Patents

Literature

38 results about "Nuclear test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Human enterovirus(EV) fluorescence quantitative PCR detecting technology

This invention relates to one human intestinal canal virus fluorescence meter test technique in the field of virus nuclear test technique, which adopts common upstream object, common downstream object and common fluorescence detector for EV each hypotype, wherein, the detector 5'end is labeled with fluorescence emission base group 6- carboxyl fluorandiol and 3'labeled fluorescence quencher base group and 6-carboxyl tetramethyl rhodamine. Due to the test agent case, it tests each EV hypotype standard blood serum for online test and to get each parameter as the following: abnormal property for 100 percent; sensitivity for 95 percent, repetitiveness CV less than 10 percent and minimum content of EV as 500 copy each ml.

Owner:河南省生物工程技术研究中心

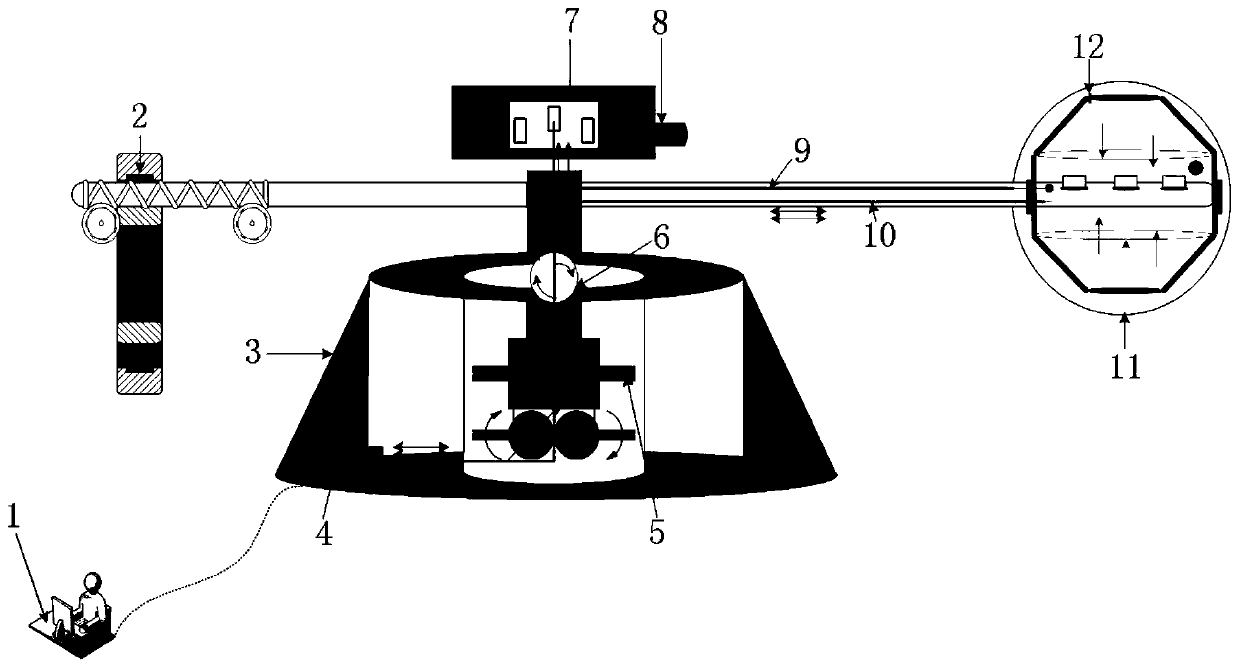

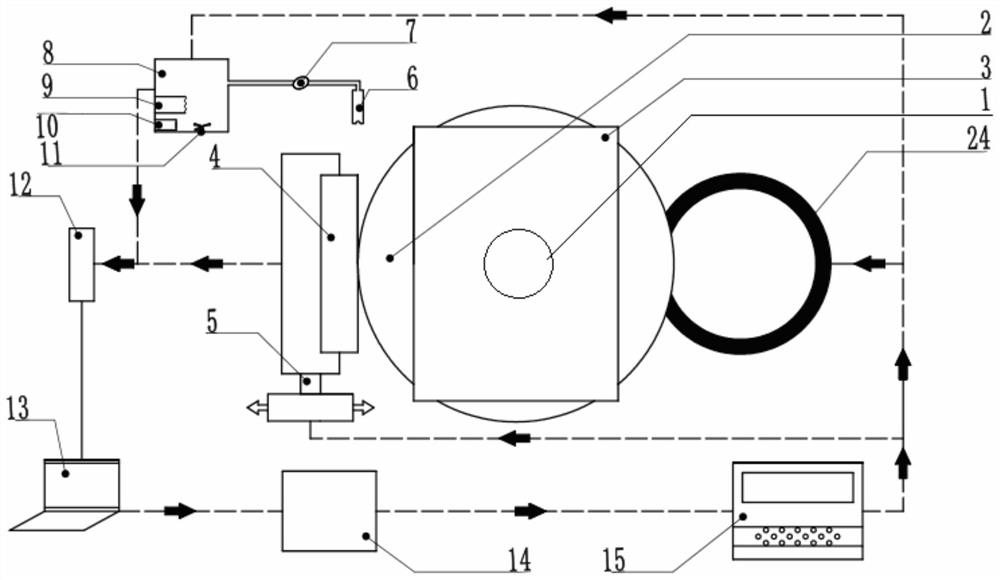

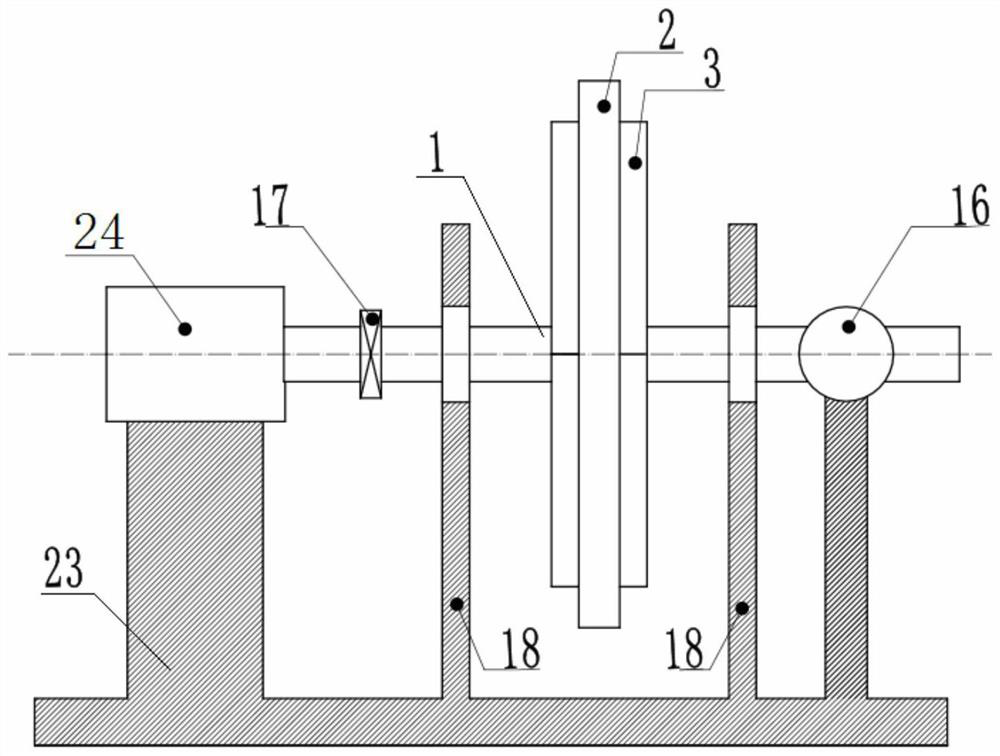

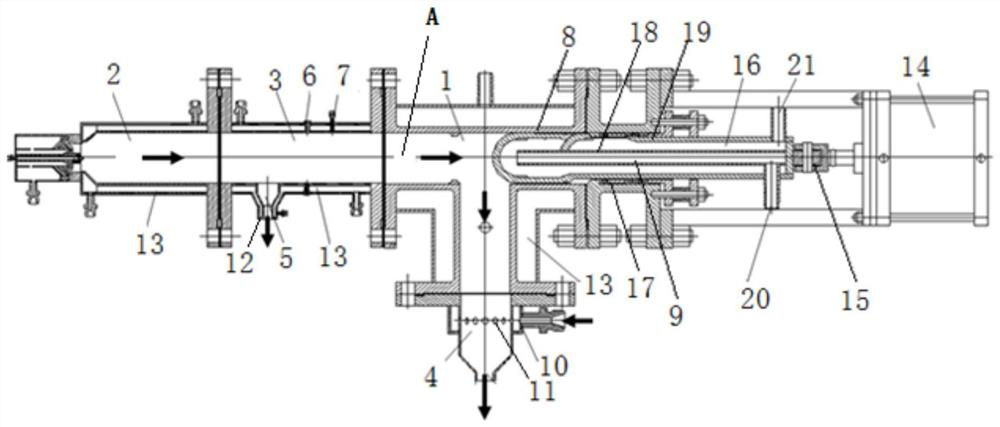

Multi-band measuring method and device for actual ship underwater explosion strong impact environment

InactiveCN102788613AEasy to installReliably obtainedMeasurement devicesClassical mechanicsLow frequency band

The invention discloses a multi-band measuring method for an actual ship underwater explosion strong impact environment. High bands over 20Hz are measured by an acceleration transducer additionally provided with a filter, and a shock spectrum base curve is obtained; medium bands between 5Hz and 20Hz are measured by an electrometric reed instrument; low bands below 5Hz are measured by a low-frequency vibrator; and obtained correction value points of the medium bands and the low bands are used for correcting the shock spectrum base curve, so that a shock spectrum correction curve is obtained finally. The method can be used for actual ship explosion test measurement of surface vessels and submarines, and also can be applied to underwater explosion test impact environment measurement of laboratory models; and moreover, by the correction method, impact environment data and safety and damage radiuses of vessel systems, equipment and personnel can be accurately and reliably obtained, and reliable test bases can be provided for formulating, supplementing and modifying shock resistance design of the vessels and for examining and testing relevant military standards.

Owner:中国船舶重工集团公司第七〇二研究所

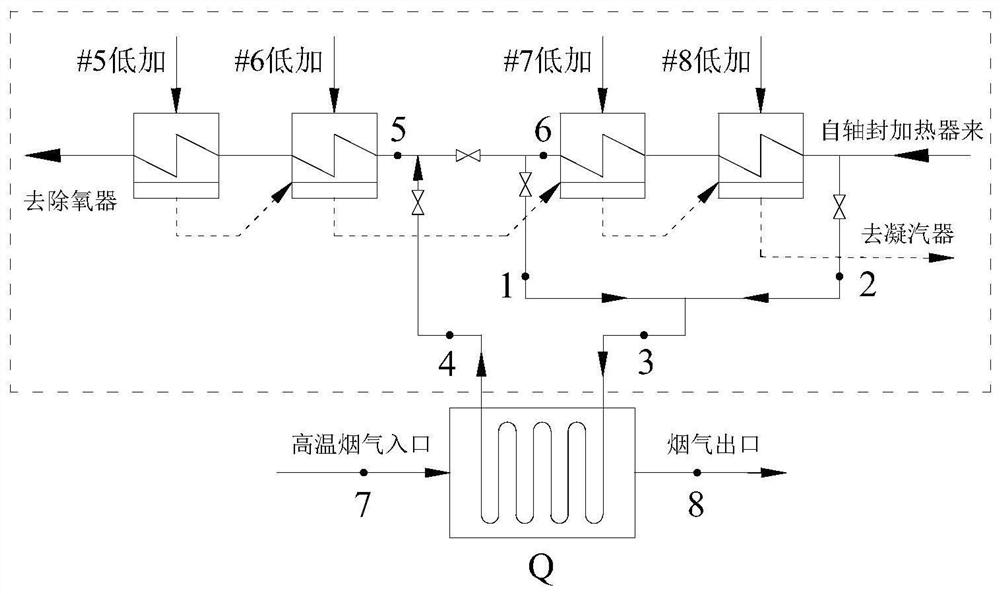

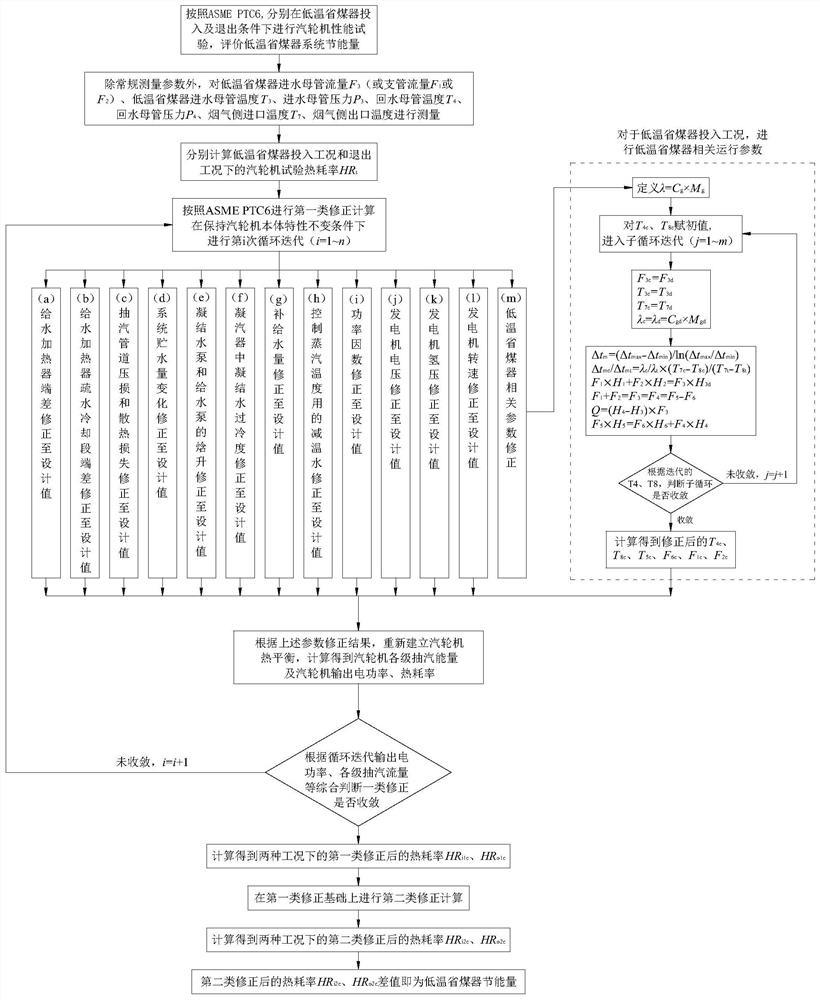

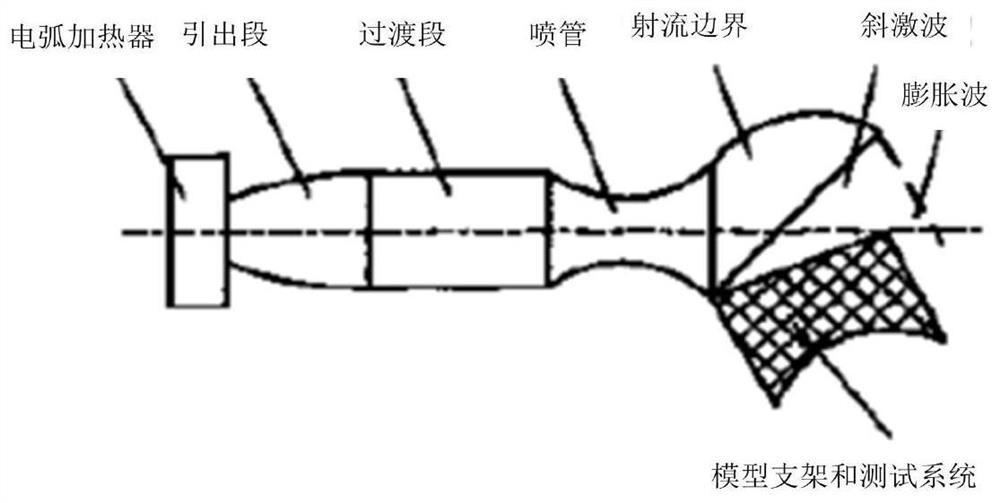

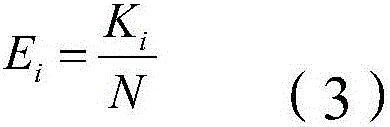

Correction calculation method for energy-saving amount assessment test of low-temperature economizer system

ActiveCN111666676AAvoid disagreementAvoid controversyDesign optimisation/simulationSpecial data processing applicationsFlue gasProcess engineering

The invention discloses a correction calculation method for an energy saving amount assessment test of a low-temperature economizer system. The correction calculation method comprises the steps: a, conducting performance tests under the working conditions of low-temperature economizer input and output according to ASME PTC6-2004 Steam Turbine Performance Test Regulations; b, calculating the actually measured heat consumption rate HRt of the steam turbine under the two working conditions; c, correcting the inlet flue gas temperature T7, the flue gas flow Mg, the flue gas specific heat capacityCg, the water supply main pipe flow F3 and the water supply main pipe temperature T3 by adding additional sub-loop iteration in the first type of correction calculation under the input working condition of the low-temperature economizer; d, carrying out second-class correction calculation to obtain the corrected heat consumption rate of the steam turbine under the two working conditions; and f, calculating the corrected heat consumption rate difference value under the two working conditions to obtain the energy-saving effect of the low-temperature economizer. According to the correction calculation method, the operation boundary condition of the low-temperature economizer can be corrected to a design value in the energy-saving amount assessment test of the low-temperature economizer system, so that the bifurcation or dispute of buyers and sellers to the energy-saving amount acceptance test result of the low-temperature economizer is avoided.

Owner:XIAN THERMAL POWER RES INST CO LTD

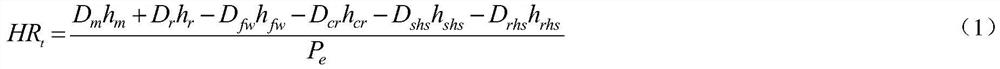

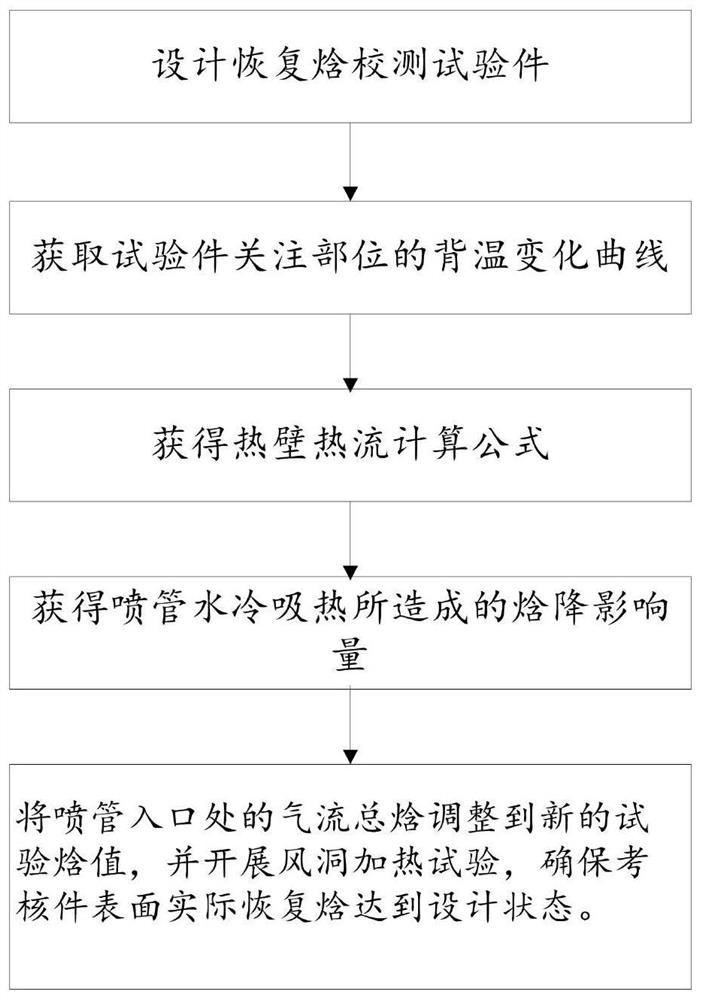

Recovery enthalpy calibration test piece and wind tunnel thermal assessment method

ActiveCN111811768ASolve problems that are difficult to accurately assessEffective guidance designAerodynamic testingHeat flowFlight vehicle

The invention provides a recovery enthalpy calibration test piece and a wind tunnel thermal assessment test method. The method comprises the following steps: designing the recovery enthalpy calibration test piece and acquiring a back temperature change curve of a concerned part of the test piece; acquiring a change curve of hot-wall heat flow on the surface of the test piece along with wall enthalpy, and acquiring a hot-wall heat flow calculation formula through linear fitting; acquiring an enthalpy drop influence quantity delta H, which satisfies the equation that H=H-h<r>, caused by water cooling and heat absorption of a spray pipe according to a difference between the actual recovery enthalpy of the surface of the test piece and the designed surface recovery enthalpy H; acquiring a newtest enthalpy value newH, which satisfies the equation that newH=2H-h<r>; and adjusting the total enthalpy of airflow at the inlet of the spray pipe to a new test enthalpy value newH, and carrying outa wind tunnel heating test to ensure that the actual recovery enthalpy of the surface of the assessed piece reaches a design state. The enthalpy drop influence quantity caused by water cooling and heat absorption of the spray pipe is evaluated through the test piece, and the test state of formal assessment is designed according to the enthalpy drop influence quantity, so a thermal protection system of an aircraft is assessed truly and effectively.

Owner:BEIJING AEROSPACE TECH INST

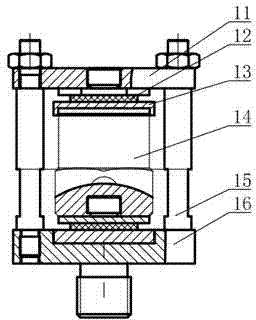

Temperature-centrifugation composite environment assessment test device and test method

PendingCN111442944AHigh strengthSmall amount of thermal deformationStructural/machines measurementStructural engineeringMechanical engineering

The invention discloses a temperature-centrifugation composite environment assessment test device and a test method. The test device comprises a centrifuge test system, a thermal loading unit and a data monitoring processing unit; the centrifuge test system comprises a centrifuge and a fairing; and the thermal loading unit is integrally mounted at the far end of a big arm of the centrifuge, the fairing is mounted outside the thermal loading unit in a sleeving manner, a vacuum environment is arranged inside the fairing, and a test piece is arranged in the thermal loading unit. According to thedevice and the method, vacuum, high temperature, centrifugal load and load history under action scenes such as space isotope heat source product ground emission, space attitude adjustment, space detection, landing and the like can be accurately simulated; a complete data testing system is arranged, multiple parameters such as the temperature, the strain, the vacuum degree and the product state canbe detected in an integrated mode in the testing process, and the product response situation of a tested product under the temperature-centrifugation composite environment can be accurately obtained.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

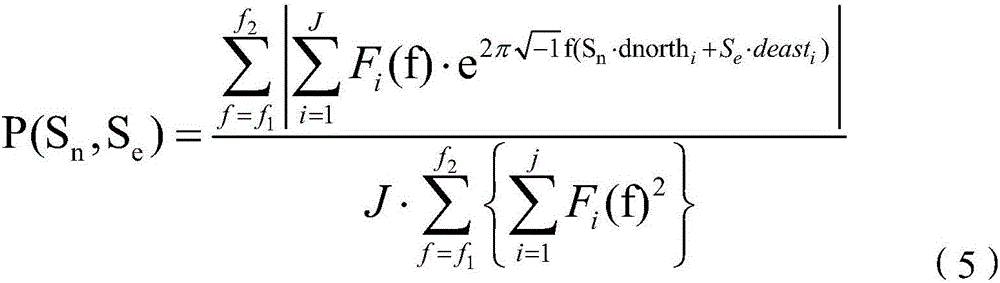

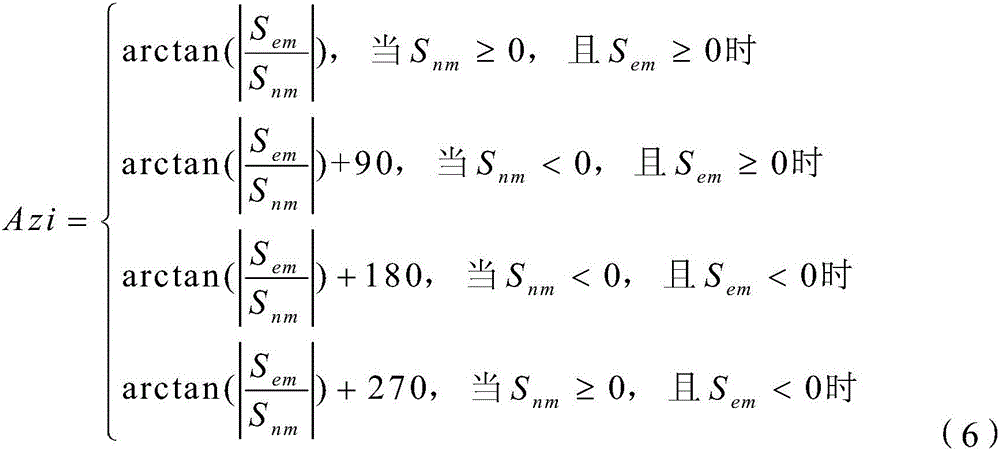

Specific region earthquake event alarm method

Owner:CTBT BEIJING NAT DATA CENT

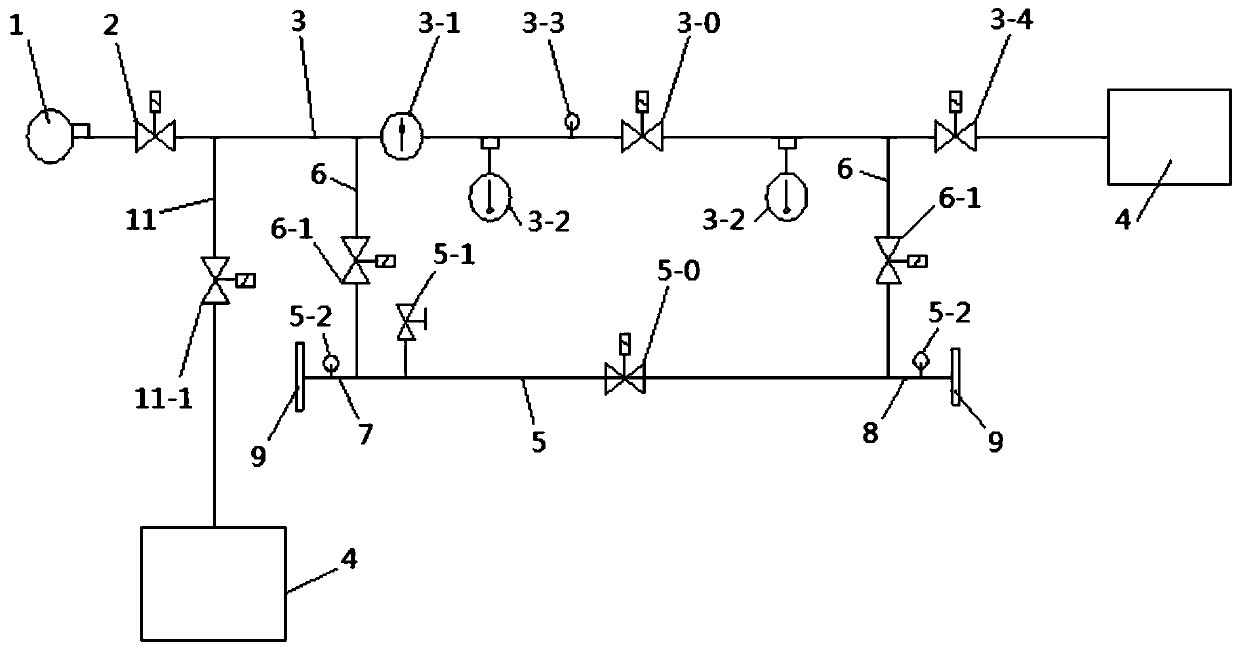

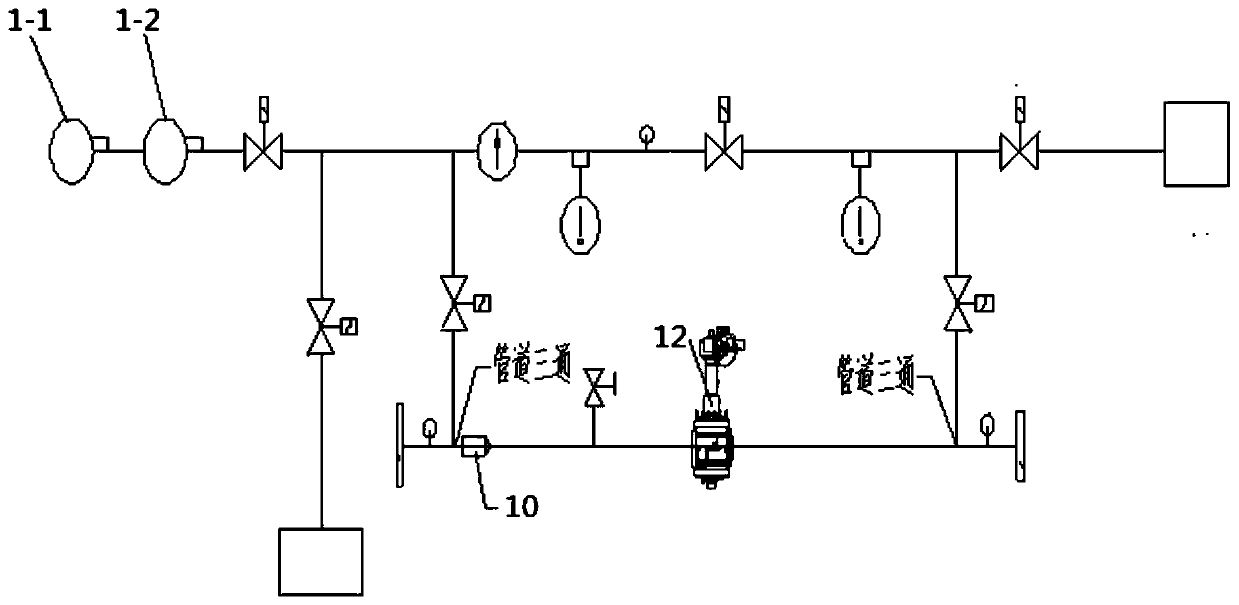

Valve load test system

PendingCN111426467AMeet the requirements of actual working conditionsAvoid huge lossesMachine valve testingMarine engineeringWater hammer

Owner:CHINA PETROLEUM & CHEM CORP +2

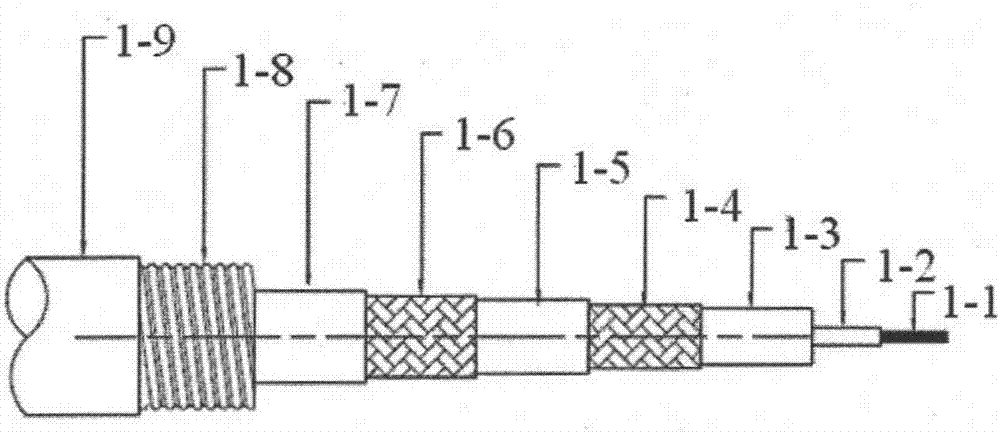

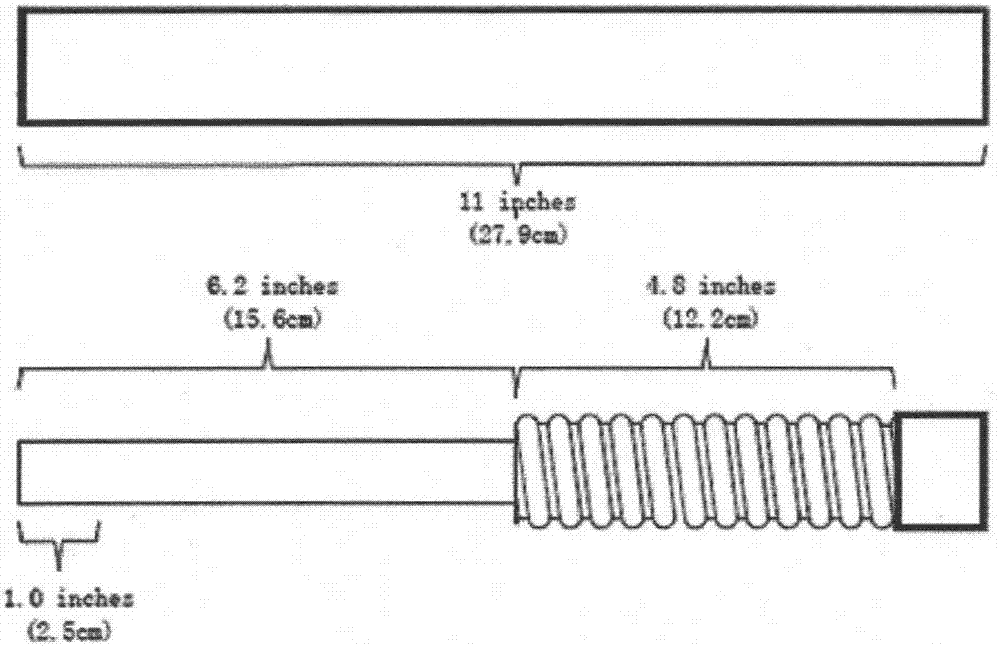

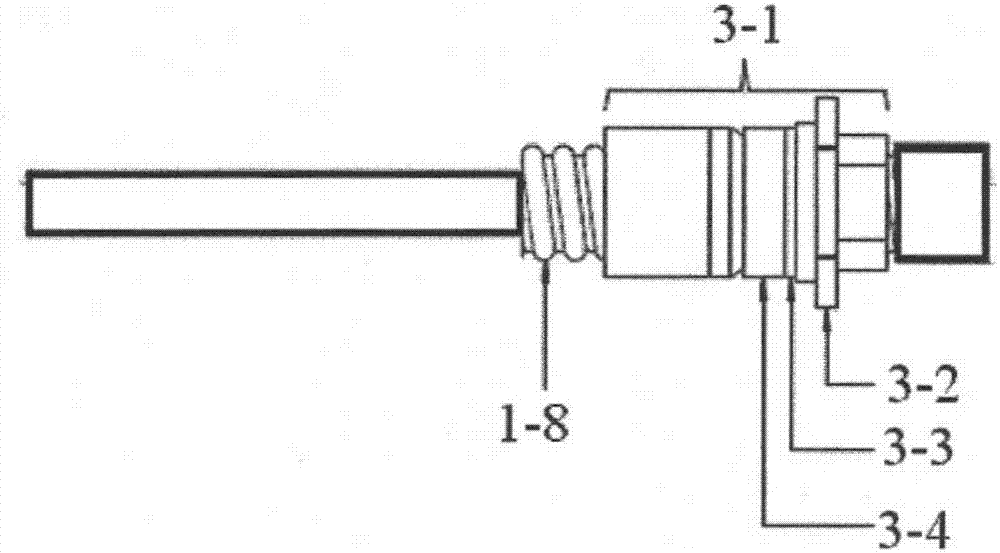

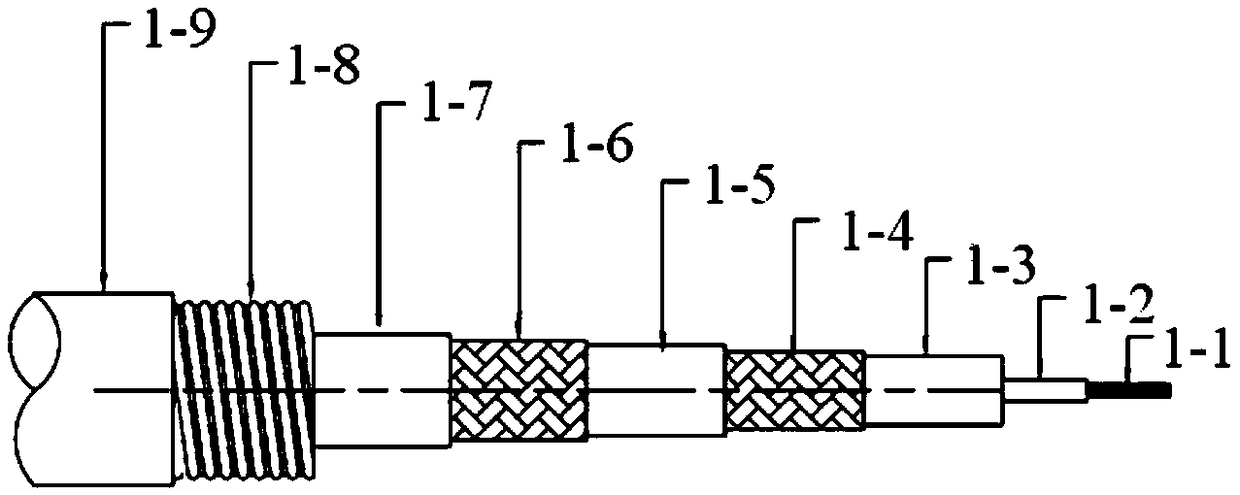

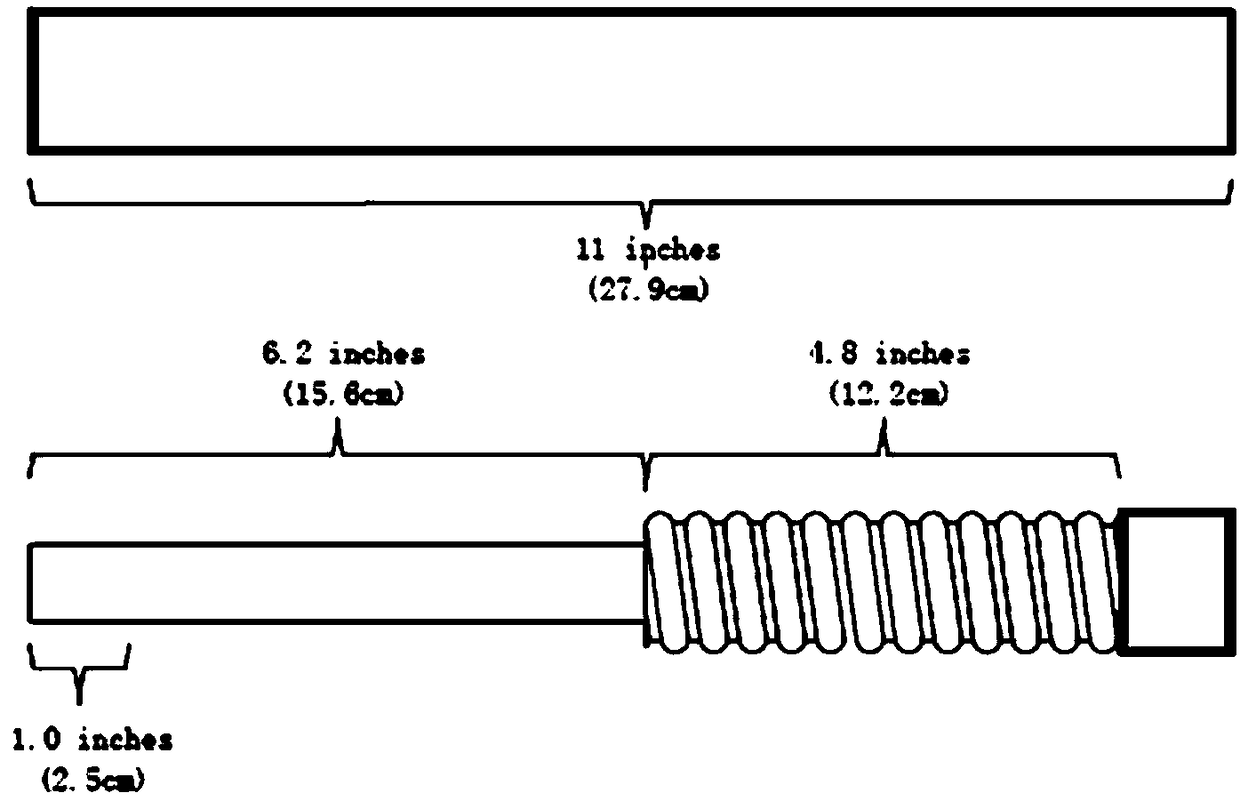

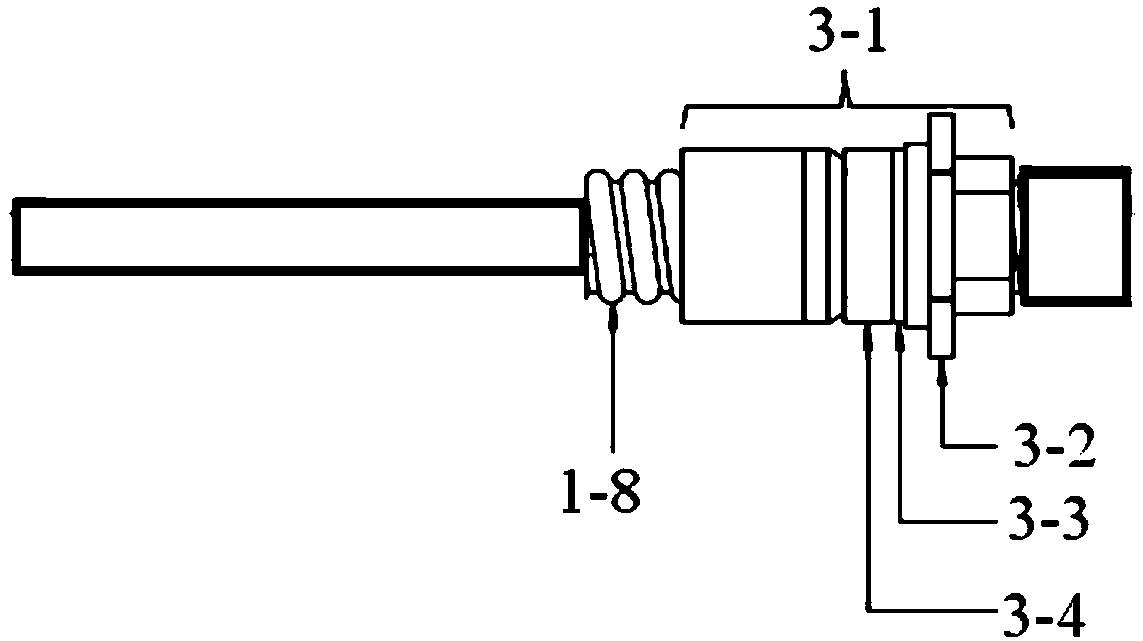

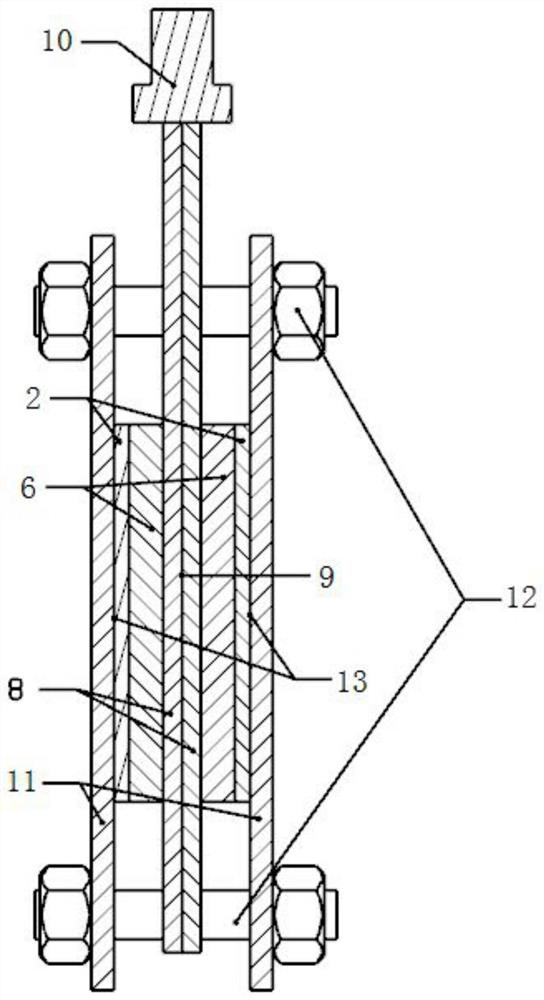

Mechanically-sealing four-coaxial cable termination technology

ActiveCN107104342AOvercome the defect of low success rate onceGuaranteed uptimeContact member cases/bases manufactureNuclear powerNuclear engineering

The invention discloses a mechanically-sealing four-coaxial cable termination technology. The technology is characterized by comprising the steps of 1) preparation of termination; 2) processing a spiral copper armored casing; 3) welding a cable sealing support; 4) inspecting the appearance after welding; 5) leak detection; 6) preparation of a three-coaxial cable joint; 7) inspecting the size of the completed three-coaxial cable joint; and 8) installing a sealing device. According to the invention, the defect that the first pass yield of the coaxial cable of a nuclear power station is low traditionally is overcome, the first pass yield can reach 100% according to verification in the San Men nuclear power station AP1000, a lot of materials and labor force can be saved, the joint is more stable and safer in operation due to advancement of the technology, and a test channel of an out-of-core nuclear test system can be used for 60 years, which is 20 yeas more than that of traditional products of the same kind, under severe environments of high temperature, high humidity and high irradiation.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

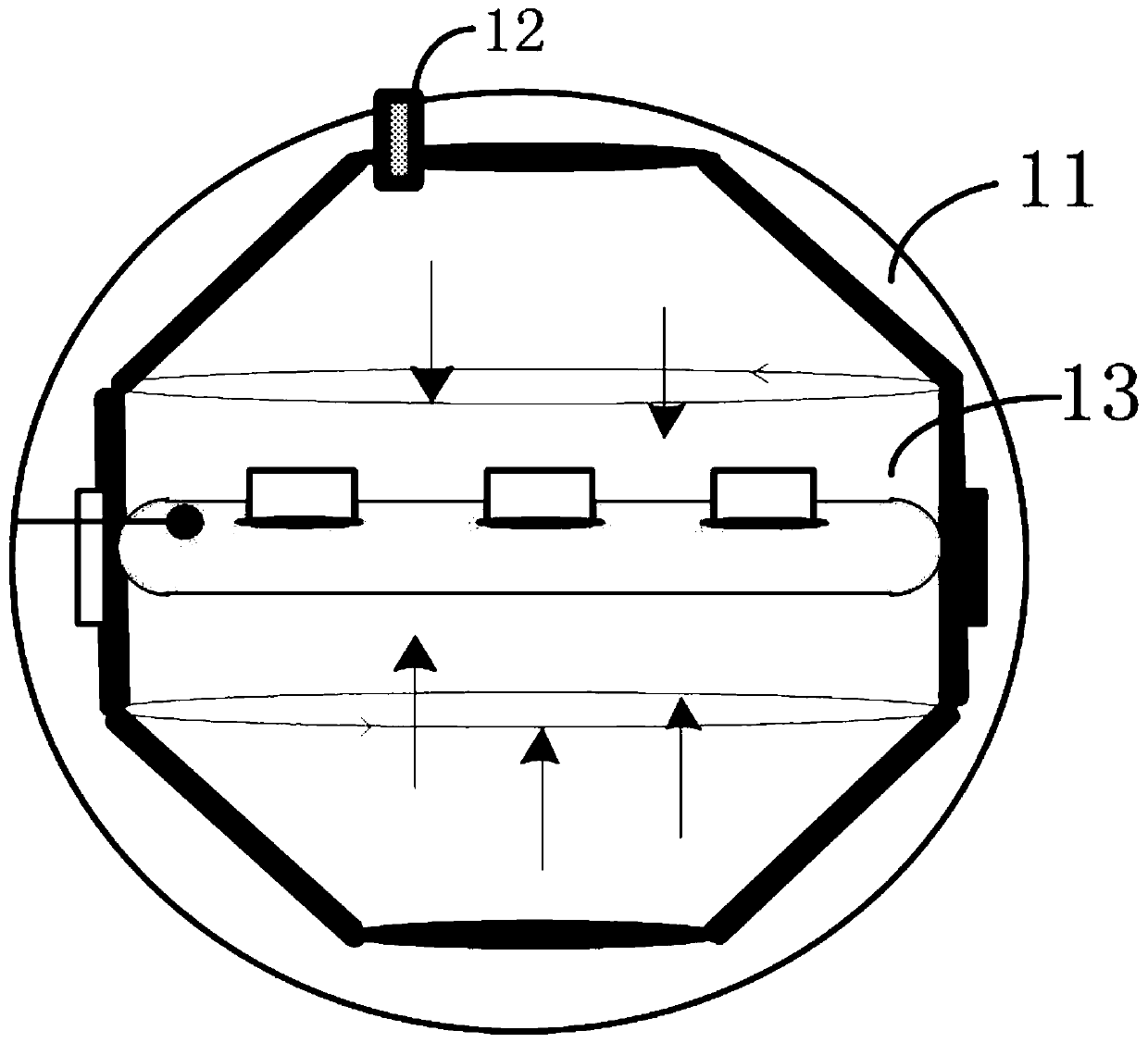

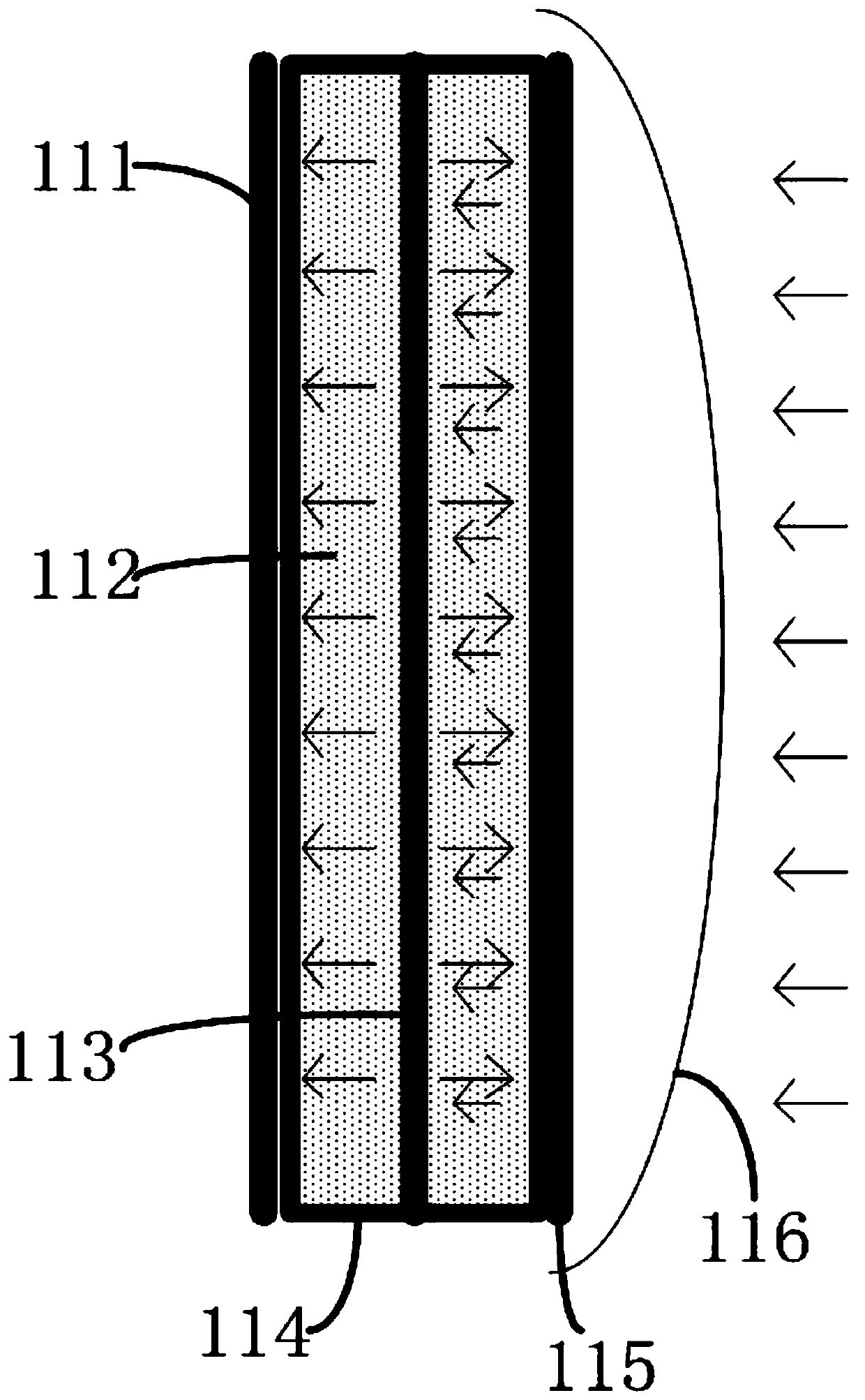

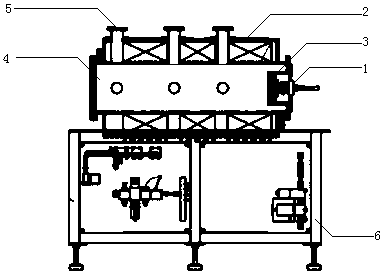

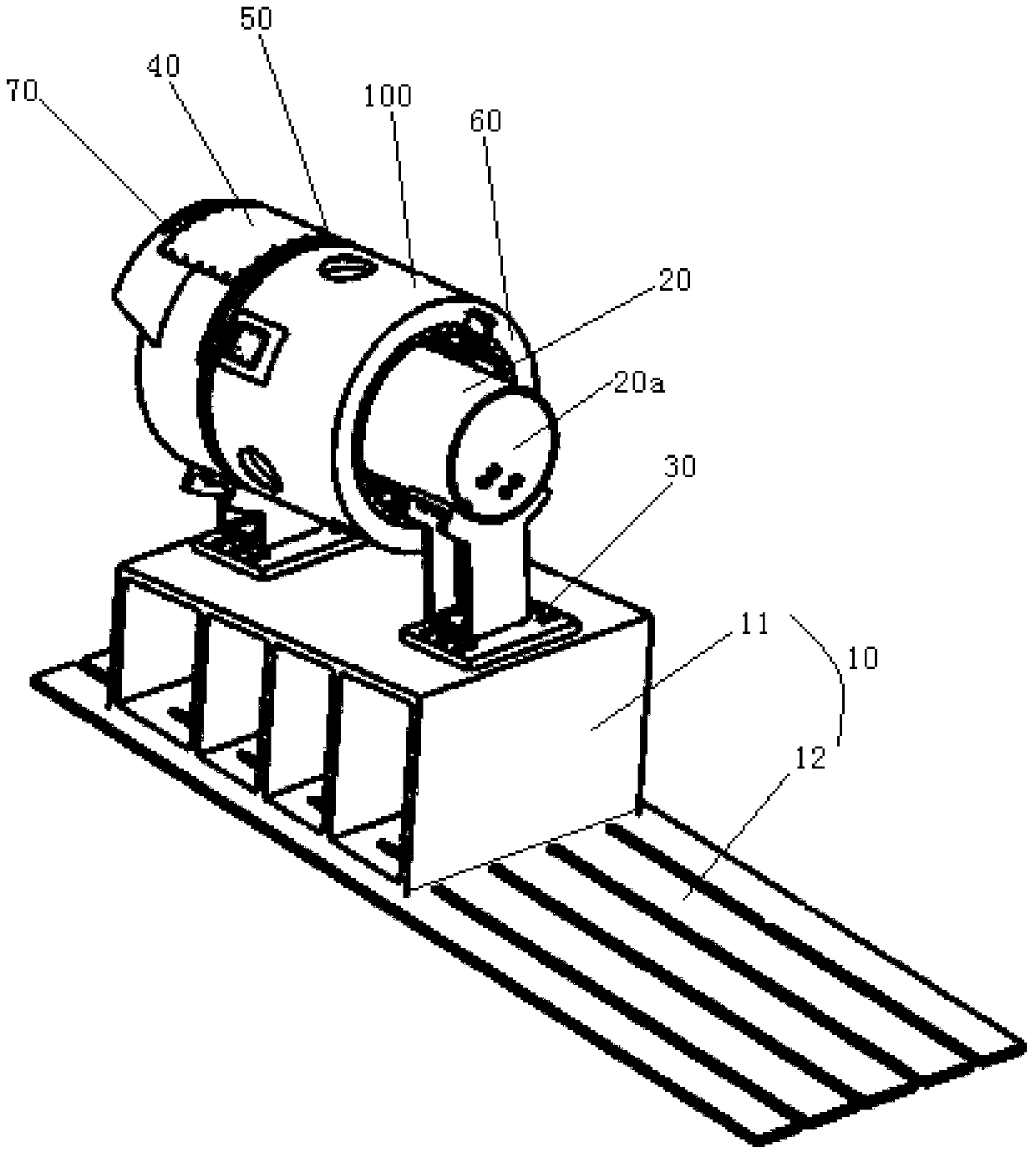

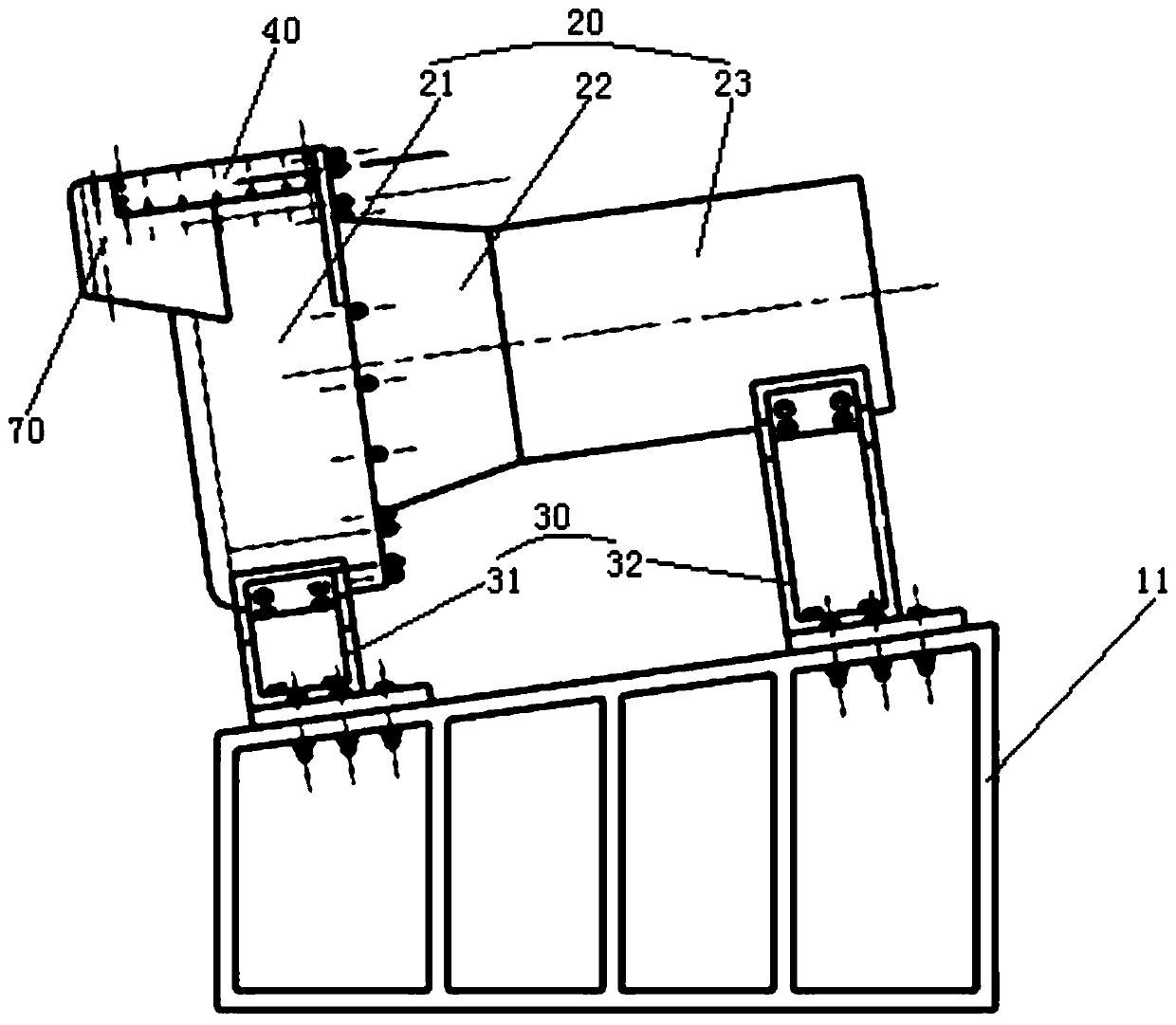

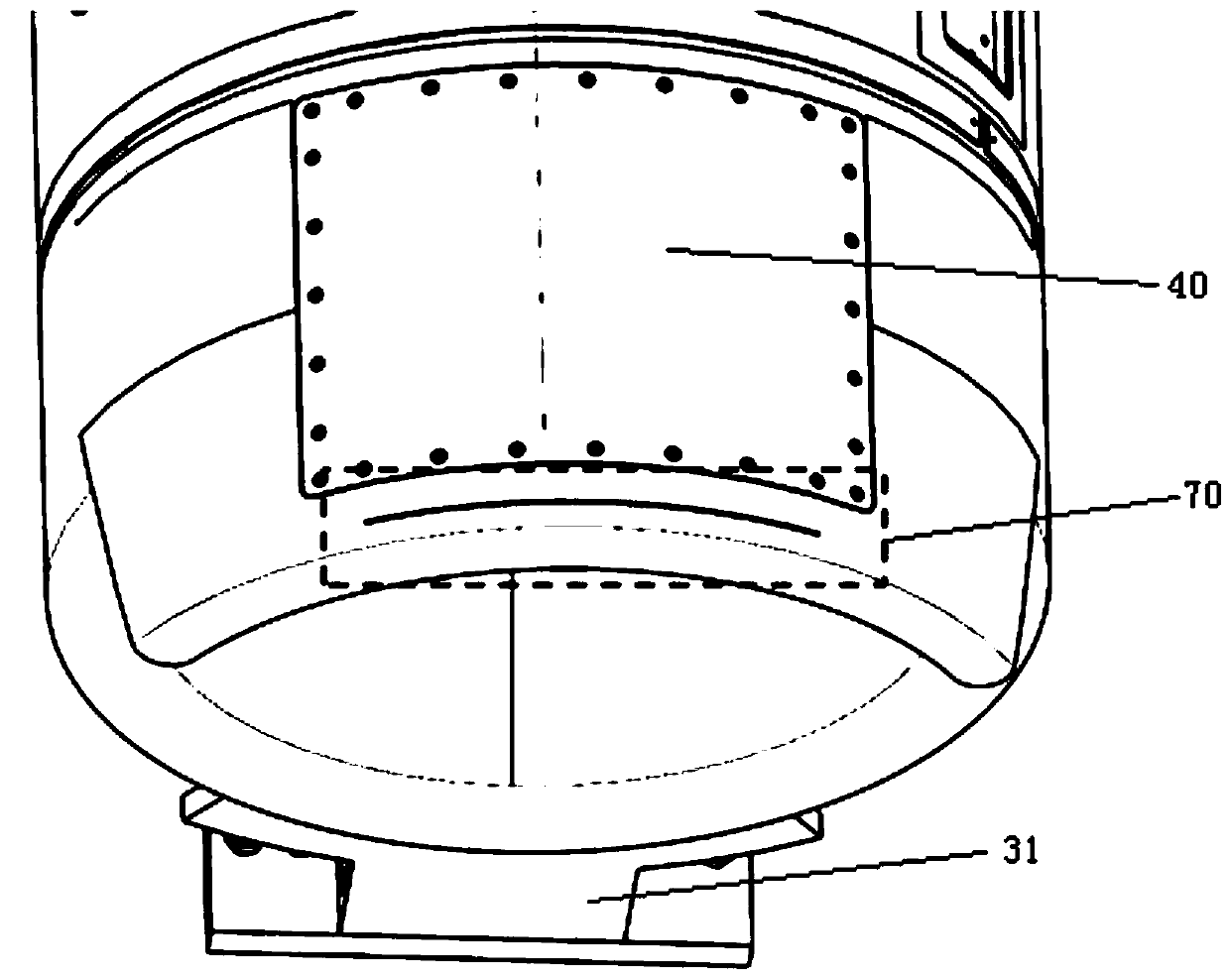

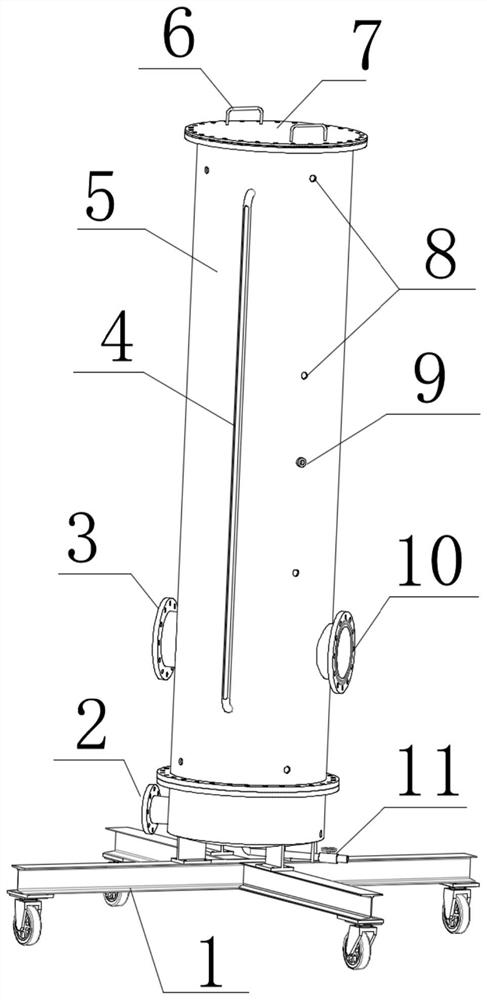

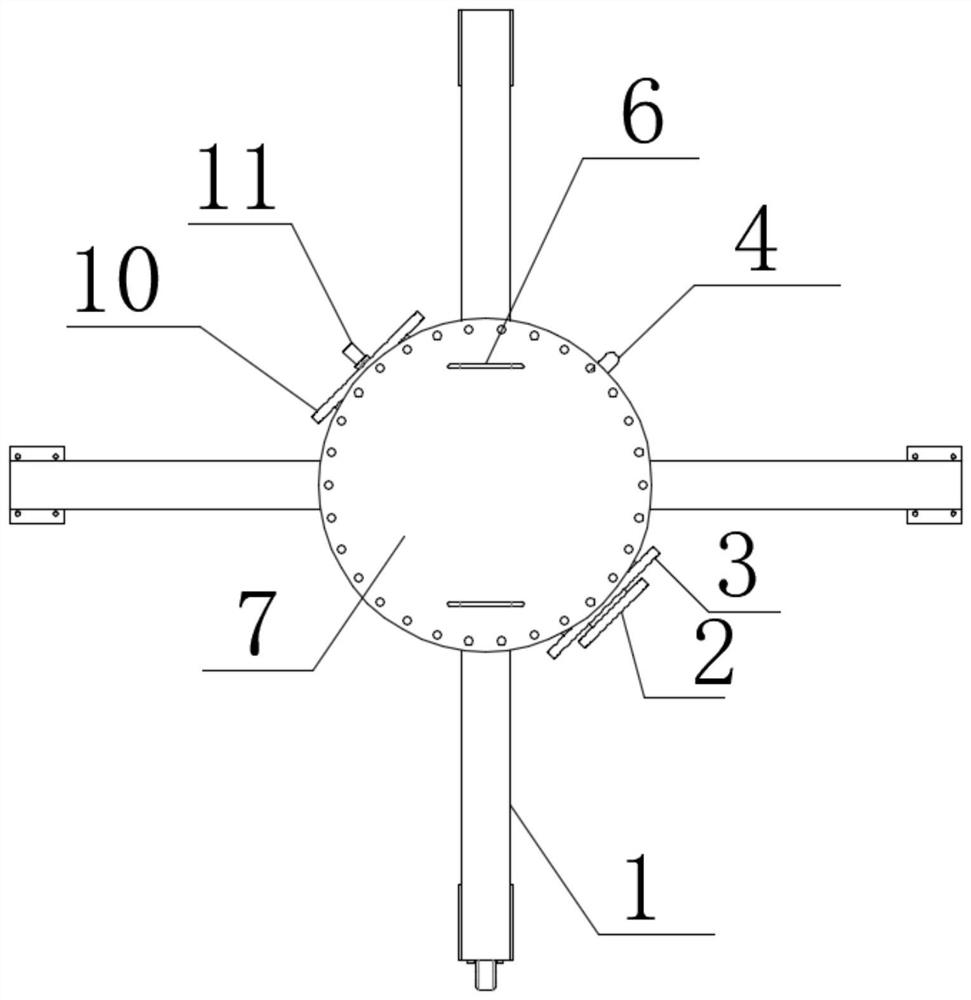

Device for efficient plasma transport of nuclear fusion experimental equipment

ActiveCN108932983AHigh densityIncrease ionization rateNuclear energy generationThermonuclear fusion reactorNuclear fusionIonization

A device for plasma efficient transport of nuclear fusion experimental equipment is disclosed and comprises an ion source device and a magnetic field coil device on a nuclear fusion experimental equipment body. The device for plasma efficient transport consists of an ion source device mounting plate, a vacuum chamber, observation windows, a fixed platform, a vacuum pump group and a vacuum pipeline; the vacuum chamber is installed on an upper part of the fixed platform, the vacuum pump group is connected to a left end of the vacuum chamber through the pipeline, the ion source equipment mountingplate is installed in the middle part of a right end of the vacuum chamber, the ion source device is installed on a right end of the ion source equipment mounting plate, a plurality of observation windows are arranged, each observation window consists of a pipeline and an observation plate, the observation plate is made of transparent material, the observation plate is installed on the upper partof the pipeline, pipes of the plurality of observation windows are respectively installed on a plurality of openings around an outer part of the vacuum chamber, and a plurality of magnetic field coildevices are respectively mounted around the outer part of the vacuum chamber. The device for plasma efficient transport disclosed in the invention helps overcome the shortcomings of conventional nuclear test equipment which is low in plasma beam density and ionization rate and incapable of meeting the requirements for processing fusion materials.

Owner:芶富均

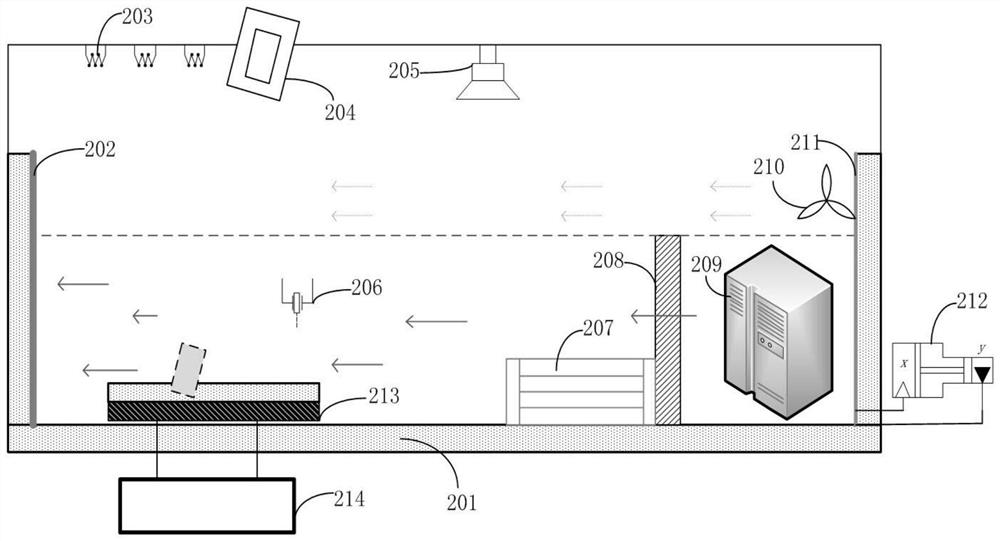

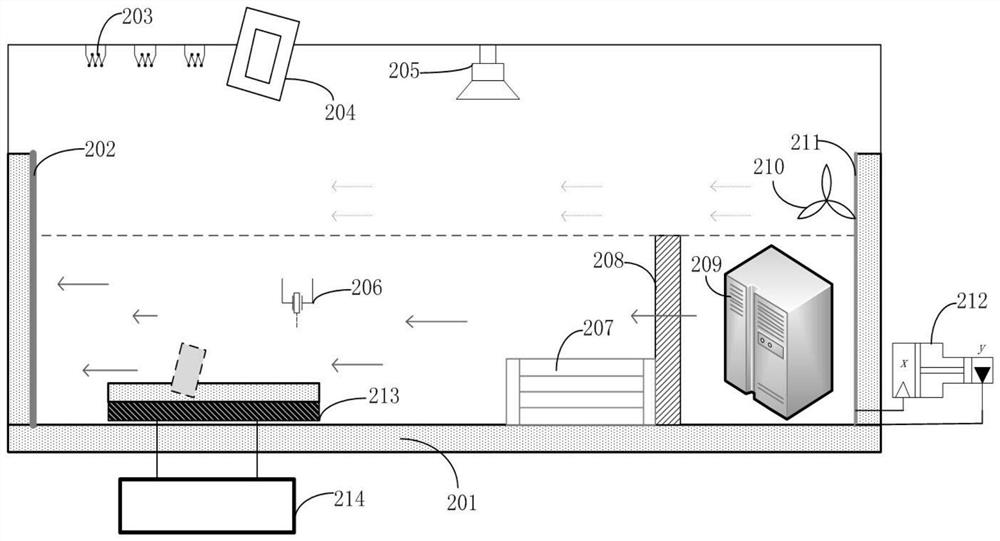

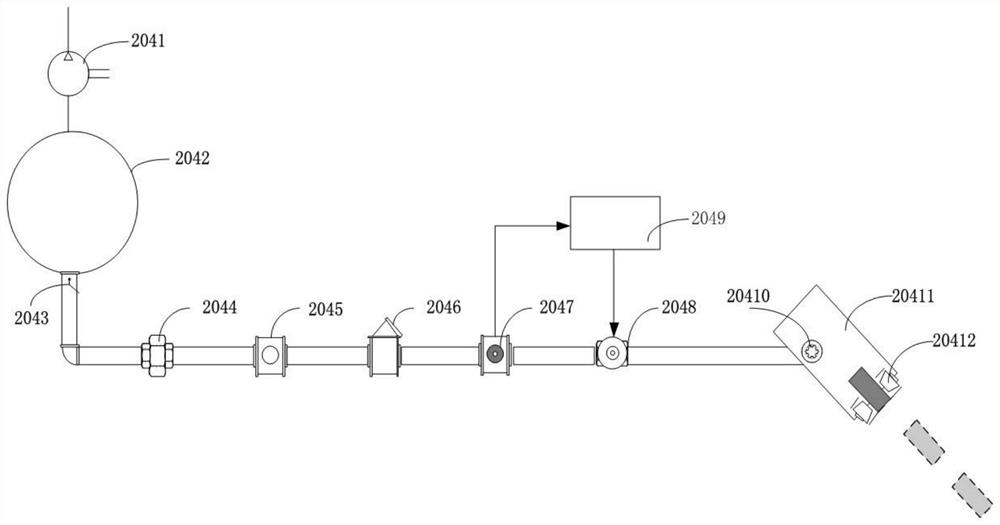

Self-heating device thermal shock water entry accident scene simulation test device and test method

ActiveCN112362375AScene simulation realRich in detailStructural/machines measurementEngineeringWater entry

The invention discloses a self-heating device thermal shock water entry accident scene simulation test device and test method, which can complete various test types such as a thermal shock test, a thermal shock water entry test, a seawater simulation test, a seabed long-term storage state environment adaptability assessment test, a seabed vibration environment adaptability assessment test and thelike. The experiment types can comprehensively simulate various accident environment loads of the self-heating device in launching and falling accident scenes, an analysis tool can be provided for product state response of the self-heating device from a dynamic scene to a deep sea storage scene, and technical support is provided for accident environment adaptability evaluation, improved design andthe like of products. The test piece launching device is used for simulating a scene when the test piece falls into seawater, can simulate the water entry angle of the test piece and can also simulate the water entry speed of the test piece, and compared with the traditional technology, the scene simulation is more real, and the detail consideration is richer.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

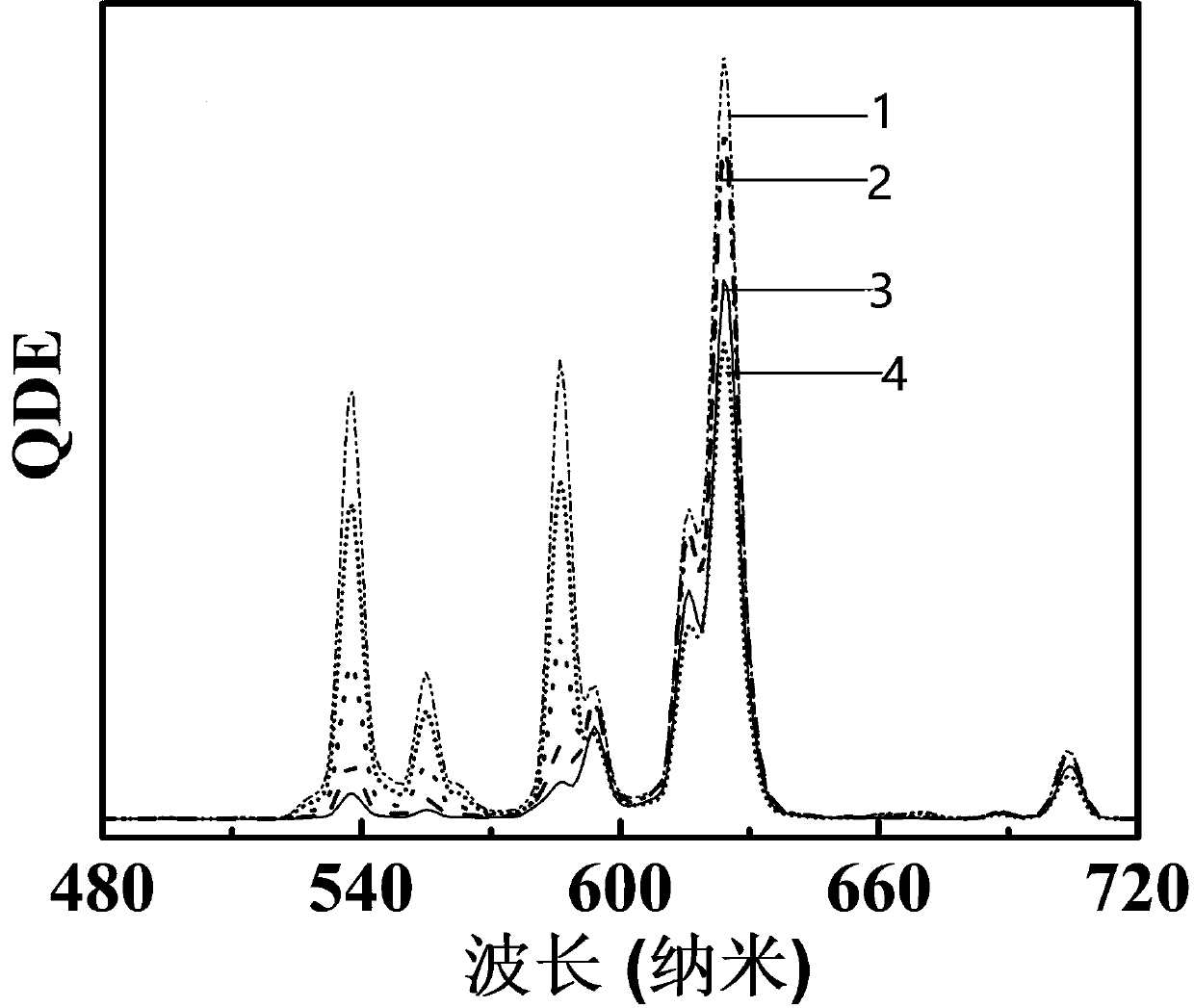

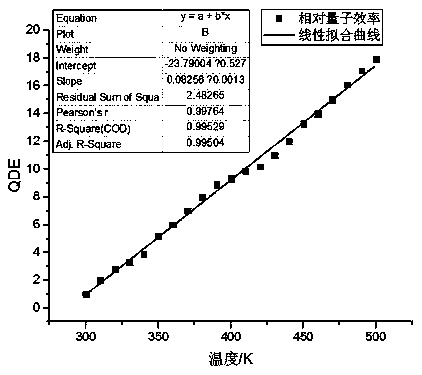

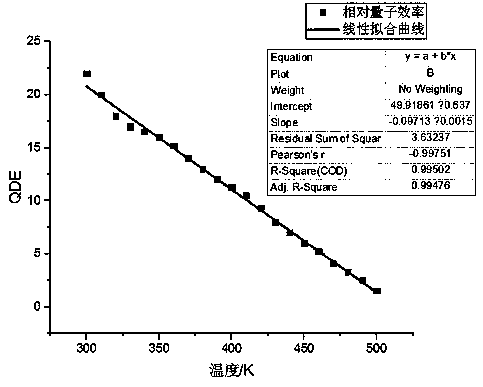

Novel nano temperature testing material preparation method

InactiveCN110240904AAchieve Response EfficiencyVisual temperature detectionThermometers using physical/chemical changesLuminescent compositionsTemperature responseLight emission

The invention discloses a novel nano temperature testing material preparation method. By using a hydrothermal method, a precursor material is synthesized by using a high-temperature reaction kettle, and by adjusting concentrations of different excitants, a material with different temperature responses is prepared in an inert and reduction atmosphere in an atmosphere reaction furnace, and the material emits orange red light of which the wavelength is 600-680nm under excitation of a light source of 200-400nm; by virtue of properties of different types of the excitants and response efficiency of different concentrations, a nano material with two properties that light emission efficiency is degraded and improved along with increase of temperatures is prepared, and synthesis of the material with controllable material granularities within 100-500nm is achieved; by using a spraying and printing process, the material is smeared to the surface of an article, and change of temperatures inside and outside the article can be achieved by detecting the light emission efficiency of the material; and in the field of wind tunnel testing, stress data of different parts can be rapidly and accurately acquired, and meanwhile, the material has optimal application prospects in special fields such as oil well exploration and nuclear test leakage detection.

Owner:SHANGHAI DONGZHOU IND

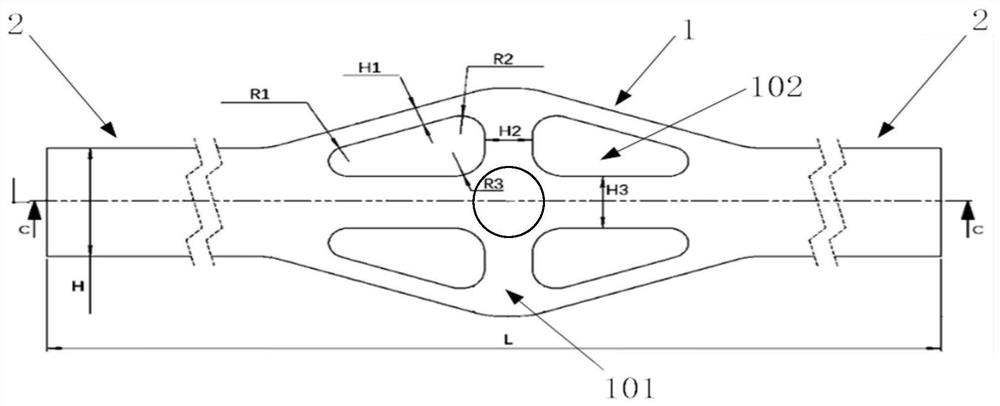

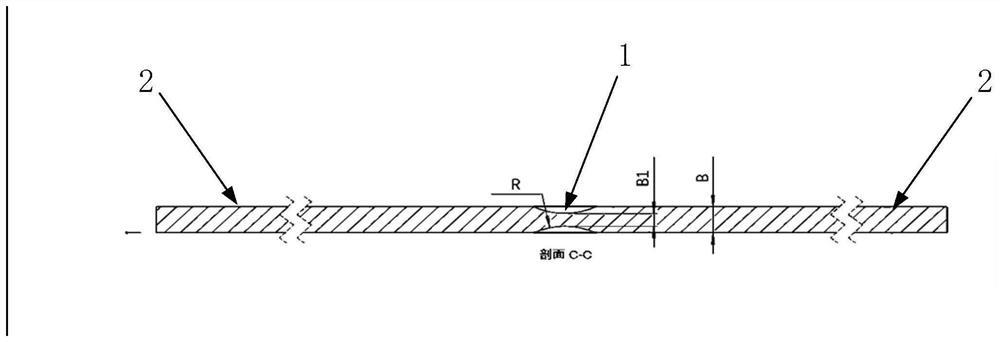

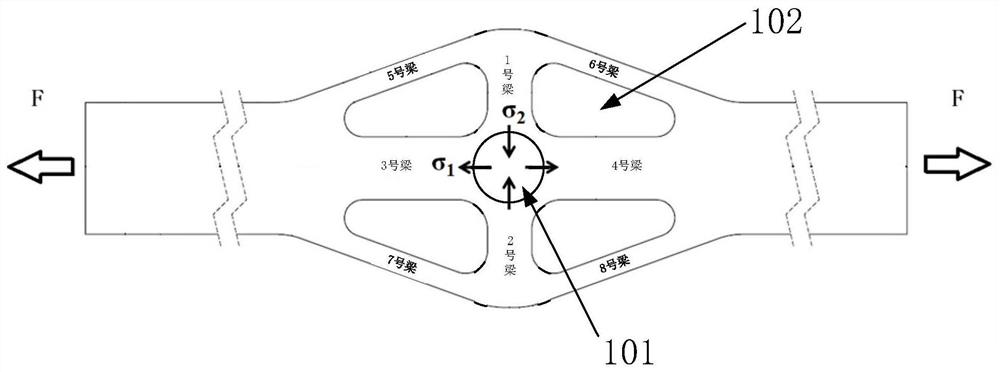

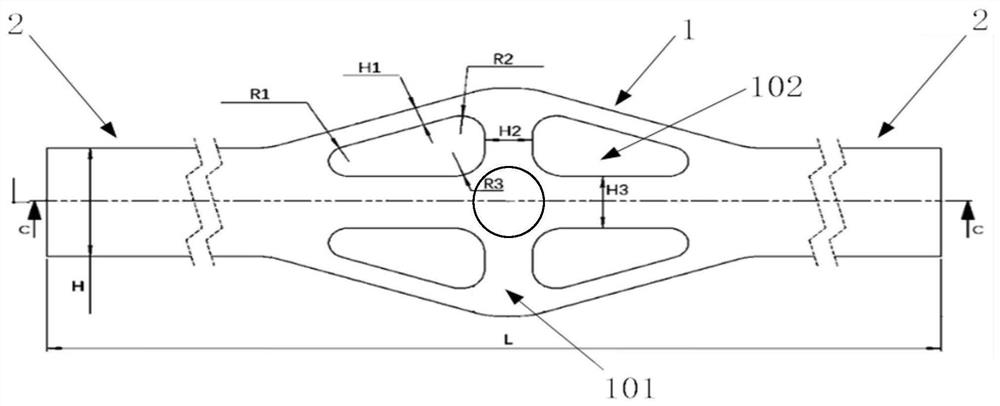

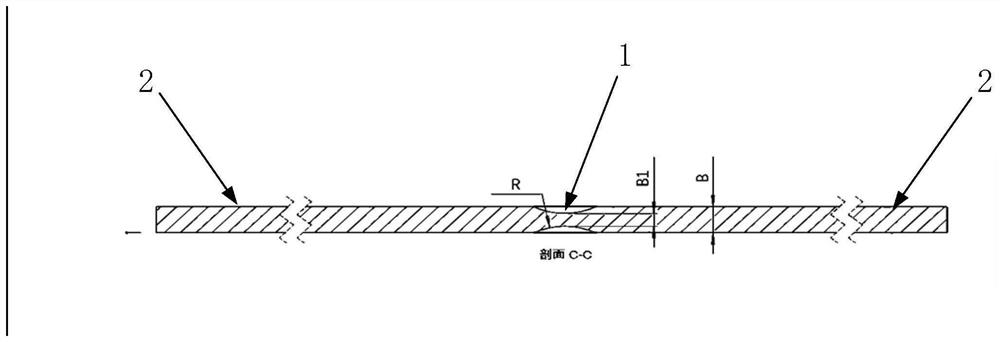

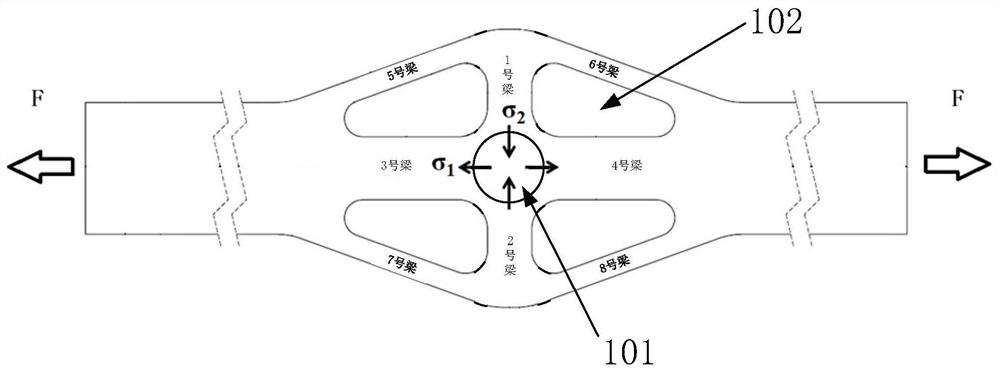

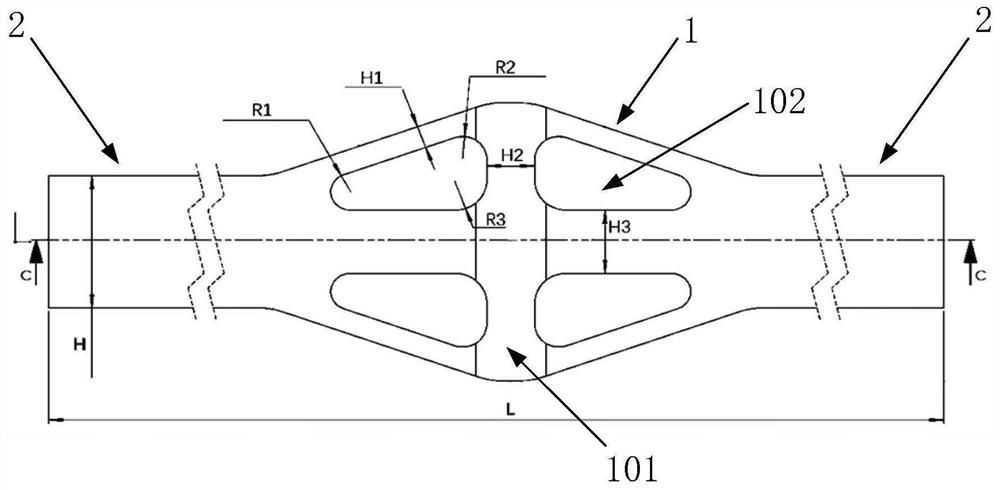

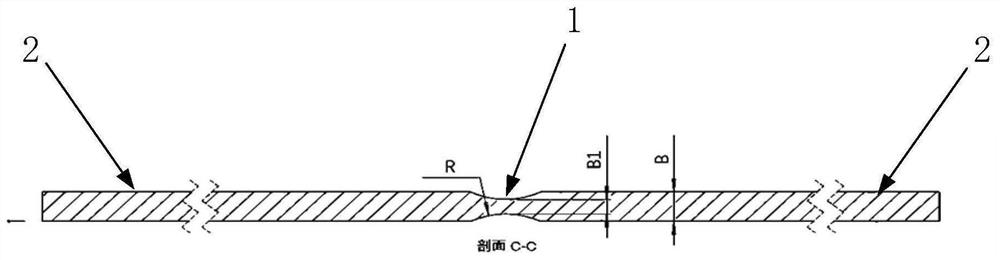

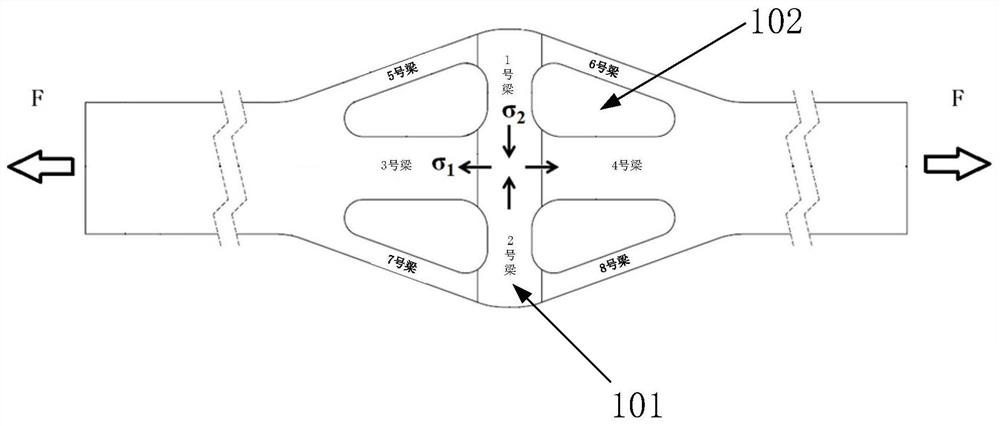

Test piece for realizing biaxial stress state through uniaxial loading of spherical working section

ActiveCN111855399AEasily damagedReduce residual deformationMaterial strength using tensile/compressive forcesDiagonalMachine

The invention discloses a test piece for realizing a biaxial stress state through uniaxial loading of a spherical working section. The test piece is integrally of a plate-shaped structure, the middlepart is a working section, the left and right sides are clamping sections, the working section is of a rhombic structure, and the two sides of two diagonal lines are partially symmetrical. Spherical recesses and special-shaped holes are designed in the working section; the spherical recesses are designed on the front and back surfaces of the working section and are positioned in the center of theworking section; the number of the special-shaped holes is four, and the four special-shaped holes are formed in the four parts, equally divided by the two angular bisectors, of the working section respectively. Loading of the test piece is achieved through a uniaxial fatigue testing machine, under the designed spherical recesses and special-shaped holes, a multi-axial stress state of stretching in the horizontal direction and compressing in the vertical direction is finally generated in the center of the whole test piece, and a typical tension / compression multi-axial stress state is formed. According to the invention, simulation of the tension and pressure biaxial state of the disc center of a turbine disc can be realized, part-level assessment tests can be partially replaced, the structural design period is shortened, and the test cost is saved.

Owner:BEIHANG UNIV

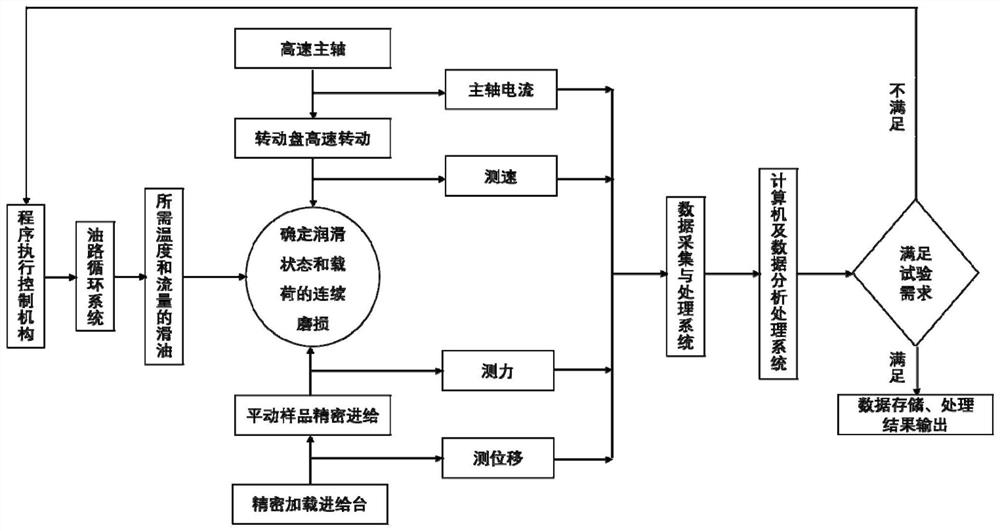

Testing machine and method for evaluating wear life of graphite sealing material

PendingCN113567287AMeet studyMeet needsInvestigating abrasion/wear resistanceAviationData acquisition

The invention relates to the field of aero-engines, in particular to a testing machine and method for evaluating the wear life of a graphite sealing material. A high-speed ring block abrasion testing machine and a PV acceleration testing method are adopted, and the problems that in the prior art, the sliding linear speed of a friction pair is insufficient, loading and lubricating modes are inconsistent with actual working conditions, and the graphite sealing material wear life evaluation period is long are solved. The testing machine comprises a rotating main shaft, a rotating disc, a precise loading feeding table, an oil way lubricating system, a data acquisition system, a computer and the like, a PV value acceleration method is adopted, the PV value of a friction pair is increased by increasing the load and the linear speed in the testing process, and accelerated abrasion testing on the wear life of the graphite sealing material to be tested is achieved. The testing machine can realize high linear speed, radial fixed loading and oil lubrication states required by the graphite sealing pair. The test adopts the PV accelerated test method, is particularly suitable for accelerated examination of long service life of sealing materials such as graphite, can effectively shorten the time required by the service life test, and has economic benefits.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Wind tunnel test deflector

ActiveCN108760221BMeet the needs of wind tunnel testsSmall structure sizeAerodynamic testingEngineeringNuclear test

The invention provides a wind tunnel test flow-guiding device. The device comprises a base, a flow guiding assembly, an angle adjusting piece and a calibration assembly, a test piece to be examined isarranged on the flow guiding assembly, the flow guiding assembly is used for smoothly transitioning air flow at a wind tunnel air outlet to a surface of the test piece to be examined, the angle adjusting piece is used for adjusting the angle of attack of the test piece to be examined to match a thermal environment state of the set test piece to be examined, the calibration assembly is used for measuring the thermal environment state of the test piece to be examined to calibrate the thermal environment state of the test piece to be examined, and when the thermal environment state measured by the calibration assembly is different from the set thermal environment state, the wind tunnel test flow-guiding device adjusts the angle of attack of the test piece to be examined through the angle adjusting piece to reach the set thermal environment state of the test piece to be examined. The technical scheme of the invention is applied to solve the technical problem in the prior art that a certain section of cabin cannot be examined separately.

Owner:BEIJING AEROSPACE TECH INST

A Mechanically Sealed Quadriaxial Cable Termination Process

ActiveCN107104342BOvercome the defect of low success rate onceGuaranteed uptimeContact member cases/bases manufactureCoaxial cableHigh humidity

The invention discloses a mechanically-sealing four-coaxial cable termination technology. The technology is characterized by comprising the steps of 1) preparation of termination; 2) processing a spiral copper armored casing; 3) welding a cable sealing support; 4) inspecting the appearance after welding; 5) leak detection; 6) preparation of a three-coaxial cable joint; 7) inspecting the size of the completed three-coaxial cable joint; and 8) installing a sealing device. According to the invention, the defect that the first pass yield of the coaxial cable of a nuclear power station is low traditionally is overcome, the first pass yield can reach 100% according to verification in the San Men nuclear power station AP1000, a lot of materials and labor force can be saved, the joint is more stable and safer in operation due to advancement of the technology, and a test channel of an out-of-core nuclear test system can be used for 60 years, which is 20 yeas more than that of traditional products of the same kind, under severe environments of high temperature, high humidity and high irradiation.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

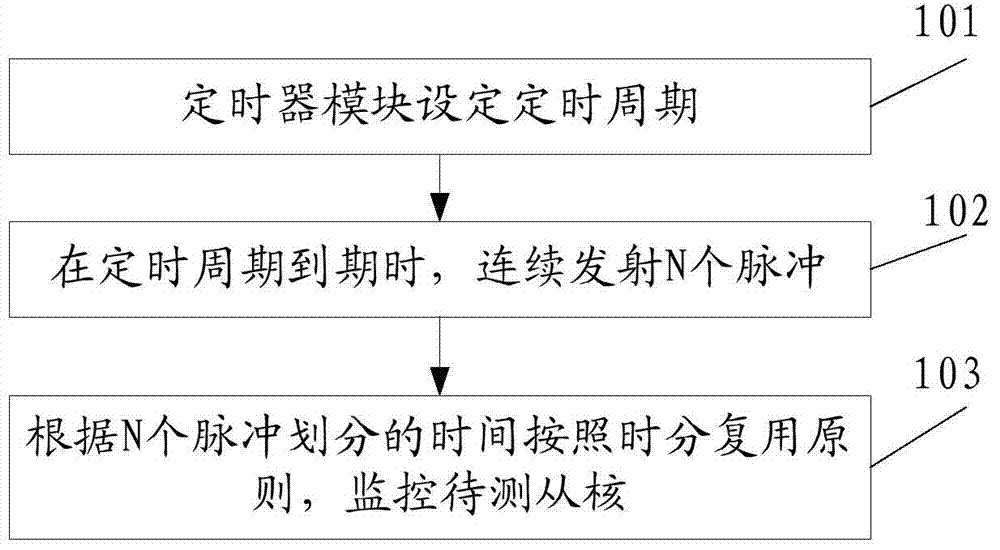

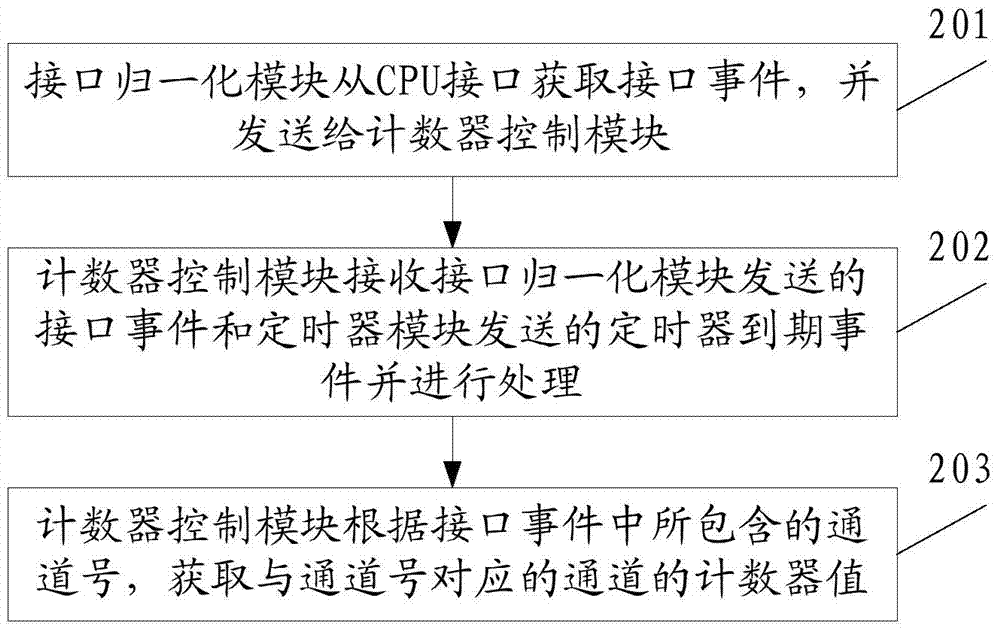

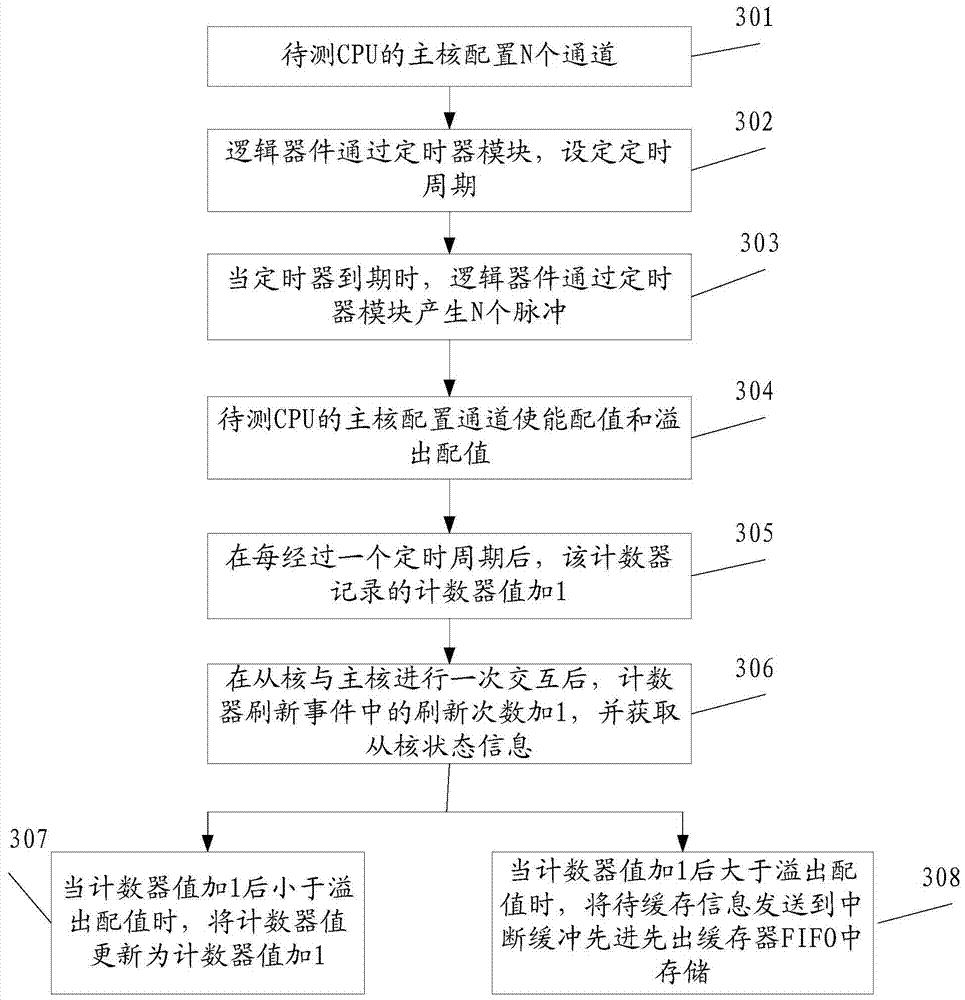

A monitoring method and device for a slave core state

ActiveCN104216813BImprove performanceReduce occupancyHardware monitoringTime-division multiplexingNuclear test

Owner:MAIPU COMM TECH CO LTD

Uniaxial loading of a spherical working section to achieve a biaxial stress state test piece

ActiveCN111855399BEasily damagedReduce residual deformationMaterial strength using tensile/compressive forcesMachineStressed state

Owner:BEIHANG UNIV

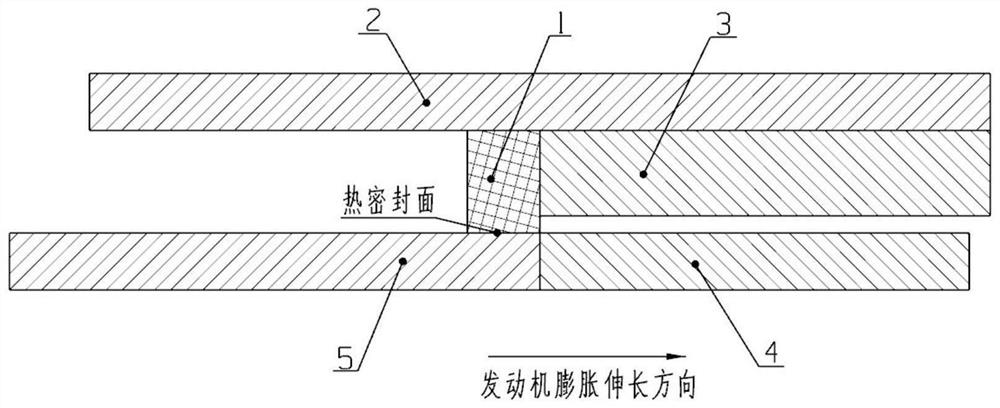

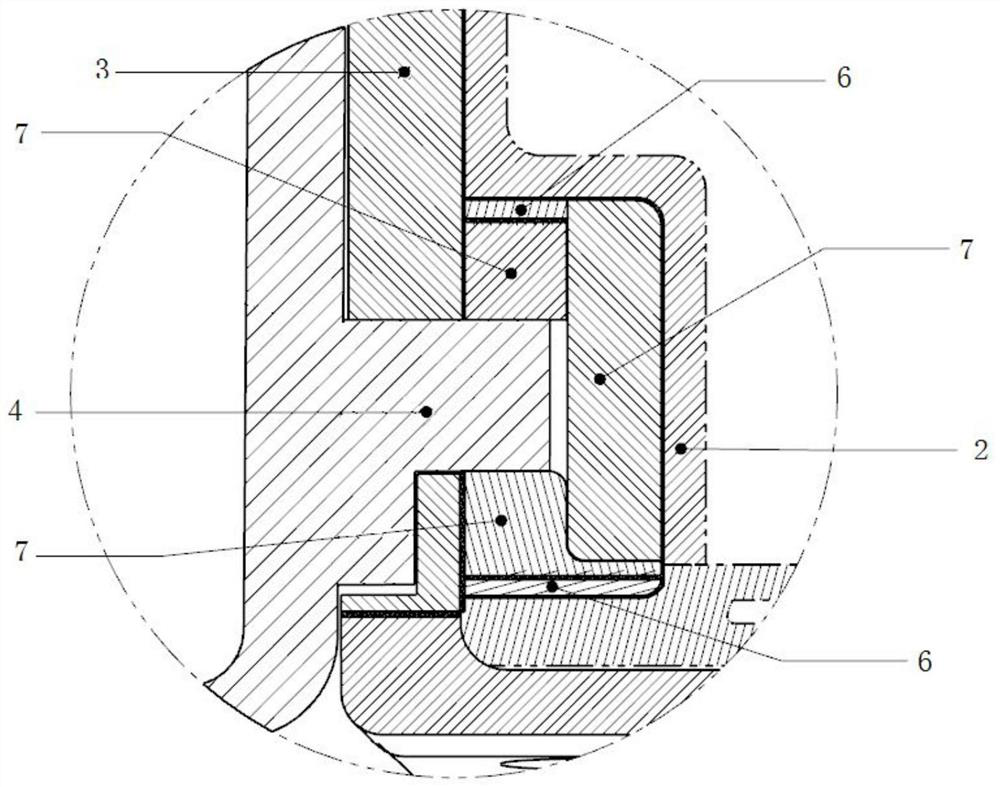

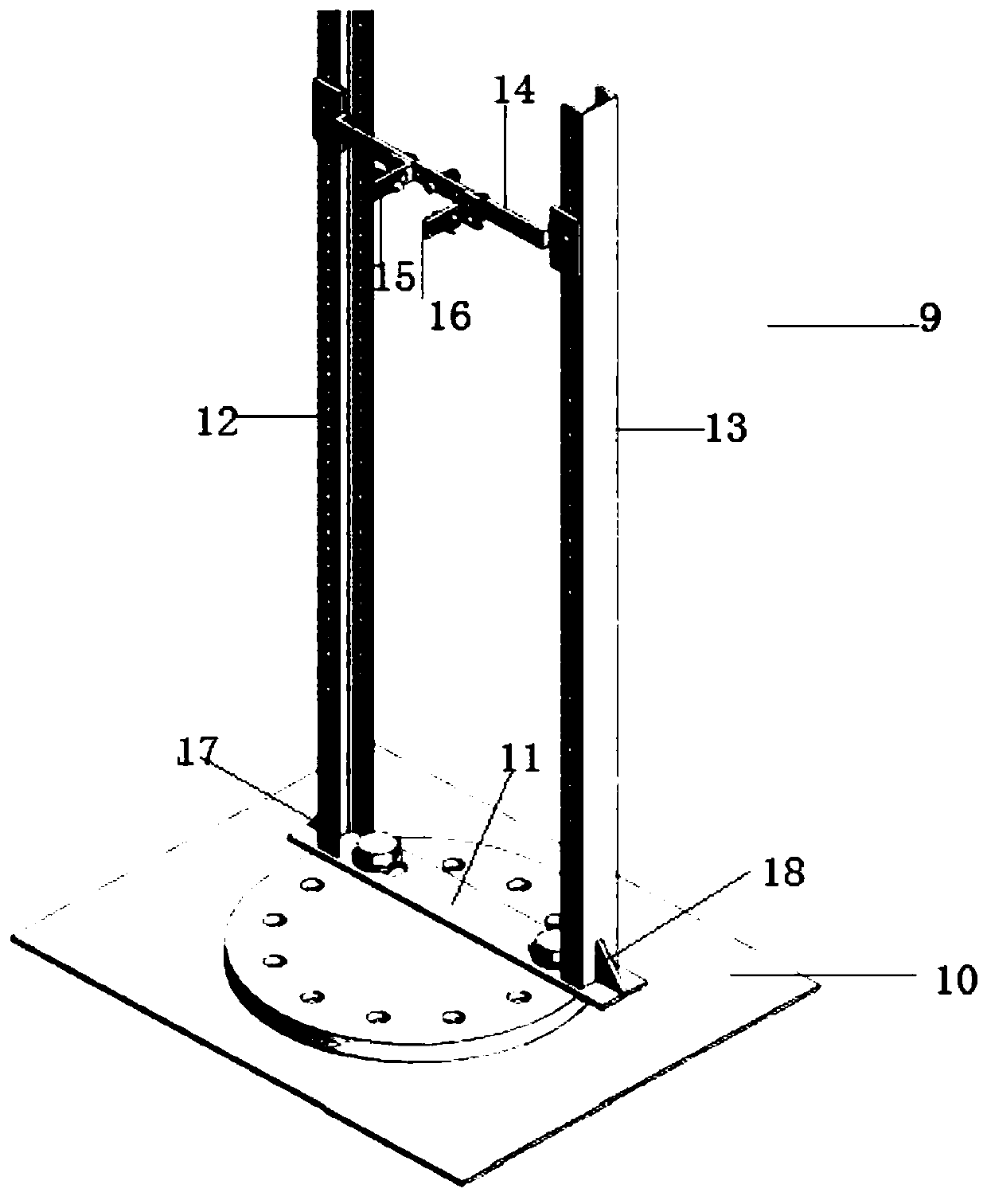

A structural thermal assessment test device with preload adjustment

ActiveCN110411769BRealize simulationEasy to controlStructural/machines measurementFlight vehicleThermal deformation

The invention provides a heat examining tester for a structure with pretightening force adjustment, and belongs to heat examining testers for heat sealing and insulation structures with pretighteningforces under effect heat deformation coordination. The tester mainly comprises a heating component, deformation coordinating plates, a loading device, an installation adjustment structure and pressuresensors, the two deformation coordinating plates are arranged in left-right symmetry, the loading device is mounted at one end of the two deformation coordinating plates, test members to be examined,bearing structures and pretightening force applying plates are successively arranged in the outer sides of the two deformation coordinating plates respectively symmetrically, the two pretightening force applying plates are compacted by the installation adjustment structure, and the heating component heats the test members to be examined in a non-contact way. Thus, pretightening force application,deformation coordination simulation and heating control are examined accurately by simulation, and the tester is suitable for heat examination test of the heat sealing and insulation structures withpretightening forces of a high speed aircraft.

Owner:BEIJING AEROSPACE TECH INST

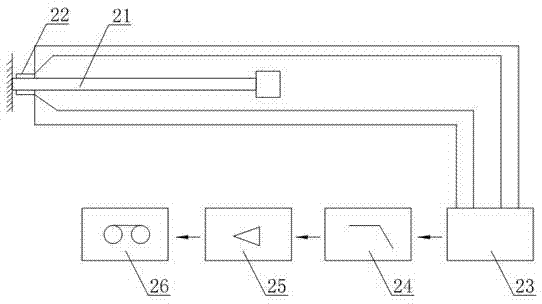

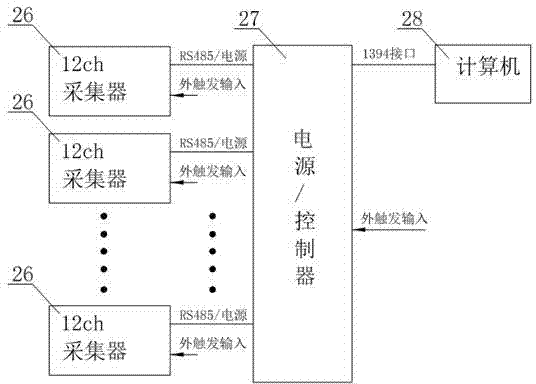

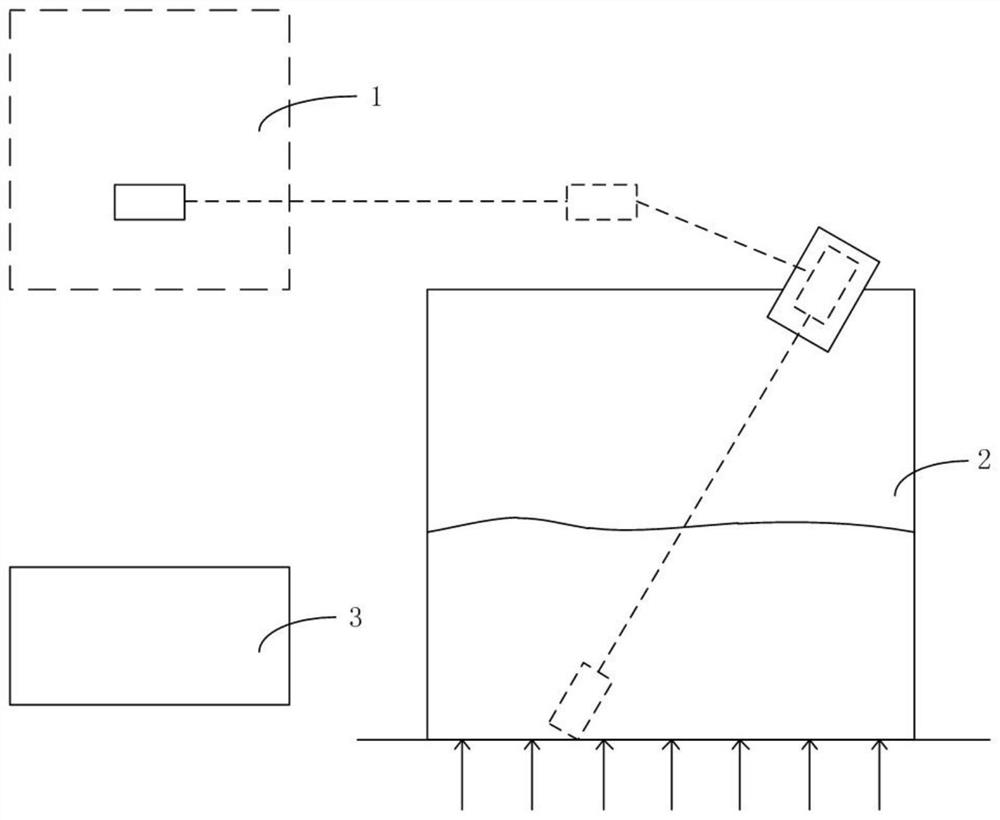

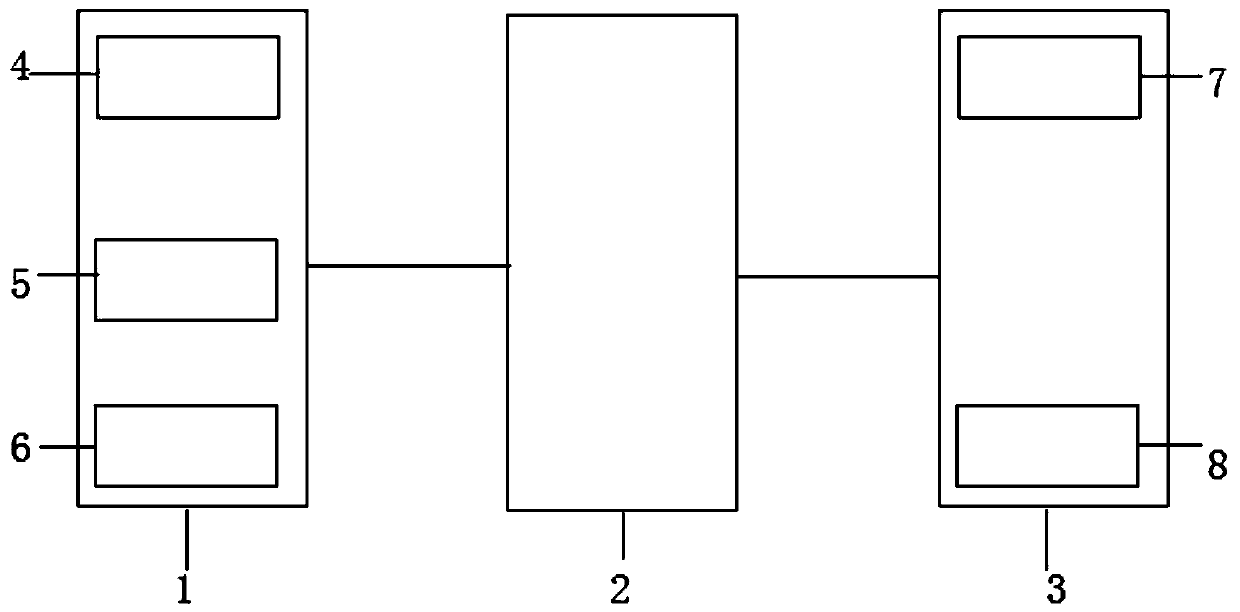

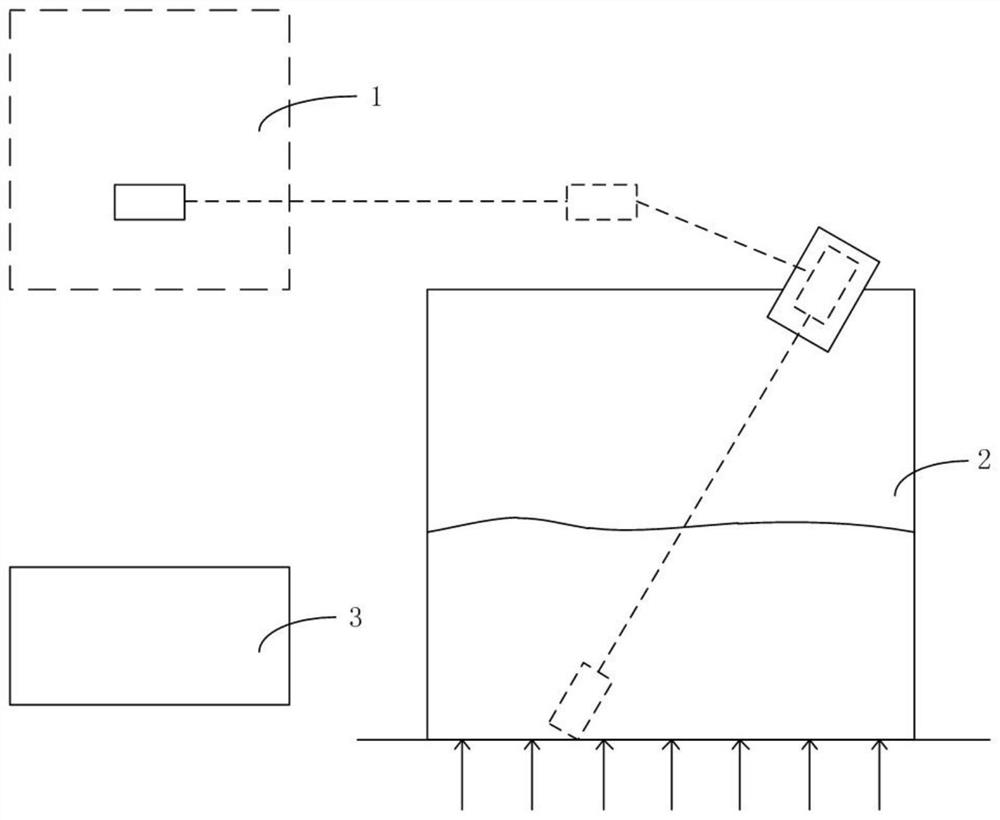

Crack in-situ monitoring system and method for disk parts in life assessment test

ActiveCN107976482BAvoid abnormal failureImprove securityUsing electrical meansMaterial magnetic variablesData acquisitionMonitoring system

The invention discloses an in-situ monitoring system and method for cracks of disc parts in a life assessment test. The in-situ monitoring system for the cracks comprises a sensor device (1), a data acquisition device (2) and a processing device (3), wherein the sensor device (1) is used for detecting the disc parts, the data acquisition device (2) is used for acquiring signals from the sensor device (1), the processing device (3) is connected to the data acquisition device (2), wherein the sensor device (1) comprises a first displacement sensor (4), a second displacement sensor (5) and a key-phase sensor (6), wherein the first displacement sensor (4) is arranged relative to an axis of a life assessment tester so as to detect a first displacement signal of the axis, the second displacementsensor (5) is perpendicular to the first displacement sensor (4) and is arranged relative to the axis of the life assessment tester so as to detect a second displacement signal of the axis, the key-phase sensor (6) is arranged relative to a key-phase groove of an axis of the life assessment tester so as to detect a key-phase signal of the key-phase groove.

Owner:XI AN JIAOTONG UNIV

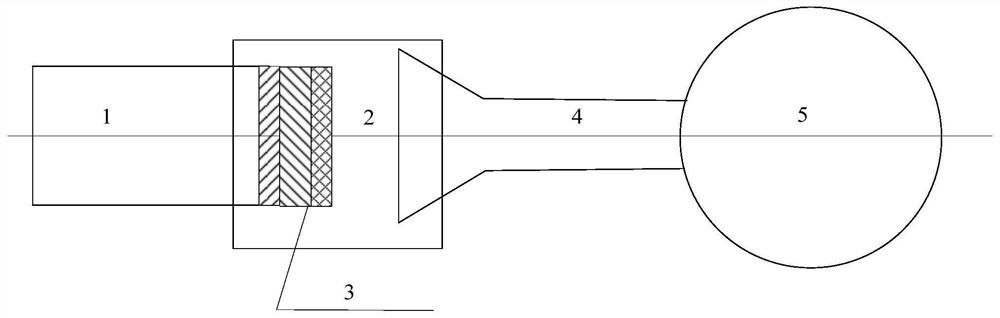

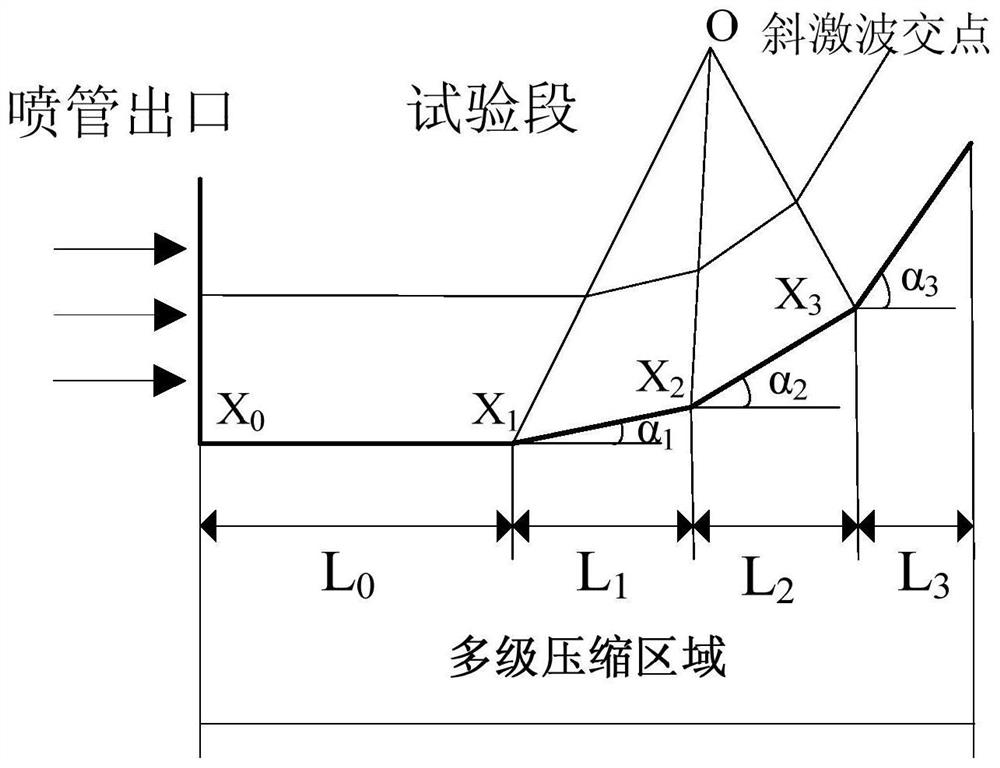

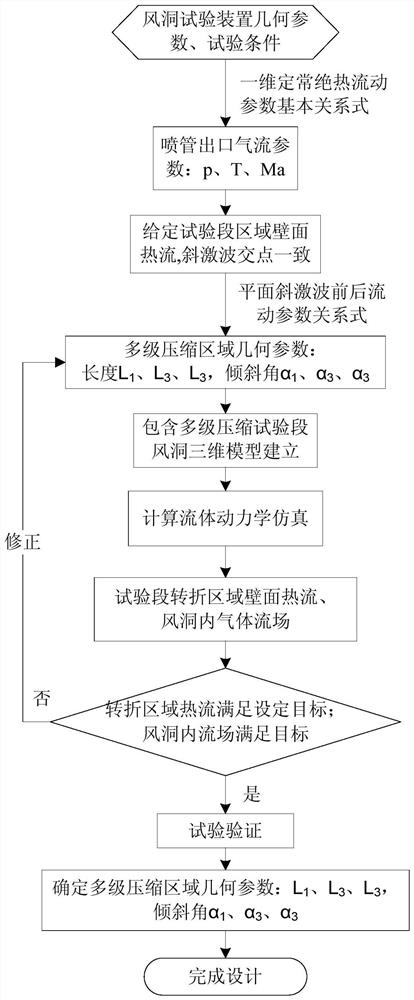

Wind tunnel test device and its design method

ActiveCN108228921BHigh engineering application valueShorten the test cycleDesign optimisation/simulationSpecial data processing applicationsShock waveHeat flow

Embodiments of the present invention provide a wind tunnel test device and a design method thereof, which relate to wind tunnel test assessment technology and can solve the problem that it is difficult to conduct multiple state assessments in a single wind tunnel test. The test and assessment device of the wind tunnel has the characteristics of multi-stage compression, and the surface profile of the multi-stage compression area is a line segment L bent by N segments 1 , L 2 , L 3 ..., L n pose, L 0 It is the length of the flow direction of the test section with an angle of attack of zero. Through the idea of continuously and gradually changing the angle of attack, a stable step-type heat flow distribution along the flow direction can be obtained in the same vehicle wind tunnel test, and it is possible to simultaneously assess the material in a variety of conditions in one vehicle test. The response in the thermal state, while considering the purity of the flow field, intersects the multi-stage compression oblique shock waves at one point, avoiding the multi-channel shock wave reflection from interfering with the flow field. It overcomes the disadvantages of low efficiency, long period and high cost of the original material assessment test, greatly shortens the test period, and has high engineering application value.

Owner:BEIJING AEROSPACE TECH INST

Scenario simulation test device and test method for self-heating device thermal shock into water accident

ActiveCN112362375BScene simulation realRich in detailStructural/machines measurementWater entryMechanical engineering

The invention discloses a thermal shock water entry accident scene simulation test device and a test method of a self-heating device, which can complete thermal shock test, thermal shock water entry test, seawater simulation test, environmental adaptability assessment test of long-term storage state on the seabed and seabed vibration environment adaptation Various test types such as performance assessment test, the above test types can comprehensively simulate various accident environmental loads of self-heating devices in launch and crash scenarios, and can be used for self-heating devices from dynamic scenarios to deep-sea storage scenarios. It provides analysis tools for the product status response of the product, and provides technical support for the product's accident environment adaptability assessment, improvement design, etc. The test piece launching device of this application simulates the scene simulation of the test piece falling into the seawater, and can simulate the test piece falling into the water. Compared with the traditional technology, the scene simulation is more realistic and the details are more abundant.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Uniaxial loading of a cylindrical working section to achieve a biaxial stress state test piece

ActiveCN111855398BShorten the structural design cycleReduce test costsMaterial strength using tensile/compressive forcesEngineeringMachine

A test piece of biaxial stress state achieved by uniaxial loading of a cylindrical working section. The whole is a plate structure, the middle part is the working section, the left and right sides are clamping sections, the working section is a diamond structure, and the parts on both sides of the two diagonal lines symmetry. The working section is designed with cylindrical grooves and special-shaped holes; among them, the cylindrical grooves are designed on the front and back of the working section, and are designed diagonally along the upper and lower directions of the working section; there are four special-shaped holes, which are respectively opened in the working section by two On the four parts equally divided by the angle bisector. The loading of the test piece is realized by the uniaxial fatigue testing machine. Under the designed cylindrical groove and special-shaped hole, a multiaxial stress state of horizontal tension and vertical compression is finally generated in the center of the whole test piece, forming a typical Tension / compression multiaxial stress state. The invention can realize the simulation of the tension and compression biaxial state at the center of the turbine disk, can partially replace the component-level assessment test, shorten the structural design cycle, and save the test cost.

Owner:BEIHANG UNIV

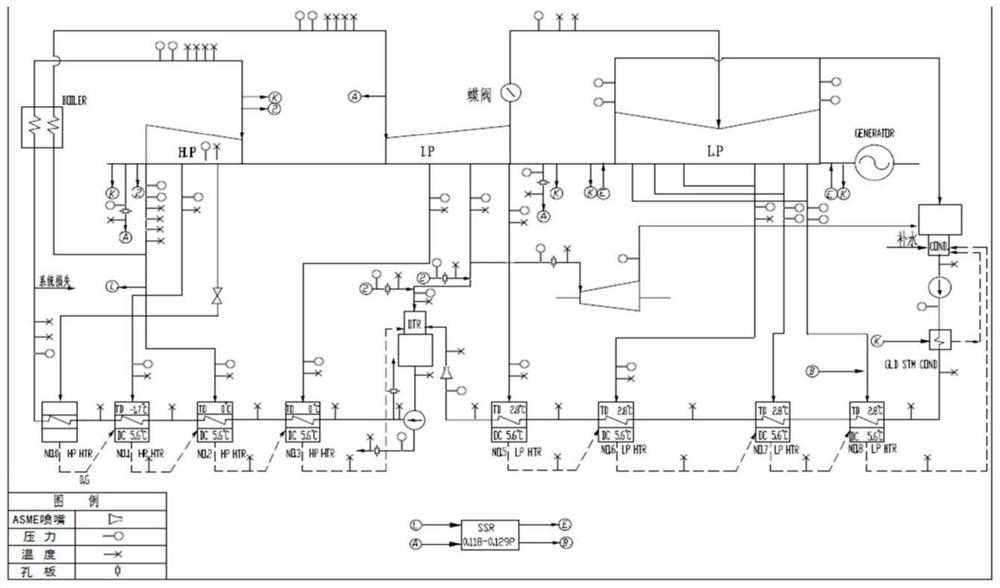

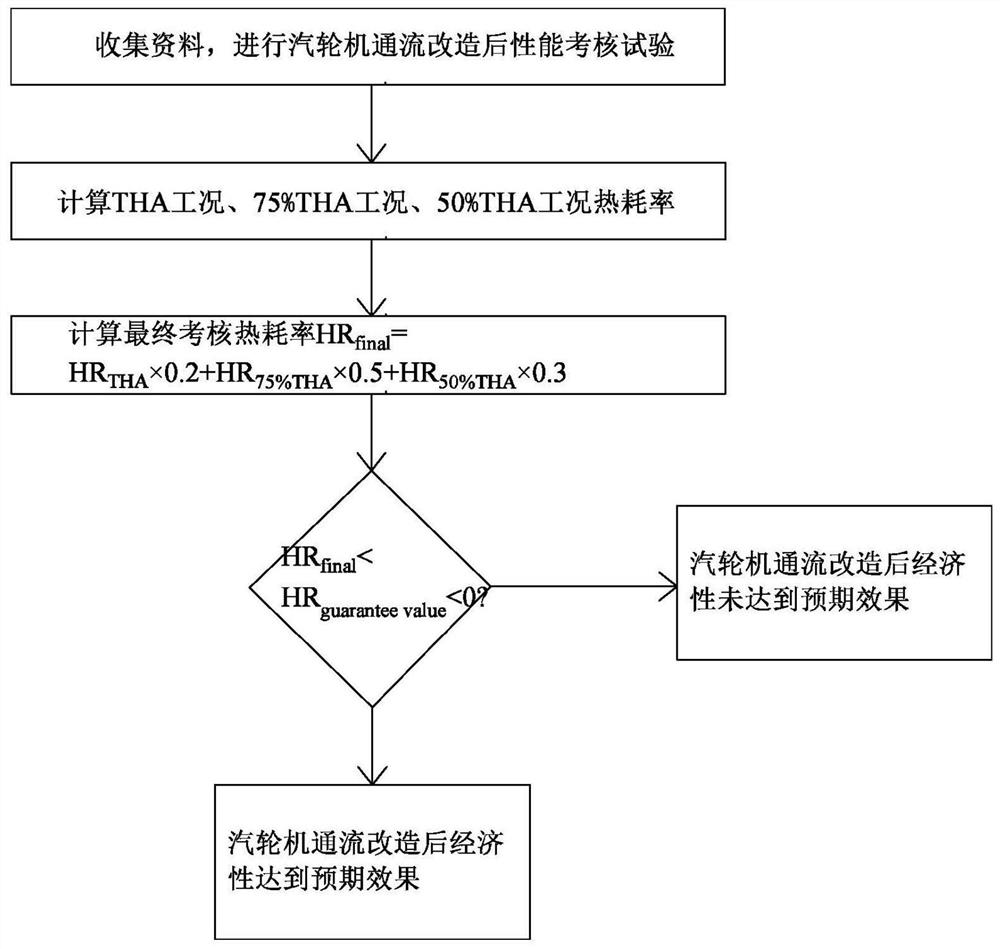

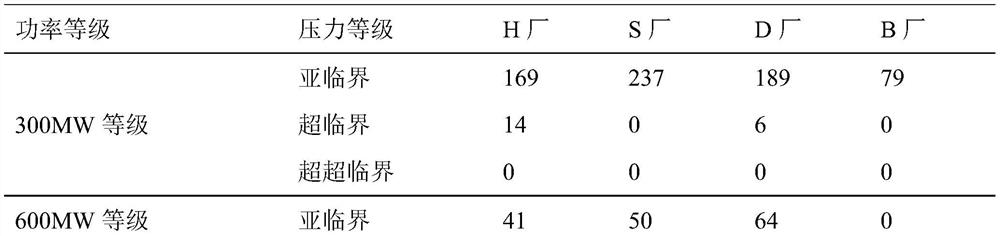

Method for calculating final examination heat consumption rate after turbine through-flow transformation

PendingCN112417685AImprove experienceGeometric CADDesign optimisation/simulationProcess engineeringTurbine

The invention discloses a method for calculating the final examination heat consumption rate after turbine through-flow transformation, and the method comprises the steps: A, calculating the THA working condition heat consumption rate x after turbine through-flow transformation, selecting the weight of the heat consumption rate as 0.2, and entering the step B; B, calculating the 75% THA working condition heat consumption rate y after turbine through-flow transformation, selecting the weight of the heat consumption rate to be 0.5, and entering the step C; C, calculating the 50% THA working condition heat consumption rate z of the turbine after through-flow transformation, selecting the weight of the heat consumption rate as 0.3, and entering the step D; D, calculating a final assessment heat consumption rate HRfinal according to a formula provided by the invention, and entering the step E; E, comparing the final assessment heat consumption rate HRfinal with the turbine through-flow transformation heat consumption rate guarantee value HRguarantee value to obtain a final assessment heat consumption rate evaluation result after final turbine through-flow transformation. The method provided by the invention is completely different from a previous performance assessment test in which only 100% THA working condition heat consumption rate is used as a final assessment index. Accordingto the invention, the user experience of performance test work is effectively improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

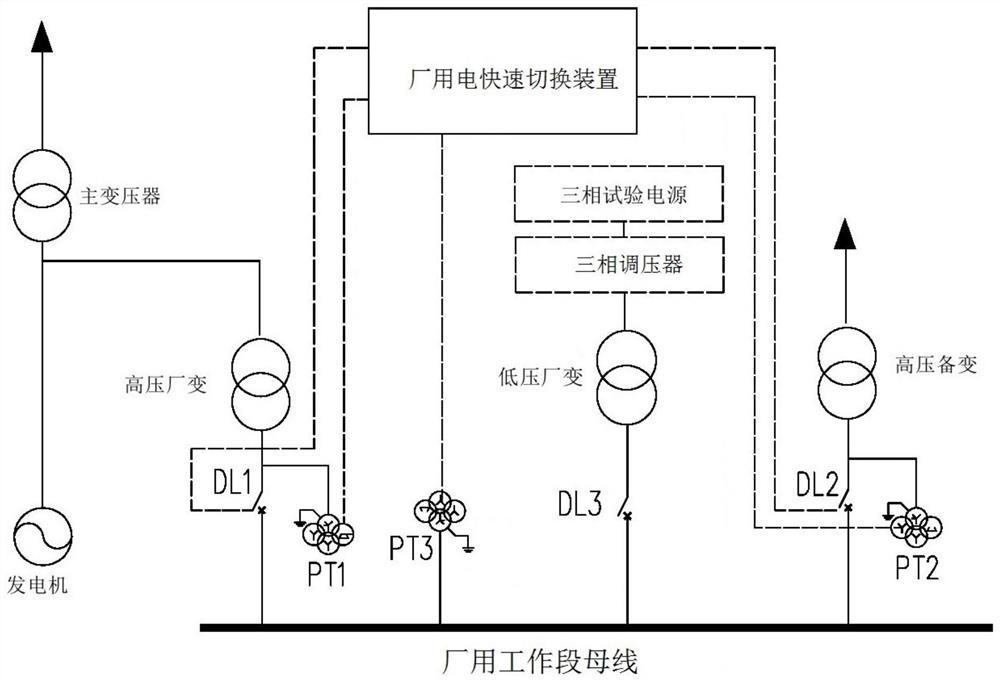

One-time pressure-through and simultaneous-phase verification inspection system and inspection method of electrical system

ActiveCN110854925BImprove construction efficiencyImprove reliabilityElectrical testingSingle network parallel feeding arrangementsTransformerControl engineering

Owner:CHINA ENERGY ENG EASTERN ELECTRIC POWER TESTING RES INST CO LTD

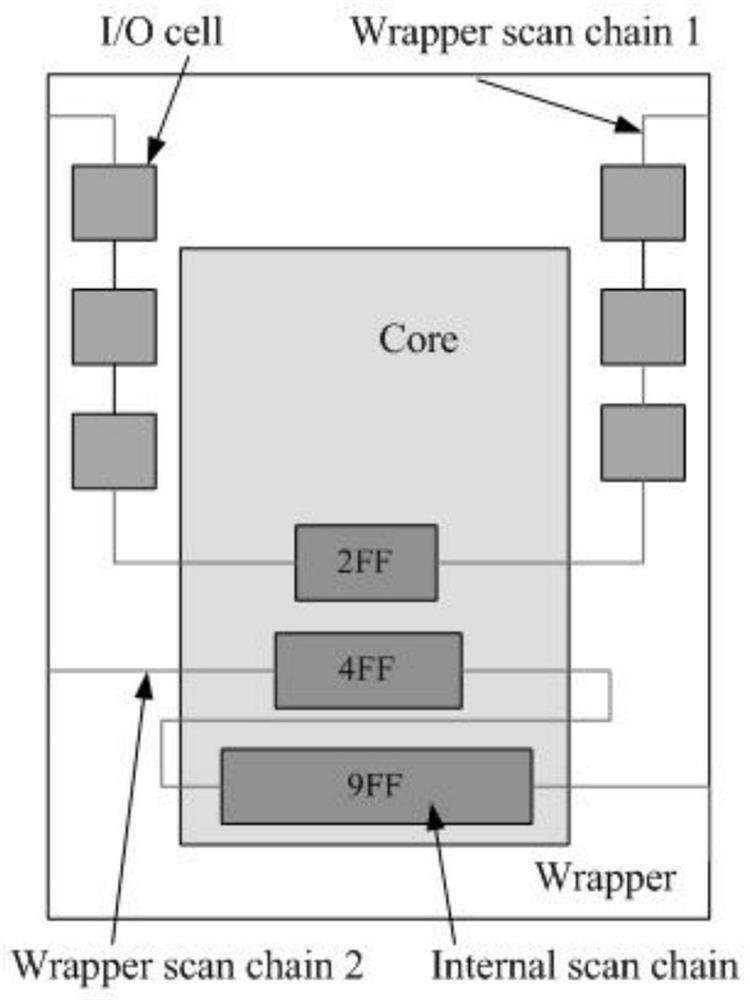

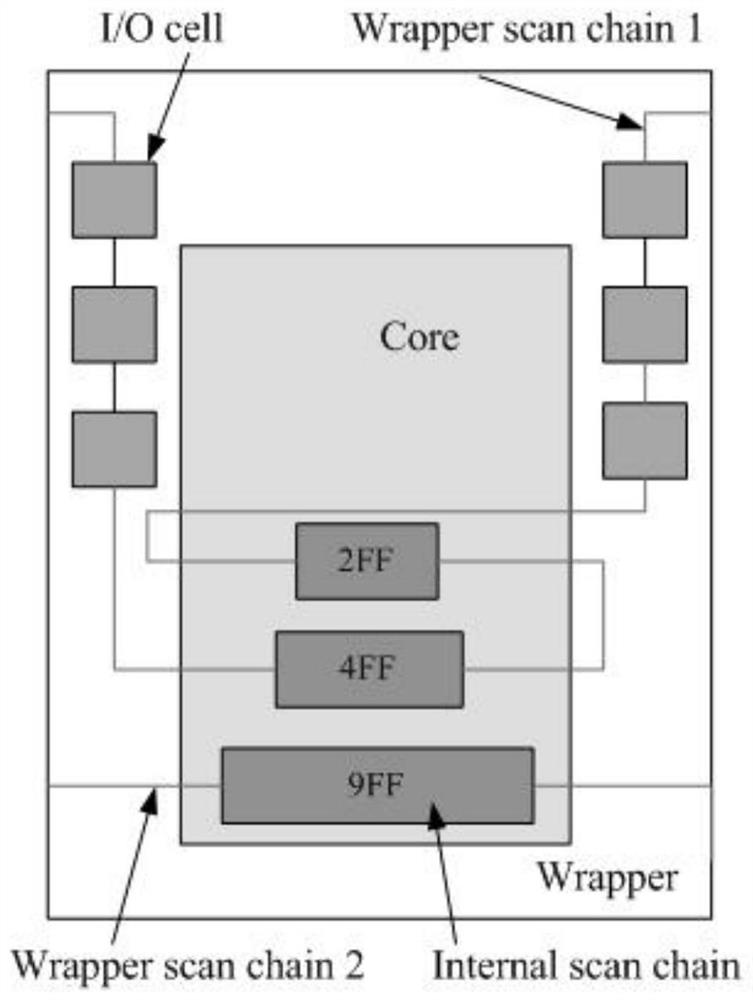

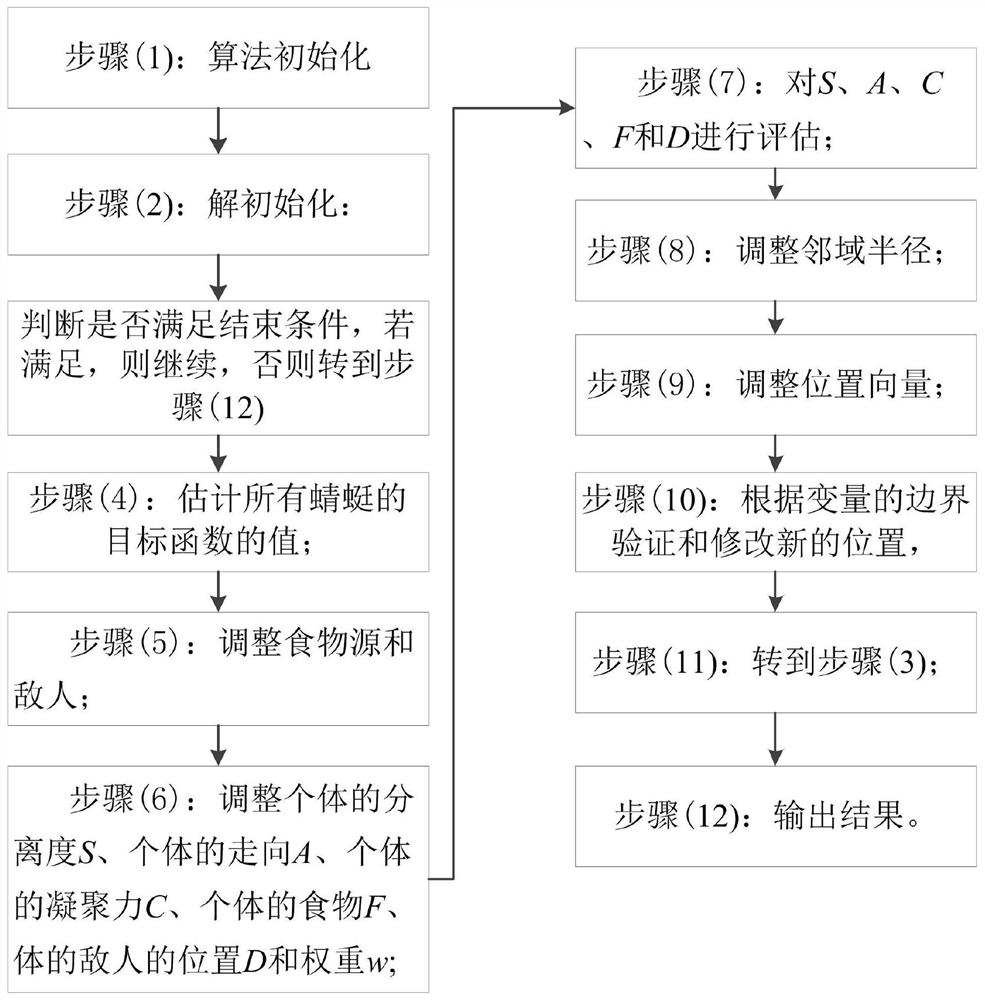

A Design Method for Embedded Core Test Package Scan Chain

ActiveCN109188257BIncrease diversitySolving NP-hard problemsElectrical testingFood bodySoftware engineering

The present invention proposes a kind of embedded core test packaging scan chain design method, including step (1): algorithm initialization; step (2): de-initialization step (3): if the end condition is not satisfied, continue, otherwise go to step (12 ); Step (4): Estimate the objective function max(s i ,s o ) value; step (5): adjust food sources and enemies; step (6): adjust individual separation S, individual direction A, individual cohesion C, individual food F, position D and weight of individual enemies w; Step (7): Evaluate S, A, C, F, and D; Step (8): Adjust the neighborhood radius; Step (9): Adjust the location vector; Step (10): Validate according to the bounds of the variables and Modify the new position, if the value of the new position is less than 1, set its value to 1, if it is greater than N, then set its value to N; step (11): go to step (3); step (12): Output the result.

Owner:GUILIN UNIV OF ELECTRONIC TECH

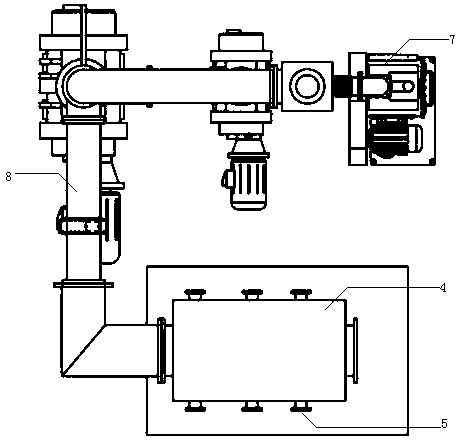

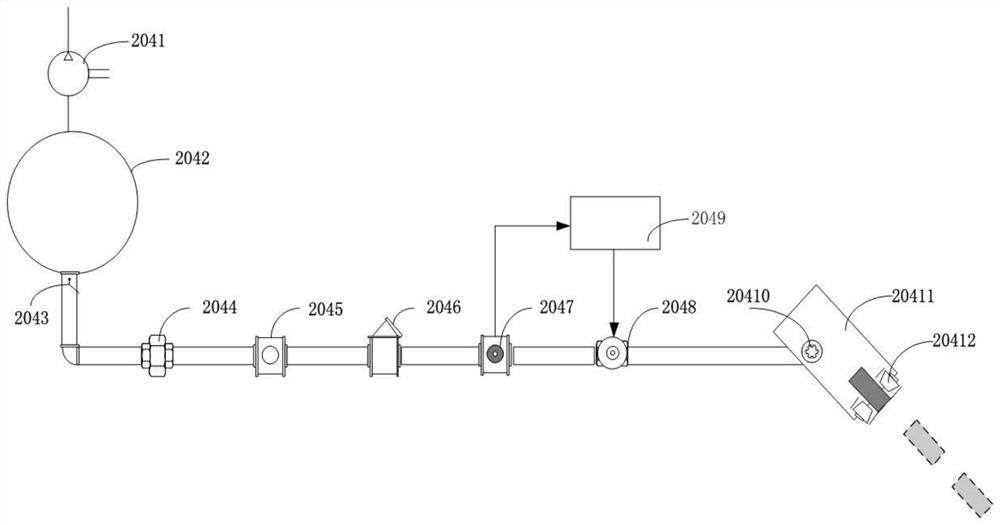

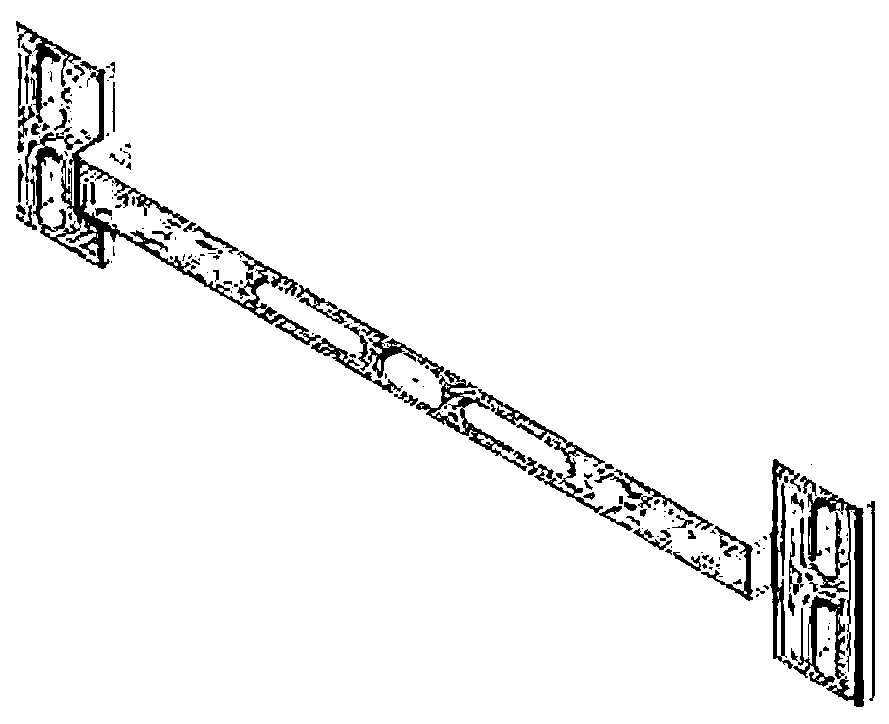

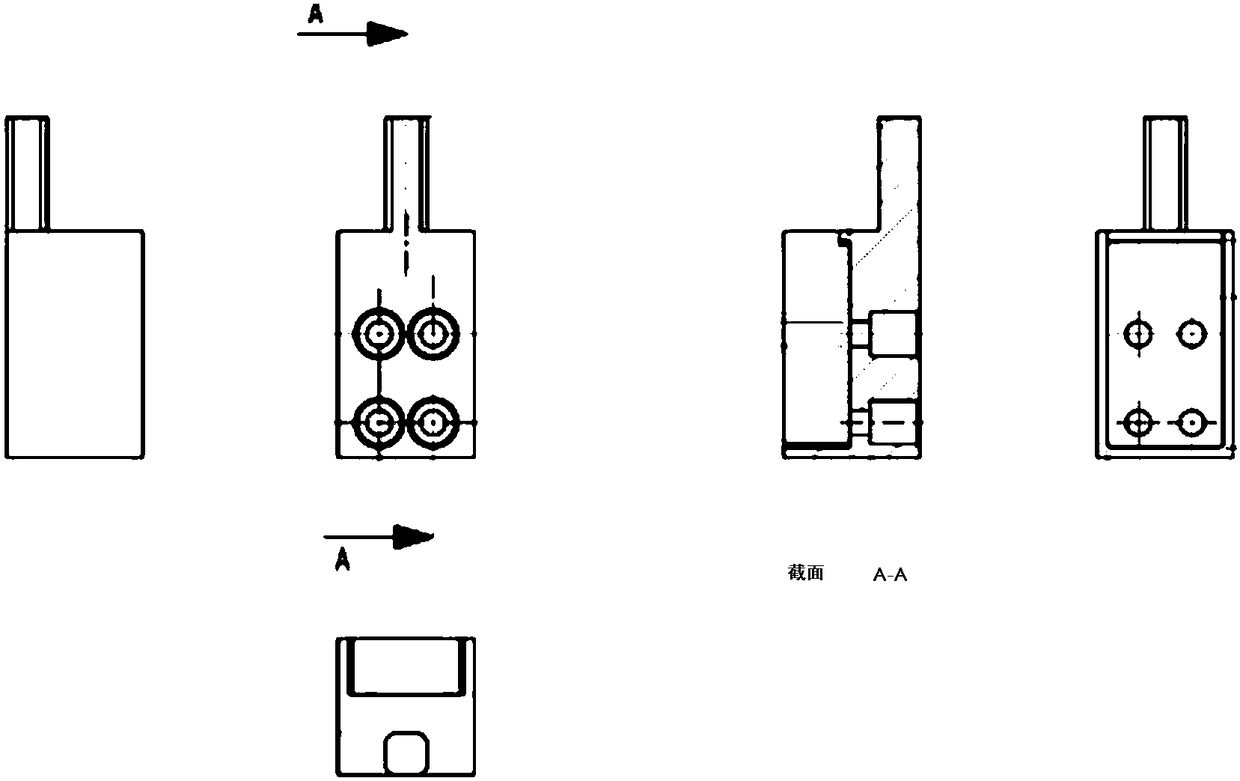

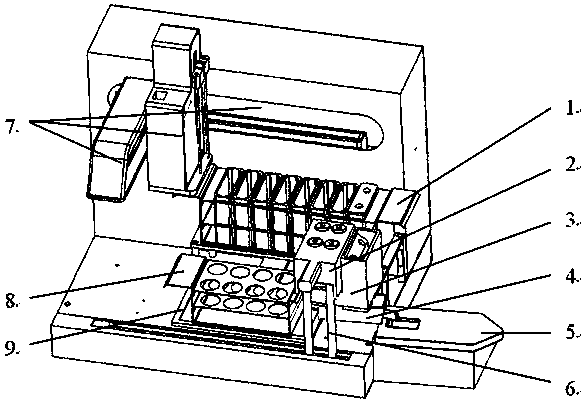

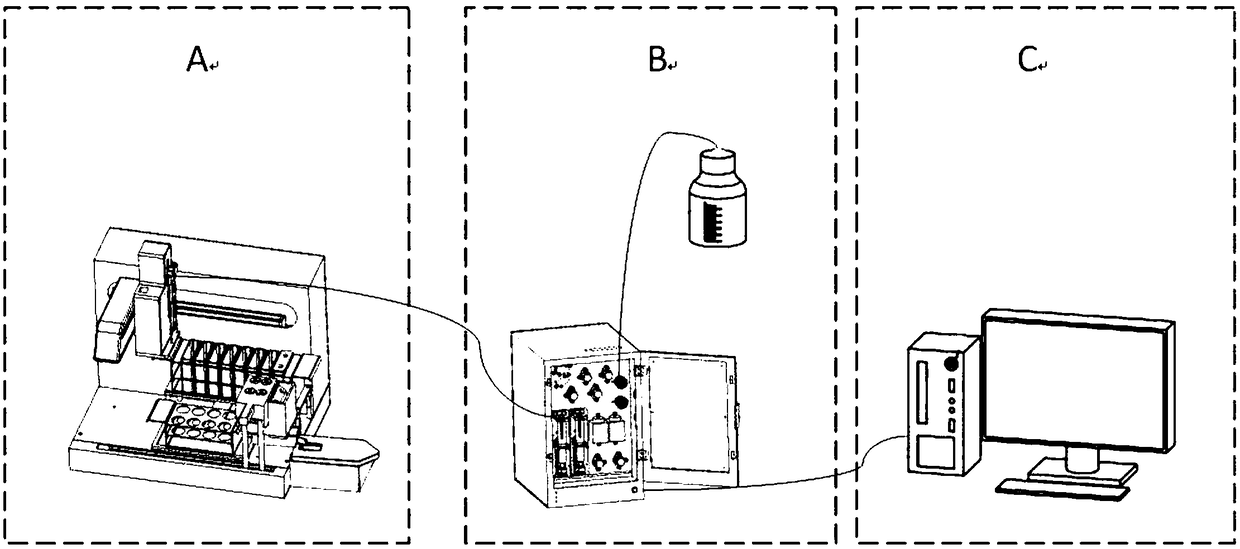

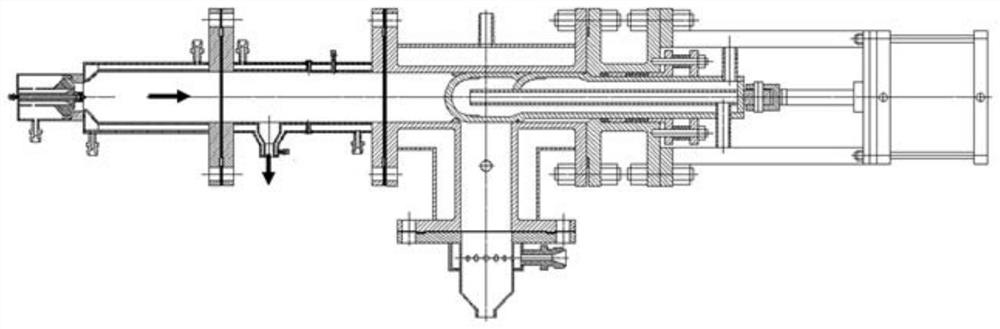

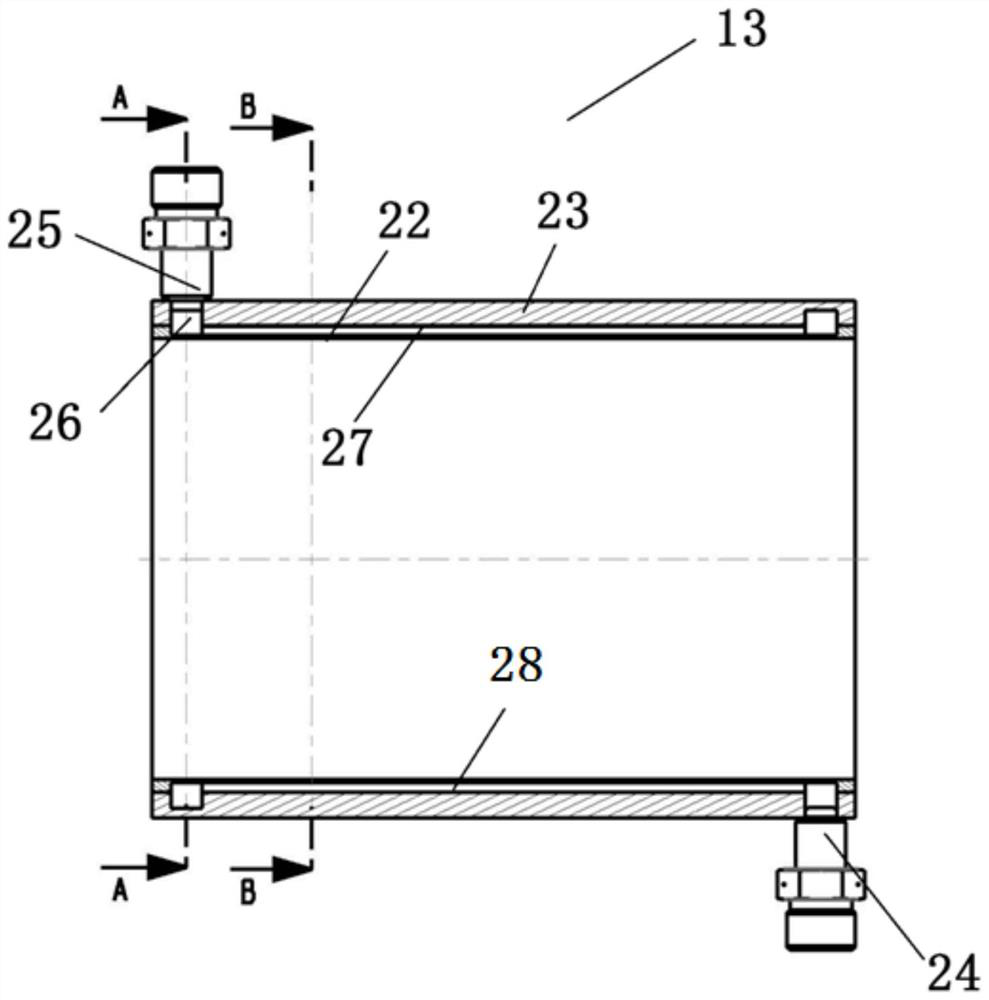

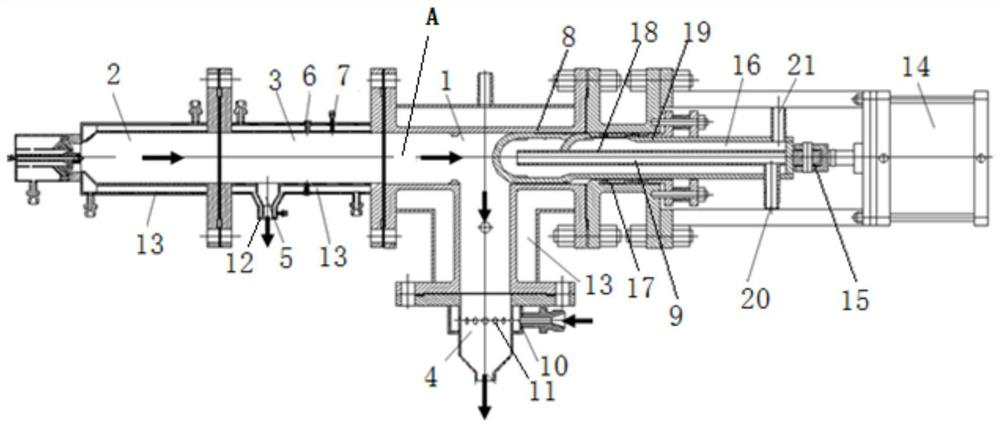

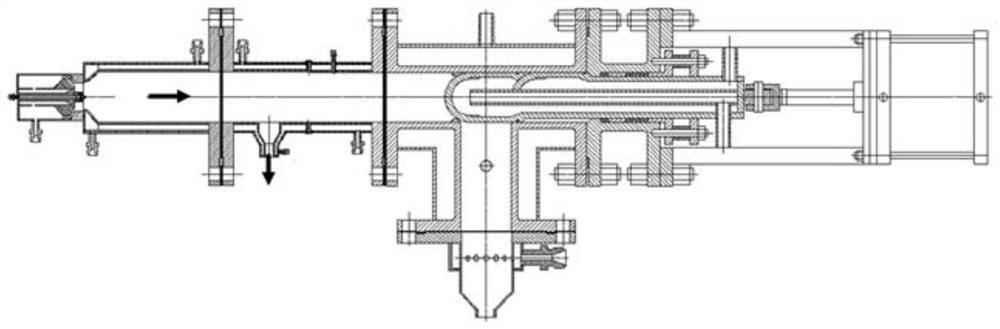

Nuclear test specimen automatic separation device

PendingCN108106919AAvoid the risk of cross-contaminationShort tripPreparing sample for investigationSolid sorbent liquid separationControl systemComputer module

The invention belongs to the field of nuclear fuel post treatment, and particularly relates to a nuclear test specimen automatic separation device. The device comprises a mechanical arm separation module, a pump module and a control system module, wherein the pump module is connected to the mechanical arm separation module and is used for reagent addition by the mechanical arm separation module and the sampling by a sampling pin; the control system module is connected to the mechanical arm separation module and the pump module, and is used for controlling the automatic operation of the pump module and a mechanical arm platform, so that the space used in a glove box is reduced; the repair and the maintenance are convenient; the flowing time of reagents and test specimens is reduced; the liquid taking precision is improved; the separation time is shortened; the efficiency is improved; the secondary sample carrying separation function after the primary eluant dilution is realized.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Appraisal and test device and method for an ultra-high temperature and high pressure globe valve

ActiveCN112326232BRealize state simulationSimple structureMachine valve testingFluid-tightness measurement using fluid/vacuumCombustorEngineering

The invention discloses an ultra-high temperature and high pressure cut-off valve assessment test device and method. The test device is designed with a cut-off valve test piece consistent with the characteristics of the actual ultra-high temperature and high pressure cut-off valve, and is equipped with an oxygen-enriched burner, an adjustable nozzle, a rectifier The measuring tube, the exhaust pressure nozzle, the temperature measuring point and the pressure measuring point have been assessed on the globe valve test piece under high temperature and low pressure conditions, high temperature and high pressure and high temperature and low pressure switching conditions, and high temperature and high pressure conditions, effectively simulating The anti-oxidation performance, thermal protection reliability, high temperature and high pressure sealing and opening and closing response characteristics of globe valves for high temperature and high pressure valves under different thermal load types were studied.

Owner:XIAN AEROSPACE PROPULSION INST

Examination test device and method for ultrahigh-temperature high-pressure stop valve

ActiveCN112326232ARealize state simulationSimple structureMachine valve testingFluid-tightness measurement using fluid/vacuumCombustorEngineering

The invention discloses an examination test device and method for an ultrahigh-temperature and high-pressure stop valve. According to the test device, a stop valve test piece consistent with an actualultrahigh-temperature and high-pressure stop valve in characteristic is designed; an oxygen-enriched combustor, an adjustable spray pipe, a rectification measuring pipe, an exhaust pressure supplementing spray pipe, a temperature measuring point and a pressure measuring point are matched with one another to examine the stop valve test piece under a high-temperature and low-pressure working condition, a high-temperature and high-pressure and high-temperature and low-pressure switching working condition and a high-temperature and high-pressure working condition; the oxidation resistance, thermal protection reliability, high-temperature and high-pressure sealing and opening and closing response characteristics of the high-temperature and high-pressure stop valve under different thermal loadtypes are effectively simulated.

Owner:XIAN AEROSPACE PROPULSION INST

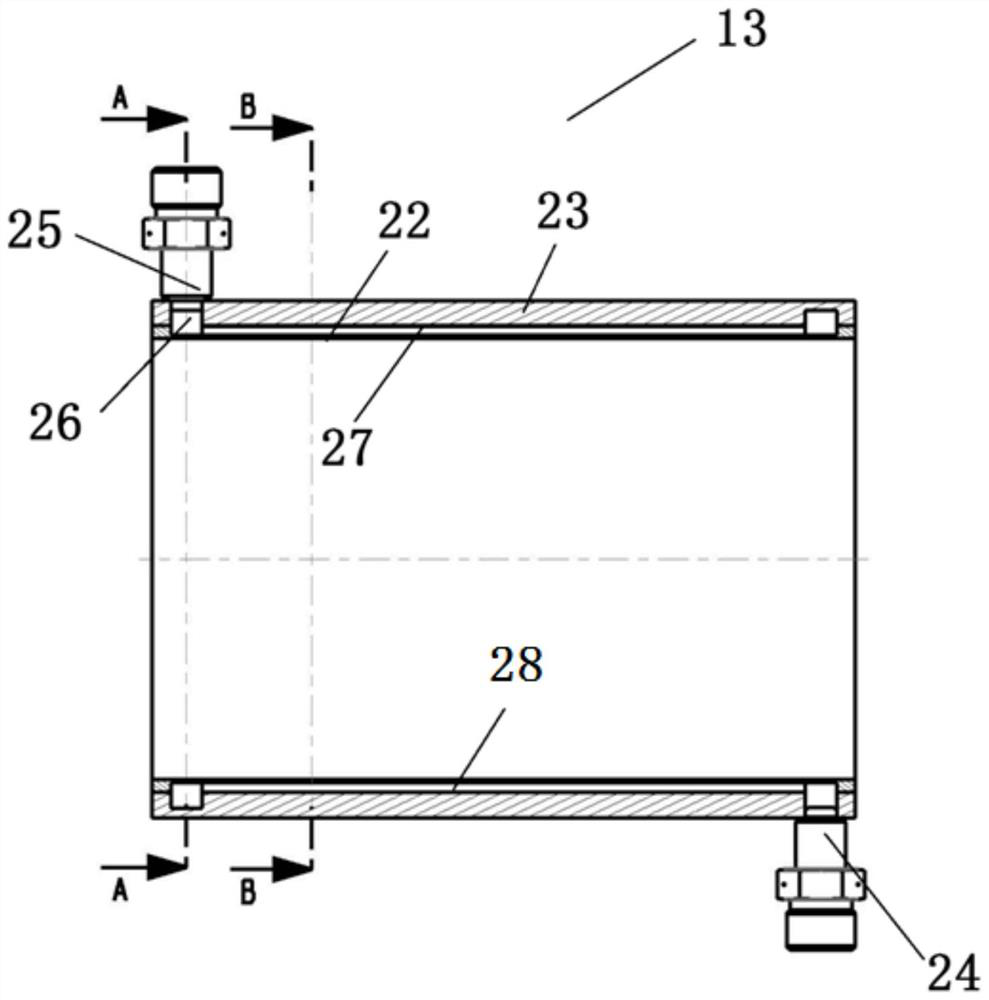

Test system of multifunctional gas-liquid state monitoring device and performance test method thereof

PendingCN111856220ASafe and stable useRealize the assessment testTesting dielectric strengthLiquid stateElectric power equipment

The invention provides a test system of a multifunctional gas-liquid state monitoring device and a performance test method thereof, which belong to the technical field of simulation tests of power equipment monitoring devices. The test system comprises a tank body, the upper end of the tank body is connected with a cover body in a sealed mode, and a plurality of installation holes are formed in the tank body and can be used for installing sensors; the test system further comprises a heating assembly which is arranged at the lower end in the tank body, a temperature monitoring assembly which isarranged in the middle of the tank body, a gas-liquid regulation and control assembly which is arranged on the tank body and can be used for regulating the density of gas and / or the volume of liquidin the tank body, and a discharge simulation assembly which is arranged in the tank body and is used for simulating discharge in the liquid in the tank body; and the discharge simulation assembly cangenerate an electromagnetic field. The test system can be used for realizing an assessment test on an insulating medium, can be used for carrying out an insulating medium performance test, has the advantages of adjustable temperature, liquid level and gas density, capability of carrying out discharge simulation and simultaneously carrying out tests on precision, sensitivity and accuracy of varioussensors, and is convenient to install and move.

Owner:CHINA ELECTRIC POWER RES INST +1

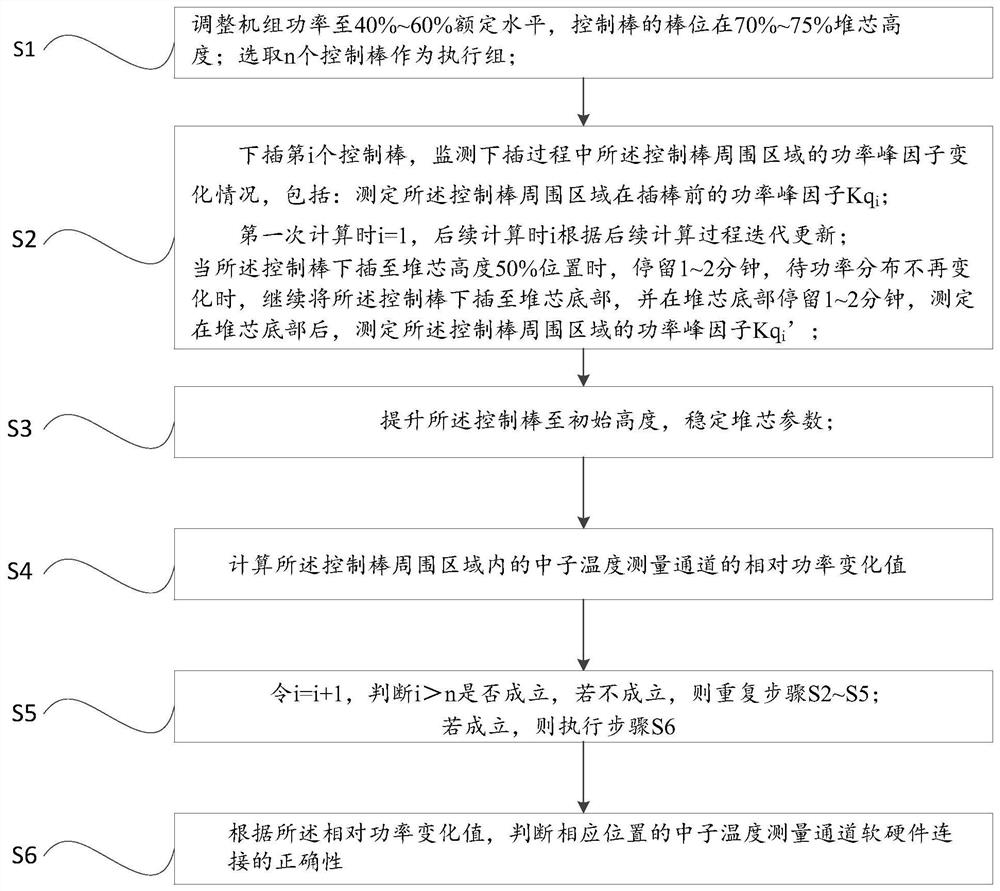

A method for checking the correctness of the software and hardware connection of the neutron temperature measurement channel

ActiveCN111799006BOptimize overhaul periodCorrectness judgmentNuclear energy generationNuclear monitoringComputer hardwareNeutron temperature

The invention relates to the technical field of core nuclear measurement systems of nuclear power plants, in particular to a method for checking the correctness of software and hardware connections of a neutron temperature measurement channel. The inspection method is as follows: adjust the power of the unit and the position of the control rods; select n control rods as the execution group; insert the i-th control rod down, and measure the power peak factor of the area around the control rods before inserting the rods; Inserting the control rods down to the bottom of the core, measuring the power peak factor after the rods are inserted in the area around the control rods; lifting the control rods to the initial height; calculating the neutron temperature measurement channel in the area around the control rods Relative power change value; make i=i+1, judge whether i>n is established, if not established, then repeat the above steps; if established, then judge the neutron temperature measurement channel software and hardware at the corresponding position according to the relative power change value The correctness of the connection. The inspection method can quickly and accurately judge the correctness of the software and hardware connection of the neutron temperature measurement channel, and is safe and reliable.

Owner:JIANGSU NUCLEAR POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com