Experimental facility for preparing fibrid

A technology of precipitating fibers and experimental devices, which is applied in the field of chemical machinery to achieve the effect of simple devices and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

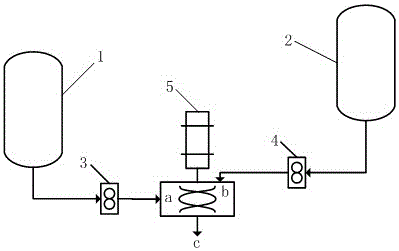

[0022] The schematic diagram of the device of the embodiment of the present invention is figure 1 As shown, the device includes: a slurry storage tank 1, a sediment storage tank 2, a slurry delivery pump 3, a sediment delivery pump 4, a sedimentation machine 5, etc.; their connection relationship is: the output port of the slurry storage tank 1 and The input port of the slurry transfer pump 3 is connected, and the output port of the slurry transfer pump 3 is connected with the slurry input port a of the precipitator 5; the output port of the sediment storage tank 2 is connected to the input port of the sediment delivery pump 4 Connected, the output port of the precipitating liquid delivery pump 4 is connected to the precipitating liquid input port b of the precipitator 5; the fibrous suspension is discharged from the output port c of the precipitating machine 5.

[0023] In the above technical solution: a heat exchange coil or jacket is provided on the periphery of the slurry sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com