Three-dimensional intermittent cut-through crack production apparatus and method of cuboid rock test sample

A rock sample and device manufacturing technology, which is applied in the field of geotechnical engineering, can solve problems such as difficult to accurately reflect mechanical properties and crack expansion mechanisms, and achieve the effects of ensuring accuracy, convenient operation, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

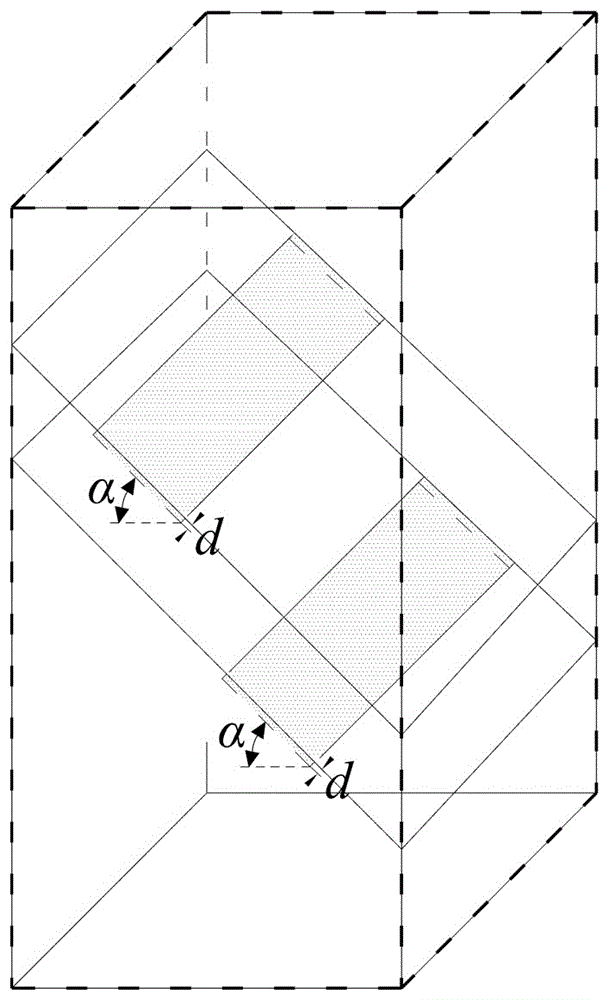

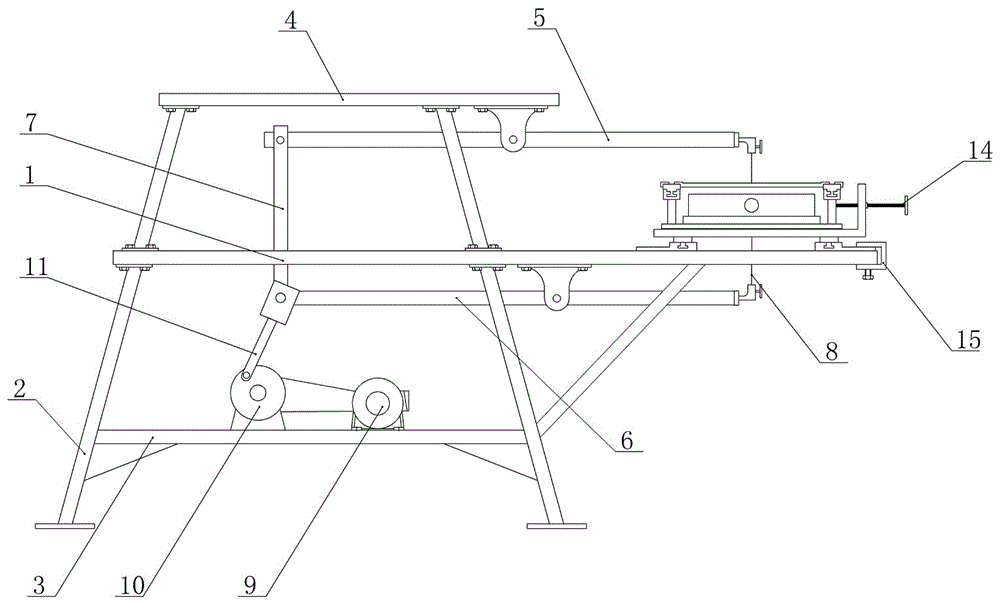

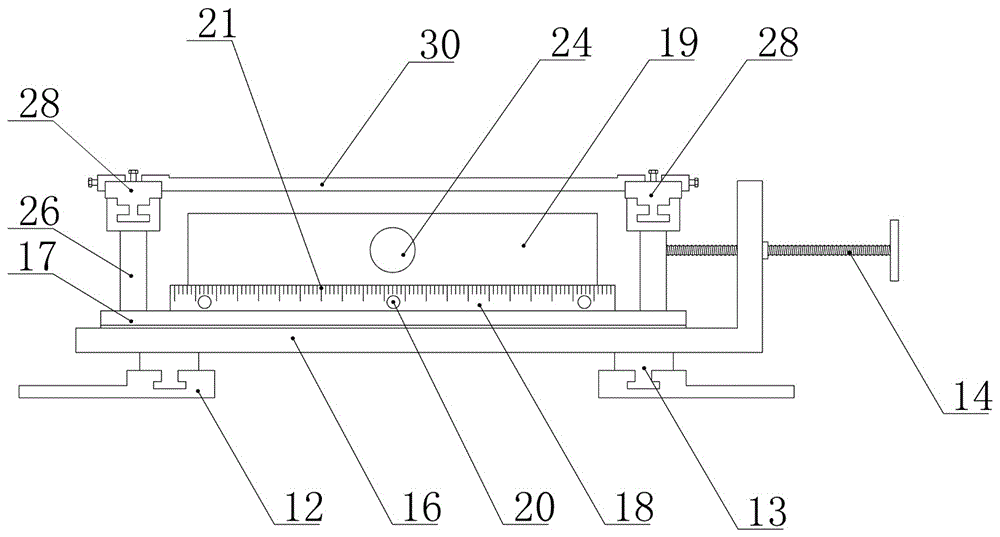

[0033] Example 1: see Figure 1-Figure 6 , the present invention is a cuboid rock sample three-dimensional intermittent through-crack production device, the cuboid rock sample three-dimensional intermittent through-crack structure such as figure 1 As shown in the figure, the rock sample includes two intermittent through fractures, the fracture width is d, and the fracture inclination angle is α. The device for making the crack in the present invention includes a frame, an electric wire saw assembly arranged on the frame, a three-dimensional moving assembly, a sample fixing assembly and a crack width control assembly.

[0034]Wherein, the frame includes a worktable 1 and legs 2, the lower part of the worktable 1 is provided with a lower support plate 3, the upper part of the worktable is provided with an upper supporter 4, and the electric wire saw assembly includes an upper The four-link cutting mechanism composed of the swing rod 5, the lower swing rod 6, the connecting rod ...

Embodiment 2

[0038] Example 2: see Figure 1-Figure 6 , a method for making cracks using the cuboid rock sample three-dimensional intermittently penetrating crack making device described in Embodiment 1, comprising the following steps:

[0039] ① Collect real rock samples, cut and grind the rock samples to form cuboid rock samples, determine the position and size of the two intermittent prefabricated fractures through solid staking, and drill holes at both ends of each prefabricated fracture to make The rock samples corresponding to both ends of the prefabricated fissures are formed with through-holes through the top and bottom surfaces, and the diameter of the boreholes is the same as the width of the prefabricated fissures.

[0040] ②Place the cuboid rock sample between the two V-shaped clamps, and adjust the orientation of the rock sample with reference to the centering scale on the bottom plate. The rod pushes the V-shaped clamps toward each other to clamp the rock sample.

[0041] ③...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com