Front safety belt upper pivot mounting bracket

A technology for installing brackets and safety belts, which is applied in the direction of belt fixing devices, etc., can solve the problems of inconvenient welding, slow production cycle, low welding precision, etc., and achieve the goal of improving safety level, improving welding efficiency and saving installation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

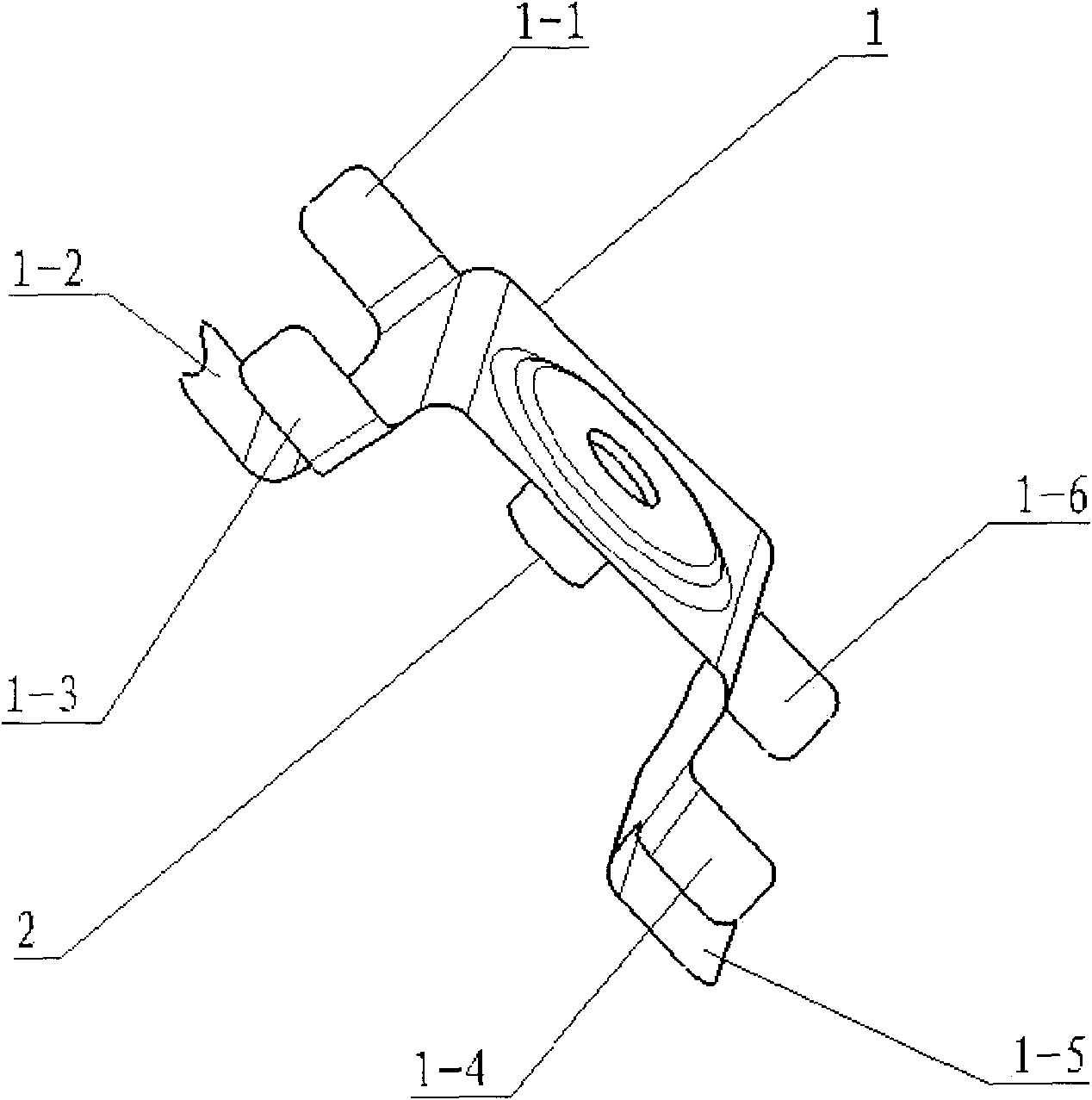

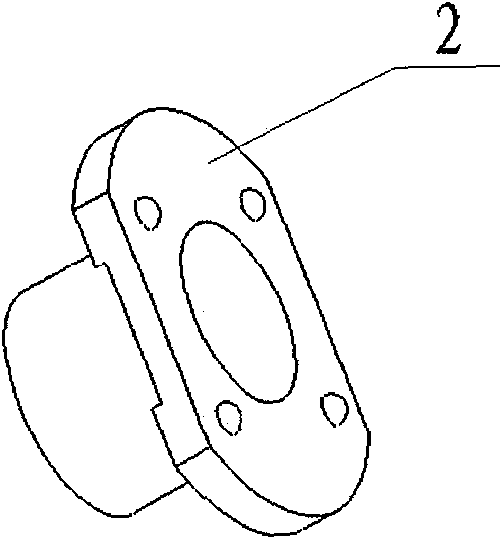

[0014] see figure 1 and figure 2 The fulcrum mounting bracket on the front safety belt shown in the figure includes a bracket body 1 and a "T" nut 2 with a cross-section in the shape of a "several", and the lower end of the bracket body is provided with a first flange 1-1 and a second flange. Flange 1-2 and the 3rd flange 1-3, the other lower end is provided with the 4th flange 1-4, the 5th flange 1-5 and the 6th flange 1-6; There is a through hole, and the bottom of the "T" type nut 2 passes through the through hole and is welded on the bracket body to constitute the present invention.

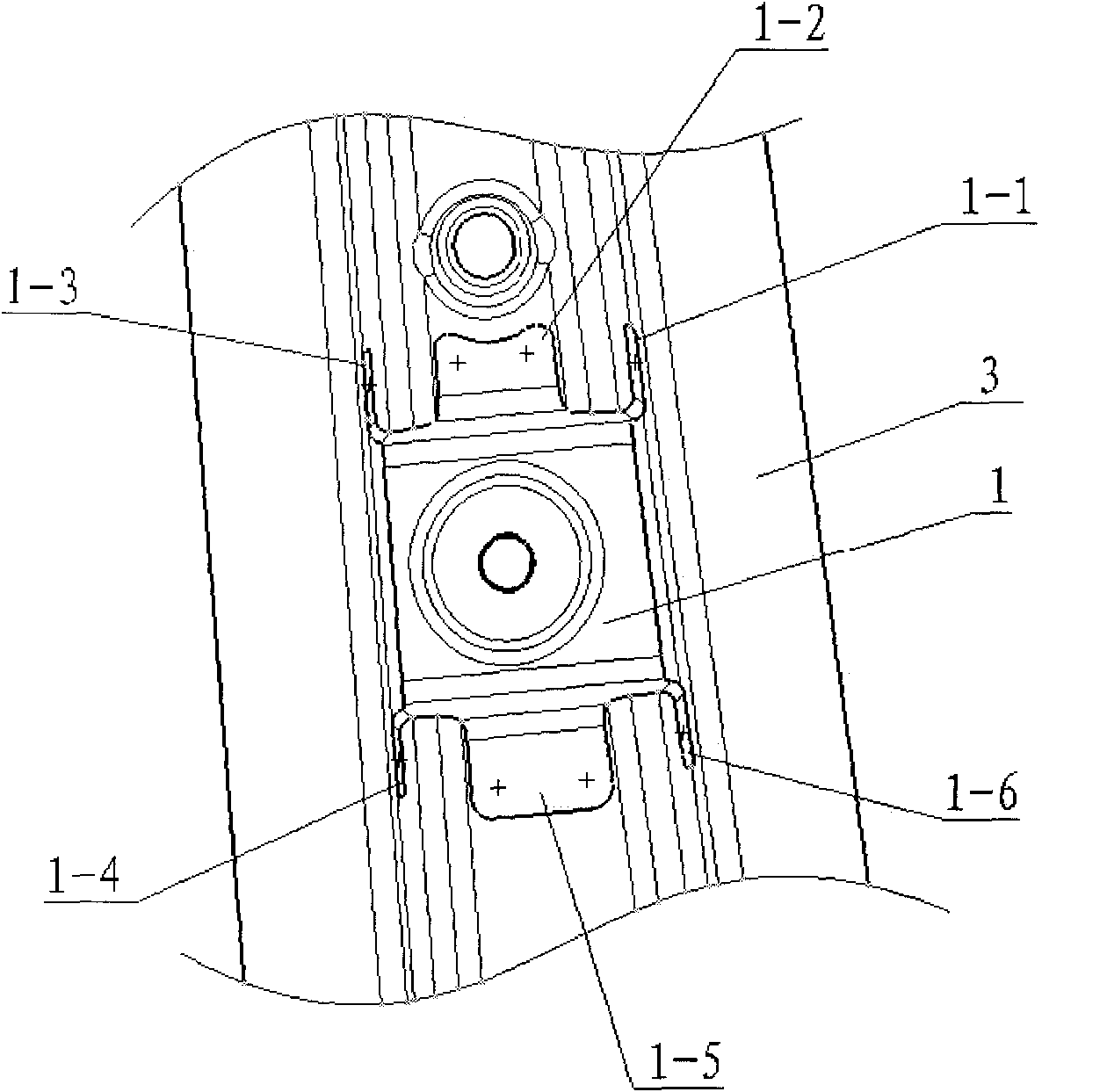

[0015] see image 3 , the six flanges provided at the two lower ends of the bracket body of the present invention are six welding surfaces, and these six welding surfaces are spot-welded with the center pillar reinforcement plate 3 of the automobile to form the center pillar reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com