a vertical walking track

A walking track and vertical technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems that the straightness and flatness of the manipulator cannot be guaranteed, and achieve the effect of improving production and processing efficiency, improving processing efficiency, and expanding the working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

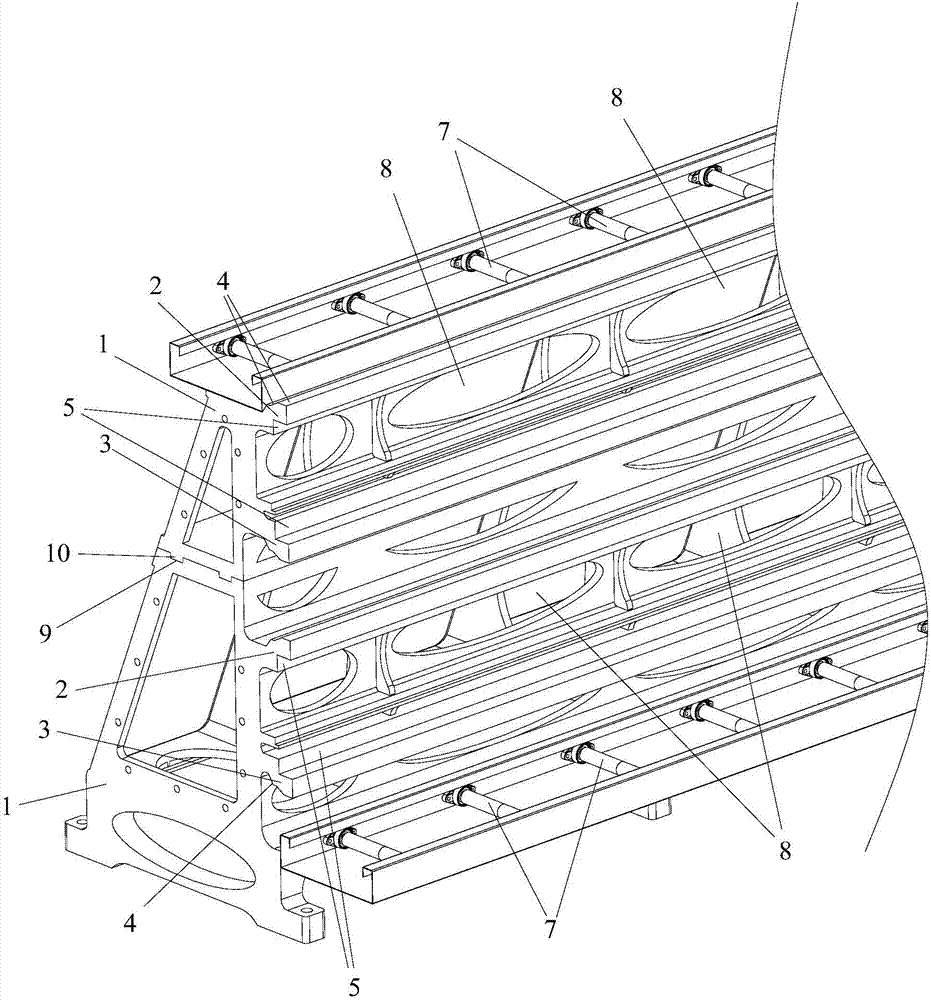

[0026] In this embodiment, the track main frame formed by superimposing two vertical walking tracks is taken as an example to describe the following.

[0027] Such as figure 1 and figure 2 As shown, the track assembly frame of the present invention is composed of two vertical walking tracks superimposed, and the groove 9 arranged at the top of the lower walking track and the convex strip arranged at the bottom of the upper walking track are passed between the two vertical walking tracks. 10 achieve superimposition, while groove 9 and ridge 10 match.

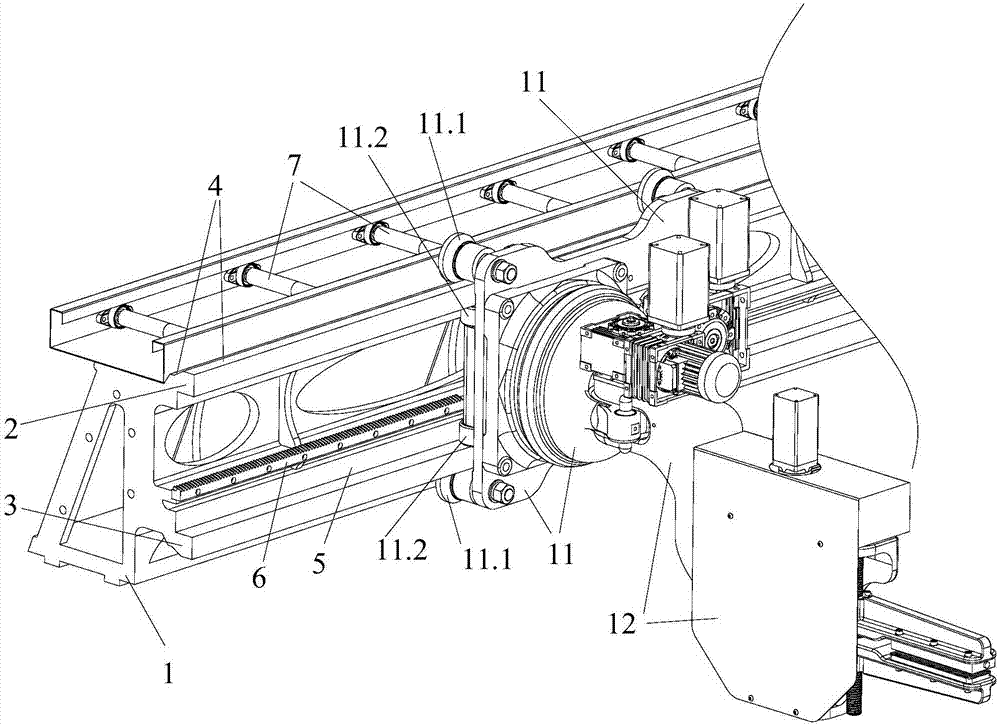

[0028] Each vertical walking track of the track assembly frame is used to slide and connect with the vertical walking mechanism 11 to realize the walking movement of the mechanical arm 12. The vertical walking track includes a frame body 1, and the side of the frame body 1 is provided with The slide rail is used for buckling and sliding connection with the running mechanism 11, so that the running mechanism 11 is suspended on ...

Embodiment 2

[0033] Each vertical walking track in the track assembly frame of the present invention can be used independently, and each vertical walking track can be used for sliding connection with the vertical walking mechanism to realize the walking movement of the mechanical arm. When only one mechanical arm is needed for motion processing, any vertical walking track can be used to realize the walking mechanism hanging on the side of the frame for walking and moving.

[0034] The structure of each vertical walking track in the present embodiment is consistent with the structure of implementing a neutral vertical walking track.

[0035] Implementation three

[0036]The only difference between this embodiment and Embodiment 1 is that this embodiment can form the main frame of the track by superimposing three or more vertical walking tracks, and the structure of each vertical walking track is neutral to that of Embodiment 1. The structure of the walking track is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com