Welding fixture and welding method for ensuring flatness of hot chamber shell

A welding method and welding fixture technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as insufficient consideration of methods and measures to prevent welding deformation, poor box flatness, and unacceptable products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

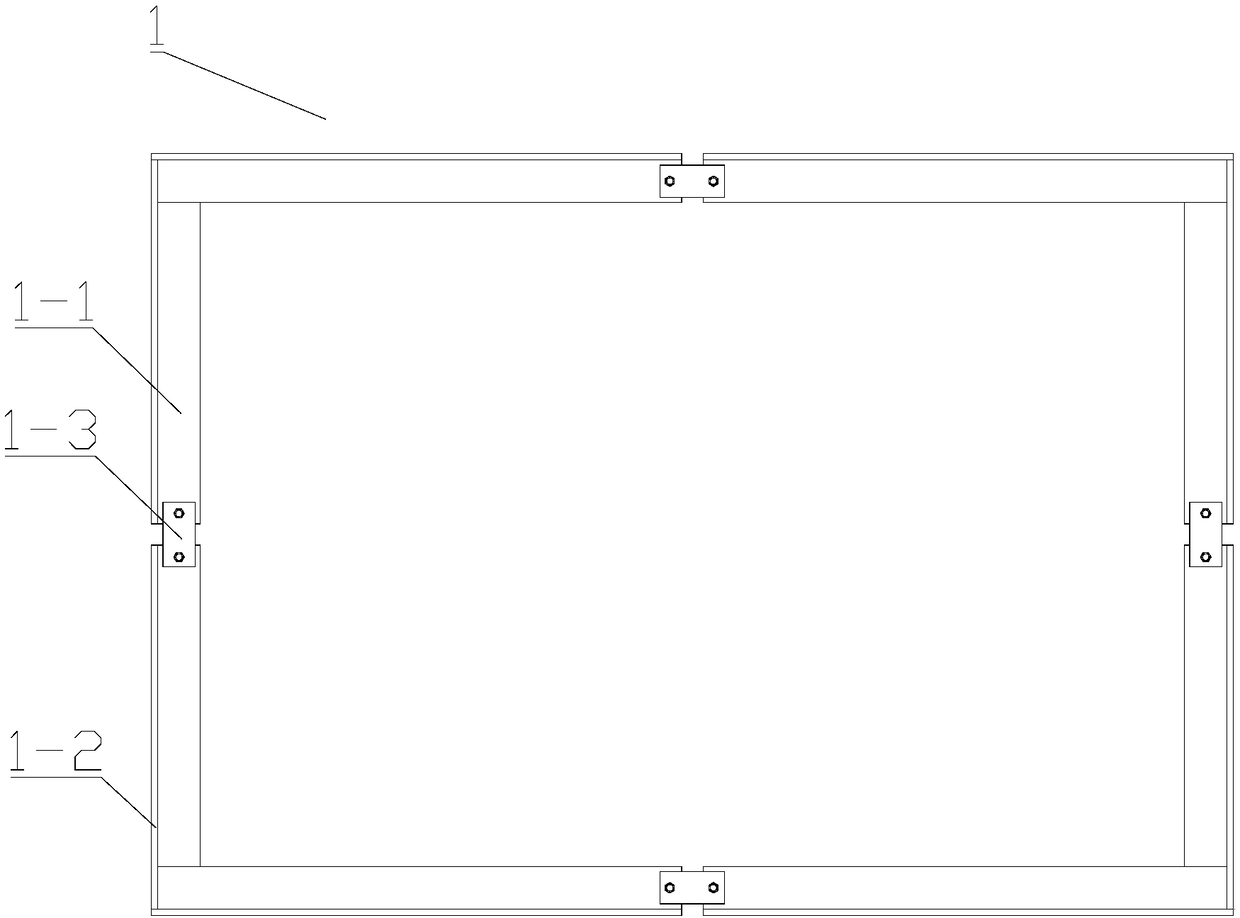

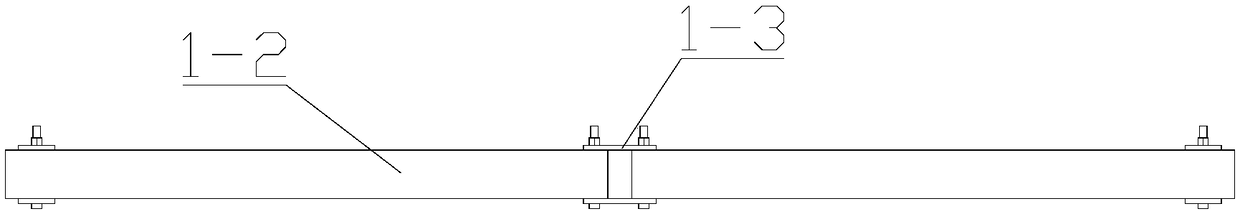

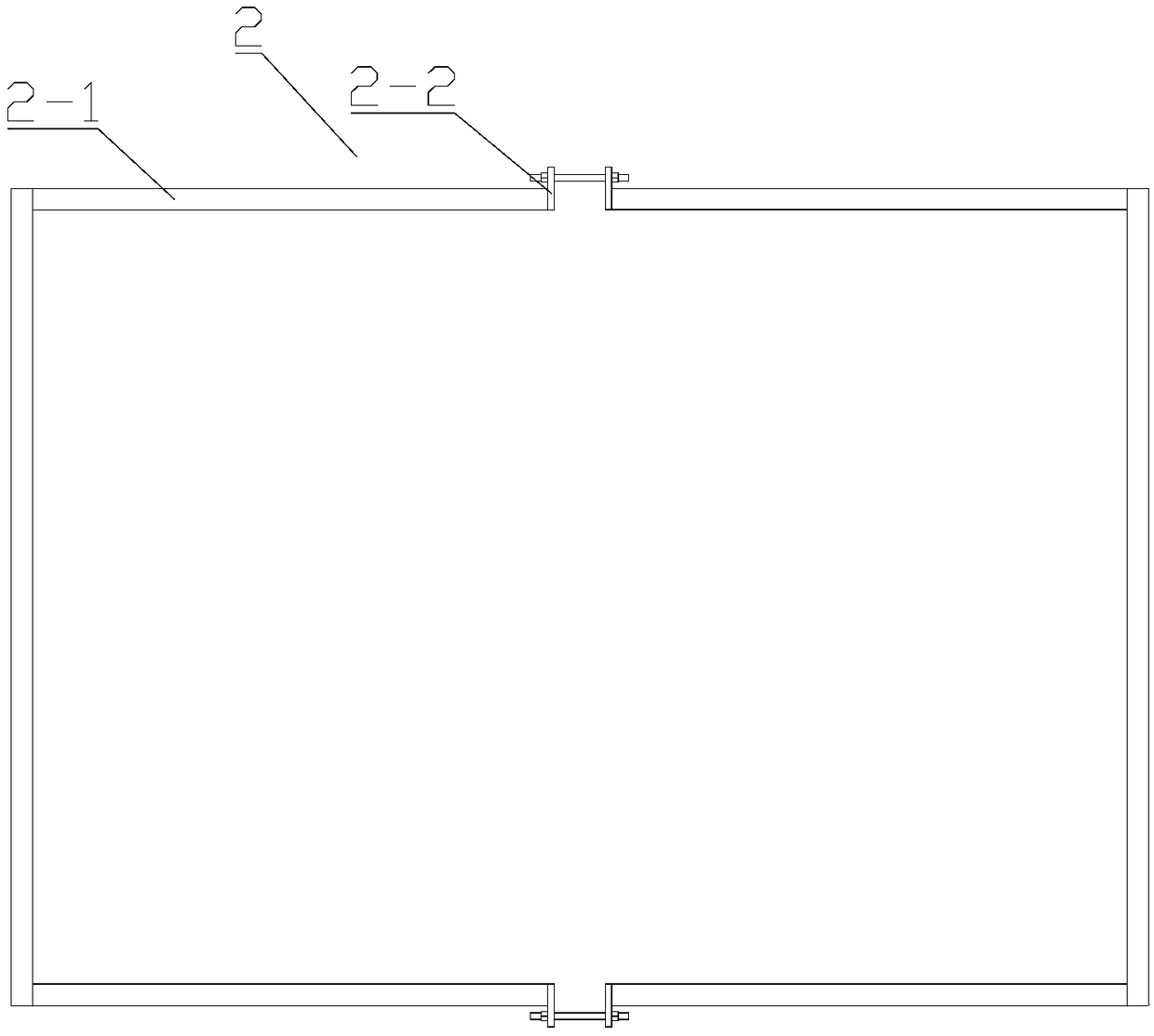

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a welding fixture for ensuring the flatness of the heat chamber shell described in this embodiment includes an inner tire frame 1 placed inside the heat chamber shell and an outer tire frame 2 placed outside the heat chamber shell, the inner tire frame The structure of 1 includes a square tube 1-1, a backing plate 1-2 and a No. 1 connecting plate 1-3. Every two square tubes 1-1 form an L-shaped structure by welding the ends, and four L-shaped structures are butted end to end to form Rectangular structure, a No. 1 connecting plate 1-3 is arranged on the L-shaped structure butted head to tail, and the No. 1 connecting plate 1-3 and the L-shaped structure are connected by bolts, and after being connected through the No. 1 connecting plate 1-3 There is a gap between the L-shaped structures, and a layer of backing plate 1-2 is pasted on the periphery of the four L-shaped structures forming a rectangular structu...

Embodiment 2

[0032] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, this embodiment describes a welding method using the welding fixture described in Embodiment 1 to ensure the flatness of the heat chamber shell, and the specific steps are as follows:

[0033] (1), place a plurality of temporary pads 5 on a flat and horizontal platform 6, place the first inner tube frame 1 horizontally on the temporary pad 5, and place several temporary pads on the first inner tube frame 1 Block 5, then place the second inner tube frame 1, adjust the position of the second inner tube frame 1 to ensure that the projections of the two inner tube frames 1 on the platform 6 are completely coincident;

[0034] (2), set the A part 3 and the B part 4 of the heat chamber shell on the inner tire frame 1;

[0035] (3), two outer tire frames 2 are sleeved outside the hot chamber shell, and the two U-shaped structures of each outer tire frame 2 are distributed on the outside of the hot chamber shel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com