A steam turbine wet steam measurement image probe

A technology for measuring images and wet steam, applied in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

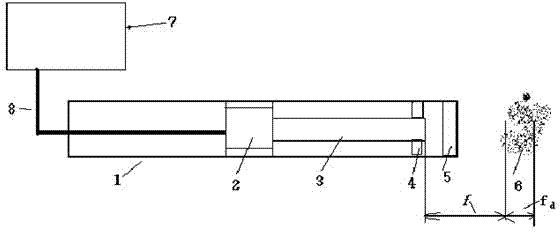

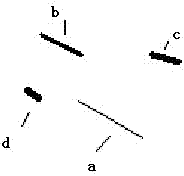

[0021] A steam turbine wet steam measurement image method probe using a telecentric lens and a CCD or COMS digital camera, such as figure 1 shown. The telecentric lens 3 is connected with the CCD or CMOS camera 2 and is installed in the probe rod 1. A glass window 5 is arranged in front of the telecentric lens to prevent secondary water droplets 6 from washing into the telecentric lens. The working distance of the telecentric lens is f , that is, the distance from the telecentric lens to one end of the measurement area, and the depth of field range of the telecentric lens is f d , that is, the length of the measurement area of the probe, the output of the CCD or CMOS camera 2 is connected to the computer 7 through the signal cable 8 for data processing and storage, when the water drop image is taken, the strong light emitted by the illumination source 4 irradiates the measured water drop 6 twice , the image of the water droplet 6 passes through the glass window 5 and is t...

Embodiment 2

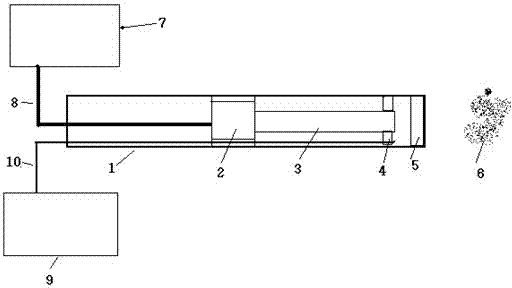

[0030] When the velocity of water droplets is very high, the exposure time of the camera needs to be very short, such as at the nanosecond level. In such a short exposure time, if the illumination light source 4 in Embodiment 1 is still used, the image of the water droplet will be underexposed due to insufficient light intensity, which will affect the measurement or even fail to measure. A pulsed laser light source 9 is added to the steam turbine wet steam measurement image probe described in Embodiment 1. The duration of the pulsed laser light source 9 is extremely short, and the laser with a high power is irradiated to water droplets twice through the laser optical fiber 10, and the water droplets are enough. Bright, two images of water droplets are captured by a CCD or CMOS camera, and the lighting source 4 is used as an observation light source.

Embodiment 3

[0032] When measuring the wet steam of a steam turbine, it is necessary to measure the water film on the surface of the blade and the process of breaking the water film at the edge of the blade, and the direction of this measurement is at an angle of 90 degrees or a certain angle with the direction of the probe. The probe in Example 1 The needle can only measure the 2 water droplets in front of the probe, but cannot measure the 2 water droplets on the side of the probe or the water film on the blade surface. In the steam turbine wet steam measurement image probe described in Embodiment 1, a corner prism 11 is added before the telecentric lens, see Figure 4, so that the probe can measure the lateral secondary water droplets and the water film on the blade surface.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com