Method for calculating final examination heat consumption rate after turbine through-flow transformation

A calculation method and heat rate technology, applied in the field of steam turbines, can solve problems such as poor user experience, high load heat rate, and high heat rate, and achieve the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

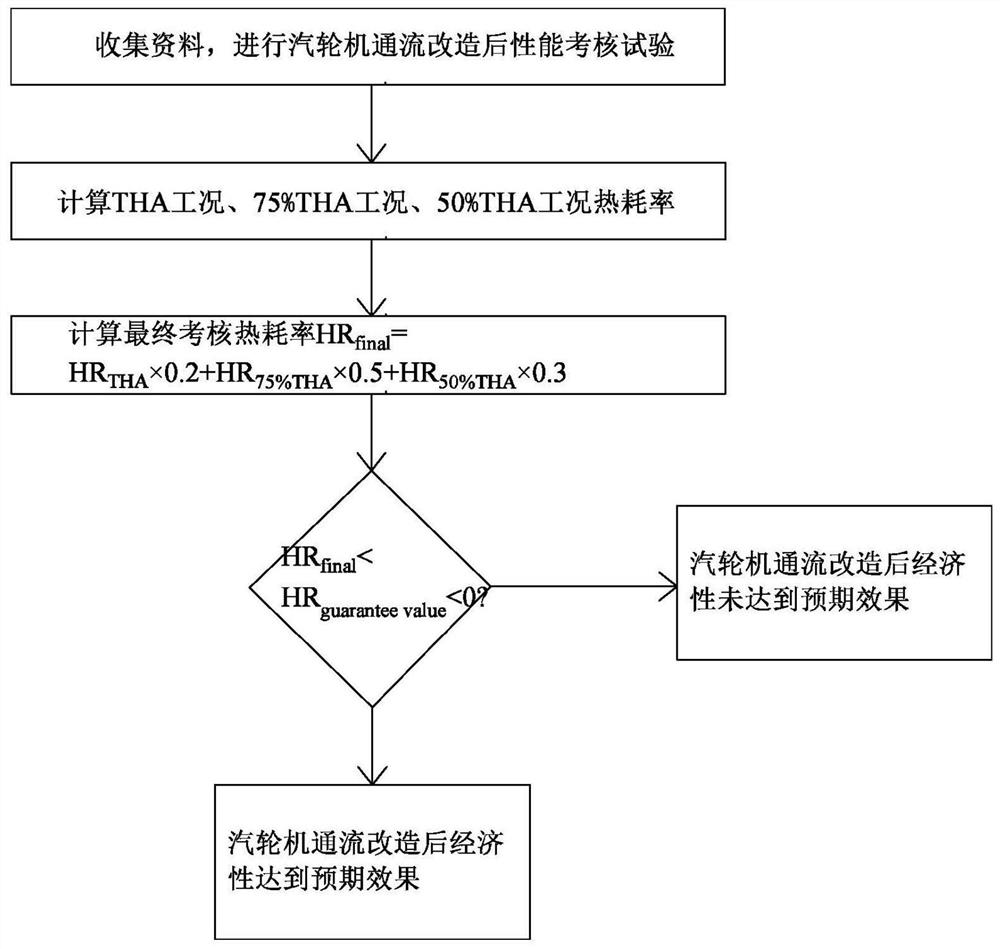

[0039] Such as figure 2 As shown, a method for calculating the final assessment heat rate after the steam turbine through-flow transformation provided by the present invention comprises the following steps:

[0040] S1 calculates the heat rate of THA working condition after steam turbine through-flow modification, and selects the weight of the heat rate as 0.2;

[0041] S2 calculates the heat consumption rate of 75% THA working condition after steam turbine through-flow transformation, and selects the heat consumption rate weight as 0.5;

[0042] S3 calculates the heat consumption rate of 50% THA working condition after steam turbine through-flow transformation, and selects the heat consumption rate weight as 0.3;

[0043] S4 calculates the final assessment heat rate HR according to the formula in Table 4 of the present invention final ;

[0044] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com