidingly connecting with a vertical walking mechanism to realize walking movement of a mechanical arm. The vertical walking rail comprises a frame; and a slide rail is arranged on the side surface of the frame in the length direction, and is used for buckling and slidingly connecting with a walking mechanism to realize walking movement of the walking mechanism by hanging on the side surface of the frame. The vertical walking rail can effectively solve the problem of incapability of guaranteeing walking movement straightness of the mechanical arm caused by uneven ground so as to improve the quality of the clamping arm clamping a profile for machining. Meanwhile, the vertical walking rail can reduce the movement floor space of the mechanical arm. The invention further provides a rail assembly; the rail assembly is formed by superposing more than two vertical walking rails; and two adjacent vertical walking rails realize superposition through a superposing part 1 arranged at the top of the lower walking rail and a superposing part 2 arranged at the bottom of the upper walking rail. The rail assembly is convenient for movement machining of multiple mechanical arms so as to improve the machining efficiency.

Owner:广东泰格威机器人科技有限公司

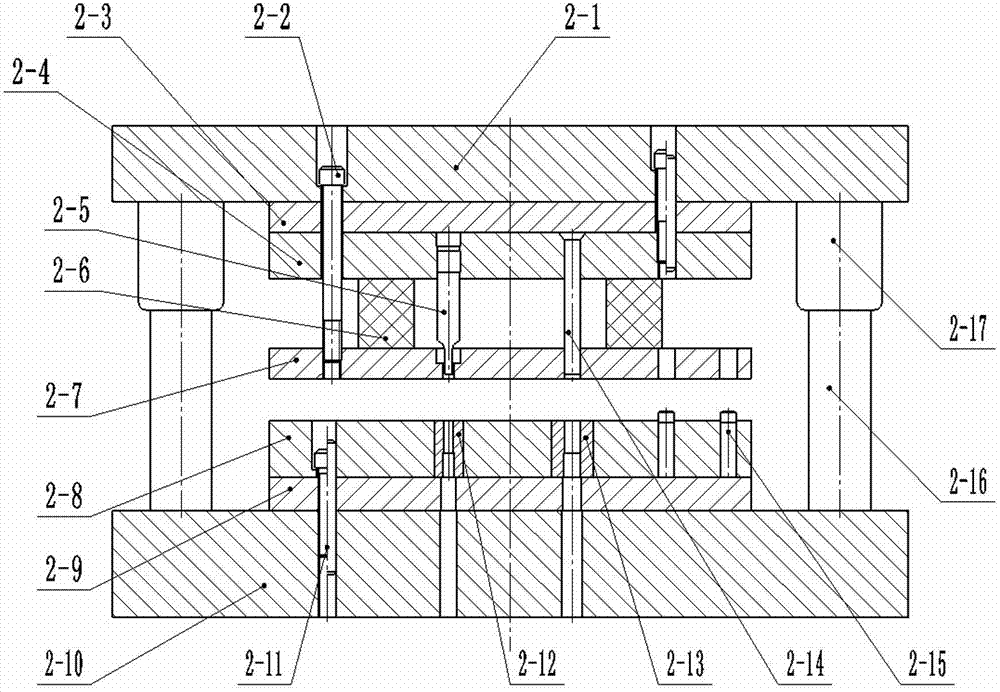

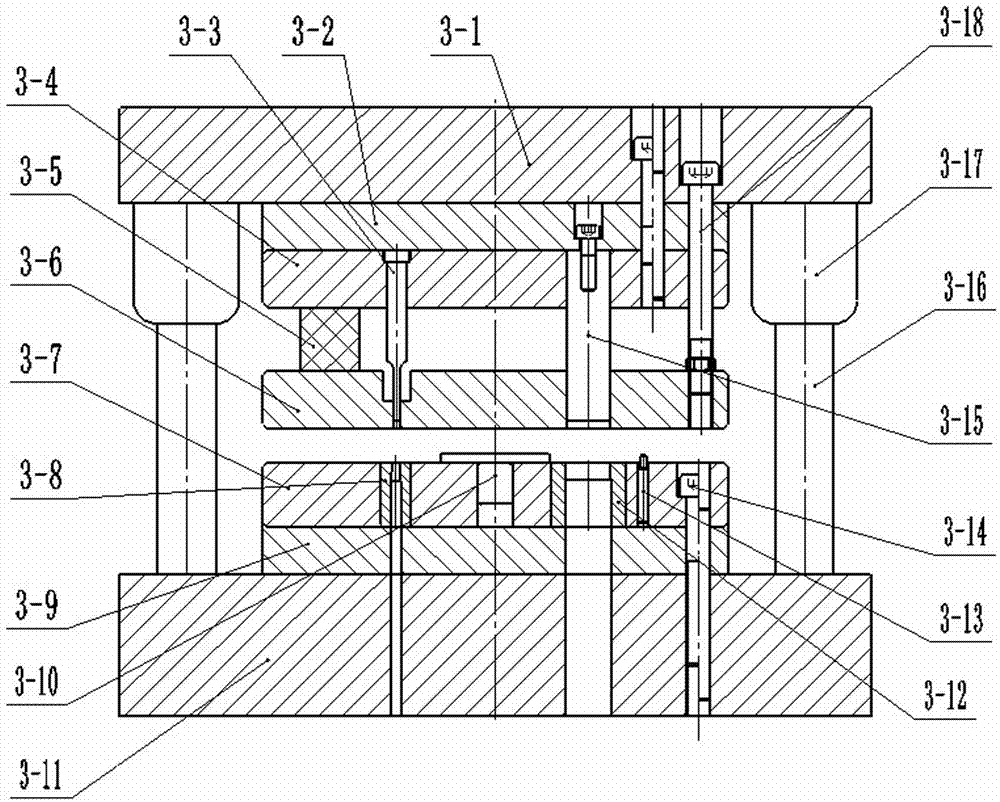

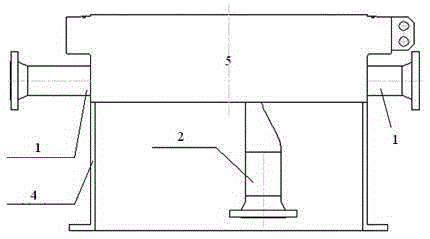

ECU sealing performance detection device with reliable sealing and pressing

ActiveCN108612751ASolve Flatness ProblemsSolve the problem of insufficient finishLinear bearingsFluid-tightness measurement using fluid/vacuumEngineeringMechanical engineering

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

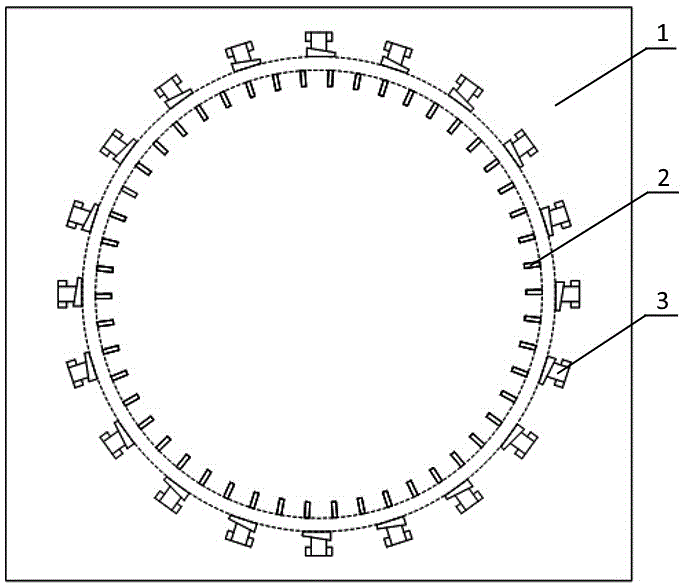

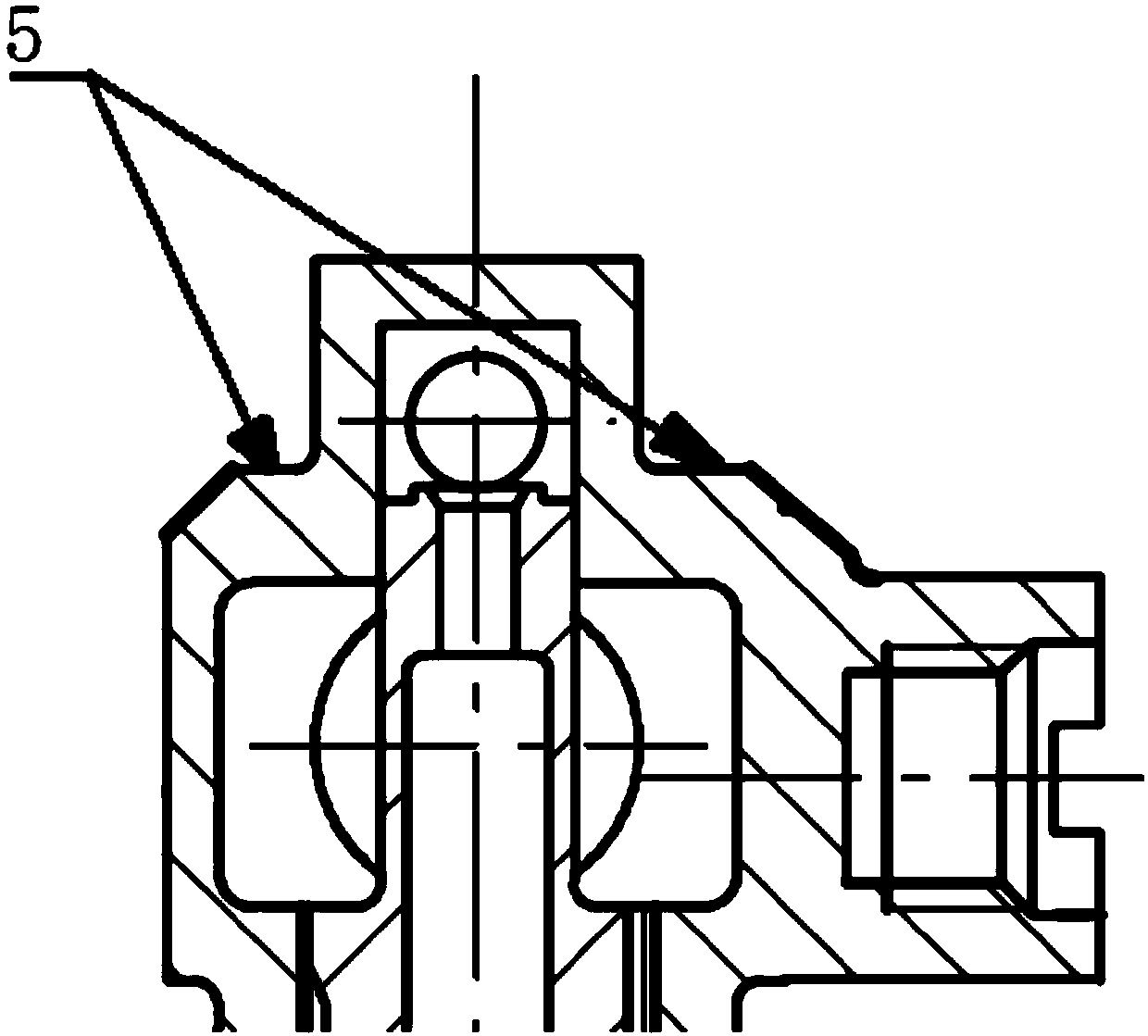

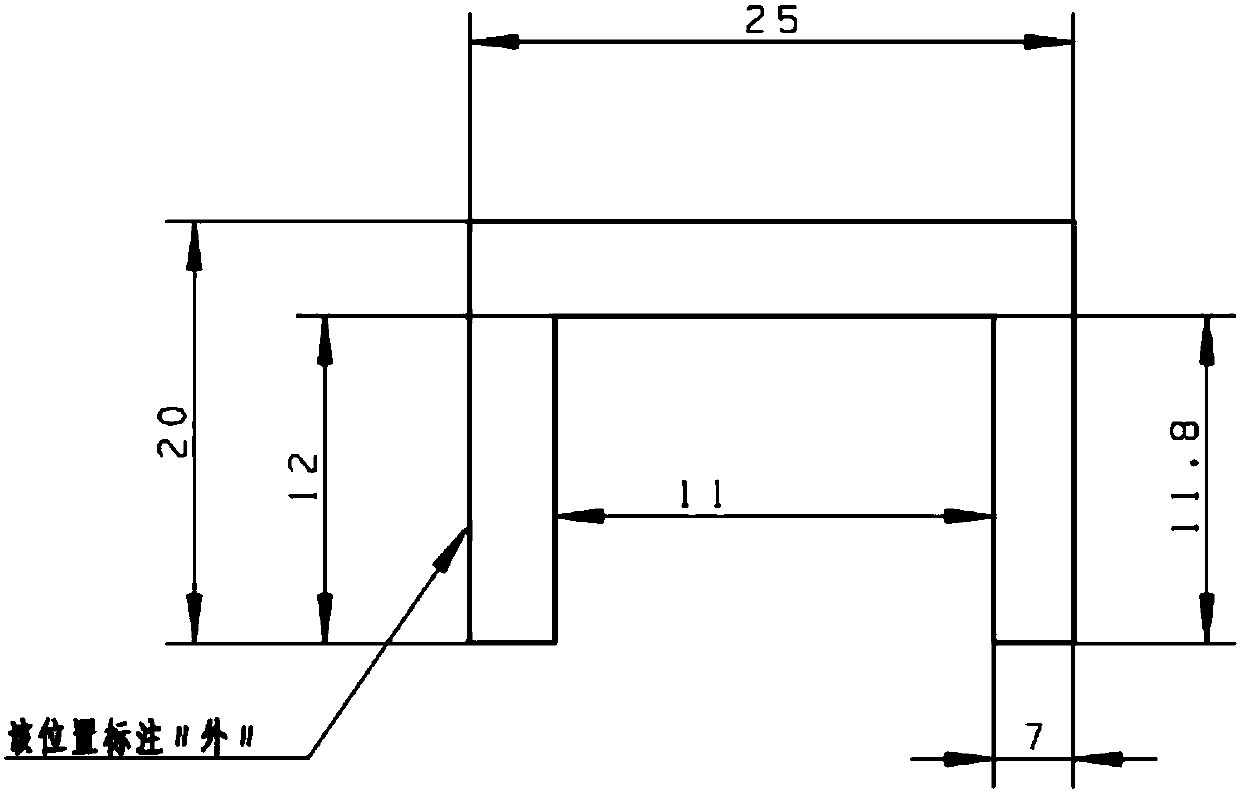

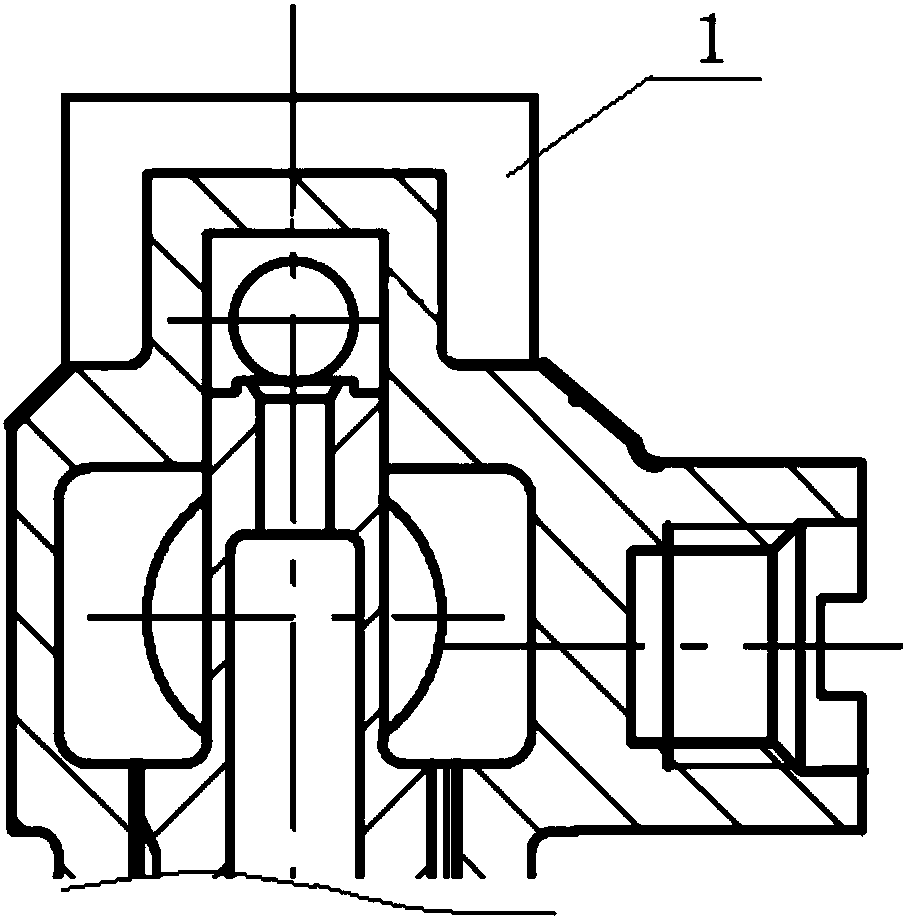

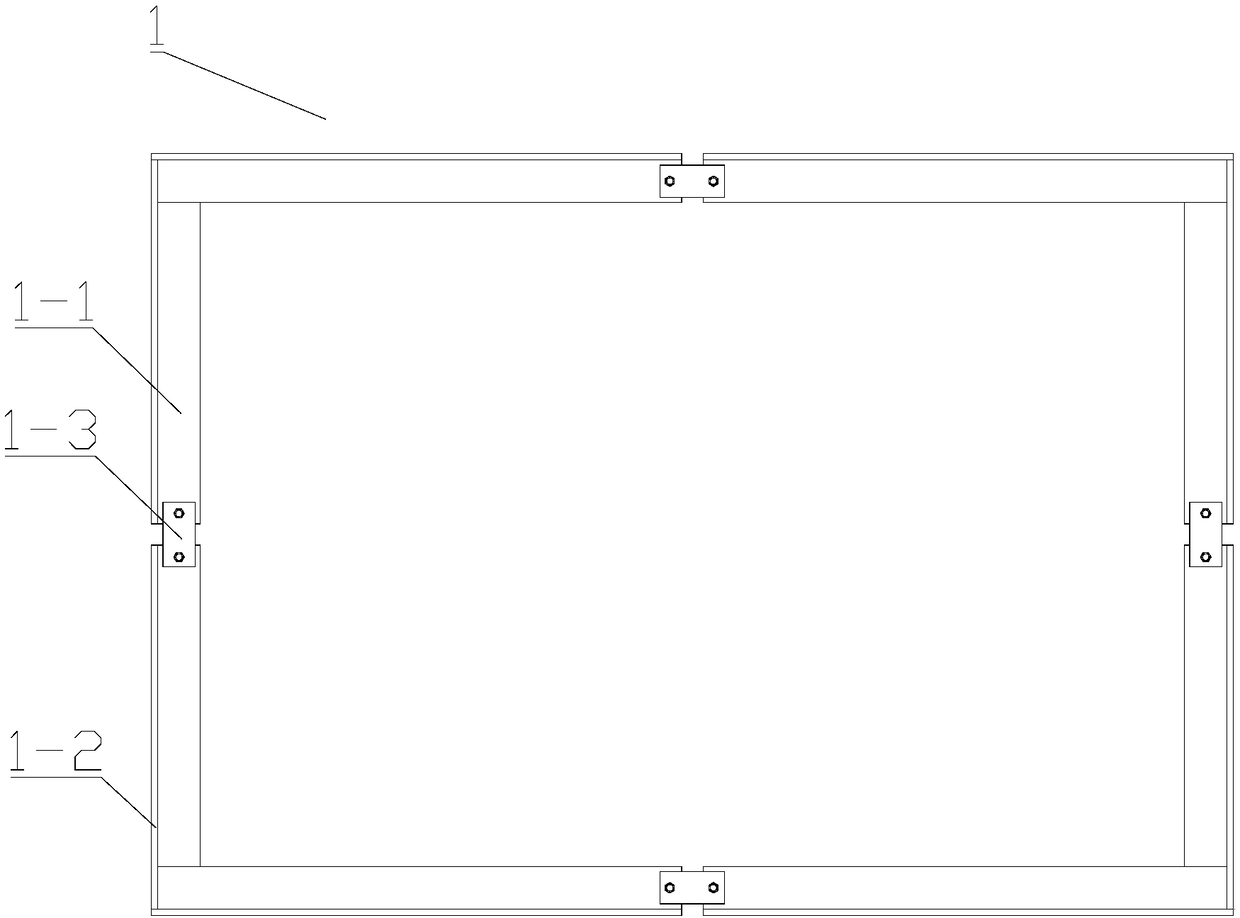

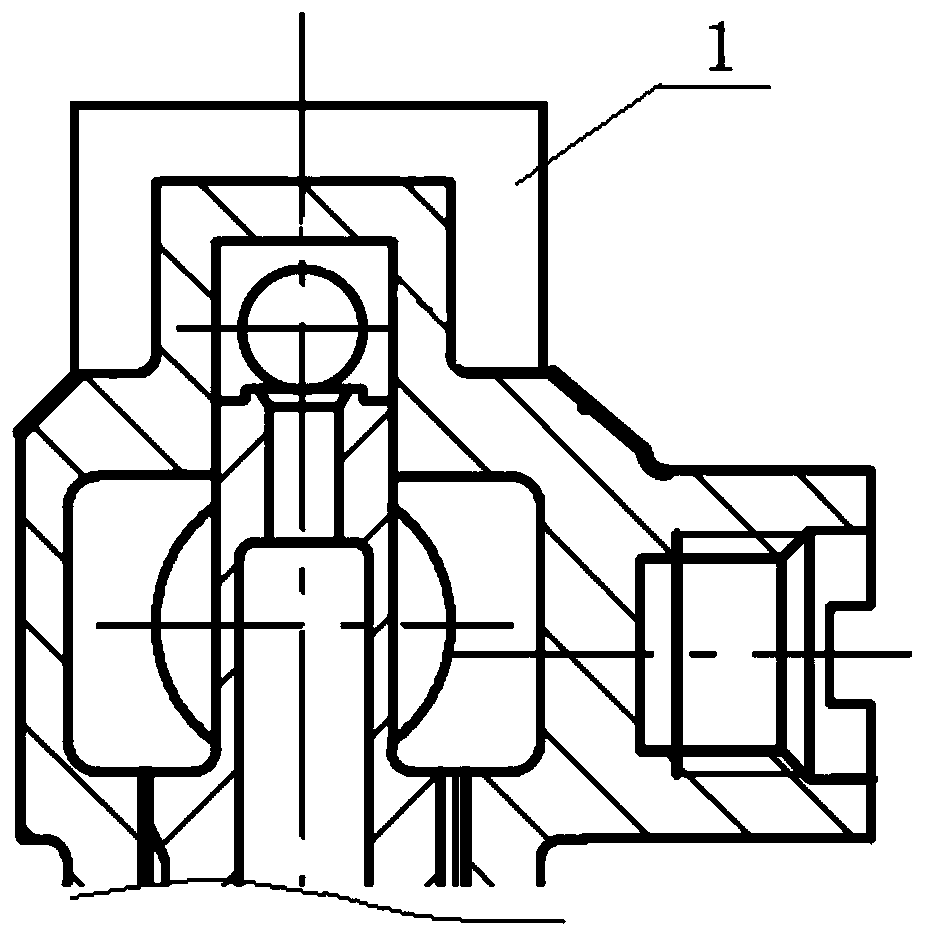

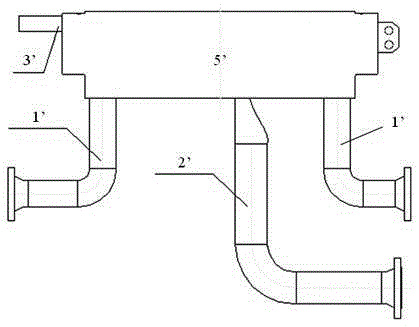

Clamp for controlling braze welding deformation of fuel manifold

The invention discloses a clamp for controlling braze welding deformation of a fuel manifold. The clamp comprises a pressing unit positioned on the upper end surface of a nozzle and a supporting unitpositioned on the lower end surface of the nozzle, wherein the pressing unit comprises a stainless steel structural part (1) with a door-shaped section; two vertical sides of the structural part (1) are equal in width, but not equal in length; the supporting unit comprises a circular-ring-shaped base body (2), wherein observing holes (3) are formed in the outer periphery of the circular-ring-shaped base body (2) at equal intervals; and a supporting base (4) is arranged on a position, on the upper end surface of the circular-ring-shaped base body (2), between two adjacent observing holes (3). The clamp overcomes the problem that the end surface of the braze-welded nozzle is irregular and tilts, so that design requirements with planeness smaller than or equal to 0.3 mm are met, follow-up correcting difficulty is reduced, correcting working hours are shortened, and production efficiency is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

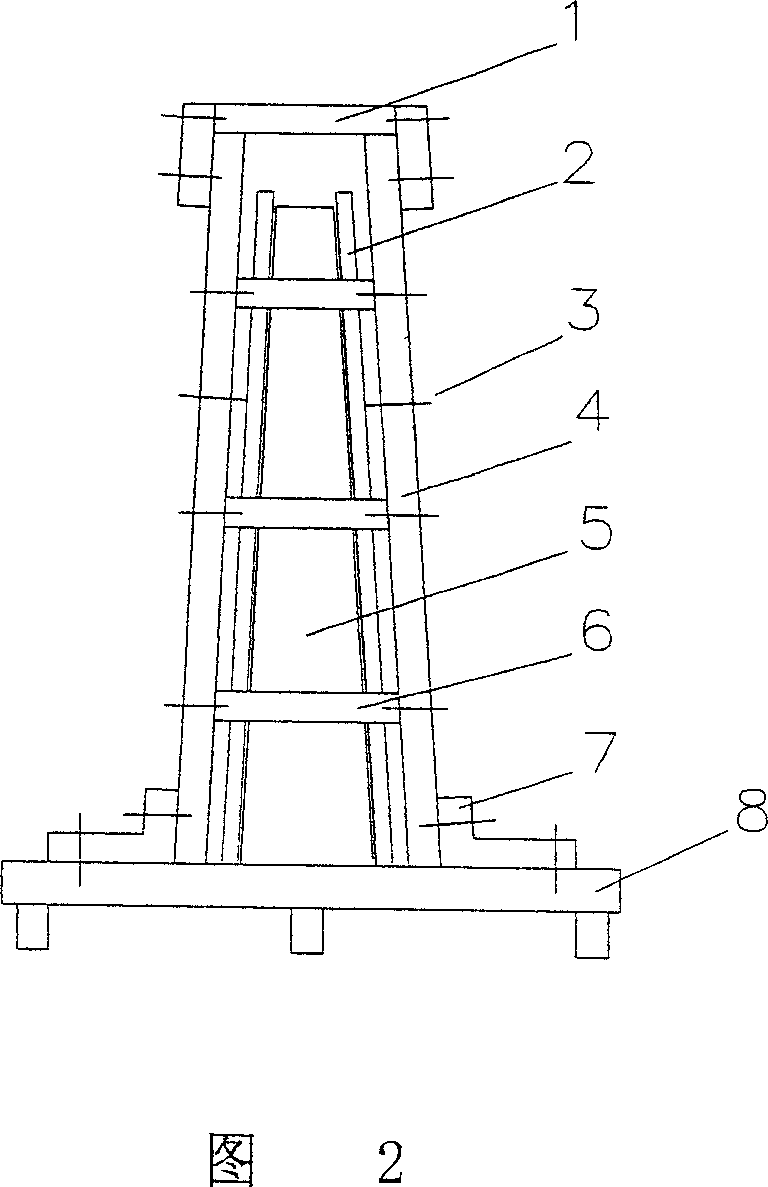

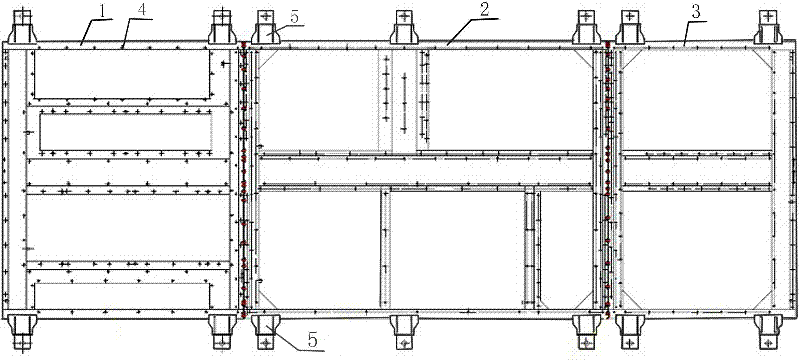

Welding fixture and welding method for ensuring flatness of hot chamber shell

PendingCN109202354ASolve Flatness ProblemsWelding/cutting auxillary devicesArc welding apparatusEngineeringWelding deformation

The invention relates to the technical field of heat chamber shell processing, in particular to a welding fixture for ensuring the flatness of the heat chamber shell. The fixing fixture comprises an inner tube frame disposed inside the hot chamber housing and an outer tube frame disposed outside the hot chamber housing. The welding method comprises following steps: (1) setting two inner tube frames on the platform and ensuring that the projections of the two inner tube frames on the platform are completely coincident; (2) a part A and a part B of the heat chamber shell are sleeved on the innertube frame; (3) two outer tube frames are sleeved on the exterior of the heat chamber shell; (4) deformation prevention is performed on the A and B parts of the heat chamber shell before welding; (5)manual argon arc welding is used to weld the butt wire of the hot chamber shell. The invention provides a welding fixture and a welding method for ensuring the flatness of a hot chamber shell, whichare improved from three aspects of an assembly mode, a tooling and welding deformation prevention, so as to solve the problem that the flatness of the hot chamber shell box is over-poor.

Owner:PINGHU HEQI HEAVY MACHINERY

Upper shear blade front pressing plate device of pendulum shear

InactiveCN104439495AFast tempoImprove straightnessShearing machine accessoriesHydraulic cylinderEngineering

The invention discloses an upper shear blade front pressing plate device of a pendulum shear. Upper shear blades are arranged at sharp corners of the lower portions of upper shear frames, vertically-coaxial through holes are formed in an upper hanging plate and a lower hanging plate of the upper portion of each upper shear frame in the rolled piece entering direction, the edges of the two through holes are each provided with a sliding sleeve, and a connecting rod is arranged in the two through holes of each upper shear frame and the corresponding sliding sleeves in a sliding mode. A protection cover is fixedly arranged on the edge of the through hole in the upper surface of each upper shear frame, the protection covers, the sliding sleeves and the connecting rods are arranged coaxially, the upper ends of the protection covers and flanges at the front ends of cylinder bodies of hydraulic cylinders are fixedly connected, piston rods of the hydraulic cylinders are connected with the connecting rods downwards through flange sleeves, and the lower ends of the connecting rods are fixedly connected with pressing plates through pressing plate nuts. According to the device, the duckbilled pressing plates can guarantee that rolled pieces enter the pendulum shear smoothly, therefore, the function of a guide belt is achieved, the problem that the rolled pieces are piled up in front of the shear blades is solved, the shear face is straight, and shear quality is obviously improved.

Owner:MCC SFRE HEAVY IND EQUIP

A vertical profile multi-track traction robot

ActiveCN105598942BImprove efficiencySolve Flatness ProblemsManipulatorEngineeringElectrical and Electronics engineering

The invention provides a vertical multi-track pulling robot for section bars. The vertical multi-track pulling robot comprises M pulling units and a control mechanism. Each pulling unit comprises a vertical travel track, a mechanical arm, a transmission mechanism and a driving mechanism, the mechanical arms are used for clamping and pulling the section bars, the driving mechanisms are used for being connected with the transmission mechanisms, and the mechanical arms are clipped on the side surfaces of the vertical travel tracks and are slidably connected with the side surfaces of the vertical travel tracks, so that the mechanical arms can be suspended on the side surfaces of the vertical travel tracks and can travel and move; the transmission mechanisms comprise first transmission gears and second transmission gears, the first transmission gears are arranged on the mechanical arms, and the second transmission gears are arranged on the vertical travel tracks; the M pulling units are spliced with one another in an overlapped manner by the aid of the vertical travel tracks, and the mechanical arms of each two adjacent pulling units are suspended on the corresponding vertical travel tracks and can cooperatively alternately travel and move, so that the section bars can be pulled in a cooperative alternative manner. The vertical multi-track pulling robot has the advantages that the section bars can be fully automatically pulled in a multi-track mode according to production requirements, and accordingly the section bar pulling efficiency can be improved.

Owner:广东省智行机器人科技有限公司

Optional processing process of clutch driven disc

ActiveCN103111523BIncrease productivityExtend your lifeShaping toolsPerforating toolsFlatness problemPunch press

The invention discloses an optional processing process of a clutch driven disc. The process is that shapes of the outside, a central hole, a phi10 hole and a phi 12 hole of the driven disc are punched by raw materials on a punch through dies for blanking and punching the central hole, the phi 10 hole and the phi 12 hole in a gap mode; then shapes of a phi 6.2 hole, a phi 5.2 hole and a spacing hole of the driven disc are punched on a pressure machine tool through dies of the phi 6.2 hole, the phi 5.2 hole and the spacing hole; and finally shapes of a window and a long U-shaped groove are directly formed on the punch through dies for punching the window and the groove for once. The optional processing process of the clutch driven disc has the advantages of canceling heat treatment and leveling, solving an extremely bad flatness problem, being environment-friendly as well as energy-saving and cost-reducing, improving work efficiency, reducing cost and errors accumulated in a plurality of processes, and improving product size procession. Subsequent processes are uniform in processing standards, processing quality and precision are guaranteed, service life of a driven disc assembly is greatly prolonged, and performance of the driven disc assembly is greatly improved.

Owner:GUILIN FUDA

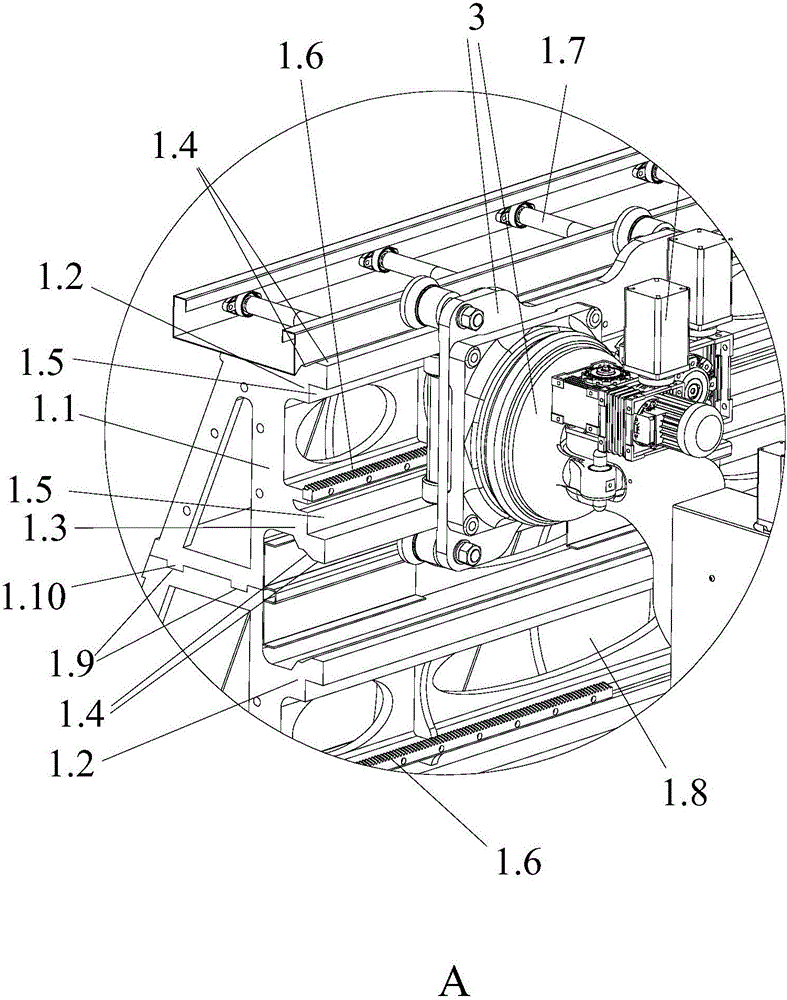

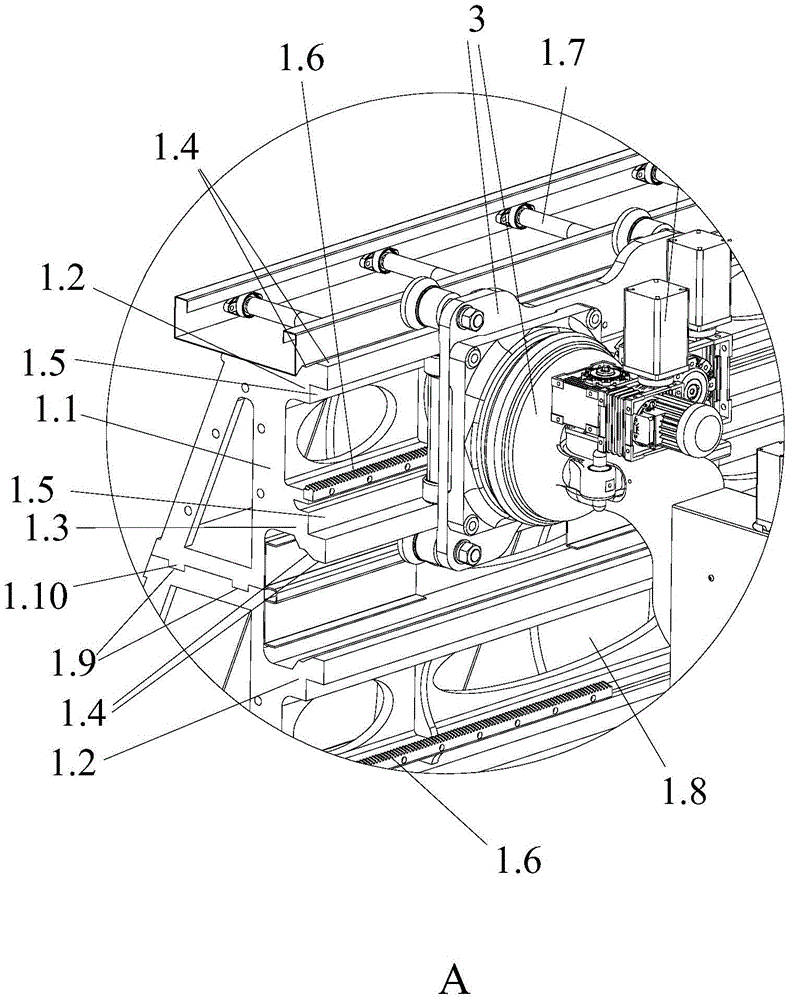

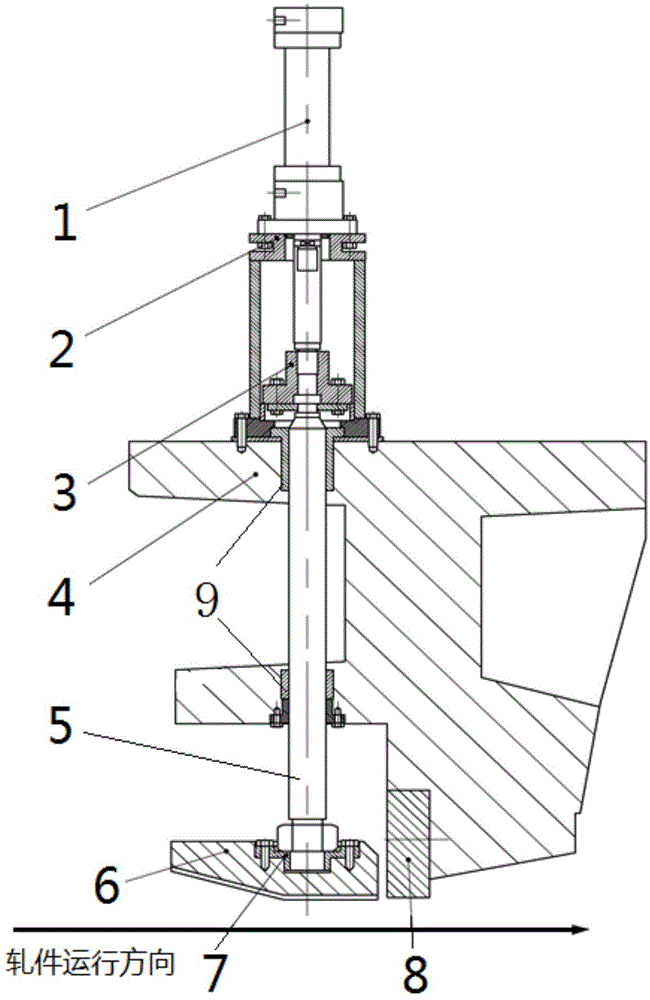

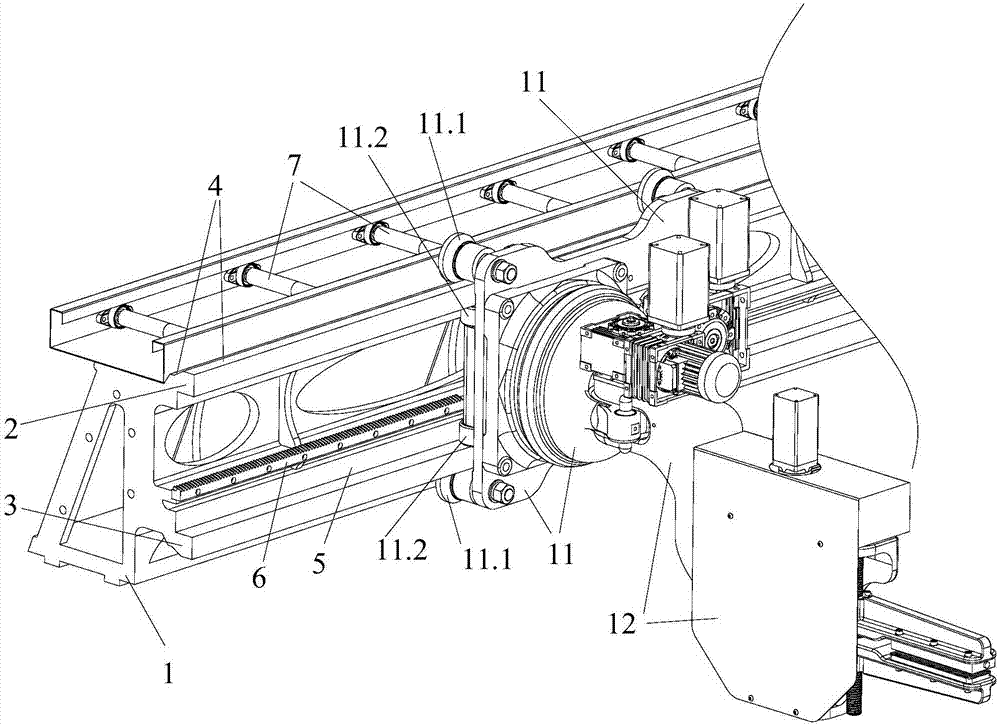

Vertical travel mechanism

ActiveCN105598731AQuality improvementSolve Flatness ProblemsDriving apparatusEngineeringControl theory

The invention provides a vertical travel mechanism. The vertical travel mechanism is used for being slidably connected with a vertical track, so that a mechanical arm can travel and move. The vertical travel mechanism comprises a frame and a base. The base is used for mounting the mechanical arm; one end of the base is detachably connected with the frame, and the other end of the base is used for being connected with the mechanical arm; a sliding device is arranged at the bottom of the frame and is used for being clipped on slide rails on the side surfaces of the vertical track and is slidably connected with the slide rails, so that the frame can be suspended on the side surfaces of the vertical track and can travel and move. The vertical travel mechanism has the advantages that the problem that the travel and movement straightness and flatness of an existing mechanical arm cannot be guaranteed due to uneven grounds can be effectively solved, and accordingly the machining quality of section bars clamped by the mechanical arm can be improved; movement occupied spaces of the mechanical arm can be reduced by the aid of the vertical travel mechanism.

Owner:广东泰格威机器人科技有限公司

A vertical probe card device and its detection method

ActiveCN114034894BBending deformation will notBending deformation is not recoverableElectrical measurement instrument detailsElectrical testingProbe cardEngineering

The invention relates to a vertical probe card device and a detection method thereof, which relate to the technical field of probe cards; the vertical probe card device includes an upper guide plate, a middle guide plate, a lower guide plate, a deformation connection device, a first probe, and a second probe , the circuit board and the first welding pad; the upper guide plate, the middle guide plate and the lower guide plate are respectively provided with a plurality of vertical limit through holes, and the array between the upper guide plate and the middle guide plate is provided with a plurality of deformation connection devices, and the plurality of the first One end of a probe passes through the vertical limit through hole of the upper guide plate and is electrically connected to one end of the corresponding deformation connection device; Push forward and closed-circuit test steps; the vertical probe card device of the present invention and its detection method solve the problem of deformation and offset of the existing probe, the contact problem of the probe and the replacement and repair problem of the probe, so as to achieve good contact and no needle marks. Clear, effective use of effects.

Owner:FTDEVICE TECH (SUZHOU) CO LTD

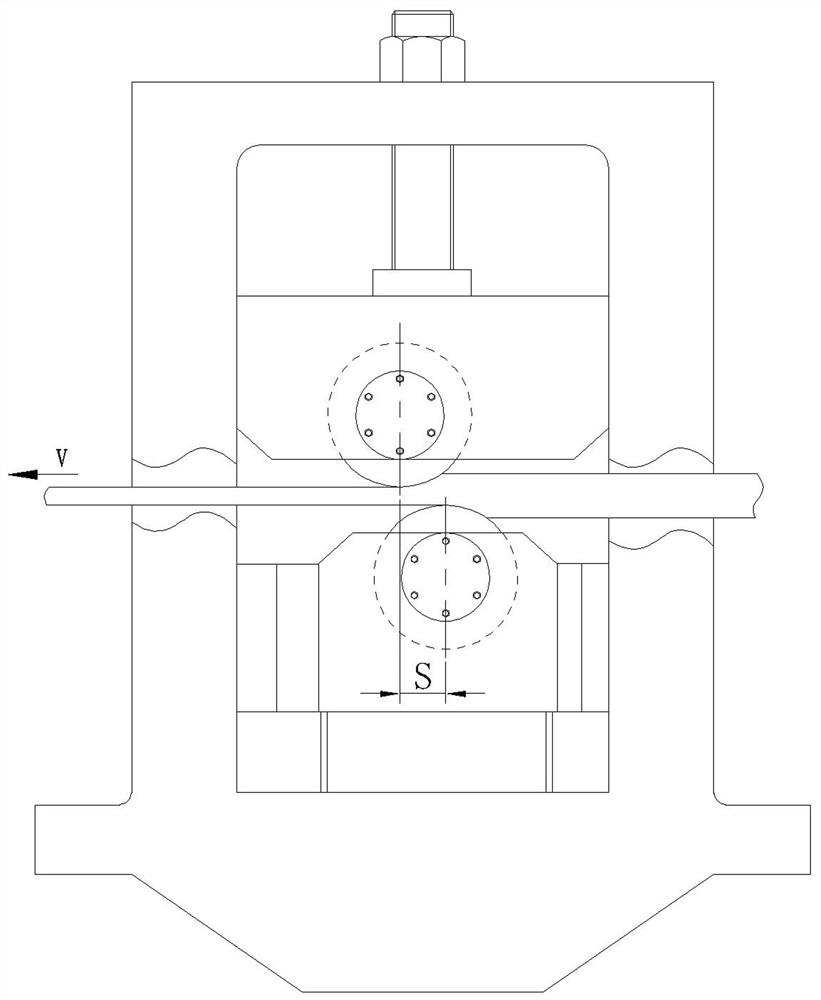

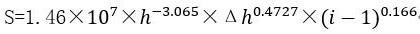

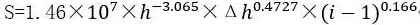

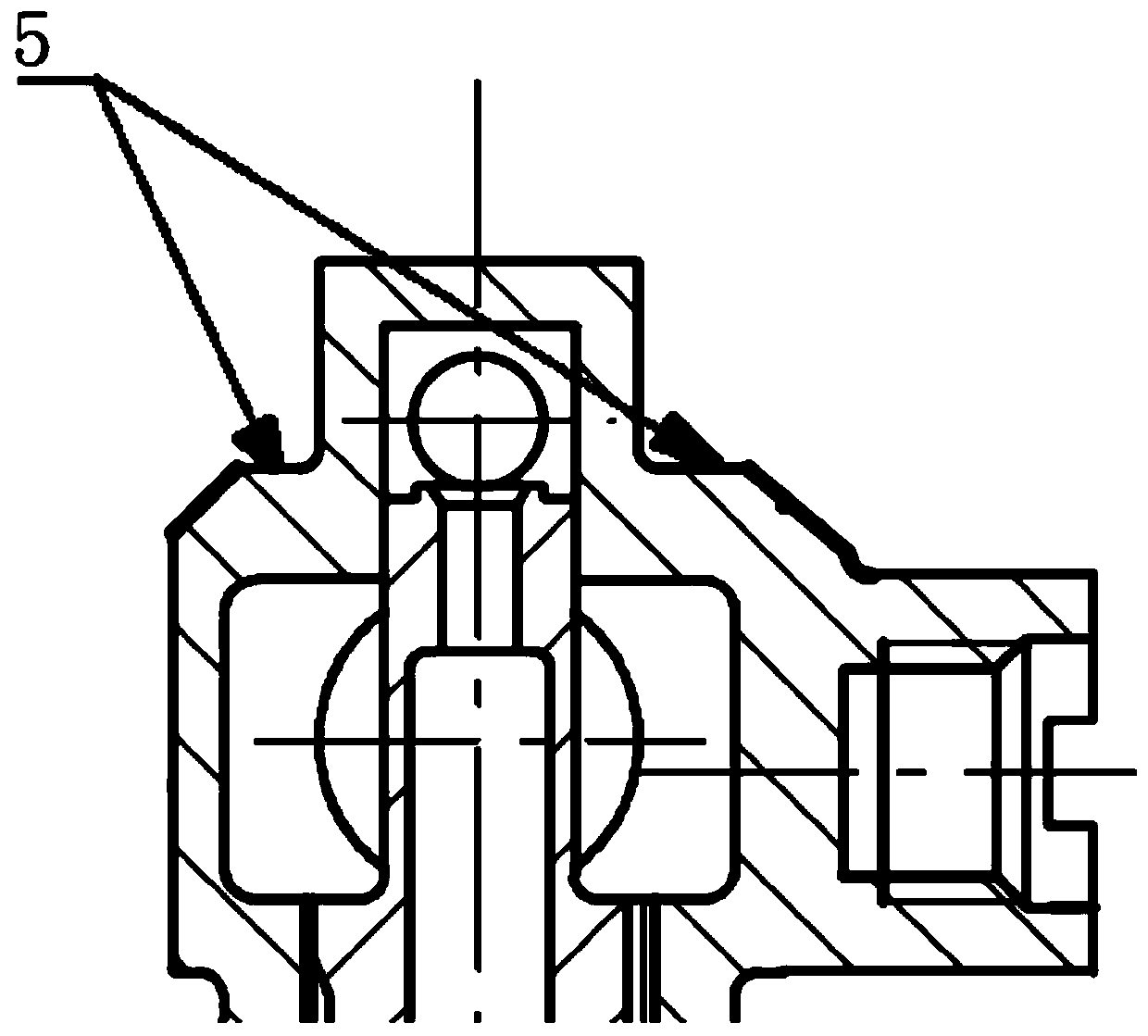

A kind of rolling process of aluminum alloy plate

ActiveCN110802112BImprove straightnessSolve Flatness ProblemsMetal rolling stand detailsMetal rolling arrangementsMaximum torqueMetallurgy

The invention discloses a rolling process suitable for aluminum alloy plates, which includes the following steps: (1) Setting rolling parameters: the maximum rolling force is 1200 tons, the maximum torque is 400kNm, the maximum downward force is 20 mm, and the upper roll is rolled The speed is 1.5~3.5m / s, the diameter of the upper and lower rolls is 100 mm, and the variable speed ratio i is 1.2; (2) For the setting of the misalignment amount S, set the misalignment amount S according to the following nonlinear regression equation. mmh-entrance thickness of rolling plate, mmΔh-down pressure, mmi-differential speed ratio, ratio of upper roll speed to lower roll speed, 1<i≤1.2 where: Δh is set to 10% of h ⑶, inspection of rolling The straightness of the rear aluminum plate. The invention has the advantage that the rolled high-performance aluminum plate has good flatness.

Owner:衡阳市鑫诚和重型机械设备制造有限公司

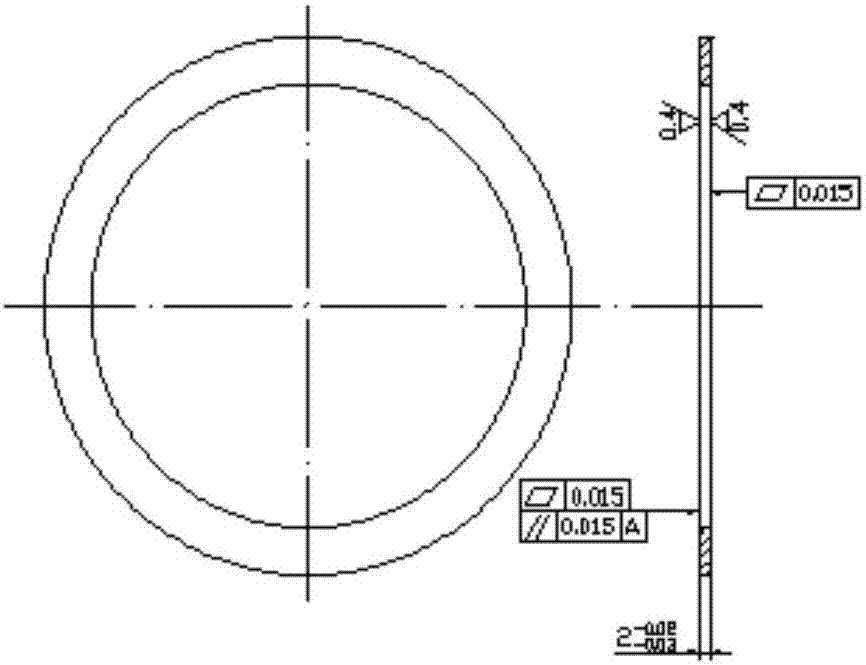

A jig for controlling brazing deformation of a fuel manifold

ActiveCN107824932BPlace stableNo tiltingSoldering auxillary devicesStructural engineeringSS - Stainless steel

The invention discloses a clamp for controlling braze welding deformation of a fuel manifold. The clamp comprises a pressing unit positioned on the upper end surface of a nozzle and a supporting unitpositioned on the lower end surface of the nozzle, wherein the pressing unit comprises a stainless steel structural part (1) with a door-shaped section; two vertical sides of the structural part (1) are equal in width, but not equal in length; the supporting unit comprises a circular-ring-shaped base body (2), wherein observing holes (3) are formed in the outer periphery of the circular-ring-shaped base body (2) at equal intervals; and a supporting base (4) is arranged on a position, on the upper end surface of the circular-ring-shaped base body (2), between two adjacent observing holes (3). The clamp overcomes the problem that the end surface of the braze-welded nozzle is irregular and tilts, so that design requirements with planeness smaller than or equal to 0.3 mm are met, follow-up correcting difficulty is reduced, correcting working hours are shortened, and production efficiency is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

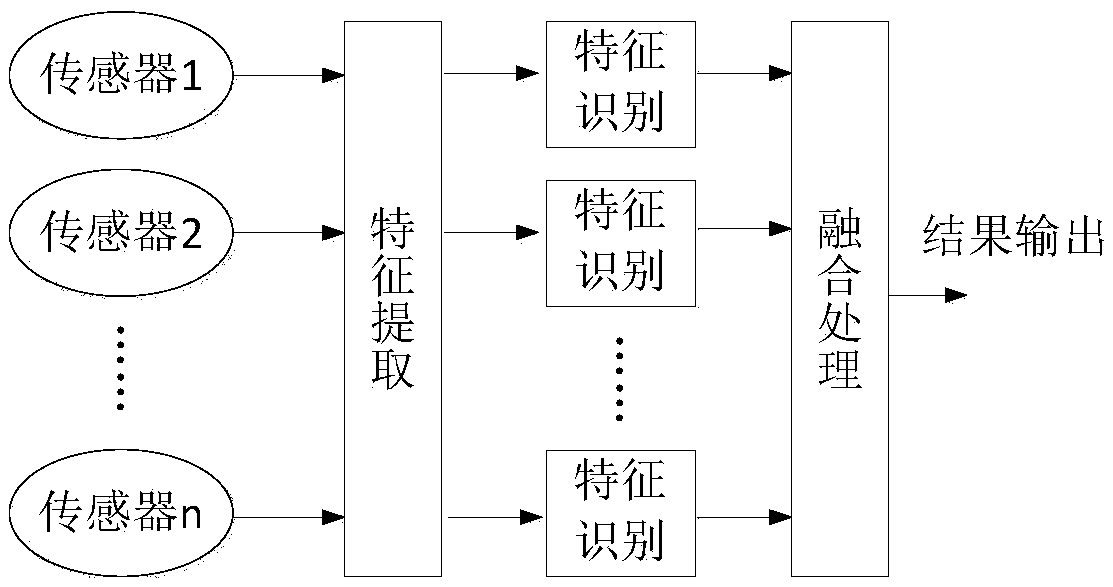

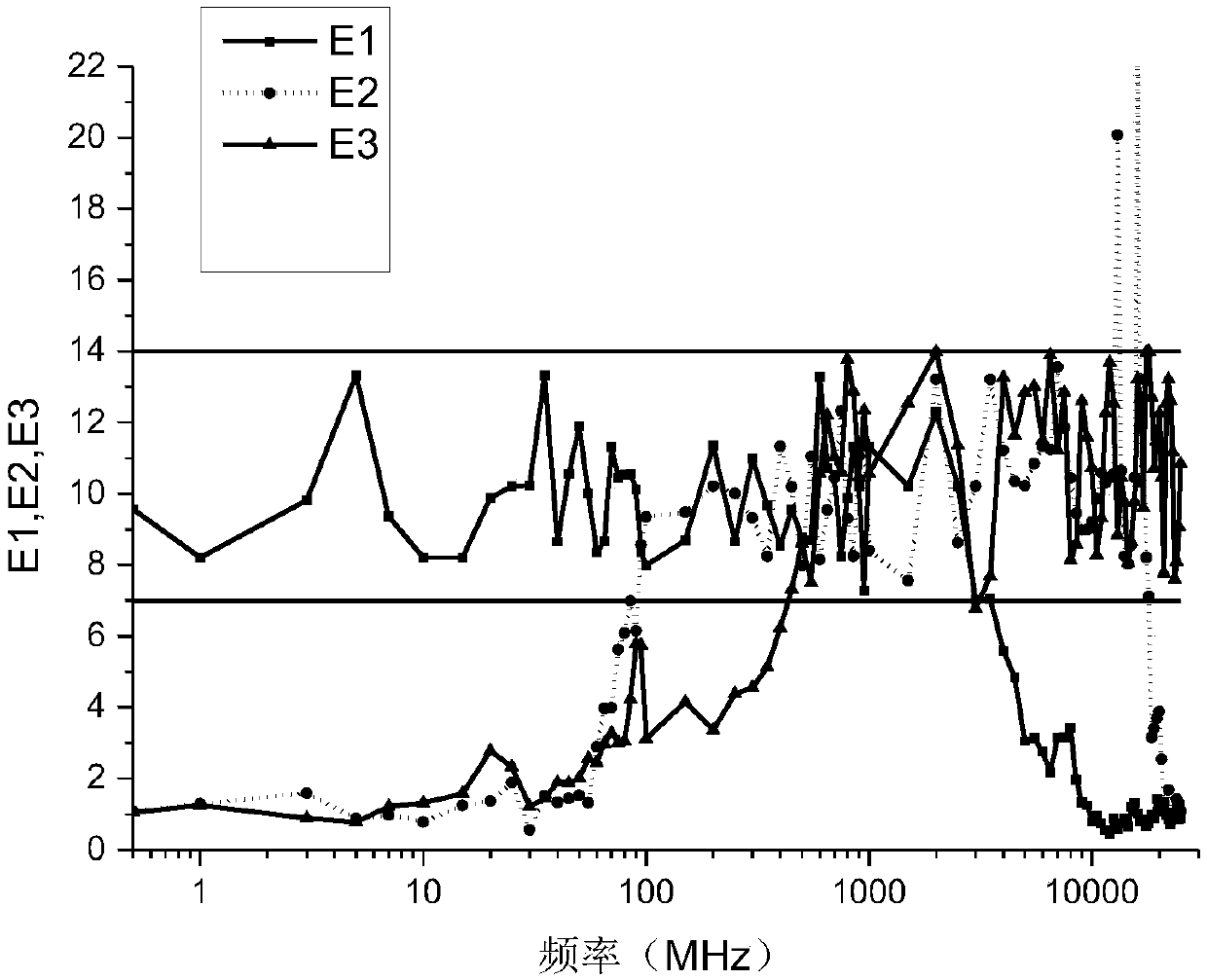

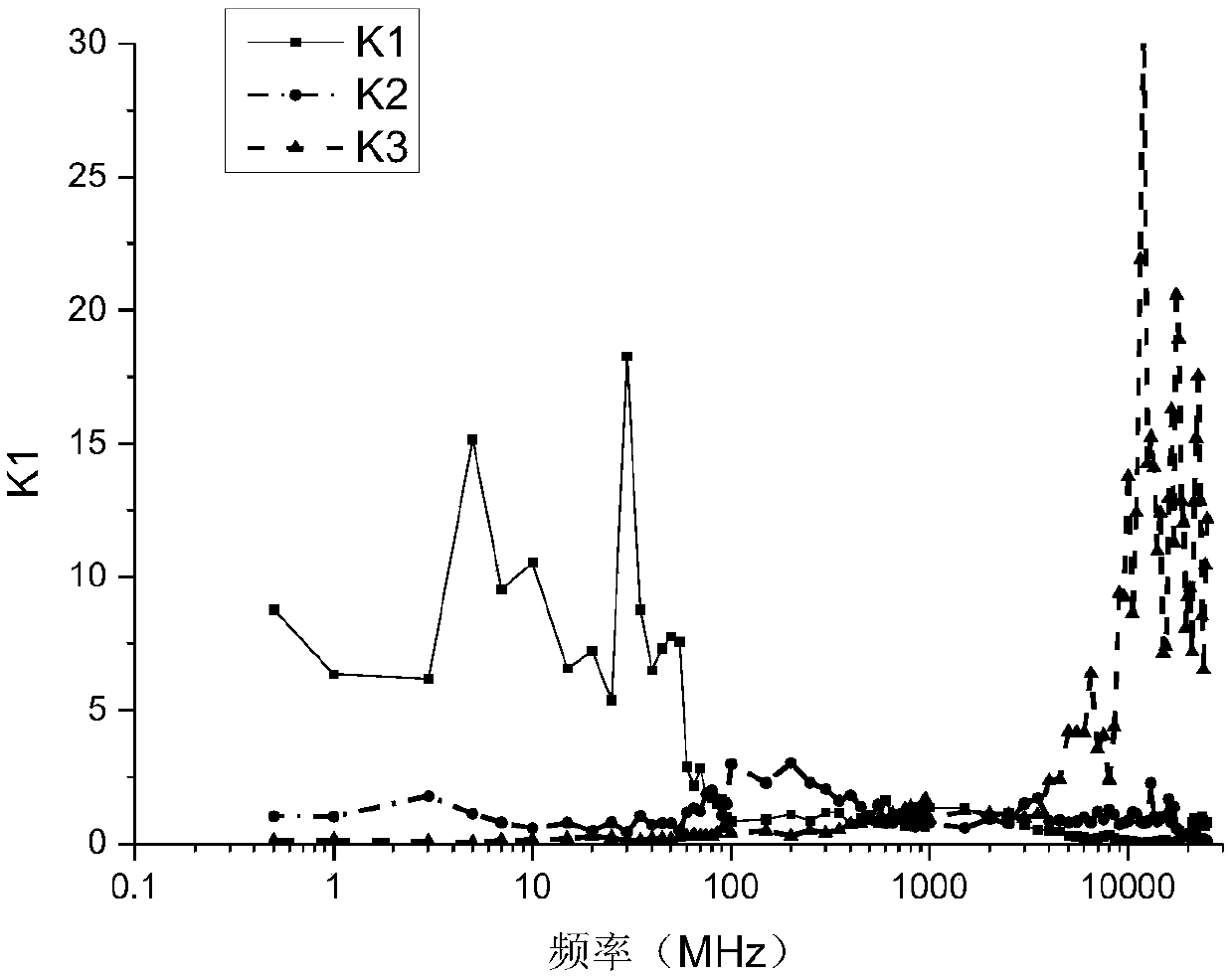

Flatness Optimization Method for Broadband Electric Field Sensor Based on Data Fusion Mechanism

ActiveCN108132450BSolve Flatness ProblemsImprove performanceElectrical measurementsElectric field sensorFeature extraction

A data fusion mechanism based flatness optimization method of a broadband electric field sensor comprises the following steps that multiple measuring frequency points are arranged in the measuring frequency range of the electric field sensor, test data, in the measuring frequency points, of different induction antennas of the electric field sensor is obtained, and light intensity measuring valuesof the induction antennas in the measuring frequency points are calculated; a characteristic determining value of each induction antenna of the electric sensor in the measuring frequency points is calculated according to the light intensity measuring value of the induction antenna in each measuring frequency point, and characteristic of the electric field sensor is extracted and identified; and field intensity data of the whole measuring frequency range is fused according to the characteristic values of the electric field sensor in different measuring frequency points, and a fused field intensity of the electric sensor is calculated. On the basis of data fusion technology, decision fusion is carried out on different paths of measurement data of the induction antennas of the electric field,advantages of the induction antennas are combined, the problem that a single group of sensing antennas has defect in local frequency range, and the probe flatness is thus optimized.

Owner:XIDIAN UNIV

A Fixing Plate Structure Facilitating Surface Reprocessing

Owner:SHANGHAI PUDONG HANWEI VALVE

Vertical profile traction robot

The invention provides a vertical profile traction robot. The vertical profile traction robot comprises a vertical walking guide rail, M traction units and a control mechanism, wherein every tractionunit includes a mechanical arm for clamping a traction profile and a sliding rack in sliding connection with the vertical walking guide rail to make the mechanical arm walk and move; the mechanical arm is clamped on the side surface of the vertical walking guide rail by the sliding rack, and is in sliding connection with the side surface of the vertical walking guide rail in order to realize the walking and movement of the mechanical arm hanging on the side surface of the vertical walking guide rail; the control mechanism is in signal connection with the sliding rack and the mechanical arms respectively ; and the M traction units are arranged on the vertical walking guide rail in parallel up and down, and the mechanical arms of the two adjacent traction units hang and synergistically alternately walk and move on the vertical walking guide rail in order to tract the profile in a synergistic alternate manner. The vertical profile traction robot can automatically tract the profile in a multi-track manner according to production demands in order to improve the profile traction efficiency.

Owner:广东省智行机器人科技有限公司

A vertical profile single track traction robot

The invention provides a vertical profile single-rail traction robot. The vertical profile single-rail traction robot comprises a vertical walking rail, a mechanical arm for clamping and towing a profile, a transmission mechanism, a driving mechanism for connecting with the transmission mechanism, and a control mechanism; the mechanical arm is buckled on the side surface of the vertical walking rail, and is slidingly connected with the side surface of the vertical walking rail to realize walking movement by hanging on the side surface of the vertical walking rail; the transmission mechanism consists of a transmission device 1 arranged on the mechanical arm and a transmission device 2 arranged on the vertical walking rail; and the control mechanism is respectively in signal connection with the driving mechanism and the mechanical arm. The vertical profile single-rail traction robot adopts the mechanical arm as an actuation mechanism for towing the profile, and is flexible in operation and convenient for control. Meanwhile, the vertical profile single-rail traction robot can shrink the floor area to reduce the production cost, and is not influenced by the ground condition to effectively solve the problem of incapability of guaranteeing the profile towing straightness caused by uneven ground so as to improve the profile towing processing quality.

Owner:广东泰格威机器人科技有限公司

a vertical walking track

ActiveCN105563455BQuality improvementSolve Flatness ProblemsManipulatorStructural engineeringControl theory

The invention provides a vertical walking rail for slidingly connecting with a vertical walking mechanism to realize walking movement of a mechanical arm. The vertical walking rail comprises a frame; and a slide rail is arranged on the side surface of the frame in the length direction, and is used for buckling and slidingly connecting with a walking mechanism to realize walking movement of the walking mechanism by hanging on the side surface of the frame. The vertical walking rail can effectively solve the problem of incapability of guaranteeing walking movement straightness of the mechanical arm caused by uneven ground so as to improve the quality of the clamping arm clamping a profile for machining. Meanwhile, the vertical walking rail can reduce the movement floor space of the mechanical arm. The invention further provides a rail assembly; the rail assembly is formed by superposing more than two vertical walking rails; and two adjacent vertical walking rails realize superposition through a superposing part 1 arranged at the top of the lower walking rail and a superposing part 2 arranged at the bottom of the upper walking rail. The rail assembly is convenient for movement machining of multiple mechanical arms so as to improve the machining efficiency.

Owner:广东泰格威机器人科技有限公司

A processing method for a stop ring

The invention belongs to the technical field of machining parts and in particular to a machining method for a stop ring. The machining method for the stop ring takes a GCr15 bearing-steel steel pipe as a raw material and the inner and outer diameters of the steel pipe are sizes of the inner and outer diameters of a stop ring blank; and then the steel pipe is cut to obtain the stop ring blank. According to the machining method for the stop ring, provided by the invention, the qualitative transition is realized by abandoning sheet material machining and replacing the sheet material machining with pipe machining, so that the utilization rate of the material is improved and material stress generated by rolling the material for a plurality of times is reduced; a cutting method is used for replacing punching so that punching machining stress of the blank is reduced and a foundation of solving a planeness problem is laid for subsequent machining; a heat treatment method is modified and the material stress, machining stress and heat treatment deformation are controlled to be minimum; and in conclusion, the problems of uncontrollable planeness, poor parallelism, poor thickness and plane roughness in an old method are solved through the machining method provided by the invention and the yield and market credibility of a product are improved.

Owner:WUJIANG SHUANGJING BEARING

A vertical walking mechanism

The invention provides a vertical travel mechanism. The vertical travel mechanism is used for being slidably connected with a vertical track, so that a mechanical arm can travel and move. The vertical travel mechanism comprises a frame and a base. The base is used for mounting the mechanical arm; one end of the base is detachably connected with the frame, and the other end of the base is used for being connected with the mechanical arm; a sliding device is arranged at the bottom of the frame and is used for being clipped on slide rails on the side surfaces of the vertical track and is slidably connected with the slide rails, so that the frame can be suspended on the side surfaces of the vertical track and can travel and move. The vertical travel mechanism has the advantages that the problem that the travel and movement straightness and flatness of an existing mechanical arm cannot be guaranteed due to uneven grounds can be effectively solved, and accordingly the machining quality of section bars clamped by the mechanical arm can be improved; movement occupied spaces of the mechanical arm can be reduced by the aid of the vertical travel mechanism.

Owner:广东泰格威机器人科技有限公司

Hanging device for traction auxiliary power supply all-in-one converter of motor train unit

ActiveCN101797920BSolve Flatness ProblemsGuaranteed hanging strengthLocomotivesAutomotive engineering

The invention relates to a hanging device of an object, in particular to a hanging device for a traction auxiliary power supply all-in-one converter of a motor train unit, solving the problem that no hanging device is suitable for the traction auxiliary power supply all-in-one converter of the motor train unit. The hanging device comprises a left hanging bracket, a middle hanging bracket and a right hanging bracket which are respectively consistent to the left part, the middle and the right part of the upper end surface of a box body of the traction auxiliary power supply all-in-one converterin shape, wherein the opposite side walls of the left hanging bracket and the middle hanging bracket and the middle hanging bracket and the right hanging bracket are provided with opposite assemblingholes; the upper end surfaces and the lower end surfaces of the hanging brackets are provided with fixed through holes; and hanging installation seats are fixed on the side walls of the hanging brackets. The hanging device ensures the hanging strength of the traction auxiliary power supply all-in-one converter equipment of the high-speed motor train unit, meets the technical requirements for the light weight of the traction auxiliary power supply all-in-one converter equipment of the high-speed motor train unit and solves the problems of the large-area hanging and the planeness of the traction auxiliary power supply all-in-one converter equipment.

Owner:CRRC YONGJI ELECTRIC CO LTD

Vertical type travelling mechanism for section bar traction

The invention provides a vertical type travelling mechanism for section bar traction. The vertical type travelling mechanism comprises vertical type travelling guide rails and a slide frame which is in sliding connection with the vertical type travelling guide rails to realize mechanical arm travelling and moving, wherein the vertical type travelling guide rails comprise frame bodies, and slide rails are arranged on the side surfaces of the frame bodies in the length direction of the frame bodies; the slide frame comprises a slide frame plate, a power module arranged on the slide frame plate and a base body for mounting a mechanical arm; the bottom of the slide frame plate is equipped with a slide device; and the slide device is clamped on the slide rails on the side surfaces of the framebodies, and is in sliding connection with the slide rails, so that the slide frame is suspended on the side surfaces of the vertical type travelling guide rails to travel and move. The vertical type travelling mechanism for section bar traction provided by the invention can effectively solve the problem that straightness and flatness of mechanical arm travelling and moving cannot be guaranteed asground is uneven, so that travelling stability and traction-processing quality when the mechanical arm grabs a section bar to perform traction-processing are improved.

Owner:广东省智行机器人科技有限公司

A profile pulling method

The invention provides a novel profile pulling method. A vertical pulling robot is used for pulling a profile. The vertical pulling robot is formed by overlapping and splicing M pulling units in the vertical direction. Each pulling unit is provided with a vertical type walking track and a mechanical arm moving on the vertical type walking track. M is a natural number which is greater than or equal to 2. The mechanical arms of every two adjacent pulling units are hung on the vertical type walking tracks and move in a cooperatively alternating and mutual avoiding mode, so that the profile is pulled in a cooperatively alternating mode. According to the novel profile pulling method, the practicality is high, the pulling speed is high, the profile can be fully automatically pulled in a multi-track mode according to production requirements, and therefore the profile pulling efficiency is improved, an efficient and stable pulling effect can be achieved, full-automatic and intelligent profile pulling processing is achieved, and the novel profile pulling method is suitable for large-scale production.

Owner:广东省智行机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com