Large filter-press cloth-washing mechanism and travel brake cleaning method

A filter press and cloth washing technology, applied in the field of large filter press cloth washing mechanism and walking brake cleaning, can solve the problems of high relative failure rate, high maintenance cost, affecting cleaning efficiency, etc., and achieve stable and reliable walking. The effect of safety, stable and reliable walking, and simple transmission mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

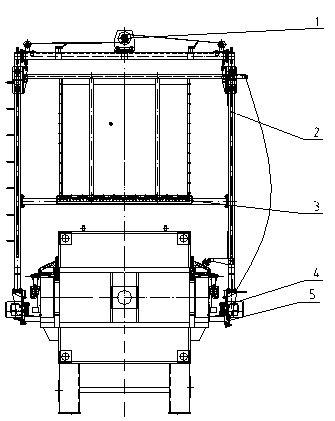

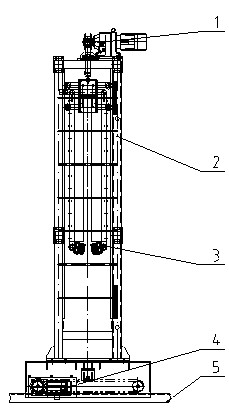

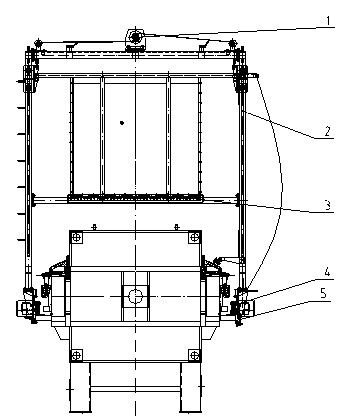

[0010] Embodiment 1: with reference to attached figure 1 and 2 . A cloth washing mechanism of a large-scale filter press, which includes a filter cloth cleaning mechanism of a filter press. The guide rails 5 in the filter cloth cleaning mechanism of the filter press are installed on both sides of the main beam of the filter press, and the support frame 2 is The four-column frame, the lower end of the four-column frame is positioned on the guide rail 5 through the horizontal walking mechanism 4 and moves along the guide rail 5, the guide rail 5 is an electromagnetic guide rail and the electromagnetic guide rail is connected with the electromagnetic controller through the control line, the lifting mechanism 1 is located at the upper end of the support frame 2 and It is connected with the cleaning frame 3 located in the support frame 2 , and the lifting mechanism 1 drives the cleaning frame 3 to lift along the inner wall of the support frame 2 .

[0011] The power input end of ...

Embodiment 2

[0014] Embodiment 2: On the basis of Embodiment 1, a large-scale filter press cloth washing mechanism walking brake cleaning method, when the cloth washing mechanism walks, the support frame 2 driven by the double motor in the horizontal walking mechanism travels horizontally on the electromagnetic On the guide rail 5, when it is necessary to stop cleaning the filter cloth, the electromagnetic controller instructs the dual motors in the horizontal traveling mechanism 4 to cut off the power according to the built-in program instructions or the position signal detected by the electromagnetic controller. The strong suction force firmly absorbs the traveling wheels in the horizontal traveling mechanism on the electromagnetic guide rail to achieve the purpose of braking; when the cleaning is completed and needs to move forward, the electromagnetic controller receives the cleaning rack in the cleaning mechanism 3 resets the travel switch or detection sensor After the cleaning signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com