A vertical walking mechanism

A walking mechanism, vertical technology, applied in metal processing machinery parts, driving devices, metal processing equipment and other directions, can solve the problem of inability to guarantee the straightness and straightness of the mechanical arm, reduce the floor space, expand the work space, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

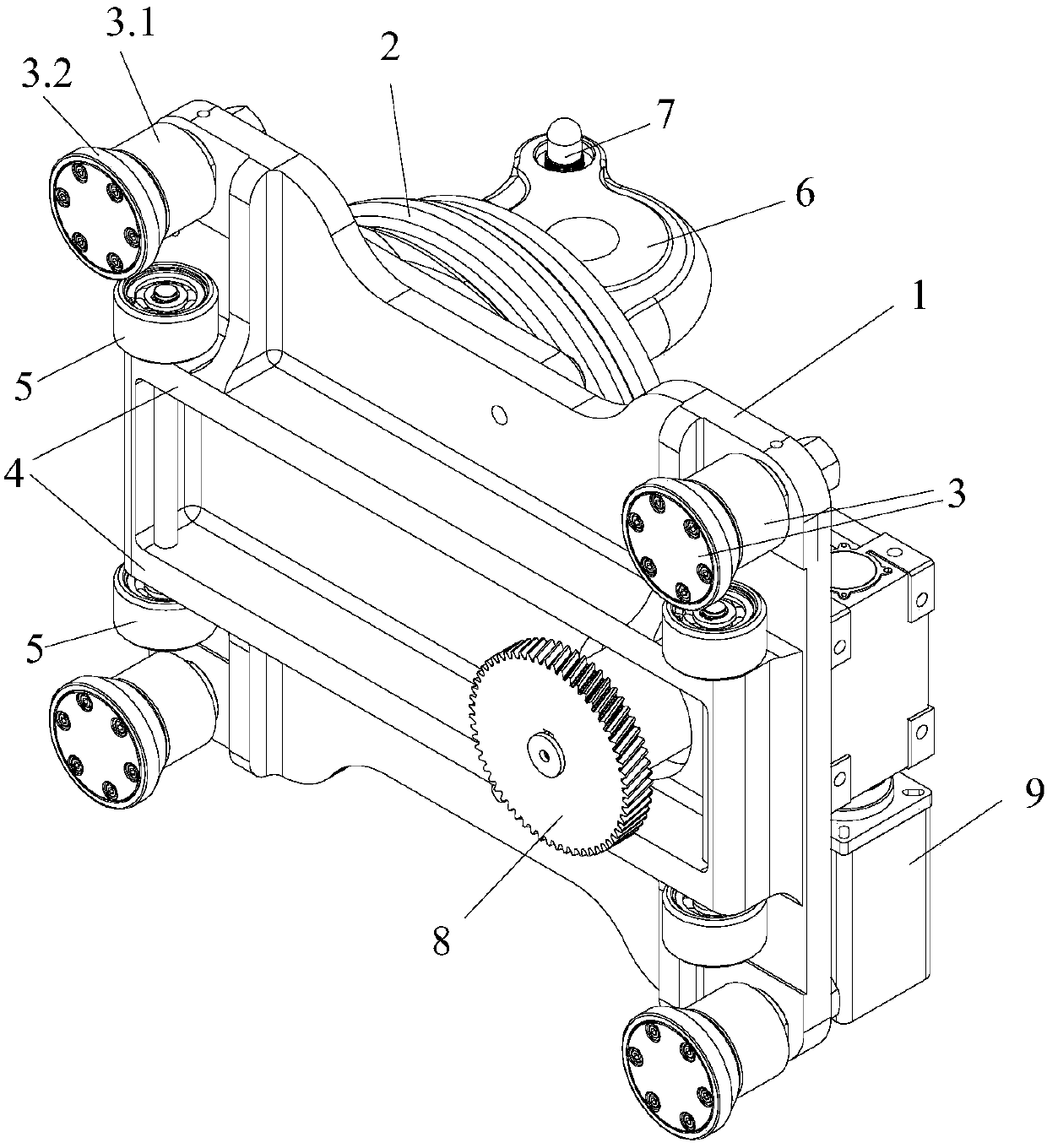

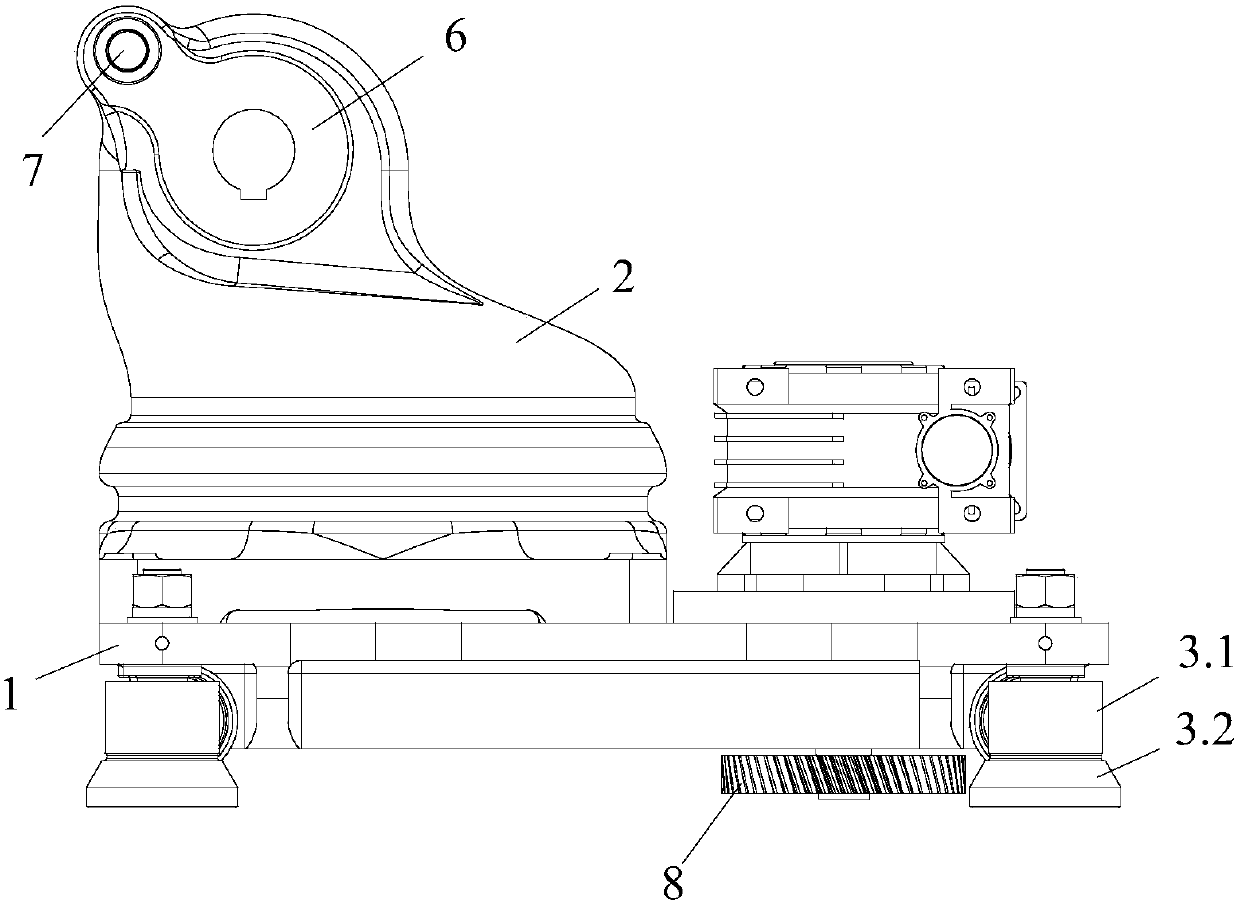

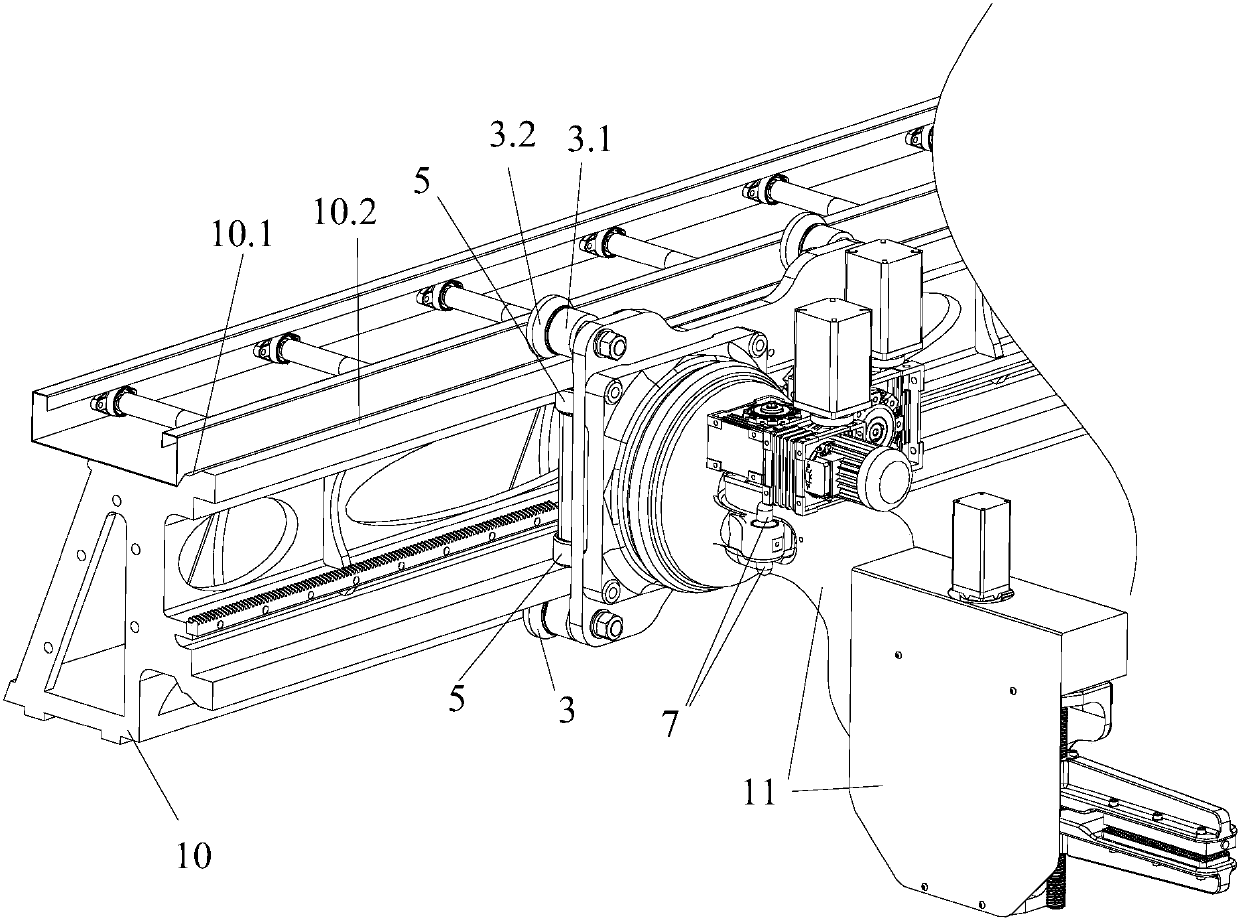

[0026] Such as Figure 1 to Figure 3 As shown, the vertical walking mechanism of the present invention is used to slide and connect with the vertical track 10 to realize the walking movement of the mechanical arm 11. The walking mechanism includes a frame body 1 and a base 2 for installing the mechanical arm 11, wherein the base 2. One end is detachably connected to the frame body 1, and the other end is used to connect the mechanical arm 11. There is a sliding device at the bottom of the frame body 1. The sliding device is used to buckle on the slide rail on the side of the vertical track 10 and slide to connect with the slide rail , to realize that the frame body 1 is suspended on the side of the vertical track 10 for walking and moving.

[0027] The sliding device of the present invention is the guide wheels 3 respectively arranged at the four top corners of the bottom of the frame body 1, and the guide wheels 3 opposite up and down on the same side are used to snap on the ...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the guide wheels of the present invention can be provided with six or eight etc. according to the specifications of the frame body, and the guide wheels are distributed symmetrically at the bottom of the frame body up and down, and the relative guide wheels up and down are used It is buckled on the slide rail on the side of the vertical track and slidably connected with the slide rail. In this embodiment, the upper and lower opposite guide wheels can be snapped onto the slide rails on the side of the vertical track to realize the stable suspension and movement of the frame body.

[0033] Similarly, one, two, three or more support wheels can be set according to requirements, so as to achieve positioning and avoid deviations in the walking of the frame body, and can further ensure the straightness and flatness of the movement of the mechanical arm installed on the walking mechanism .

[0034] Other structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com