Testing machine and method for evaluating wear life of graphite sealing material

A graphite sealing and wear life technology, used in the analysis of materials, testing wear resistance, instruments, etc., can solve the problem of inability to simulate the working conditions of aero-engine gearboxes and casing accessories sealing devices, wear life of graphite-free sealing materials, friction pairs Insufficient linear speed of motion, etc., to achieve the effect of accurately determining the accelerated test time, reasonable layout of the whole machine, and high reliability of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

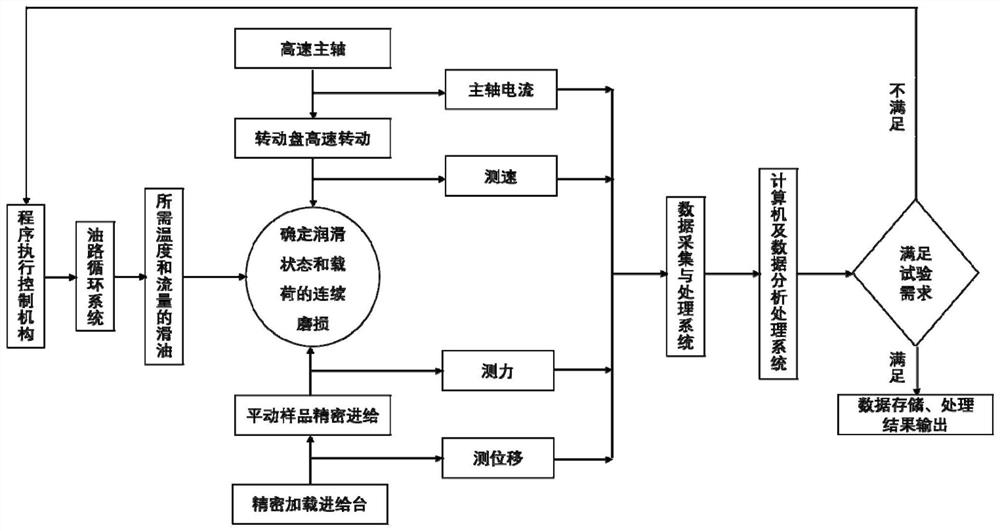

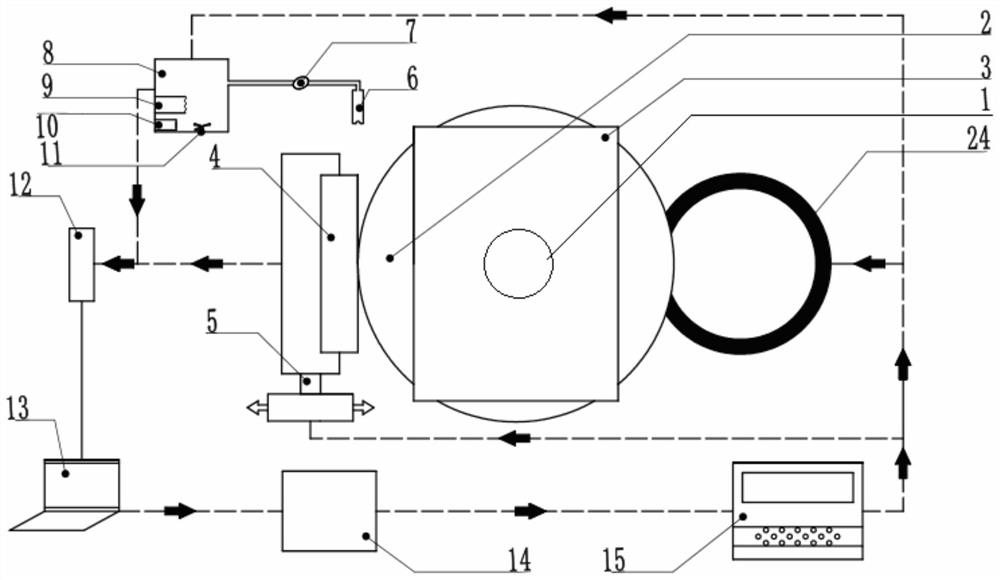

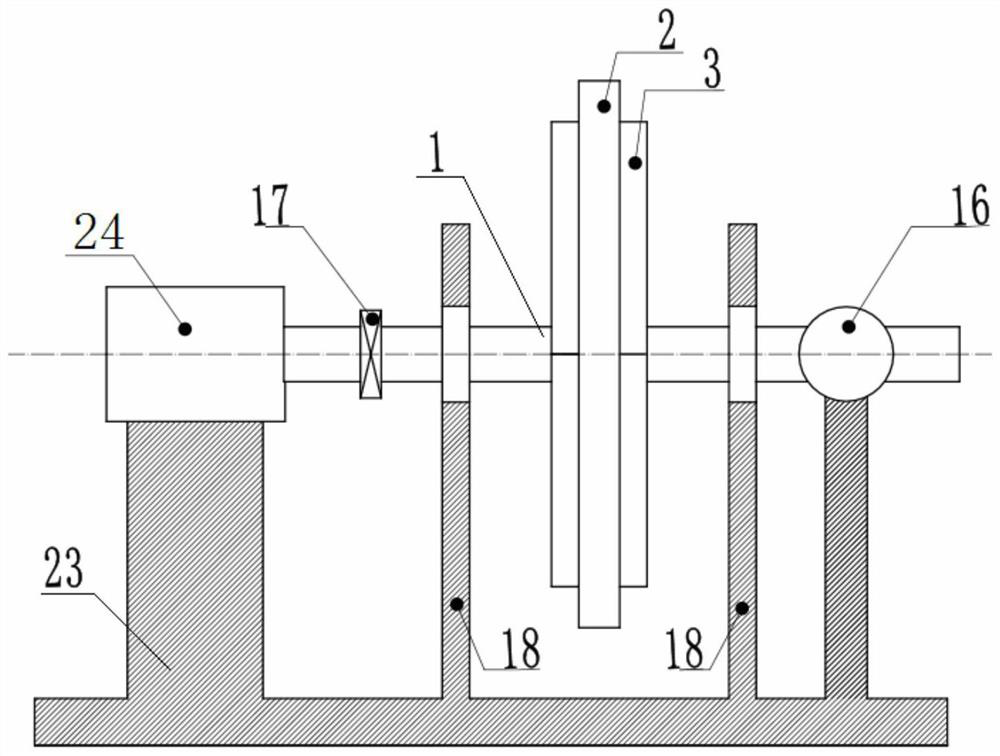

Method used

Image

Examples

Embodiment

[0090] In the accessories of a domestic turboprop engine, the graphite ring (impregnated with inorganic salt graphite) and the superalloy counterpart (GH4169) form a dynamic sealing pair, and the thickness of the graphite ring is about 2mm. The typical service conditions of the dynamic seal pair are: the contact stress is 0.1-0.15MPa, the relative linear velocity is 60.1m / s, the seal pair is lubricated by oil mist splashing, the lubricating oil used is Pegasus No. It is 60-65°C. Requires its service life t l Not less than 3000h, that is, after running for 3000h, the total wear amount of the graphite ring (wear depth / thickness) h l less than 2mm.

[0091] If the engineering assessment and verification is carried out directly through the engine test run, the cost is high, the cycle is long, and there are many interference factors. Therefore, by the high-speed ring block testing machine of the present invention and the PV value accelerated test method, carry out the accelerate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com