Bending forming process and tool for square pipe

A forming process and rounding technology, applied in the field of square tube rounding forming process and tooling, can solve the problems such as the roundness and flatness of the ring body cannot be achieved, the accuracy requirements, and the arc wrinkling, etc., to eliminate internal residual stress, Improve structural strength and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Manufacture the front steel frame of the shroud supporting structural parts of the 2.0MW wind turbine.

[0036] The main structure of the front steel frame of the shroud of the 2.0MW wind turbine supporting structural parts is a 40mm×40mm square tube with a curved circle, and the diameter of the ring body reaches 3m after forming. The roundness error is required to be ≤±1mm, and the flatness error is ≤1mm.

[0037] Follow the steps below to implement:

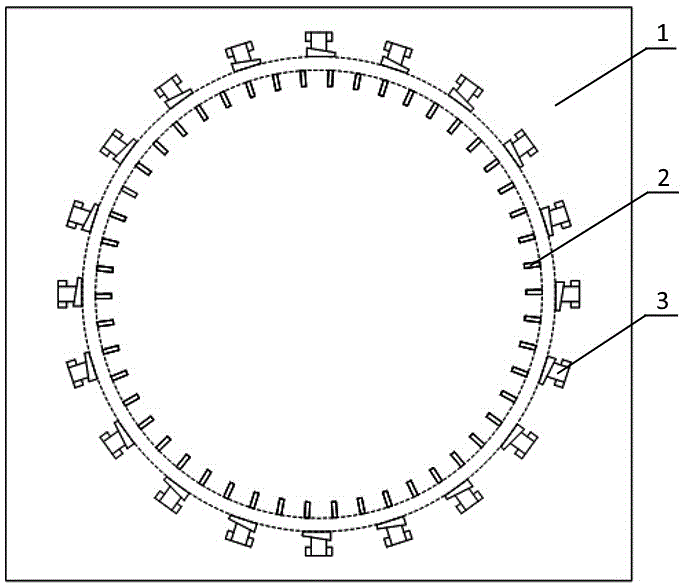

[0038] (1) Tooling design and production: as attached figure 1 As shown, the special tooling is designed and manufactured according to the size requirements of the square tube bend, and the tooling is composed of a base plate (1), a circular baffle (2), and a pushing device (3); the base plate (1) is used as a reference plane for calibration The flatness of the workpiece, the base plate is a hot-rolled plate with a thickness of 40-50mm, and the circular baffle (2) is fixedly connected to it, and the distance between the...

Embodiment 2

[0048] Manufacture the rear steel frame of the shroud supporting structural parts of the 2.0MW wind turbine.

[0049] The supporting structure of the 2.0MW wind turbine generator set, the rear steel frame of the shroud is composed of three arc segments, the main material is a 40mm×40mm square tube, and the diameter of the spliced ring reaches 4m, and the overall roundness error is required to be ≤ ±1mm, flatness error≤1mm.

[0050] According to the steps of Example 1, the difference is:

[0051] The fixed connection between the base plate (1) and the round baffle (2) is welding;

[0052] The fixed connection between the base plate (1) and the pushing device (3) is a bolted connection;

[0053] The pushing device (3) is a wedge-shaped structure, which is convenient for operation;

[0054] The substrate is a hot-rolled plate with a thickness of 40-50mm;

[0055]The heating temperature in the workpiece thermal correction in the step (4) is controlled at 500-600°C;

[0056]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com