Ultra-large-breadth continuous-size rock mass structural plane shear strength test system

A technology of shear strength and test system, which is applied in the direction of applying stable shear force to test material strength, strength characteristics, instruments, etc., which can solve the problem of normal load eccentricity, inability to meet thin sample installation test, safety protection and reset , Unable to meet the problems of vibration and product service life, and achieve the effect of good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

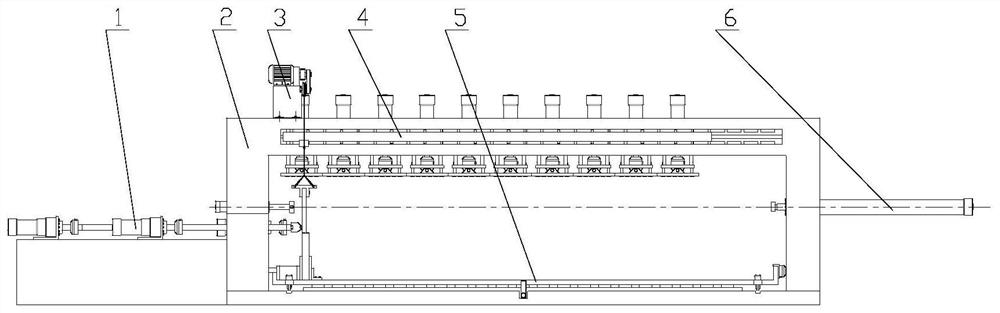

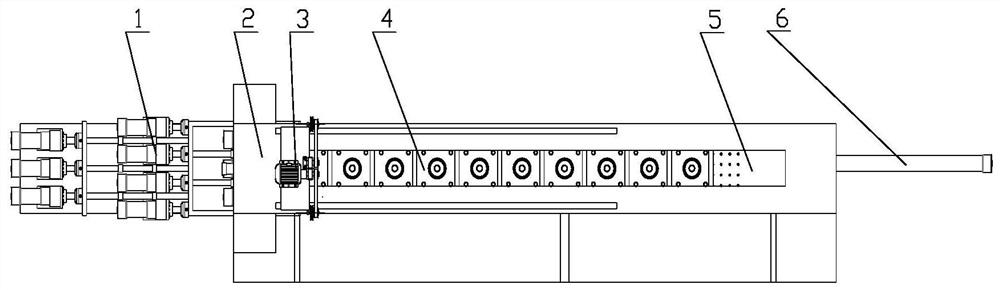

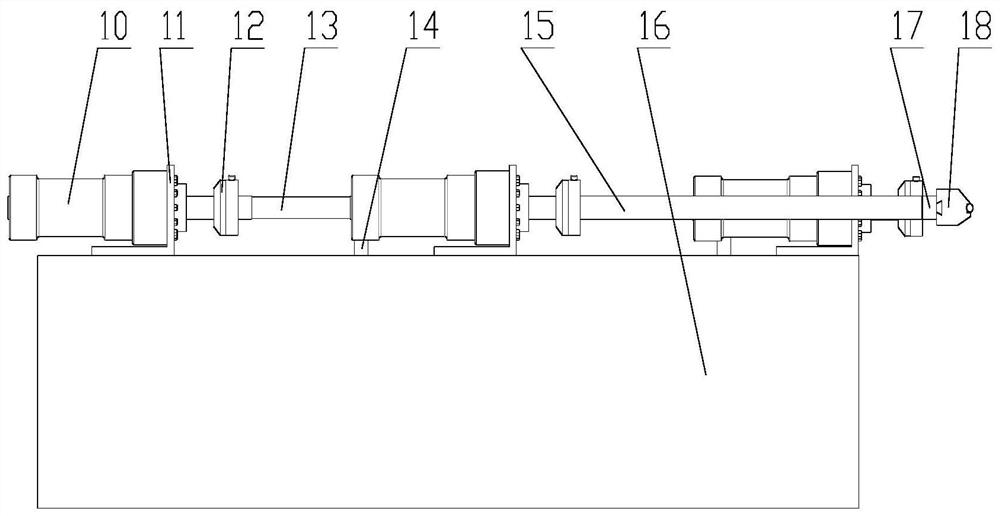

[0037] refer to Figure 1 to Figure 15 , a shear strength test system of rock mass structural surfaces with large and wide continuous dimensions, including a frame 2, a tangential combined loading mechanism 1, a normal combined loading mechanism 4, a lifting mechanism 3, a transport trolley 5 and a sample reset device 6. The sample of the rock mass structural surface with continuously adjustable width is divided into the upper sample and the lower sample with the fracture surface as the boundary. The width of the sample refers to the length change of the continuous size sample from thin to super long. Mechanism 1 and sample reset device 6 are located on both sides of the frame. The loading position of tangential combined loading mechanism 1 is on the left side of the upper sample near the fracture surface. Any lower sample with different widths is fixed on the transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com