Machining method for stop ring

A processing method and stop ring technology, applied in the field of machining parts, can solve the problems of low product qualification rate, difficult product qualification rate, unstable stress, etc., to reduce material stress, meet quality requirements, and improve material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For ease of understanding, the processing method of the stop ring will be described below in conjunction with examples. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

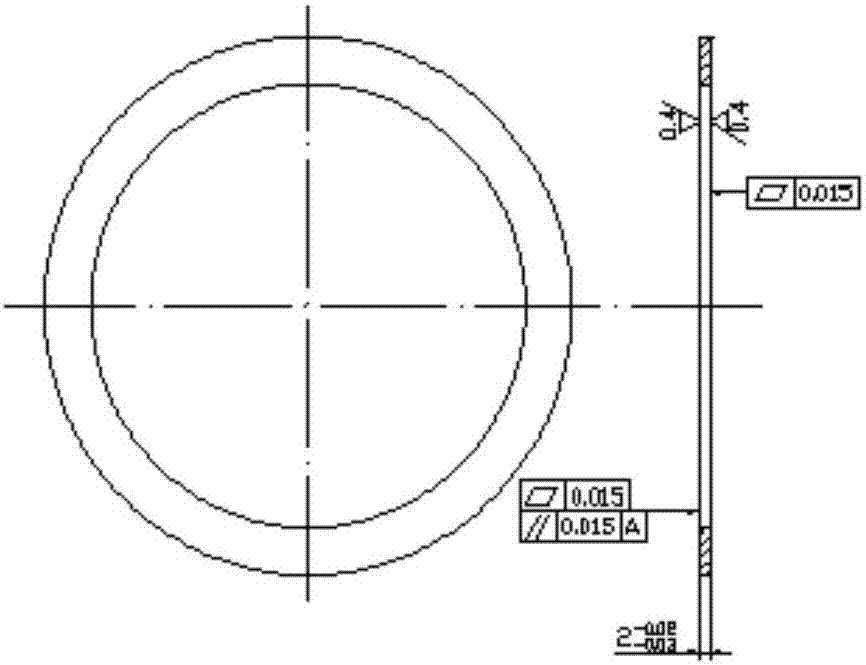

[0034] Such as figure 1 As shown, the stop ring is a product packed in a large circular ring with thin slices, and the size requirements are as follows:

[0035] thickness

[0036] Two-plane roughness <0.4mm;

[0037] Flatness<0.015mm;

[0038] Parallel difference <0.015mm.

[0039] The machining process of the above stop ring is as follows:

[0040] 0. Material selection

[0041] GCr15 bearing steel plate with a thickness of 2.5 mm needs multiple times of heating and rolling to form, and unstable stress accumulates in the plate. This stress is continuously released during the processing of large rings, causing plane warping, while thin large ring products The flatness requirement is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com